Mesh bed leveling not working

-

My ender with the duet boards runs flawlessly, but my anet a8 plus prints to close on one side and extremely high on the other. The printer has a PEI bed with an inductive sensor, G29 S1 at the start of every print. printer is on RRF 3.3. G32 for independent leveling works.

I've tested a different bed surface with capacitive sensor, no matter what it prints at an angle and is always high on one and low on the other.

I've seen a file mesh.g mentioned but neither printer saves that file

Thanks for the help; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 27 2021 09:31:03 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes Backwards

M569 P4 S0 ; physical drive 4 goes backwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E396.00 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M906 X900 Y900 Z900 E950 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-13 Y-10 Z0 S1 ; set axis minima

M208 X300 Y300 Z340 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"!^zprobe.in" H3 F300 T7500 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y-50 Z3 ; set Z probe trigger value, offset and trigger height

M557 X15:290 Y15:245 S30 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 R0.169 C511.4 D2.46 S1.00 V23.3 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 R1.713 C195.9 D6.17 S1.00 V23.3 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S275 ; set temperature limit for heater 1 to 275C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M671 X-25:365 Y150:150 S2 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

T0 ; select first tool

-

I tested a few capacitive sensors and found that their response time was quite slow compared to inductive sensors.

Have you tried lower the probing speed from 300 to, say, 100?

You may also want to probe each point multiple times. To do that add A10 to your M558 command. With the default value of S=0.03 it will probe up to 10 times trying to get 2 consecutive readings within 0.03 as specified by S.

You can also force averaging of a number of readings. For example if you include A3 and S-1 it will probe each point 3 times and average them.

Frederick

-

@fcwilt it was at 150 until earlier this morning when I mirrored the settings on my ender.

I'll give those a shot, thanks

-

-

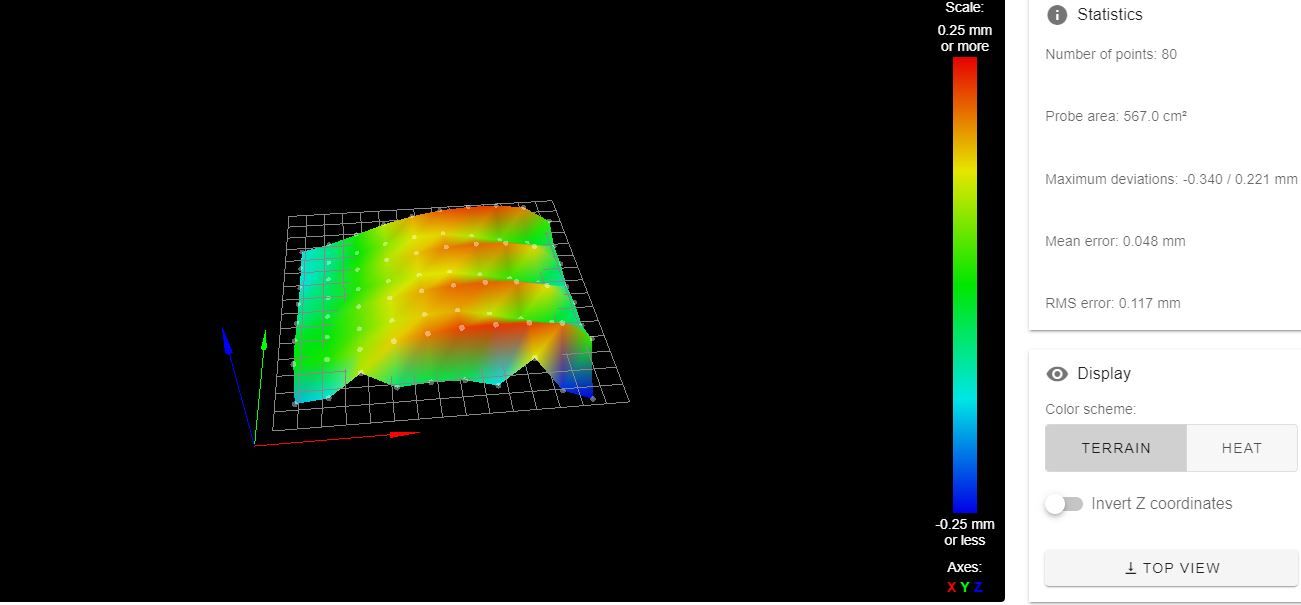

80 points is not a very dense grid.

I probe the max which is around 400 or so.

Frederick

-

it prints about 2mm in the air on one side and scrapes the bed on the other, don't think probe density is the issue

-

@pats-prints said in Mesh bed leveling not working:

it prints about 2mm in the air on one side and scrapes the bed on the other, don't think probe density is the issue

2mm? That is a lot.

Still if mesh compensation is working it should be able to cope unless there is a Z speed issue - I think I remember reading something about that.

I see you are using G32 to auto-level the bed.

Is that working? If auto-level is not setup correctly each pass makes things worse.

You should complete the auto-level procedure by setting the Z=0 datum with a G30 positioning the probe at the center of the bed.

You also follow auto-level with G29.

Do you have a file mesh.g?

Frederick

-

@pats-prints said in Mesh bed leveling not working:

@fcwilt

M558 P5 C"!^zprobe.in" H3 F80 T5000 A10

tested slower probing, same issue. The lead screws turn while its running so I know mesh is at least working. I had the same issue when I had a bl touch on the printer.

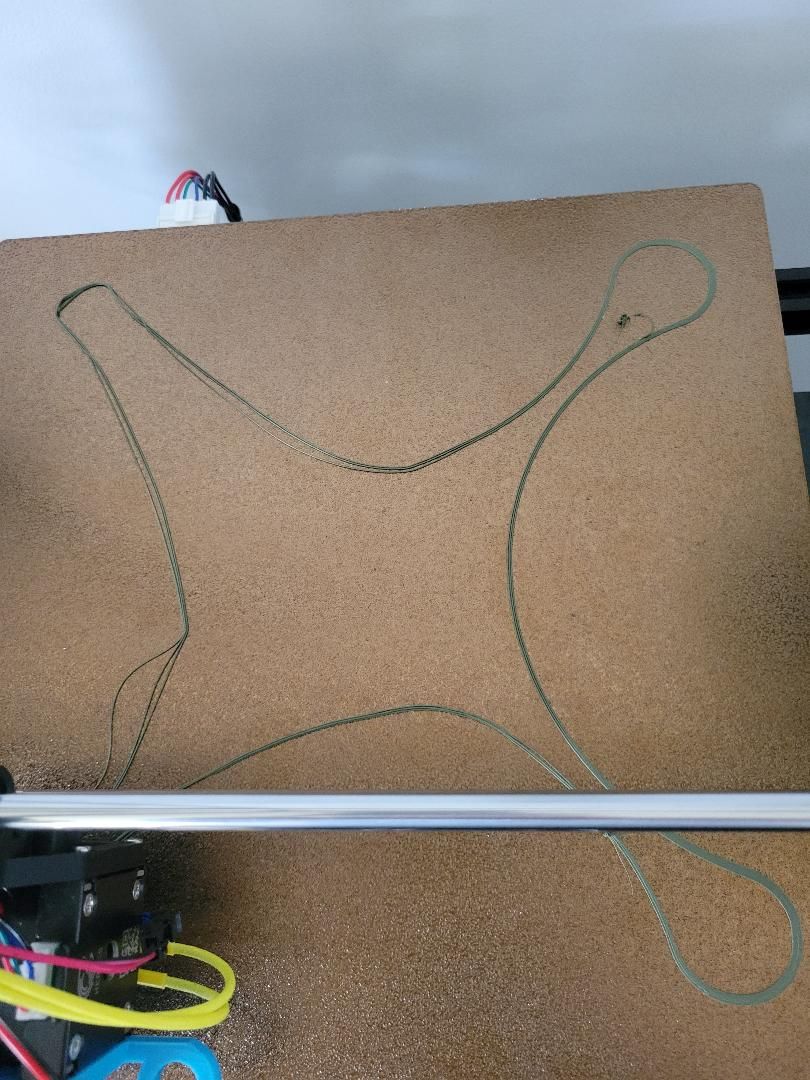

Those ridges look like backlash causing your print head to tilt back and forth causing the probe to move up and down depending on the direction.

Do you have a lot of play if you grab the print head and try and move it by hand? Are your belts tight?

-

I've tried with the same results running both g29 and g32, neither of my printers save a mesh.g file, not sure why

There is a fair bit of play in the gantry, belts are tight

-

@pats-prints said in Mesh bed leveling not working:

neither of my printers save a mesh.g file, not sure why

Because it's a file you create akin to bed.g.

G32 calls bed.g

G29 would call mesh.g if it existed.@pats-prints said in Mesh bed leveling not working:

There is a fair bit of play in the gantry, belts are tight

If you move the X axis back and forth can you visually tell that it's tilting the probe/nozzle back and forth as well?

-

@phaedrux no, moved it back and forth rapidly no issues, hotend doesn't seem to move at all.

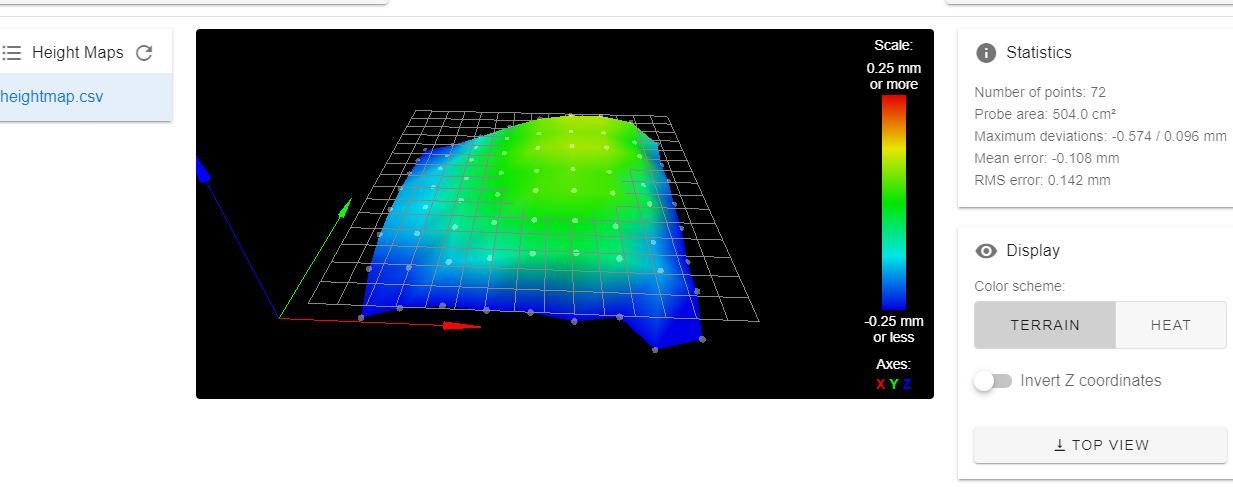

My last ditch effort I just tried was moving my ender's pei sheet and calibrating on that. Same problem.

A thought just crossed my mind that on the cheapo anet they used two different lead screws? Causing this issue no matter what I do to fix it

-

Well the image of your heightmap is tell tale backlash. It's higher in one direction and lower in the other. Until you identify and eliminate that backlash, it will persist.

-

@phaedrux I'll see if the prusa X helps, otherwise this printer is going in the trash

-

What's a prusa X?

-

I see your probe‘s offset is 15mm on Y.

If your axis is slightly tilted it’s more pronounced for the probe and the mesh is not usable. -

@phaedrux meant the prusa bear x upgrade

-

@argo the probe is offset x 0 y -50, it has happened across multiple sensors and bed types the nozzle slopes to be in the air on the low end of the x and scrapes the bed on the higher end of the x

I guess I should also mention I started with 2.0 firmware and recently switched to 3.3 to see if it would help

-

The bear parts didn't fit but I tried 2 LMU88 bearings on each side for the x carriage and had horrible binding. Went back to the stock long bearing- and still the exact same issue. the bed looks fine on the height map viewer.

I think I'm just going to buy some corexy machine and throw the anet in the trash

thanks for your input

-

Sometimes that is the best thing to do.

I had three deltas and decided I didn't like them - gave two away, trashed the third.

Frederick