I recently picked up a voron 2.4 from a guy who turned out to have had worked at E3D and it was a low-use test machine. I have 2 CNC machines running duet, but this is my first printer so a little new that side of things.

He mentioned that the machine had some early test boards. It has a revo roto, a duet roto toolboard and a revo PZ probe. The PZ probe has no mounting holes, for example, so is likely pre-production.

I am not sure this is the reason for my issues. I am getting an initialization error when I try to do input shaping. I can see it with M122 B1.

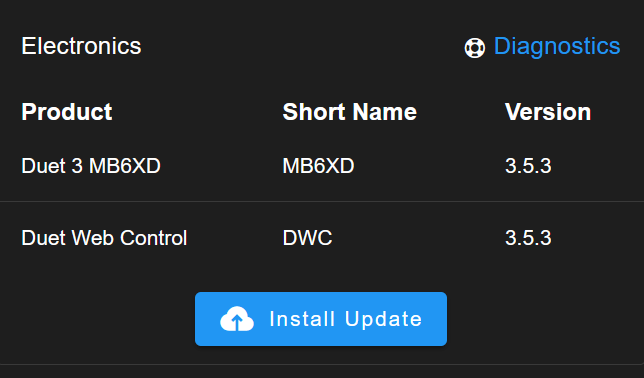

I am running the most recent RC though I am getting a warning of incompatible versions. Not sure why.

Duet 3 Mini 5+ 3.6.0-rc.3

Duet 3 Expansion TOOL1RR 3.6.0-rc.3

Duet WiFi Server n/a 2.2.1

Duet Web Control 3.6.0-rc.3

My config file has this, which seems to be in order

; Accelerometer

M955 P1.0 I01

I also tried

; Accelerometer

M955 P1.0 I01 S1600 R8

M122 B1 says: INT1 error only after running input shaper, otherwise 00. Not sure how to get it to initialize.

m122 b1

Diagnostics for board 1:

Duet TOOL1RR firmware version 3.6.0-rc.3 (2025-04-29 14:50:37)

Bootloader ID: SAME5x bootloader version 2.9 (2023-10-06)

All averaging filters OK

Never used RAM 170600, free system stack 200 words

Tasks: Move(3,nWait 7,0.0%,176) TMC(2,delaying,1.3%,51) HEAT(2,nWait 6,0.1%,112) CanAsync(5,nWait 4,0.0%,70) CanRecv(3,nWait 1,0.0%,73) CanClock(5,nWait 1,0.0%,63) ACCEL(3,nWait 6,0.0%,47) MAIN(1,running,97.9%,320) IDLE(0,ready,0.0%,29) AIN(2,nWait 2,0.7%,255), total 100.0%

Owned mutexes:

Last reset 00:08:58 ago, cause: power up

Last software reset at 2023-10-25 10:23, reason: deliberate HardFault zeroDiv, available RAM 165012, slot 1

Software reset code 0x8060 HFSR 0x40000000 CFSR 0x02000000 ICSR 0x00000803 BFAR 0xe000ed38 SP 0x200023a0 Task MAIN Freestk 782 ok

Stack: 00000001 00000000 20001168 00000004 00000001 00010ee7 00012394 41000000 a5a5a5a5 a5a5a5a5 a5a5a5a5 0001ce53 00000000 00000000 20002dc8 a5a5a5a5 00000000 11af7900 00000040 0300eb65 200032f8 0002fa86 200032f8 0002fa86 000000ce 00010c15 41200000

Moves scheduled 0, hiccups 0 (0.00/0.00ms), segs 0, step errors 0 (types 0x0), maxLate 0 maxPrep 0, ebfmin 0.00 max 0.00

Sync err accum 65, peak jitter -4/4, peak Rx delay 180, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 3890958943 ticks, disabled

VIN voltage: min 24.2, current 24.2, max 24.2

MCU temperature: min 16.9C, current 27.9C, max 27.9C

Driver 0: pos 0, 2682.0 steps/mm, standstill, SG min 0, temp 31.4C, read errors 0, write errors 0, ifcnt 13, reads 43930, writes 0, timeouts 0, DMA errors 0

Last sensors broadcast 0x00000002 found 1 181 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 4426, send timeouts 0, received 1923, lost 0, ignored 0, errs 0, boc 0, free buffers 38, min 38, error reg 0

dup 0, oos 0/0/0/0, rxMotionDelay 0

Accelerometer: LIS2DW, status: 00, INT1 error!

Inductive sensor: never activated

Integrated filament monitor not present

I2C bus errors 0, naks 0, contentions 0, other errors 0

M122 for good measure

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-rc.3 (2025-04-30 14:42:33) running on Duet 3 Mini5plus WiFi (standalone mode)

Board ID: DVFNG-3096U-D65J0-40KMW-LK03Z-RXN4D

Used output buffers: 4 of 40 (21 max)

=== RTOS ===

Static ram: 94764

Dynamic ram: 94324 of which 0 recycled

Never used RAM 52236, free system stack 142 words

Tasks: NETWORK(1,ready,16.9%,201) HEAT(3,nWait 6,0.0%,325) Move(4,nWait 6,0.0%,264) TMC(4,nWait 6,1.5%,65) CanReceiv(6,nWait 1,0.0%,766) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,346) MAIN(1,running,80.5%,655) IDLE(0,ready,0.2%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,255), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:04:15 ago, cause: software

Last software reset at 2025-05-15 16:28, reason: User, Gcodes spinning, available RAM 52196, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU temperature: min 21.2, current 23.4, max 24.9

Supply voltage: min 24.0, current 24.2, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/28/8, gc cycles 0

Events: 1 queued, 1 completed

Date/time: 2025-05-15 16:33:10

Slowest loop: 34.50ms; fastest: 0.16ms

=== Storage ===

Free file entries: 20

SD card 0 detected, requested/actual speed: 25.0/24.0MBytes/sec

SD card longest read time 3.6ms, write time 2.1ms, max retries 0

=== Move ===

Segments created 6, maxWait 107441ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 29680.00/29680/0.00 5680.00/5680/0.00 1996.00/1996/0.00

No step interrupt scheduled

Driver 0: standstill, SG min 0, r/w errs 0/1, ifcnt 21, reads/writes 23150/10, timeouts 0, DMA errs 0, CC errs 0

Driver 1: standstill, SG min 0, r/w errs 0/1, ifcnt 37, reads/writes 23143/17, timeouts 0, DMA errs 0, CC errs 0

Driver 2: standstill, SG min 0, r/w errs 0/1, ifcnt 38, reads/writes 23143/17, timeouts 0, DMA errs 0, CC errs 0

Driver 3: standstill, SG min 2, r/w errs 0/1, ifcnt 65, reads/writes 23129/31, timeouts 0, DMA errs 0, CC errs 0

Driver 4: standstill, SG min 0, r/w errs 0/1, ifcnt 64, reads/writes 23130/30, timeouts 0, DMA errs 0, CC errs 0

Driver 5: standstill, SG min 0, r/w errs 0/1, ifcnt 37, reads/writes 23143/17, timeouts 0, DMA errs 0, CC errs 0

Driver 6: standstill, SG min 0, r/w errs 0/1, ifcnt 37, reads/writes 23143/17, timeouts 0, DMA errs 0, CC errs 0

=== DDARing 0 ===

Scheduled moves 18, completed 18, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000803, drives owned 0x00000803

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== CAN ===

Messages queued 2247, received 5136, lost 0, ignored 0, errs 1, boc 0

Longest wait 5ms for reply type 4014, peak Tx sync delay 228, free buffers 26 (min 25), ts 1209/1208/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 11.21ms; fastest: 0.00ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 2 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.2.1

Module reset reason: Power up, Vcc 3.34, flash size 2097152, free heap 39340

MAC address f0:08:d1:03:80:3b

IP address 192.168.1.94

Signal strength -91dBm, channel 7, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-rc.3 (2025-04-30 14:42:33) running on Duet 3 Mini5plus WiFi (standalone mode)

Board ID: DVFNG-3096U-D65J0-40KMW-LK03Z-RXN4D

Used output buffers: 18 of 40 (33 max)

=== RTOS ===

Static ram: 94764

Dynamic ram: 94324 of which 0 recycled

Never used RAM 52236, free system stack 142 words

Tasks: NETWORK(1,ready,16.5%,201) HEAT(3,nWait 6,0.0%,325) Move(4,nWait 6,0.0%,264) TMC(4,nWait 6,1.5%,65) CanReceiv(6,nWait 1,0.0%,766) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,346) MAIN(1,running,81.0%,655) IDLE(0,ready,0.1%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,255), total 99.9%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:04:15 ago, cause: software

Last software reset at 2025-05-15 16:28, reason: User, Gcodes spinning, available RAM 52196, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU temperature: min 23.1, current 23.4, max 23.4

Supply voltage: min 24.1, current 24.2, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/28/8, gc cycles 0

Events: 1 queued, 1 completed

Date/time: 2025-05-15 16:33:11

Slowest loop: 4.88ms; fastest: 0.16ms

=== Storage ===

Free file entries: 20

SD card 0 detected, requested/actual speed: 25.0/24.0MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Segments created 6, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 29680.00/29680/0.00 5680.00/5680/0.00 1996.00/1996/0.00

No step interrupt scheduled

Driver 0: standstill, SG min 0, r/w errs 0/0, ifcnt 21, reads/writes 63/0, timeouts 0, DMA errs 0, CC errs 0

Driver 1: standstill, SG min 0, r/w errs 0/0, ifcnt 37, reads/writes 63/0, timeouts 0, DMA errs 0, CC errs 0

Driver 2: standstill, SG min 2, r/w errs 0/0, ifcnt 38, reads/writes 62/0, timeouts 0, DMA errs 0, CC errs 0

Driver 3: standstill, SG min 2, r/w errs 0/0, ifcnt 65, reads/writes 62/0, timeouts 0, DMA errs 0, CC errs 0

Driver 4: standstill, SG min 2, r/w errs 0/0, ifcnt 64, reads/writes 63/0, timeouts 0, DMA errs 0, CC errs 0

Driver 5: standstill, SG min 0, r/w errs 0/0, ifcnt 37, reads/writes 63/0, timeouts 0, DMA errs 0, CC errs 0

Driver 6: standstill, SG min 2, r/w errs 0/0, ifcnt 37, reads/writes 62/0, timeouts 0, DMA errs 0, CC errs 0

=== DDARing 0 ===

Scheduled moves 18, completed 18, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000803, drives owned 0x00000803

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== CAN ===

Messages queued 5, received 10, lost 0, ignored 0, errs 0, boc 0

Longest wait 0ms for reply type 0, peak Tx sync delay 3, free buffers 26 (min 26), ts 3/3/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 19.52ms; fastest: 0.09ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 2 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.2.1

Module reset reason: Power up, Vcc 3.34, flash size 2097152, free heap 39340

MAC address f0:08:d1:03:80:3b

IP address 192.168.1.94

Signal strength -93dBm, channel 7, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0