Wavy surface problem.

-

@hiroaki said in Wavy surface problem.:

@tpra Hello.

From your experience which is better

1.Core XY (By belts)

2.Lead screw or Ball screw.User @mendelevium has a leadscrew driven CoreXY, he might be able to tell the pros and cons?

@tpra said in Wavy surface problem.:

The only difference i see is all the machines i have that run correctly run rrf2. This particular one runs rrf3.

We all cross our fingers, that there's no backdraw using RRF3, but may I ask you a favor and print one of those with a printer running RRF2.x ?

-

@o_lampe Hello.

Sure, can you send me the STL file?

Regards -

-

@o_lampe said in Wavy surface problem.:

We all cross our fingers, that there's no backdraw using RRF3, but may I ask you a favor and print one of those with a printer running RRF2.x ?

I have absolutly no idea if it's related to RRF3, and i honestly doubt about it.

I'll still try downgrading to rrf2 because i tried so much things...

It's so hard to be 100% sure that there is no mechanical problem. But i changed so much things that there is not much possibilities left. + i changed one thing at a time so i dunno.At the moment i am 99% sure that it is stepper related.

I have built a moire / VFA stl file that amplifies the problem and will post a test process soon. I am preparing a more rational test approach than what i did before, but it takes a lot time and i'm stuck into SpoolMonitor project atm.Btw i really decided to solve this thing. It's a pain in my quest to perfect print quality

I ordered several other boards and different drivers so i can really tweak all settings. The post about VFA on prusaprinter forum is a treasure, take time to read it, and like people say, be ready to fall into the rabbit hole : https://forum.prusaprinters.org/forum/original-prusa-i3-mk3s-mk3-user-mods-octoprint-enclosures-nozzles-.../stepper-motor-upgrades-to-eliminate-vfa-s-vertical-fine-artifacts/

: https://forum.prusaprinters.org/forum/original-prusa-i3-mk3s-mk3-user-mods-octoprint-enclosures-nozzles-.../stepper-motor-upgrades-to-eliminate-vfa-s-vertical-fine-artifacts/ -

@tpra

I had issues with 0.9 steppers, too. Mainly with lost position. (lost steps, but worse)

But I also know how good my parts looked before I used RTOS firmware. (even most 8-bit RAMPS/Marlin prints looked better). RRF2 was a dead end street, let's hope RRF3 will be worth the wait. -

@o_lampe Hello. I have just now started to print. Let's see!

-

@o_lampe Hello. It's done! How does it look ?

-

@tpra Yes, I agree to you. Maybe slicers make differences!

-

@tpra Maybe I try this in a future....

-

@hiroaki said in Wavy surface problem.:

@o_lampe Hello. It's done! How does it look ?

That looks excelent! Can you tell a bit more about the slicer settings?

Nozzle 0.4 I guess and RRF2.? -

@o_lampe Hello.

Is it ?

Actually I not really satisfied...

That's FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 2.05.1

Nozzle is 0.4mm dia.

Layer thickness is 0.15mm

I made the G code by Simplify 3D.

This machine has 1.8Degree stepper motors. Not 0.9...

Regards -

@hiroaki said in Wavy surface problem.:

Is it ?

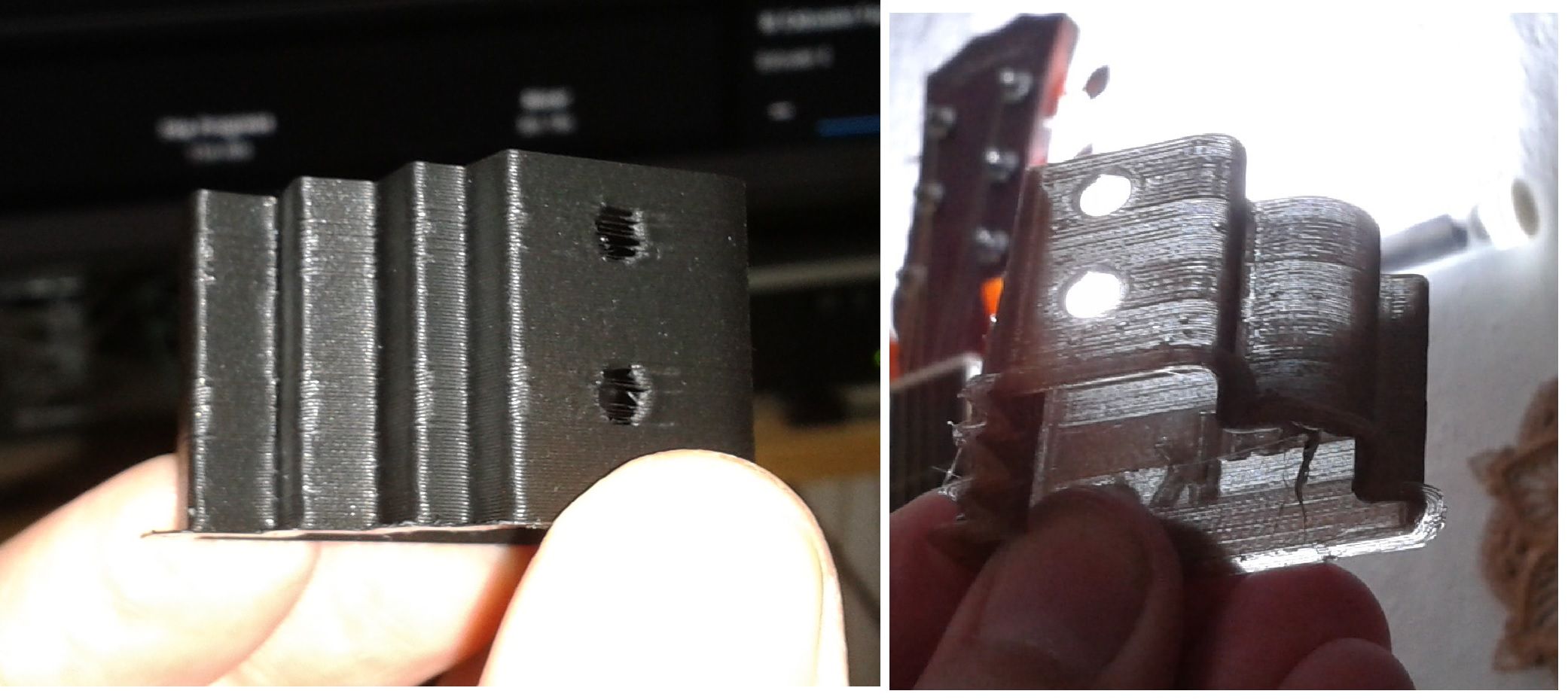

Actually I not really satisfied...It also shows vertical lines, same as your 'problematic' printer. But other prints looked really bad around the holes:

-

@o_lampe I think you can egt better result if you increase the retruction ammount. Mine is at this moment 5mm.

Or If your printer is borden, the teflon tube between extruder and nozzul has too much friction or too long.

So when extruder motor stops to stop extruding, it contines extruding.

The following guys had a video how to tune your printer I think.

https://www.youtube.com/watch?v=TDxpVSXmKiE -

So in my desperate quest about those motor vibrations, i switched to Klipper.

It was not that easy, but it solved all my problems. Maybe it's because trinamic chopper values, maybe it's because input shaper somehow deals with steppers vibrations, i don't know.

My tests are not enough serious / scientifically made to pull a conclusion.All i can tell is i spent a lot of time and money on this, and i litteraly searched in every possible direction.

TBH the firmware is the really last thing i suspected.

I know VFA's are something you see in very special cases, but imho rrf default trinamic chopper values should be revised and modified to be closer to what Klipper use.

And it's not like i tried with only one stepper type, i tried a lot of different common steppers on the market. -

You should be able to go back to RRF and command the drivers to use klipper's default settings

-

@luke-slaboratory said in Wavy surface problem.:

You should be able to go back to RRF and command the drivers to use klipper's default settings

Never. Just because of all the time and money lost to fix that.

There has been a LOT of people saying they had this problem. It has always been ignored, with blurry answers or gently explaining the guy that it is a mechanical problem or ghosting when it is obviously not ghosting (htf could ghosting have an amplitude that doesn't decrease ?)...Now the problem is solved, why bother with correcting something that's out for years with a major mistake in it ?

I'm currently switching all my other duets to klipper and will never go back. If you add the input shaper, the difference with rrf is stellar. Now my printer prints just like it should.I wish i had built a rigourous test process and took pictures to show that i'm not crazy...

-

@tpra said in Wavy surface problem.:

So in my desperate quest about those motor vibrations, i switched to Klipper.

It was not that easy, but it solved all my problems. Maybe it's because trinamic chopper values, maybe it's because input shaper somehow deals with steppers vibrations, i don't know.

My tests are not enough serious / scientifically made to pull a conclusion.All i can tell is i spent a lot of time and money on this, and i litteraly searched in every possible direction.

TBH the firmware is the really last thing i suspected.

I know VFA's are something you see in very special cases, but imho rrf default trinamic chopper values should be revised and modified to be closer to what Klipper use.

And it's not like i tried with only one stepper type, i tried a lot of different common steppers on the market.I've just had a look at the TMC2660 default config from Klipper and it seems to be the same that RRF defaults to... Did you already finetuned input shaping?

I'm also interested in this because my 0.9º Moons motors are WAY louder than my noname motors in a crap Marlin board. They are bearable, but I've already changed the X/Y motors two times: first were the typical steppteronline motors, that sounded like a chainsaw. Then a pair of smallish 0.9º Moons, that were quite noisy too, and finally another pair of beefier 0.9º Moons that are bearable, but not as silent as I'm used to. All of them were low induction.

-

@zipzap Hello. I appreciate your post. I have just received Gater genuine belt and tried!

The result was much better !

I guess the teeth side of the belt has to be cloth to have enough slipperiness. -

@hiroaki Sorry "Gates "

-

have you run them through the EMF calculator? if you're driving them fast with low VMOT, they can get noisy as the stepper drivers are unable to deliver a smooth curve to the motors.

@Hiroaki proper 2gt is almost always better

I'm a klipper afficionado - just was suggesting since some people prefer RRF's configs and other features.