Motors for duet 2 wifi

-

@timcurtis67

What did you do for the heat-bed? Aluminum plate? I am a bit concerned about the possibility of warping with the heat pad under the plate and losing the flatness... -

@mendelevium said in Motors for duet 2 wifi:

If I increase the feed like F1000, the motors will simply vibrate and whine and do not move

Two likely reasons:

-

You have set the acceleration too high in the M201 command.

-

The combination of steps/mm of your machine, motor choice and supply voltage means there is insufficient supply voltage to drive the motor that fast. However, F1000 is a low speed, so that should only be the case if either your machine has a very high steps/mm value, or the motors have high inductance. Use the EMF calculator at https://www.reprapfirmware.org/ to check.

@mendelevium said in Motors for duet 2 wifi:

This printer is one of two prototypes I designed and manufactured and spent much time with it. I wish to maybe market in the future.

Definitely change to 24V power then.

-

-

my extruders/ Water cooling/ hot end

-

@mendelevium, unfortunately the uploads attached to your last post failed. If you are using Chrome, try uploading them from Firefox instead - that's what I do when I have this problem [frequently].

-

@mendelevium said in Motors for duet 2 wifi:

@timcurtis67

What did you do for the heat-bed? Aluminum plate? I am a bit concerned about the possibility of warping with the heat pad under the plate and losing the flatness...Here is what I use for my bed.

https://www.midweststeelsupply.com/store/castaluminumplateatp5It is very stable when heating. I do have it leveled at 70C. I usually run anywhere from 60C-70C while printing. I used the 1/4" thick plate.

-

@timcurtis67

The heat-bed plate looks great. What thickness did you manage to get. The thinnest I found was 5mm. It will be a bit heavier but with ball-screws it will be more powerful... -

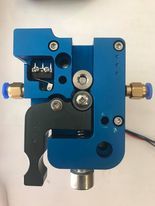

Some of the gear on my 3D printers. Everything manufactured in house, including the anodizing This is the Extruder I produced x 3 reduction, the water cooled hot end the water cooler.

I will load some more pics with the ball screws

-

@mendelevium said in Motors for duet 2 wifi:

@timcurtis67

The heat-bed plate looks great. What thickness did you manage to get. The thinnest I found was 5mm. It will be a bit heavier but with ball-screws it will be more powerful...I used a 1/4" thick plate for my build. 18" X 18" X .250"

That is a very nice looking extruder. Dual drive for the filament?

-

@mendelevium

I have received the steppers 60mm Nema 17 and changed the control for 24V. Runs ok and I am happy with the help you all contributed. Thank You -

@mendelevium, I'm glad it's sorted now! I'll mark this as solved.