Toolboard V1.0 error

-

X and Y are OK only Z is giving me problems.

-

@tecno what Z probe is it?

how many wires etc. Picture -

-

@tecno Bit of RTFM required

With Duet 3 main board, expansion board or tool board: Connect the VCC, GND and OUT pins of the sensor to 3.3V, GND and IN respectively on an IO probe connector, and select mode 8 in the M558 command.So pick a IO port such as IO_1, connect as above.

-

Got it workin with homeing. Did miss the correct port under endstops.

; Endstops

M574 X1 S1 P"!^121.io2.in" ; configure active-high endstop for low end on X via pin ^io3.in

M574 Y1 S1 P"!^io0.in" ; configure active-high endstop for low end on Y via pin ^io0.in

M574 Z1 S1 P"!!121.io1.in" ;; Z-Probe

M558 P"!121.io1.in" X0 Y0 Z1 H3 F200 T5000 R0 ; P"!^io6.in"

M557 X15:400 Y15:400 S20 ; define mesh gridNow to next Hotend Heater

-

Hotend tuning on its way now.

-

Glad you are getting there.

-

M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"121.out0" T1 ; create nozzle heater output on out2 and map it to sensor 1

M307 H1 B0 R3.567 C155.0 D5.77 S1.00 V24.3 ; disable bang-bang mode for heater and set PWM limit B0 S1.00

M143 H1 S280 ; set temperature limit for heater 1 to 280CWrong port

So hopefully the last issue.

M950 F0 C"121.out2" Q500 ; create fan 0 on pin out5 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"121.out1" Q500 ; create fan 1 on pin out6 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned onFan0 is for what??

Fan1 ditto?Some small mixed errors in config such as ports I assume.

At boot parts fans are on, heating hotend no toolfan.

-

I think I found my fan issue, changing ports was all needed.

But....

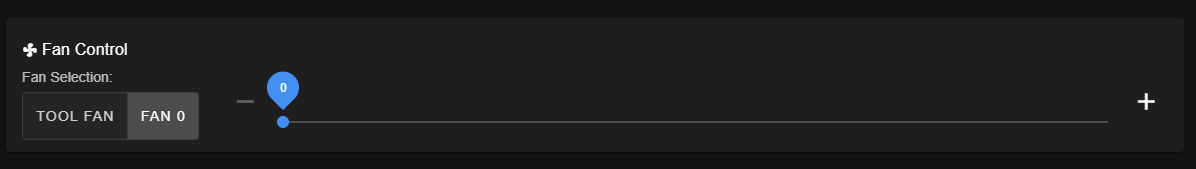

Toolfan starts up at +45°C and that is fine. If I want to adjust the fanspeed say to 50% then all fans are set to that value and that is not wanted. You can choose fan in the fancontrol but it locks all to same value !!

Is this a bug ?

-

@tecno Glad you sussed it, I was cooking Makhani Dahl.

Fan0 should be part cooling, due to some slicers being inflexible.

Fan1 is the tool fan, the one that cools the heatbreak on the nozzle.Yes, the Tool Fan and Fan0 buttons are confusing........

-

Now I got a grip of this but I am convinced that I will find some issues

I envy you guys that live in UK, you have a magnitude of spices, weggis and fruit we never see here.

So I think we can put a lid on this thread.

I want to thank you Paul and Jay for helping me out with this, much appreciated.

Cheers

Bengtps. some very irritating details as regards this board will come later.

-

@tecno said in Toolboard V1.0 error:

ps. some very irritating details as regards this board will come later.

Going from one control board to another is a steep learning curve.

I went from Marlin to Duet three years ago on an Ender3 before @Phaedrux wrote the guide.

Last year I tried Klipper firmware on SKR boards, the config is massive and you cannot do on the fly changes like RRF, so much so, My latest addition is running a Duet Mini instead of the SKR.

Tried Klipper on Duet2 Eth + Duex5, Bed tramming was awful experience and did not always work. Back to RRF and it trams perfectly.IMO, I will not use another manufacturer if I am controlling a 3D printer. I tried and hated it, and i do not give up easily!

Duets Dozuki is good and I normally have the GCode page open and pinned!

Hope you can get your first print out ok.

Glad to of helped.

P.

-

My original TriGorilla board gave up on me so I was going for a SKR 1.4 but BTT in CZ screwed up my order. They have some employee problems.

So I took the bull at the horns and ordered my first Mini 5 that I had issues with = no fans working so it was a DOA bord. Meanwhile I was waiting for the new Mini5 I decided to get rid of Anycubic's cabling that is horrible and purchased the toolboard.

This setup with the printhead will be of temporary nature as I will design a new one with the toolboard.

Also the new hotend Dragon from Phaetus will be nice to test. Still a virgin = no filament extruded yet.https://bantam.design/mount/gallery

I have the one to right = my own iteration adapted to my Anycubic Chiron. Will play around with this for a while so I can see what can be altered to my satisfaction.Take care, now time to relax with Netflix.