sensor ir

-

hello everyone, i have problems configuring my mini ir sensor can you help please

hello everyone, i have problems configuring my mini ir sensor can you help please -

@sgk if you post your config.g file, the chance for help is extremely higher

-

-

; ====================== Network ===========================M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable TelnetM669 K1 ; select CoreXY mode

; ======================= Endstops =========================M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on ZM575 P1 S1 B57600 ; Set things up for the PanelDue

; Filament sensor;M591 D0 P1 C"e0stop" S1 ; Set Filament sensor Simple type (High) for extruder drive 0, connected to endstop input 3 (E0

; ======================= Drives ===========================M569 P0 S0 ; Drive 0 goes backwards blv: its was S1

M569 P1 S0 ; Drive 1 goes backwards blv: its was S1

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes backwards WAS 0

M569 P4 S0 ; Drive 4 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping; ===================== Drive Settings =====================M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X200,120 Y200,541 Z800 E714.36 ; Set steps per mm for orbiter

M566 X600 Y600 Z800 E600 ; Set maximum instantaneous speed changes (Jerk) (mm/min)

M203 X20000 Y20000 Z600 E7200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z100 E700 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1200 I10 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; ===================== Axis Limits ========================M208 X-23 Y0 Z0 S1 ; Set axis minima

M208 X320 Y320 Z350 S0 ; Set axis maxima; ======================== Z-Probe =========================M558 P1 C"^zprobe.in" H5 F200 T9000 I0 R0.5 ; Set Z probe type mini ir sensor

G31 P500 X-2.24 Y-20.81 Z1.044 ; Set Z probe trigger value, offset and trigger height

M557 X20:270 Y20:270 S240 ; Define mesh grid; ======================== Heaters =========================M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M307 H0 R0.345 C165.9 D7.58 S1.00 V23.6 ; Heatbed PID

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; define E0 temperature sensor

M950 H1 C"e0heat" T1 ; heater 1 uses the e0heat pin and sensor 1

M307 H1 R2.697 C168.9:154.1 D9.06 S1.00 V23.6 ; Hotend PID .4mm

M143 H1 S260 ; set temperature limit for heater 0 to 260C

M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor; ======================== Tools ===========================M563 P0 S"T0" D0 H1 F1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; ========================= Fans ===========================M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"HE Fan" S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on 100% at 45deg;Tool Fan/ Layer Fan

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off;MB cooling fan layer

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"MB Fan" S1 H2 T35:55 ; set fan 2 value. Thermostatic control is turned on Temp Range of 35 - 55 deg; ===================== Custom settings ====================M572 D0 S0.275 ; Set bowden extruder elasticity compensation for E0

;M207 S4.0 F2400 Z2.275 ; Set firmware retraction parameters

M207 S4.0 F2400 Z0.075 ; Set firmware retraction parameters

M564 H0 ; Let the Jog buttons work blv: added to allow jog buttons; Scanner support (debug);M750

; Set up DHT sensor on channels 101-102;M305 P101 X405 S"DHT temperature" T11

;M305 P102 X455 S"DHT humidity [%]" T11; Automatic power savingM911 S21 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss

; ====================== Miscellaneous =====================M501 ; load saved parameters from non-volatile memory

M500 ; save

T0 ; select first toolM575 P1 S1 B57600 ; enable support for PanelDue

;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

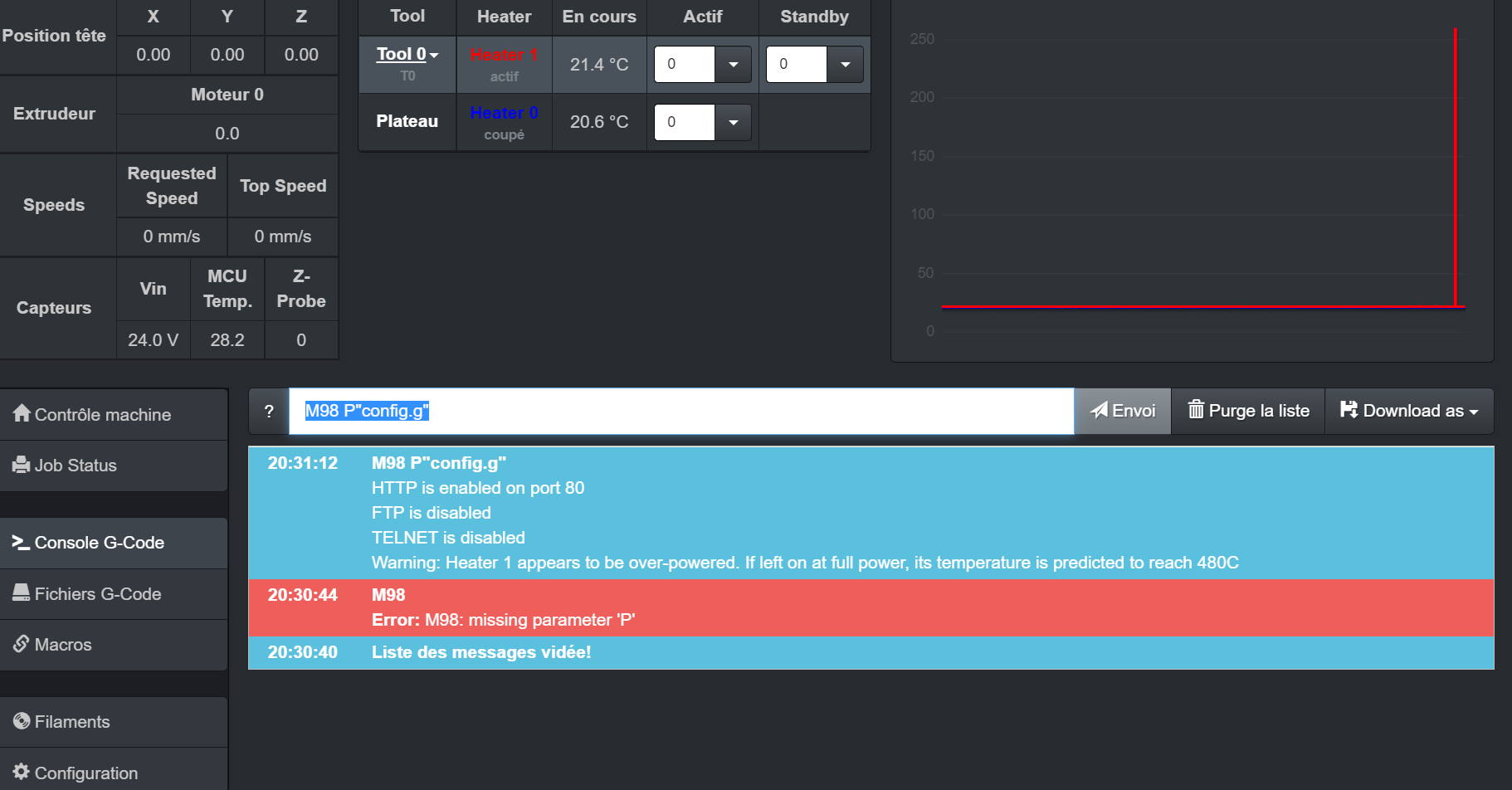

@sgk

; ===================== Drive Settings ===================== M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X200,120 Y200,541 Z800 E714.36 ; Set steps per mm for orbiterReplace the comas with a dot after that go to the console and enter g98 P"config.g" and post the result.

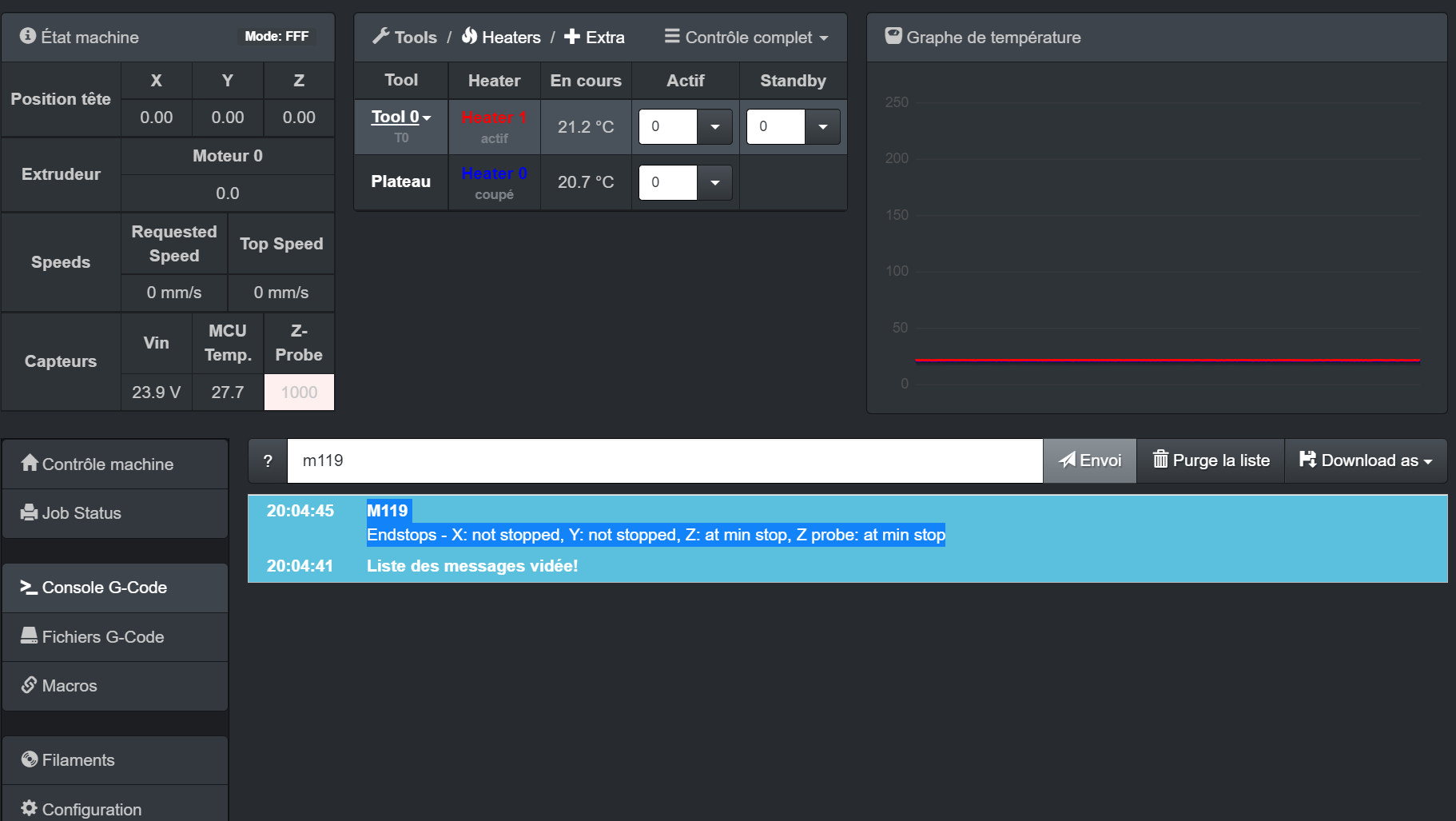

When you now enter M119 in the console look if the Z probe is triggered if it so change the following lineM558 P1 C"^zprobe.in" H5 F200 T9000 I0 R0.5 ; Set Z probe type mini ir sensorto

M558 P1 C"!^zprobe.in" H5 F200 T9000 I0 R0.5 ; Set Z probe type mini ir sensoran retest with M119

-

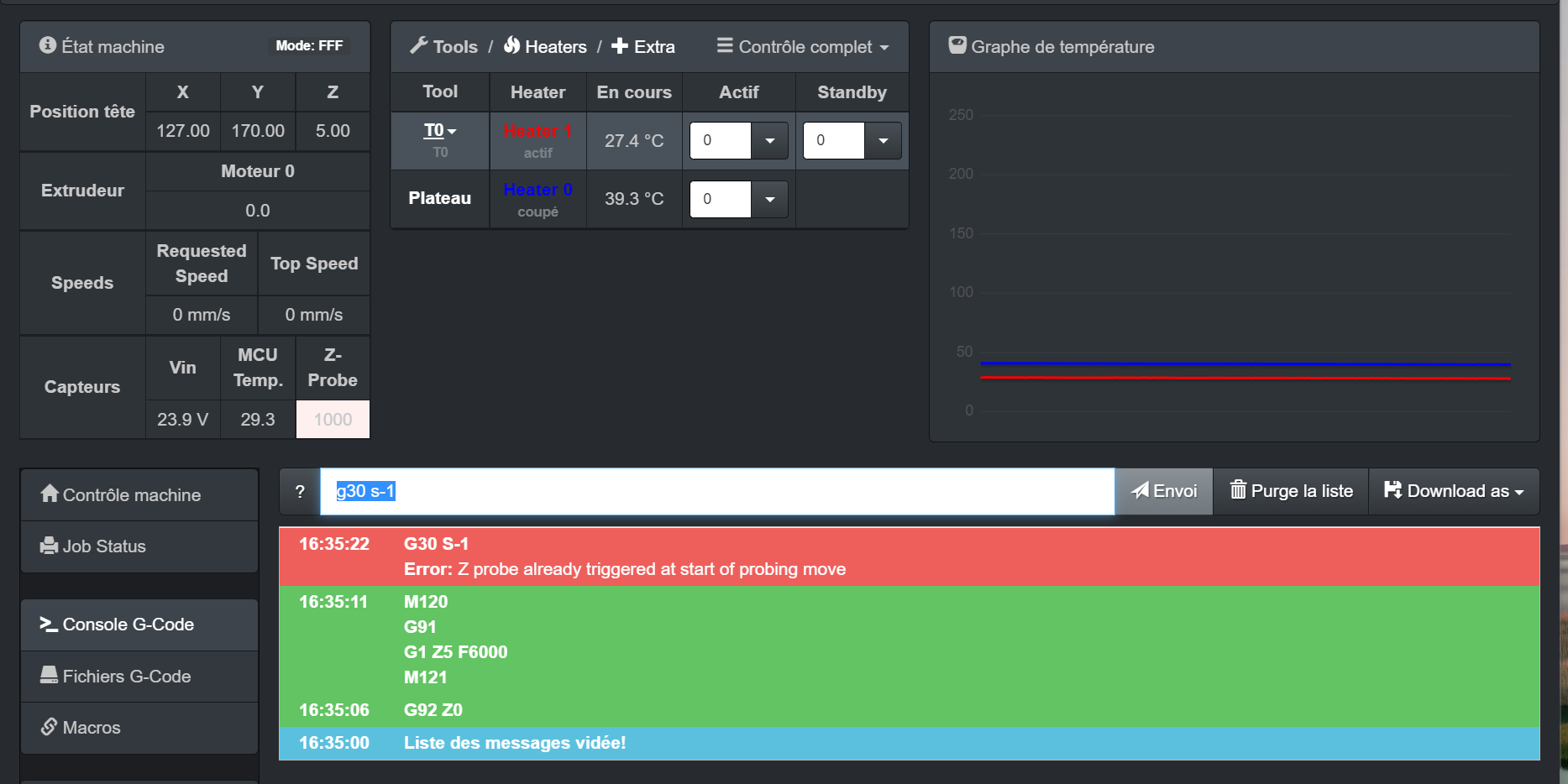

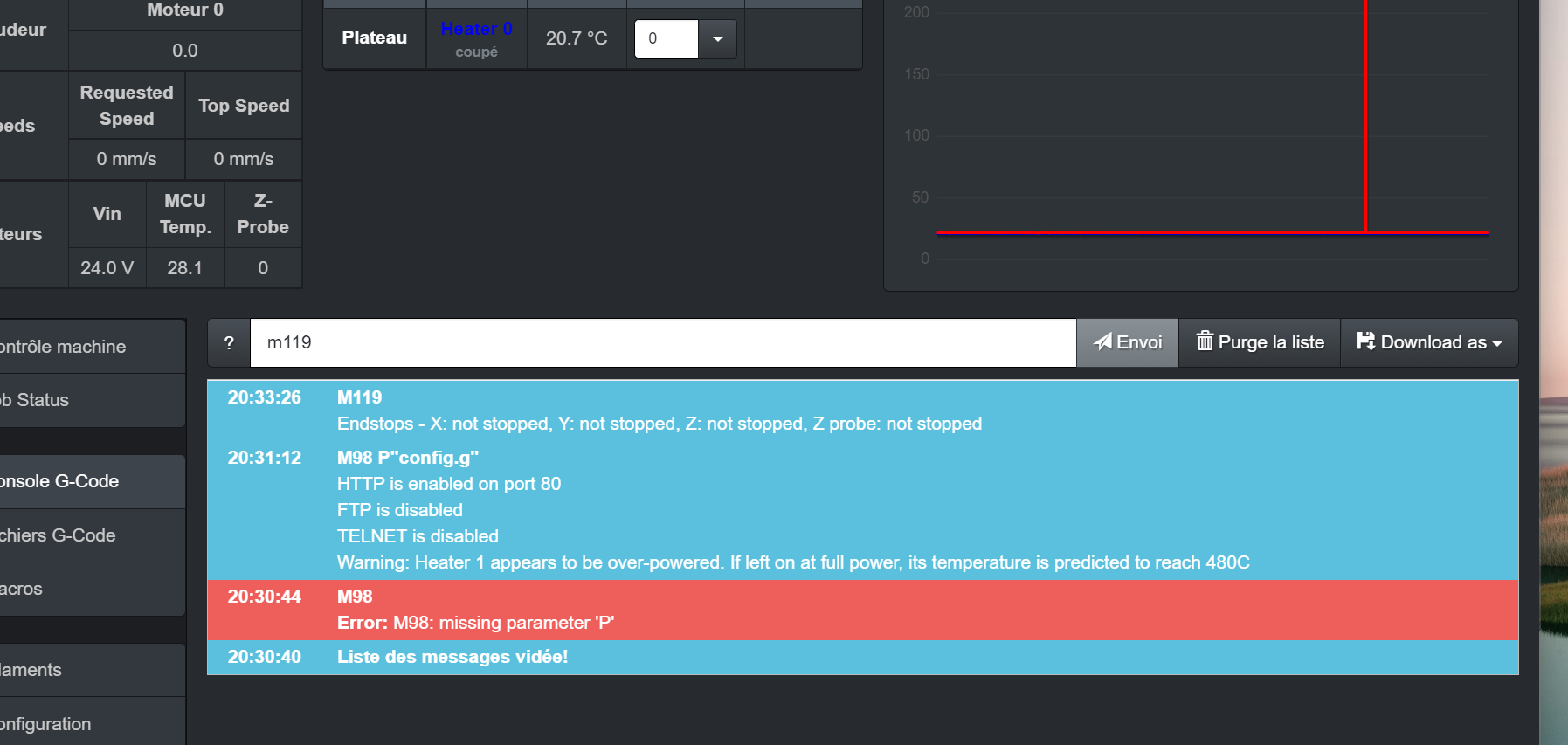

@siam i have M119

Endstops - X: not stopped, Y: not stopped, Z: at min stop, Z probe: at min stop -

-

@sgk have you made the changes which I have provided in my last post? And can you post the result of M98 P"config.g"

-

-

M558 P1 C"!^zprobe.in" H5 F200 T9000 I0 R0.5 ; Set Z probe type mini ir sensor

-

-

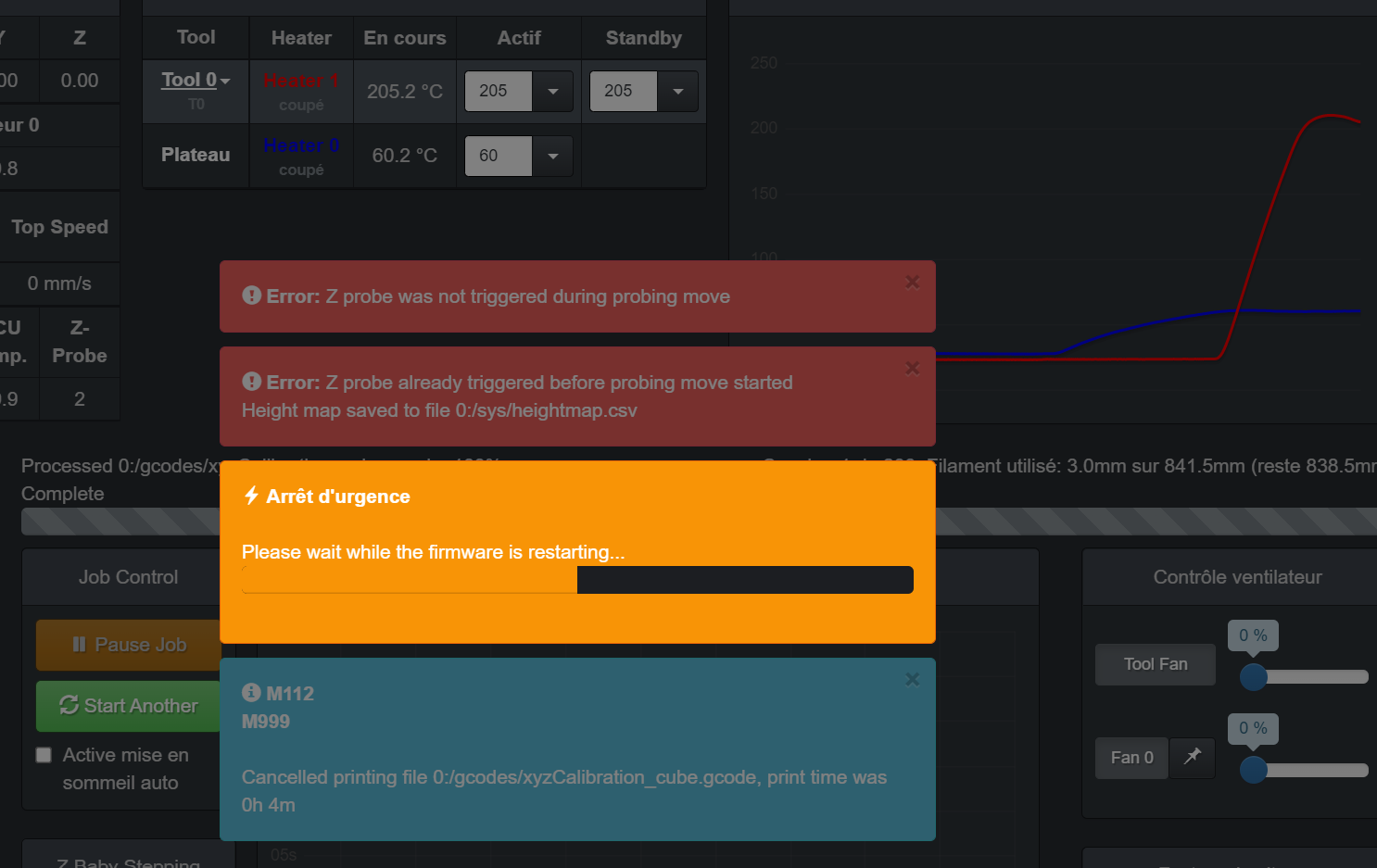

when I do Calibrate the Z probe trigger height the bed crashed into the nozzle when I hit g30 s-1

-

@sgk trigger height needs to be a positive value for the IR probe in RepRapFirmware.

-

thank you for answering me.

when i type g30 s-1 the bed doesn't stop -

is normal -

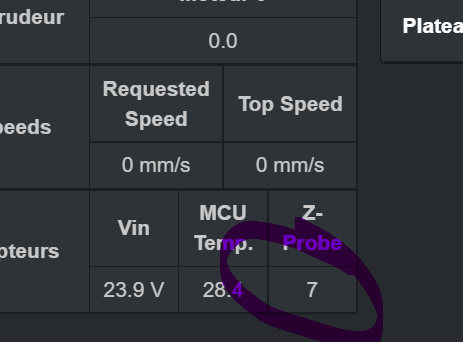

@sgk if you have the gantry high enough do that you can trigger the probe by putting your finger under it, can you see that the z probe value on DWC goes up?

Also, what kind of bed material do you use?

-

-

@sgk this bed

-

@sgk pei sheet is semi transparent and I've had mixed success with the IR board on it. I take it you also tested it with the paper underneath?

-

@oliof yes yes but the bed does not stop