Homming issues strange Behaviors

-

@bartekp please post your complete config.g file also homex.g homey.g homez.g and homeall.g

-

@siam

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 17:20:53 GMT+0200 (czas środkowoeuropejski letni); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 Z16 E16 I0 ; configure microstepping without interpolation

M350 X16 Y16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z2756.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z150.00 E600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min)

M201 X5000.00 Y5000.00 Z50.00 E1000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X500 Y500 Z600 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop; Z-Probe

M558 P1 C"zprobe.in" H5 F120 T12000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X70:500 Y70:500 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"pt1000" R4700 ; configure sensor 1 as PT1000 on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1 T45 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

T0 ; select first tool; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 17:20:53 GMT+0200 (czas środkowoeuropejski letni)

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 X-505 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X5 F12000 ; go back a few mm

G1 H1 X-505 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F12000 ; lower Z again

G90 ; absolute positioning; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 17:20:53 GMT+0200 (czas środkowoeuropejski letni)

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 Y-505 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y5 F12000 ; go back a few mm

G1 H1 Y-505 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F12000 ; lower Z again

G90 ; absolute positioning; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 17:20:53 GMT+0200 (czas środkowoeuropejski letni)

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 Z605 F1800 ; move Z up until the endstop is triggered

G92 Z600 ; set Z position to axis maximum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F200 ; lift Z relative to current position

;G90 ; absolute positioning; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 17:20:53 GMT+0200 (czas środkowoeuropejski letni)

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G1 H1 X-505 Y-505 F1800 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X-505 ; home X axis

G1 H1 Y-505 ; home Y axis

G1 X5 Y5 F12000 ; go back a few mm

G1 H1 X-505 F360 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y-505 ; then move slowly to Y axis endstop

G1 H1 Z605 F360 ; move Z up stopping at the endstop

G90 ; absolute positioning

G92 Z600 ; set Z position to axis maximum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F200 ; lift Z relative to current position

;G90 ; absolute positioning -

@bartekp said in Homming issues strange Behaviors:

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwardsYou have the Y-Axis to drive Backwards, was this a Test? If not then let the Y axis drive forwards and retest

-

@siam both directionts won't work corectly

-

@siam yes that was test and this solution dont work

-

In addition, I noticed that when I start HOME Y axis, it starts with the first Z axis.

This is to be expected - it is fairly normal to raise Z a bit before homing on this sort of printer so that if the nozzle happens to be on the bed then it wont drag across the bed while homing.

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 17:20:53 GMT+0200 (czas środkowoeuropejski letni) G91 ; relative positioning G1 H2 Z5 F12000 ; lift Z relative to current position G1 H1 Y-505 F1800 ; move quickly to Y axis endstop and stop there (first pass) G1 Y5 F12000 ; go back a few mm G1 H1 Y-505 F360 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F12000 ; lower Z again G90 ; absolute positioningCan you do the following test:

- With the printer powered down, SLOWLY move the Y axis so it is in the middle of its range by hand. you need to do this slowly so that the motor does not back power the board.

- Power the printer on and Home Z then Home X. Do not home Y yet.

- Send G92 Y250 that will tell the printer that the Y axis is at 250mm (which is not correct because you moved it by hand, but should be good enough for the short moves we are going to do as a test.

- Using the dashboard in DWC jog Y +10 the Y-10. Does the axis move in the +/- directions as expected? If not send M569 P1 S1 or M569 P1 S0 (the opposite of what it is currently set to and then test again. It should now move in the correct direction.

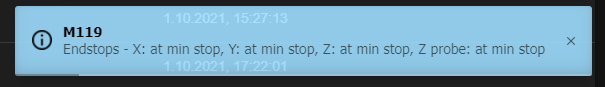

- Now we need to test if your endstop is working. Send M119 and it should report Y: not stopped. now manually hold down the Y endstop and send M119 again it should report stopped. If that is working then we know the endstop is working correctly.

- With a working endstop and motor going the right direction you can confirm that config.g has the correct M569 setting for Y based on the test in #4.

With those steps done try and home Y, have your hand over the power to switch it off if it goes the wrong direction. It should be going to Y minimum as that is where you have set your endstop to be.

-

@t3p3tony HI thanks for help,

I cant home Z because is alert that I did't homed XY

how to ? -

@bartekp If I made by hand homing jog +10 is out of endstop and -10 on Y is to endstop direction

I put new config g file wich is

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Wed Oct 24 2018 17:07:50 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM667 S1 ; Select CoreXY mode

; Network

M550 PTronxy X5S ; Set machine name

M552 S1 ; Enable network

M587 S"WIFI NAME" P"PASSWORD" I192.168.1.69 J192.168.1.1 K255.255.255.0 ; Configure access point and IP addresses. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z800 E830 ; Set steps per mm

M566 X600 Y600 Z12 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z180 E1500 ; Set maximum speeds (mm/min)

M201 X3000 Y3000 Z100 E10000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1100 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X500 Y500 Z600 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S0 ; Set active low endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H5 F120 T6000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X-19 Y0 Z2.65 ; Set Z probe trigger value, offset and trigger height

M557 X30:315 Y30:305 S59 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 C0 R4700 X2 ; Set thermistor + ADC parameters for heater 0 and remap it to channel 2

M143 H0 S80 ; Set temperature limit for heater 0 to 80C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S250 ; Set temperature limit for heater 1 to 250C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 S"Extruder" ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

M671 X20:295:20:295:170:170 Y10:305:305:10:10:305 P8 ; adjusting screws at rear left (-15,190), front middle (100,-10) and rear right (215,190), thread pitch 8mm

M572 D0 S0.13 ; Set pressure control to 0.13

M307 H1 A459.4 C167.2 D4.1 ; PID for Extruder

M307 H0 A101.4 C1123.0 D10.0 B0 ; PID for Bed

M592 D0 A0.015 B0.0012 L0.2 ; Nonlinear adjustment

M591 D1 P1 C4 S1 ; Enable E1 Endstop for filament run out detection

M581 E1 S0 T1 ; invoke trigger 1 when a falling edge is detected on the E1 endstop input -

-

@bartekp z probe is not connected

BY switching endstops M119 reports that endstops working good -

@bartekp now is that when I use All axis homing X goes home Z move home and Y go out of endstops

when I change direction of Y is the same situation but Y motors jumping with X motor but when i use only X homing moving all axis and y goes in the same direction as always .

When Use homing Y X goes home and Z and Y goes to endstops but jumping with X and I did this two times ant after this Y comes home but with jumping . -

@bartekp Solved, connection issue by wrong axis , corexy I didnt know exacly wich motor in corexy is X and wich is Y. My mistake .

-

@bartekp ahh right ok, thanks for letting us know what the issue was!