Looking for help with CNC builds to help me start.

-

So, NEMA23 is the standard for the mounting plate face of a stepper motor.

It has basically nothing to do (basically) with the power of the stepper motor.

You can get NEMA23 motors which are less powerful than NEMA17 motors, so I wouldn't focus on the mounting face right now.I would build a Cartesian machine where the bed moves in Z and the carriage moves in X and Y.

You should be able to find a LOT of information about building your own CNC machine online.

Let us know what you find that looks like what you want to build and we can help you understand it's good and bad parts.

-

Thank you for all your information. Yes I agree with you, there is a lot of information, it's a lot to take in and absorb. I am looking for a beginners level build that I can do some light cutting on or maybe get a laser and experiment with that. I am not really sure what the best way to build the frame is, I have seen a lot of people using the 80 20 extruded aluminum. I am just looking for a simple effective project that I will be successful with and be able to learn from and experiment with. What build would you recommend for a beginner to start with. What size would you recommend ? Maybe 12" x 12", I am not really sure where to begin. Thanks for your information on the motors, I did not know that. What motors do you recommend that I start with ? I need to learn a lot and the more I learn a lot more, I am really happy that I found this forum so I can continue learning correctly. What do you recommend and what parts should I start with ? This first build will be mainly for learning and experimenting on.

I really appreciate your time and efforts in helping me.

Ecmaker

-

You could stat out with a CNC kit from one of the many manufacturers of those kinds of things.

How much money do you want to spend?

Here's one for US$130This kit would allow you to build everything and get started and then you could upgrade to using a Duet controller later when you need to do so.

-

Thanks for the reply and input. Looking at all the examples I have seen I think that $ 300.00 to 400.00 would be a good place to start. I understand that the Duet3D boards have the stepper motor drivers included so that would really help. What I don't understand is what is the best affordable option for the linear motion. I have seen a lot of people using the belts and pulleys to transfer the rotation energy to your linear motion. If I buy a kit I would want to be able to get tech support with it, I looked at the cnc that you sent me the link for and I could not find any contact info or an owners manual listed. What would I be able to get for around $ 300.00 to $ 400.00 ? Do people have detailed plans on here for cnc builds they have done ?

Thank you,

Ecmaker

-

You should check out the Moot One plans. I built one and it works great. There is info for different bed sizes and a bill of materials. The plates can cut for you, the rest you source. https://miscpro.com/product/moot_one-desktop-cnc-machine/

-

Thank you for your reply, Yes I am looking for a project that has a good chance of working after I complete it.

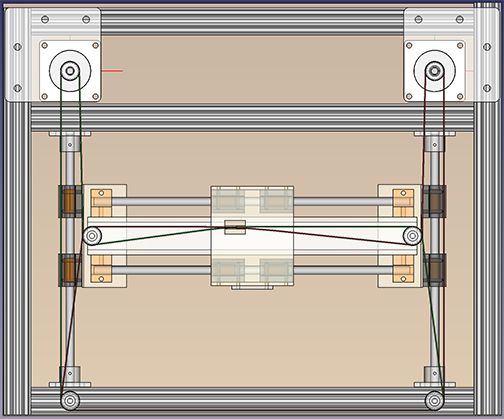

I have also been working on a CAD design, this uses a Core XY design that I read about and found a lot of people using. I hope I built my model correctly, I placed my Y axis rods inline with my stepper motors and the pulleys below. I

would appreciate any advise or recommendations on this prototype. What are the best places to order the linear motion supplies, motors, belts and etc. ?I am going to study the information you provided me and see what I can do with it. The one issue I need to learn more about is how to calibrate the stepper motors step distance and figure out what micro stepping settings I should use.

I have more pictures of my first Core XY model that I can upload to this forum thread if you or anyone wants to see more.

Thanks.

-

@ecmaker the corexy model is wrong, as most of the belt lines need to be straight, and your's are skewed.

But that's not the main reason why I write. 3D printing and CNC have different requirements:

- 3D printing through the nozzle without force in XY direction with fast speed

- CNC using mill/router/cutter with high force to remove wood or other material, speed is slow

So using belts (fast, but limited force) is the wrong method for the axes. Instead, trazepoidal spindle or ball screws are used. The two recommended solutions (buy a kit or buy a plan) use those methods.

-

Thanks for your information and advise, I do have a lot to learn and that's why I joined this forum. After looking at my options I think that the CNC option would be the best to start with, it appears that CNC is less complicated but let me know. I am going to look at the Moot One information and see what options they offer, I think a kit would be my best option. This would insure that I get all the correct components. I plan to spend $ 300.00 - $ 400.00 $USD on my first project. Is this a good range to start with. I want something that I can use on wood and other soft materials and be able to produce some useful items.

Ecmaker

-

-

@ecmaker said in Looking for help with CNC builds to help me start.:

a kit would be my best option.

I agree that a kit would be your best choice, if you're aware that you may be unsatisfied with it and want to improve later. But this approach has advantages

- start fast

- low risk to invest too much

- the topics to solve are overwhelming first, so you can concentrate on some of them, like the software

Just be aware that you'll throw away most of it later, reusing a few parts.

-

@ecmaker I wanted to add another aspect.

Similar to the comparison of different requirements and following consequences of how to build a 3D printer or a CNC machine, there is a difference between CNC machine for wood or for metal:

- the CNC machine for wood typically wants to work on big parts like doors, up to 2.20 x 0.80 m, and precision needed is in the range of 1 mm, material is rather soft

- CNC for metal typically works on objects in the range of a few cm of its dimensions, precision wanted is in the range of 1/100 mm and material is rather hard

If you buy a kit, this will probably allow to work on aluminium also, but later it is a good choice to buy (or DIY build) two CNC machines, each specialized to its domain.

-

Thanks for all the additional information, I have started to look at some of the kits and there are a lot to look at. Yes, I understand that I will be replacing parts as I upgrade, I will learn about the advantages of upgrading to higher precision parts and how the new parts will improve my CNC. I do like the low risk investment option since I am starting to understand the complexity of building a CNC and all the correct decisions needed to have a successful build. I think I should start with something that will cut soft materials and then I can upgrade to harder materials later. There is a lot of information out there, I even noticed that a lot of people are using lasers on their CNC's to do the cutting. My options are endless, I just need to get something so I can get started.

Ecmaker

-

@ecmaker I wish you success and if you have a question, please ask.

There's a lot to learn, but I always have a good feeling when I build something, be it 3D printed or abrasive. Laser is something on my wishlist.

-

Yes, I agree. I really enjoy building things, You learn so much and get a great feeling of accomplishment. I have been wanting to try CNC for a long time and have been trying to learn as much as I can, I think it will be a lot of fun. I am really glad that I found this forum.

Thanks,

Ecmaker