Polar Printer Steps/Degree?

-

@phospherus 16 teeth on the small gear and 258 teeth on the large gear, i just want highlight that the drawing is skewed with round edges,

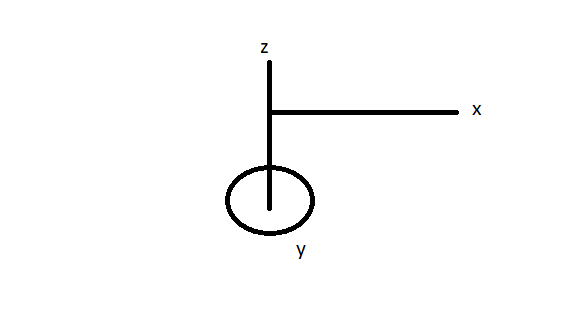

I mean this machine should move Y= Theta, and X= R where are the SQRT (XX + YY)

is that correct ?

-

@phospherus 16teeth on the small gear and 258 teeth on the large one

-

@dc42 Hi I just tested different reprapfirmware version on my SKR1.4 almost all have the same behavior which indicates the issue is not in the firmware however in the configurations, can you advise the possible configurations ?

-

-

@phospherus said in Polar Printer Steps/Degree?:

gain as soon as I have a chance. I did however get my BLtouch and mesh bed setup on 3.2.2 on the polar as a delta using radius and seems to work very well.

@dc42 In my case actually Y plate is turntable and X and Z are both moving as they are located on the table, did you test the same and it works ? if possible to share the config.g that you have tested at ?

have you tested for this design ?

-

This post is deleted! -

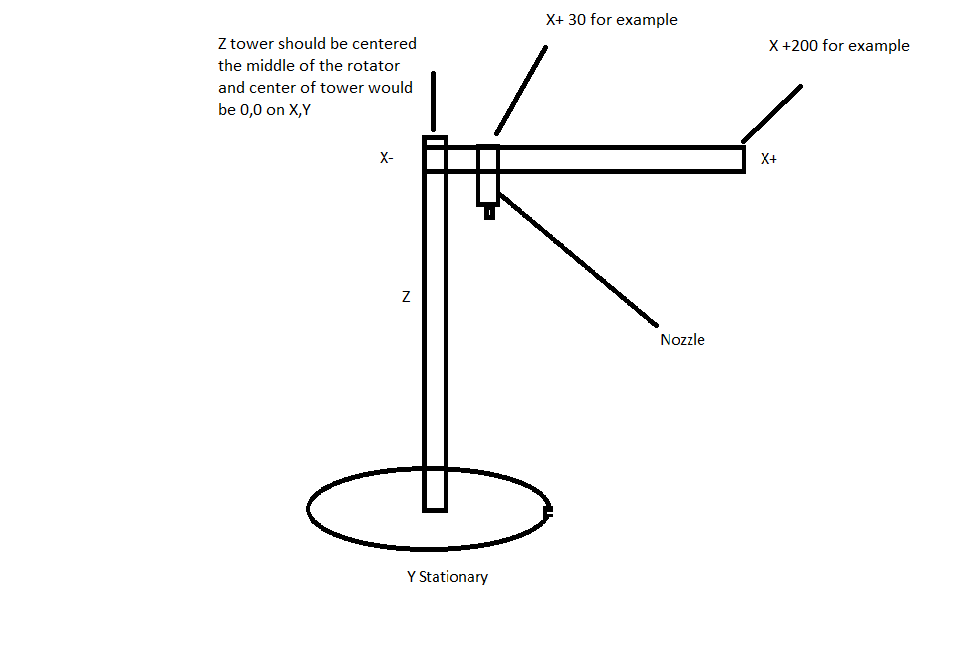

Ok on a polar printer the center of the turn bed or rotating plater is 0,0 for the X and Y axis. On your design with the z tower being in the middle and rotating you will have to measure from the center of the tower out to the closest position to the tower that the x axis can get to. I would measure from center of tower to max X position and home to the + instead of minus. But your lowest X position will be the distance from center of tower to the nozzle.

Also on a polar with the bed rotating the y axis goes in the clockwise direction for plus. On your design the Z and X would need to go counter clockwise.

As for steps per mm for the X. I need to know belt pulley teeth count on stepper and belt pitch to help with that.

I hope I explained this well enough.

-

This post is deleted! -

-

For your M92 X100 Y14.33 Z401 E84

-

This post is deleted! -

Where is your X axis Endstop is it by the tower or at the end of arm?

If you X homes to min and is near tower. Then you need to to home to the switch and in your homing file do a G92 X105 to set the X at the homing switch to X105. but you will have to change your M208 parameter.

; Axis Limits

M208 X105 Y0 Z0 S1 ; set axis minima

M208 X445 Y360 Z400 S0 ; set axis maximaAlso like I said rotating bed or Y axis normally go clockwise. since you are rotating X you need it to go counterclockwise.

-

@phospherus Yes it home at lower end that is right but i did not yet fixed the switch

-

The X arm itself does not need to be the nozzle itself needs to be perfectly centered.

-

OK then position by hand with motors off M84. Then once in position do a G92 X105 Y0 Z0 to set positions.

-

@phospherus ok i will test and update you i really appreciate you help

-

This post is deleted! -

That was with the x axis at 105mm from center of z tower and you did G92 X105 to set position?

And how do you have your slicer setup?

-

@phospherus yes it was however slicer is cura with normal setup as if I slice for any Cartesian printer is there specific setup I just make the plate eclipse and make the origin is center so it is plate with origin

-

I used simplify 3d so can not comment on Cura but In simplify I just leave it as Cartesian because Delta seems to mess things up. My diameter is 240 for bed so I set that for X and Y then do 120 offset to get nozzle in middle.