How to unclog a Mosquito or Dragon hotend

-

@garyd9 Not quite sure how we started with "How to unclog a Mosquito hot end" and end with "how to claim your Dyze nozzle sealing washers" but I pleased for you that we did.

-

So, my baking project had the following results:

The heat break is cleared, though it's lost all it's color. It went from a very pretty shiny copperish color to something that looks more grayish. I think the oven burned off all the simulated pretty copper color and left whatever metal is really there.

The nozzle I put in there is still clogged. I think it's a lost cause. I took a surprising sharp photo of the end of the nozzle (after baking and sitting in acetone for several minutes, followed by a brass wire brush) and the clog is pretty obvious. As best as I can tell, it's something metallic - perhaps a sliver of something from the Chinese manufacturing process, or some contaminant in the Hatchbox wood filament I was printing. After baking, I tried forcing it out from the nozzle tip end using 0.4mm stainless steel needle (which I confirmed does fit in the hole of a brand new 0.4mm E3D nozzle), but whatever is in there is stuck in there good and I can't get it out.

That's an expensive disappointment. It's one of the tungsten carbide nozzles from 3D Maker Engineering. They don't have any more in stock (and from experience, I know it can take them months to get more stock) so I ordered a different tungsten carbide nozzle from "Spool3D" in Canada (which turned out to cost nearly twice as much with shipping.)Just to swing this back on topic: That nozzle clog was what started my experience in a clogged dragon heat break. The filament couldn't extrude, so it baked in the nozzle, hot block, and eventually in the lowest part of the heat break (below the cooling fins.)

At least a good oven cleaning fixed the heat break, if not the nozzle.

-

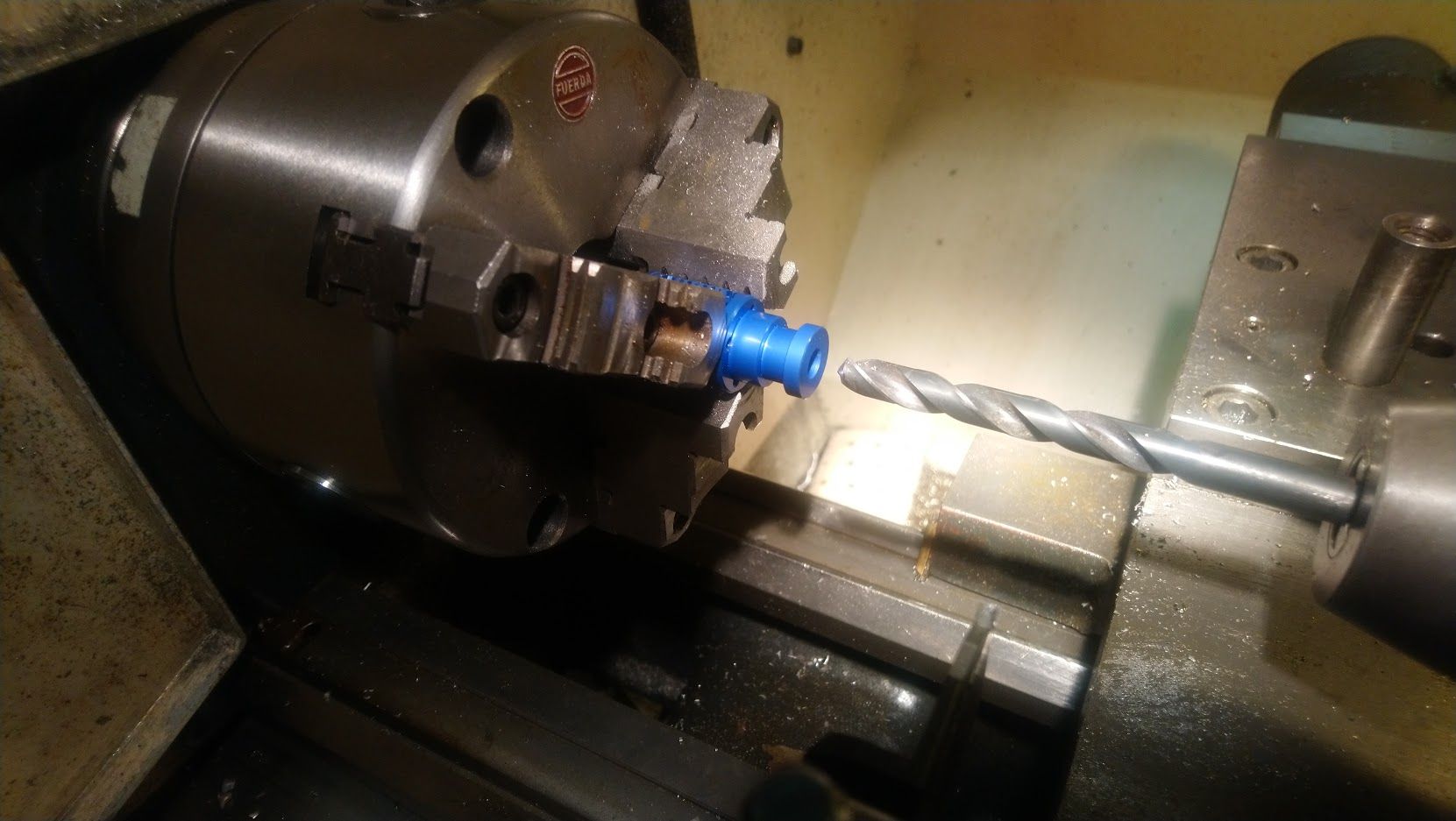

Ouch ..... seeing that you have nothing to loose and assuming that at least the beginning section of the 0.4 mm passage is clear on the back, I would go ahead and drill it out. The carbide will prevent the drill from doing any damage to the nozzle.

HIGH RPM ... as high as possible, and careful peck drilling. Nothing should be hand held or you will break off the drill bit. Line it up so that the drill bit enters the 0.4 mm passage without deflecting and short of the obstruction being part of the carbide from the nozzle itself, you should be ok. -

@jens55 I don't have the tools for that. Even if I could find the right size drill bit in the US, I'd need a press to ensure a straight shot down, etc.

The thing that really annoys me about this is that it's NEVER happened to me with a brass, copper, or hardened steel nozzle. No.... the universe waited until I put an expensive nozzle on, and only let me play with it for a week, and then this happened.

-

@garyd9, where you seriously thinking that the universe would choose any other time to mess with you (well it DID allow one week of play time so it had some compassion)

Don't toss the old nozzle, you might run across someone in your are that has the available tools and is wanting to show off! If you were in my part of the country (Canada wet coast) I would certainly take a shot at it. I would also try the old propane wrench just in case .....

-

So even I encountered this clogging, not so sure anymore that it was the steel nozzle

More leaning towards the bad Bowden clip that is not strong enough. Forgot to retract and clear as mud the filament (PETG) bulged out at the end of bowden tube. So here my cure...

Time will tell ....

Cheers

Bengt -

Good evening guys,

This Dragon is driving me nuts as it is clogging way up in the heatbreak (PETG). Bad cooling?

What kind of fans are you guys using? Below the ones I use.

-

@tecno, I use a standard tiny little fan similar to the V6 fan (at least in size) with a shroud that is , again, similar to the V6 shroud in that it kinda wraps itself around 3/4 of the frame of the Dragon. Measured top temperature of the V6 style top of the Dragon is around 45C when I am printing PLA at 200C. Note that this is the frame and not the bimetal heat break.

I would say that fan is marginal and I will probably replace it with a physically bigger fan to get more air flow going .... but it has been working just fine unless the filament stops moving for a significant period of time, probably more than 30 minutes, with the hot end still powered up.

My first attempt was with the fan just sitting in space in front of the hot end and I didn't think that was sufficient air flow over the heat sink itself. -

@jens55

So it is probably not a fan issue, will order a new heatbreak and see if it helps. Maybe it got damaged the first time trying to get clogged filament out. -

@tecno I'm using the actual 24V E3D heatsink fan. The genuine E3D V6 shroud will work, but it might be loose and rattle.

I modeled something that (in my opinion) holds the 30mm fan to the dragon heat sink better. It's on this thingiverse thing:

https://www.thingiverse.com/thing:4818787 -

I know this post is old, but I found a nice way to unclog dragonfly style hotend with the heat break clog without disassembling anything.

Heat up the hotend to max temp.

Remove the bowden tube, and place a tiny allen key inside of the heat break against the clogged material (it must be touching the clog).

Take a soldering iron and heat up the allen key, try not to let it touch any plastic material around. After about 10-20s of heating up the allen key (carefully adding some solder to the tip about halfway through) I remove the key and place a needle in from the top and it went all the way through, moving it up and down to remove as much material as possible.

Then I put back the bowden tube, and pushed some filament through. I returned the temp to appropriate level for the filament ~200 (PLA) and extruded a bunch (like 50cm).

After that, turn off the hotend and all was back to normal.