Large Format Dowell to Duet conversion

-

Okay so I removed all of the wires connected to the wiring block for the first extruder and I am using the wiring block and wires for the second extruder and this seems to have stopped it shorting at the nozzle end of the printer.

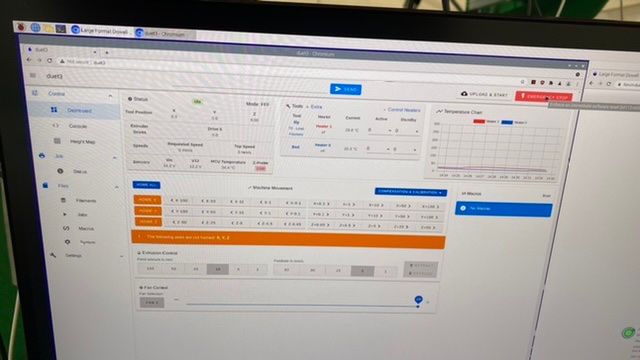

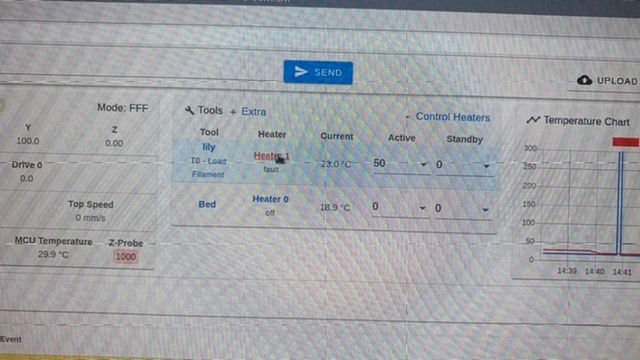

However when I set ‘active’ to 50 and click heater 1 to heat I get ‘fault’. Please advise

Many thanks

Charles -

@charles-fraser said in Large Format Dowell to Duet conversion:

Please can we also run some tests on motors, endstops, and any other parts we need to so that we can make sure we have components that work with these boards now so I can order the parts now? Is there a way to test the endstops and motors are working and set up right please?

Yes. Because there were a lot of issues to start with I have broken this down into a step by step process to keep on top of whats happening.

@charles-fraser said in Large Format Dowell to Duet conversion:

So I went down to the noz and when I held the thermistor I was getting a constant electric shock. Nothing too bad but enough to make me have to let go. I then laid the thermistor on the bed and the temps were 2000C

Ok so i would isolate the power to the heaters on the nozzle and anything else going through that set of connection blocks and investigate those - you should not be getting any form of electric shock ofc. What is particularly concerning is its unlikely you would feel a 24V DC shock so i suspect AC (unless it was a one off static shock). I can't really help much with AC wiring remotely. The wiring block is obviously a prime suspect if the heater itself is ok (based on your next post). Given all the issues that we have had with that wiring block I would be tempted to remove it from the system entirely if you can.

If you are now using the second extrude heater wires then did you update the heater connection on the Duet (its plugged into out1 on on the 3HC.

Also for the bed PT1000 can you confirm you have it plugged into temp0 and you made the config changes i mentioned?

M308 S0 P"1.temp0" Y"PT1000"Finally send config.g again to check for errors.

-

I'd strongly suggest you properly ground the printer frame for safety, and link the power supply negative to the frame, to avoid electrical noise pickup.

-

My god.... i need see a printed Benchy from this printer... a 1000 mm bechy, you can fit with a outboard motor

-

@peirof a benchy?

-

@rjenkinsgb thanks Robert J it is grounded as you describe already.

-

@t3p3tony thanks captain. I have disconected everything from the first extruder Mounting / block and am using the second block. This gets rid of all these low power tingly shocks when I touch the thermistor (not sudden but a painful prickle as long as I hold the thermistor when plugged into that block. I think the noz heater or fan wires must have rubbed down or melted down or something because that whole block is messed up. If you remember the BL-Touch was shorting too (I’m ordering a 3D Touch because it will come with some actual paperwork.

I’ll post the config G file here just now, I replaced all the lines you showed me however. I must have done something wrong. Thanks so much, sorry this is such hard work.

Is anyone at the Additt conference this week? We need to find a manufacture partner for this opensource pellet extruder that Juan has invented. His Spanish partners just dropped out www.recycl3dprint.com

-

Plugged into temp 0 and temp 1 on the 3HC

Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 16:59:54 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ; Wait a moment for the CAN expansion boards to start G4 S2 ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M569 P1.0 S1 ; physical drive 1.0 goes forwards M584 X0.0 Y0.1 Z0.2:0.4:0.5:0.3 E1.0 M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X2800 Y2800 Z1200 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1200 Y2000 Z1600 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"^1.io1.in" H100 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"1.temp0" Y"PT1000" M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S80 ; set temperature limit for heater 0 to 80C M308 S1 P"1.temp1" Y"PT1000" ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"1.out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out8" Q0 ; create fan 0 on pin out8 and set its frequency M106 P0 S0 H T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"lily" D0 H1 F0:1 ; define tool 0 G10 P0 X100 Y100 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined -

@charles-fraser ok so do you get errors when config.g is run using M98? and are both heaters showing correctly in the U and heating when commanded?

-

27/10/2021, 13:47:35 M98 P"0:/sys/config.g"

=

27/10/2021, 13:47:36 Error: M143: Heater 0 does not exist

27/10/2021, 13:47:36 Error: M307: Heater 0 not found -

-

@charles-fraser just noticed in your most recent config.g that the command to create the bed is missing, must have been deleted in error. please add the line

M950 H0 C"1.out0" T0

so your heater section should look like this:; Heaters M308 S0 P"1.temp0" Y"PT1000" M950 H0 C"1.out0" T0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S80 ; set temperature limit for heater 0 to 80C M308 S1 P"1.temp1" Y"PT1000" ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"1.out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300Csorry i did not spot this earlier.

-

Okay so that works! Thanks!

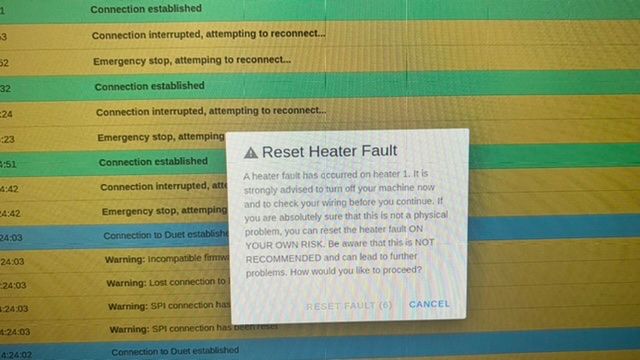

When I set ‘active’ to 50C on the noz and click ‘heater 1m the mosfet light goes blue which means the signal is going to the mosfet from the right heater on the 3HC but after a few secs it just says ‘fault’ so I emergency stop!

NB I still cant find a 3x15mm pt1000 thermistor anywhere! So at the moment I have this rather high tech workaround with the 6x50mm pt1000 where the thermistor is just held against the heating block with some tape so we can at least see if it’s getting warmer. Does this indicate that the heating cartridge is faulty?

Also when I set the heated bed to 30C on the active setting and turn it on it did seem to get warmer (went up by a degree) then reported fault

-

@charles-fraser The faults are probably because the bed and nozzle are not tuned. There is not much point in tuning them right now if thats the case because the setup is not how it will be in normal operation (PT1000 taped to the outside).

When you say you got a "fault" what fault did you get reported in the console?

I cant see anything in the photos of DWC that you upload. its better to cut and paste the text from the console into this thread (using the </> block for formatting. -

So when I set noz ‘active’ to 50 it starts heating and shortly after just says fault where it used to say active:

But if I just leave it it does work, the noz heats up. However when I stop it it says

The same is true for the bed but the bed does not heat up! I’ll try switching the polarity of the wires joining that relay!

Also what is this new: ‘incompatible firmware’ message. I didnt see that before.

-

@charles-fraser lets deal with the incompatible firmware bit and then come back to the heaters.

Please send M115 and M115 B1. copy the results from the console into here.

Then look at the "settings" machine and General to get the DWC and DSF versions.

-

27/10/2021, 15:36:37 M115 B1

Duet EXP3HC firmware version 3.4.0beta5 (2021-10-12 13:58:36)27/10/2021, 15:36:25 M115

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.3 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2021-06-15 21:45:56 -

Duet Web Control 3.4.0-b5

Board: Duet 3 MB6HC (MB6HC)

DSF Version: 3.4-b5

Firmware: RepRapFirmware for Duet 3 MB6HC 3.3 (2021-06-15) -

@charles-fraser ok so when you upgraded to 3.4b5 the mainboard did not get upgraded

-

@Charles-Fraser take this file:

Duet3Firmware_MB6HC.bin

From here

https://github.com/Duet3D/RepRapFirmware/releases/tag/3.4.0beta5and upgrade using the System->Upload System Files