Hotend stalling during movement and baby stepping issue

-

@jumpedwithbothfeet said in Hotend stalling during movement and baby stepping issue:

Fault.mp4

Thanks for the video. I wouldn't have called that stalling movement. In the context of stepper motors stalling would mean motion is completely halted. That would appear to be smooth slow down during curves.

Aside from the IR sensor problem in standalone mode, are you now able to execute the same moves without that slow down occuring?

-

@jumpedwithbothfeet said in Hotend stalling during movement and baby stepping issue:

my DC42 IR sensor is reporting as triggered before homing and has the red LED dimly lit at all times , the wiring I believe is correct using IO7 and I cant find any shorts -

Most likely there is a bad crimp connection or other break in the 3.3V wire to the sensor.

-

@jumpedwithbothfeet thanks for the video. Are you using mesh bed compensation? If so then I think the issue may be that you are using large amounts of compensation and the Z jerk is set too low (M566) to permit the Z speed changes that would be needed to allow smooth motion.

-

@phaedrux @dc42 thankyou both for your replies I got kinda side tracked by the IR sensor and it being fathers day apparently your supposed to play with your kids and not your printer

Anyway I disconnected the IR sensor and tested it independently and confirmed it is working correctly, very very very carefully checked the voltage on IO7 and it is producing 3.3v but not at the hot end so yup must be a break somewhere in the wire.

I do use use a bed mesh along with G32 as I'm experimenting with a tilting bed like the HEVORT and the bed is glass (black paper backing) with kapton/ABS applied so the bed mesh can vary.

I have not managed to reproduce the fault in standalone yet but I have not been able to probe the bed and implement the mesh bed yet either so that sounds like a winner to me, given my XY steppers where under supplied my Z motors will most likely be too so I will check them as well change M566, would it be best to slowly increase the figure and repeat until it no longer fails?

-

The default values for Z speeds from the config tool are very conservative to protect your Z axis in case it's very heavy and slow.

M566 Z60 for jerk and M201 200 for acceleration should be enough to stop any jerky motion from the mesh compensation being active.

You can check if mesh is active in M122, or simple force it active with G29 S1 and deactivate it with G29 S2 in order to compare.

-

@phaedrux Thanks for the figures, I've found the cause of the IR sensor failure it is a JST plug that has an intermittent connection frustrating only on the 3.3v pin and also a poor soldered joint on the sensing line.

I figure I will try and repeat the fault, then change to the new figures and try to get it to fail again fingers crossed it'll all be good!

-

@dc42 @phaedrux managed to get it to fail on the first attempt, M122 showed mesh active, repeated with M566 Z60 and M201 set to 200, it failed again but the motion was much less jerky so it has had a positive affect, I will keep adjusting in small amounts until it smooths out, I think I may look at a different build plate to help the IR sensor as well, I'll post the results once I get them.

Thanks to you both for all your help and time it's very much appreciated

Cheers Jim

-

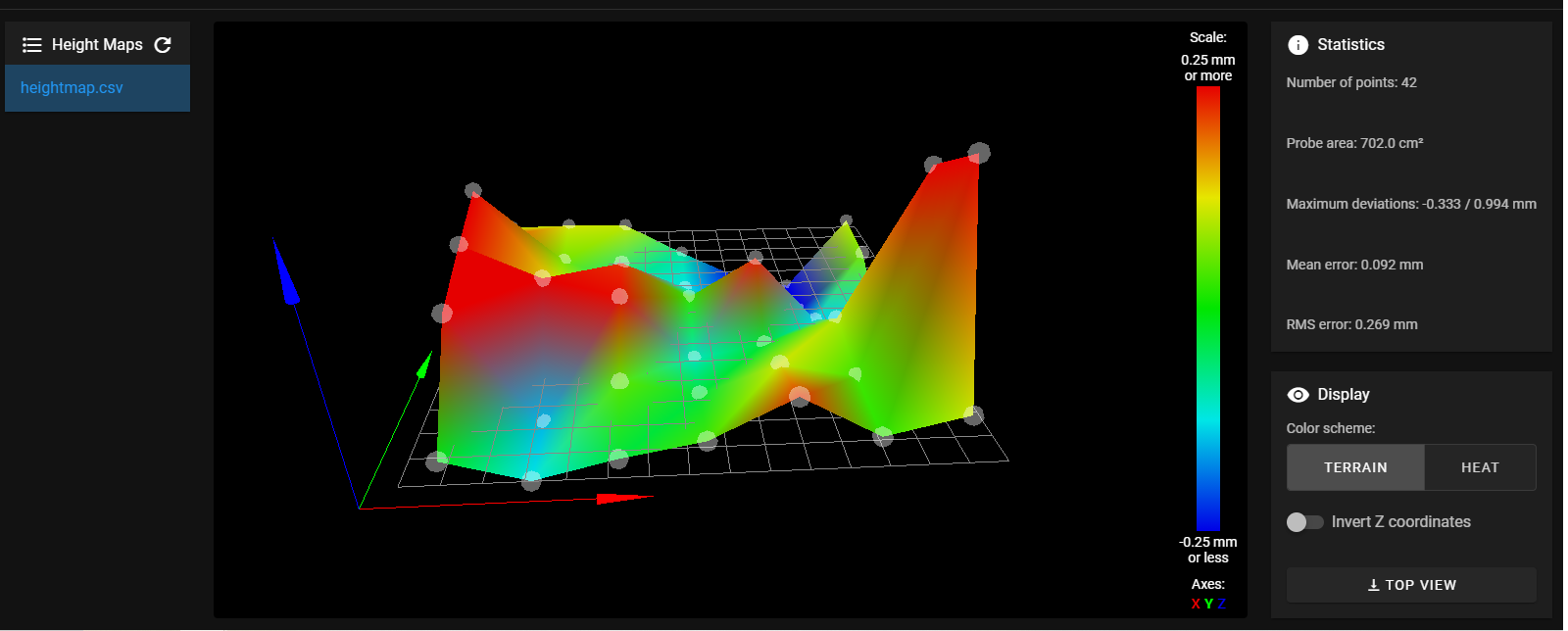

Can you post a photo of your heightmap image with the deviations, etc?

Can you also post the gcode file you're executing? How fast are the moves?You may be able to use M376 to set a taper off height for the compensation, so that the slower first layers are compensated to allow for good first layer and then slowly over a few mm it tapers off.

https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M376_Set_bed_compensation_taper

-

@phaedrux after looking at the height map from my first few attempts, I have given my heat bed a clean and repeated the test it now moves without jerking but the bed ain't flat by far!

the gcode I test with is

G28 XY

G0 X100 Y100 F10000

G3 X100 Y100 I25

G3 X100 Y100 I25

G0 X10 Y10

G0 X100 Y100 F10000

G2 X100 Y100 I25

G2 X100 Y100 I25

G0 X10 Y10

(repeated over and over)this is essentially a series of circles both clockwise and anti-clockwise @ 168mm/s, I will take a look at M376 along with a further clean of my bed hopefully it will help get me back printing until I can figure out better flatter build surface that I can print on that doesn't cost the earth to replace from time to time!

-

I think we see now the reason for the halting motion. I suspect that your bed surface isn't ideal for the IR probe, and so those large spikes are actually just spurious from a bad IR detection. Those spikes then require the Z axis to lurch up and down rapidly during the fast moves. The slow Z jerk/accel force it to slow down in XY as well.

Try placing a piece of plain paper over your bed surface and re-probing the mesh to see if it becomes flatter.

-

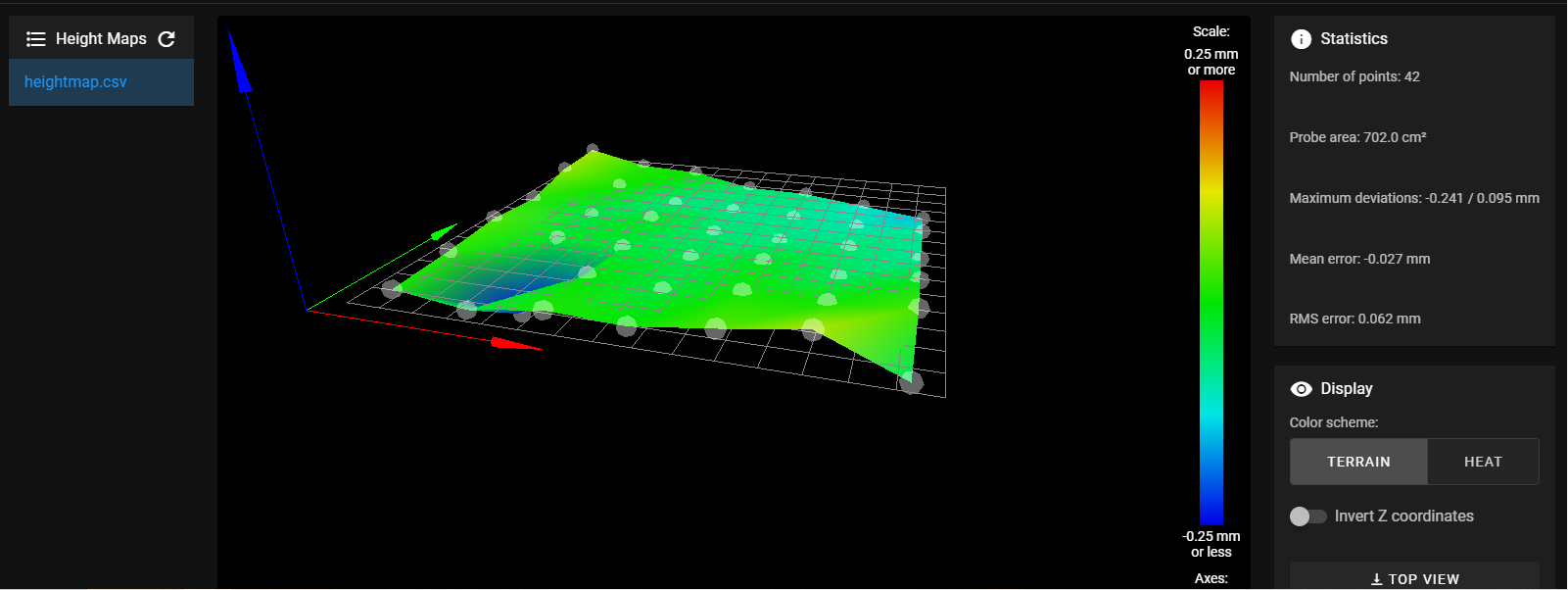

@phaedrux, After multiple attempts with both black and white paper including a comical poor chase the hot end around with the paper, I resorted to using just the bare unpolished aluminium bed, pretty much proof the glass bed is causing the sensor a head ache the two blue areas are chamfered screw holes I believe.

I have ordered some Lokbuild to replace the kapton tape.

Thankyou all for your help and for educating me