Vertical banding on COREXY machine

-

@phaedrux I don't know if this counts, but I have two Bondtech BMG extruders, and I tried both with the same results. The one piece which I didn't change is the stepper gear.

-

@zabana The upper few mm of this print illustrate the effect of increasing perimeter speed from 80mm/sec to 120mm/sec, which I accomplished by lowering jerk to 110mm/sec (maintains adhesion on concave curves, but makes them ugly; paradoxically, my corners now look wonderful):

-

@donstauffer yes I detected similar improvement in my prints if I increase the speed regarding the periodic rippling but if a piece is small or need to reduce speed to print it the problem will be there.

Right now I am refining the extruder because just in case and of course a smoother meshing and movement never hurts.I also did a test printing at 180 degrees instead of 200 as someone advised to increase back pressure but it did not work at all so the more test I do the more prone I am to think in something fw related with small speed on the extruder because it not only happen in a sherpa extruder but also in "good" ones like BMGs

-

@o_lampe said in Vertical banding on COREXY machine:

@zabana

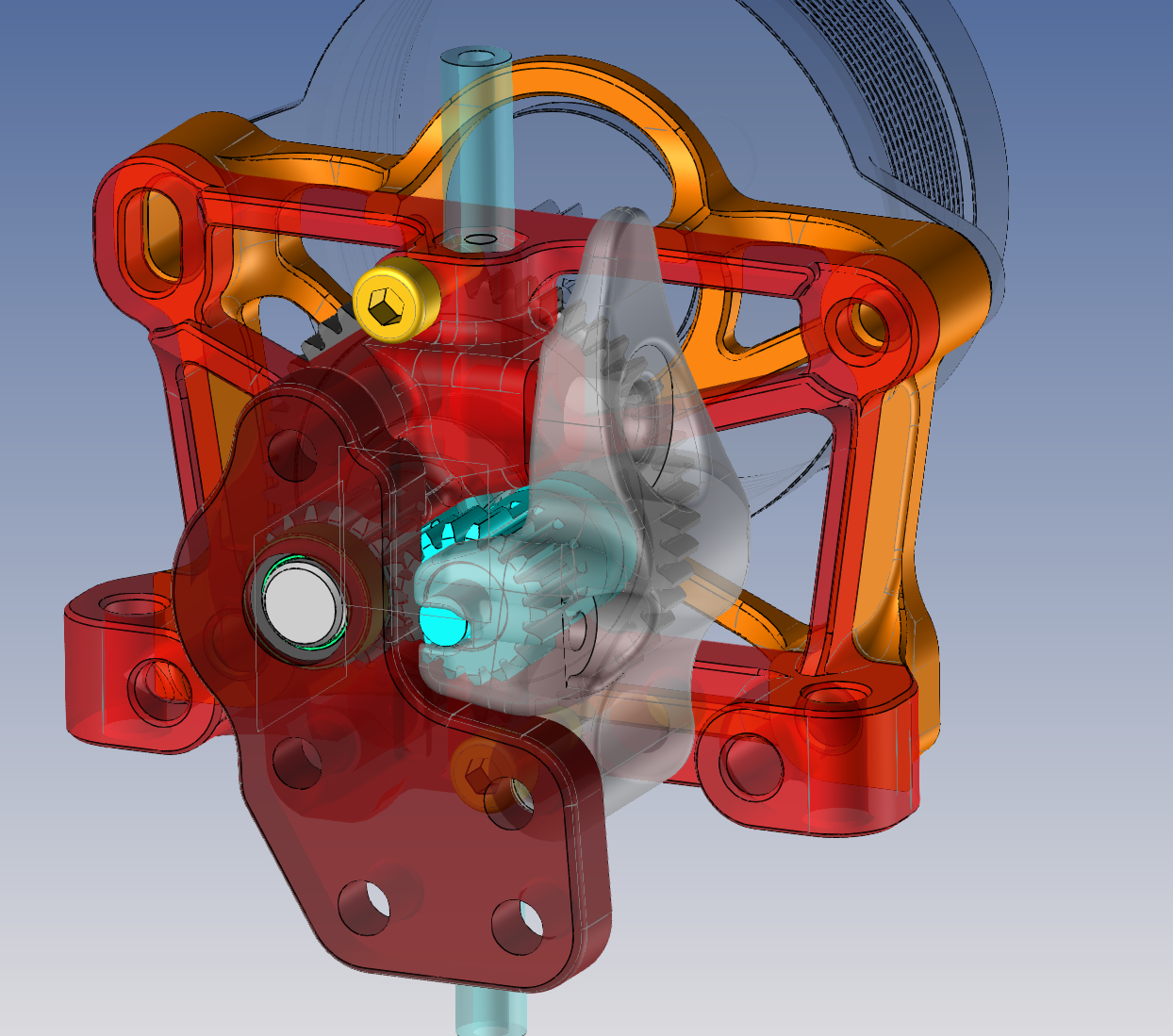

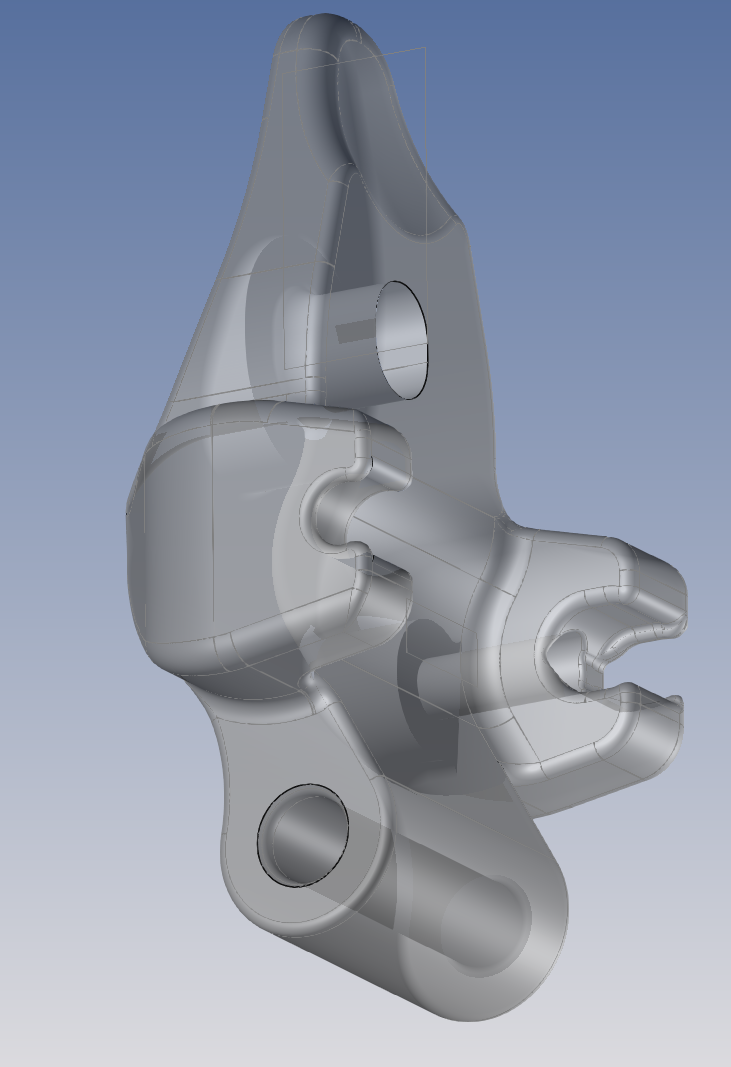

Since you are using a sherpa mini too, I think I will reconstruct the front bearing holder with a slightly larger distance between the main shaft and the hole that takes the pinch bracket shaft. The dual gears must not mesh too hard before the filament pinch force is right.

A bit of play between the gears is easier to accept than 'clenched teeth'I went a different direction in separating the gear lash from the filament crush. Gear side axle support is elongated, allowing an M2.5 bolt to act on the axle and dial in gear lash independently:

-

@zabana I am quite certain that these vertical lines are not caused by a firmware issue. RRF produces highly regular stepper motor pulses, unlike some other firmwares.

Unfortunately, vertical banding such as you illustrate in your original post is common. I remember that Prusa carries out a long investigation into it several years ago, because it was affecting their printers. They even put a Duet WiFi into one of their printers to see if it solved the problem (it didn't).

The likely causes are uneven extrusion, or uneven XY motion. To test which, find a simple print that illustrates the problem well, such as a square vase print. Then change the layer height, for example increase it by 50%. If the problem is uneven extrusion, then the period of the lines will change in inverse proportion to the layer height, assuming you keep the same extrusion width.

If this confirms that the problem lies with the extruder, the next step is to calculate the period in terms of the filament input to the extruder. If you are doing a square vase print, look at the GCode to see how much filament length is extruded for each side of the square. Divide that length by the number of vertical lines per side to get the period at the input. Then try to relate that to characteristics of the stepper motor, e.g. the amount extruded for each gear tooth, and the stepper motor steps per mm.

-

@dc42 said in Vertical banding on COREXY machine:

@zabana I am quite certain that these vertical lines are not caused by a firmware issue. RRF produces highly regular stepper motor pulses, unlike some other firmwares.

Unfortunately, vertical banding such as you illustrate in your original post is common. I remember that Prusa carries out a long investigation into it several years ago, because it was affecting their printers. They even put a Duet WiFi into one of their printers to see if it solved the problem (it didn't).

The likely causes are uneven extrusion, or uneven XY motion. To test which, find a simple print that illustrates the problem well, such as a square vase print. Then change the layer height, for example increase it by 50%. If the problem is uneven extrusion, then the period of the lines will change in inverse proportion to the layer height, assuming you keep the same extrusion width.

If this confirms that the problem lies with the extruder, the next step is to calculate the period in terms of the filament input to the extruder. If you are doing a square vase print, look at the GCode to see how much filament length is extruded for each side of the square. Divide that length by the number of vertical lines per side to get the period at the input. Then try to relate that to characteristics of the stepper motor, e.g. the amount extruded for each gear tooth, and the stepper motor steps per mm.dc42 replied to one of the other threads re: vertical lines, but it fit's here too and partly confirms our findings.

-

@ccs86

I did something similar on my printed bracket, but used a dremel bit to widen the holes for the idler bracket shaft.

It runs much smoother now.

The downside of the misalignment could be a higher wear on the teeth? But most probably the filament teeth are worn out before... -

@dc42 Mine was the same with different layer heights. So I assume an XY movement problem.

-

@donstauffer All pulleys replaced with brand name. No improvement. Next I'll replace the belt and carriage. Then, the only moving parts I haven't replaced will be the rails themselves, and the Z-axis steppers and lead screws.

I'm becoming absolutely convinced this is not a problem with moving parts.

-

@donstauffer said in Vertical banding on COREXY machine:

@donstauffer All pulleys replaced with brand name. No improvement. Next I'll replace the belt and carriage. Then, the only moving parts I haven't replaced will be the rails themselves, and the Z-axis steppers and lead screws.

I'm becoming absolutely convinced this is not a problem with moving parts.

have you check your rail that support your extruder ? when i build my printer i first used cheap linear rail to only find that there was enough play to rotate the printing head of a least 1-2 degree , i ended up replacing that rail with a hiwin HGR 15 and it solved my problem.

-

@dad003 I used Zyltech rails and when I built it, I cleaned them thoroughly and replaced all the balls and relubricated. In the process I returned one rail plus one carriage because I couldn't get them smooth enough. When I was done I could hold the end of the rail in my hand, tip the other end down on about a 45 degree angel and watch the carriage slowly and smoothly slide from end to end. I didn't stop working until every single rail was that smooth. So I'm convinced it isn't the quality of the rails.

-

@donstauffer said in Vertical banding on COREXY machine:

I'm becoming absolutely convinced this is not a problem with moving parts.

So what is your current theory?

Many CoreXY machines are running the current firmware (3.3.0) without issues like this.

I am finishing up a CoreXY that started life as a Two Trees Sapphire Pro and with the upgrades I made it is printing very well.

Frederick

-

@fcwilt I don't really have a theory. But I'm running out of moving parts to replace. So I'm frustrated and uncertain.

-

@donstauffer said in Vertical banding on COREXY machine:

@fcwilt I don't really have a theory. But I'm running out of moving parts to replace. So I'm frustrated and uncertain.

I can relate.

I got rid of three delta style printers because I could not get them to work as I wanted.

I did that after getting my first Cartesian which worked so much better.

Frederick