Large Format Dowell to Duet conversion

-

@charles-fraser said in Large Format Dowell to Duet conversion:

NB I still cant find a 3x15mm pt1000 thermistor anywhere!

-

I’ve got that PT1000 now and will spend the next few days getting this all calibrated again.

I will fit the PT1000 into the heating block but the block is now separated from the screw and needs to be heated up whilst on the screw in order for the hardened plastic to become soft enough to allow it to be pushed all the way up against and bolted to the mounting block.

I can do that by just setting ‘active’ to 190C right? After that what’s the command for the PID autotune for the nozzle again please?

The homing seems to be working on the x and y and I set a z min endstop up in the same way as the x and y as a fallback option to the 3D touch.

I’ll rewire the 3D touch to the second extruder mounting block that seems to be free of shorts. I’ll follow the earlier instructions on how to do that. Is that possible to have a 3D touch and second z endstop? I replaced the probe code with the z min endstop switch code so wonder if you could point me in the right direction for the 3D touch code please?

Many thanks

Charles -

@charles-fraser said in Large Format Dowell to Duet conversion:

can do that by just setting ‘active’ to 190C right?

Yes once you are happy the thermistor is reading properly and the heater wiring is not shocking anything!

@charles-fraser said in Large Format Dowell to Duet conversion:

After that what’s the command for the PID autotune for the nozzle again please?

See the description here:

https://duet3d.dozuki.com/Wiki/M303

At its simplest its:

M303 T0 S200@charles-fraser said in Large Format Dowell to Duet conversion:

Is that possible to have a 3D touch and second z endstop?

Yes one as a Z probe and one as an endstop. I would have the endstop at Z max because it will allow you to home Z onto the endstop even with a print on the bed (e.g. a power fail part way through a print).

@charles-fraser said in Large Format Dowell to Duet conversion:

I replaced the probe code with the z min endstop switch code so wonder if you could point me in the right direction for the 3D touch code please?

Its here:

https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe#Section_Software_setup_RepRapFirmware_Num_3You will need to modify it based on which inputs you put the probe. The probe should be on the same board as your Z motors.

-

Thank you Tony, I stupidly seem to have forgotten the thermistor. If I use the thermistor that came with the extruder it's a NTC 100k. Is that easily copatible if I just change the code please? Many thanks

-

@charles-fraser oops sorry i meant the PT1000 that you have bought to replace the thermistor! I thought we had determined that the extruder thermistor was faulty way earlier in this thread?

-

No we didnt establish that thermistor was faulty,I just didn't know what kind it was. It's type 13 in marlin, that's the type listed above. Can we edit the config.g file to use this one please?

-

@charles-fraser said in Large Format Dowell to Duet conversion:

type 13 in marlin

13 : 100kΩ Hisens up to 300°C - for "Simple ONE" & "All In ONE" hotend - beta 3950, 1%

from:

https://github.com/MarlinFirmware/Marlin/blob/2.0.x/Marlin/Configuration.hSo

M308 S1 P"1.temp1" Y"thermistor" T100000 B3950

this is plugging it into port temp1 on the 3HC (which you currently have setup for the PT1000 on the hotend.

-

Thanks, regarding PID autotune: when the extruder is extruding pellets at full flow rate through a 3mm nozzle the heating characteristics are very different then when just sat idle. Is there a way to autotune while the extruder is extruding please?

Regarding endstops: is this okay? The z switch is so that if the bed comes so close to the nozzle and starts to push against it the switch is closed and the z motion should stop

; Endstops M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin io2.in M574 Z1 S1 P"io0.in"For the z probe I have.

; Z-Probe M558 P9 C"^1.io1.in" H100 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X15:215 Y15:195 S20 ; define mesh gridif I want to change it to io3 on the 6HC should I change it to

M558 P9 C"^0.io3.in" H100 F120 T6000 -

Great that is working well and PID tuning now.

-

Just for the record

Edit the M307 H1 command in config.g to match this. Omit the V parameter if the heater is not powered from VIN. 03/11/2021, 13:42:50 Auto tuning heater 1 completed after 3 idle and 30 tuning cycles in 1842 seconds. This heater needs the following M307 command: M307 H1 B0 R1.465 C296.7:296.7 D8.30 S1.00 V24.0 03/11/2021, 13:42:49 Warning: Turning on the print cooling fan did not increase hot end cooling. Check that the correct fan has been configured. 03/11/2021, 13:38:35 Auto tune starting phase 5, tuning with fan on 03/11/2021, 13:38:34 Warning: heater behaviour was not consistent during tuning 03/11/2021, 13:18:05 Auto tune starting phase 4, tuning with fan off 03/11/2021, 13:14:58 Auto tune starting phase 3, heating system settling 03/11/2021, 13:12:11 Auto tune starting phase 2, heating up 03/11/2021, 13:12:07 M303 T0 S200 Auto tuning heater 1 using target temperature 200.0°C and PWM 1.00 - do not leave printer unattendedI have now wired the two fans either side of the pellet loading chamber in parallelp to out8 on the 6HC. I can't here it idling however. Maybe I should swap polarity.

Is it possible to wire the 3D touch to the 3HC as the wires can't reach the 6HC where it is?

For reference:

Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 16:59:54 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ; Wait a moment for the CAN expansion boards to start G4 S2 ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S0 ; physical drive 0.4 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M569 P1.0 S1 ; physical drive 1.0 goes forwards M584 X0.0 Y0.1 Z0.2:0.4:0.5:0.3 E1.0 M350 X16 Y128 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y1280.00 Z1926.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z500.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X2800 Y2800 Z1200 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1200 Y2000 Z1600 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin io2.in M574 Z1 S1 P"io0.in" ; Z-Probe M558 P9 C"^1.io1.in" H100 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"1.temp0" Y"PT1000" M950 H0 C"1.out0" T0 M307 H0 B1 R0.138 C790.6 D13.87 S1.00 V24.0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S80 ; set temperature limit for heater 0 to 80C M308 S1 P"1.temp1" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"1.out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 R1.465 C296.7:296.7 D8.30 S1.00 V24.0 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 S0 H T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"lily" D0 H1 F0:1 ; define tool 0 G10 P0 X100 Y100 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined -

@t3p3tony the fans are not working. Not sure why I’ve tried reversing the poles

-

@charles-fraser said in Large Format Dowell to Duet conversion:

M307 H1 B0 R1.465 C296.7:296.7 D8.30 S1.00 V24.0 03/11/2021, 13:42:49 Warning: Turning on the print cooling fan did not increase hot end cooling. Check that the correct fan has been configured.

You may need to re run the tuning after fixing the issues below.

M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 S0 H T45this is wrong. I assume the fans on out8 are to cool the pellet extruder itself (not the print) in the same manner as a hotend cooling fan that cools the cold side of a heatbreak on a filament hotend? In that case this should be:

M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 H1 T45This tells the Duet that when heater sensor 1 gets over 45C, turn on fan0. It wont be on until the hotend sensor goes over 45C

The print cooling fan is ok, assuming you have it plugged into out 9

M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned offhowever the fan associations for the tool are not right:

@charles-fraser said in Large Format Dowell to Duet conversion:

M563 P0 S"lily" D0 H1 F0:1

should be

M563 P0 S"lily" D0 H1 F1as the tool is associated with the print cooling fan (the otehr fan is alsready assoicated with the heater.

-

Okay the "heat-break" fans are working well now. The print cooling fan is not working even if I turn the 'TOOL FAN' slider up to 100 and switch polarity of the wires. Maybe it needs to actually be printing for that to come on?

okay next I am gonna keep rewiring this BL touch

-

Oh Quick question: Is it possible to do a PID tuning while extruding because this extruder pushes out so much material it will need a different heating tuning I recon to make it work best. Also which line is the steps per mm of extruded material please? The Extruder has a 20:1 gear NEMA17 that needs to spin jolly fast to get that screw moving around.

-

@t3p3tony PS: is there no way to wire the 3D touch to the 3HC? Cables just don’t reach the 6HC

-

@charles-fraser said in Large Format Dowell to Duet conversion:

and switch polarity of the wires

https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_fans#Section_Caution

Caution

Fans are polarised. When connecting a fan to a fan connector, the positive wire (usually red) must be connected to the VFAN pin of that connector. The negative wire (normally black) must be connected to the FAN- pin if it is a controlled fan connector, or the GND pin if it is an always-on fan connector.

If you connect the fan the wrong way round, you may damage the fan, the Duet, or both.

Ian

-

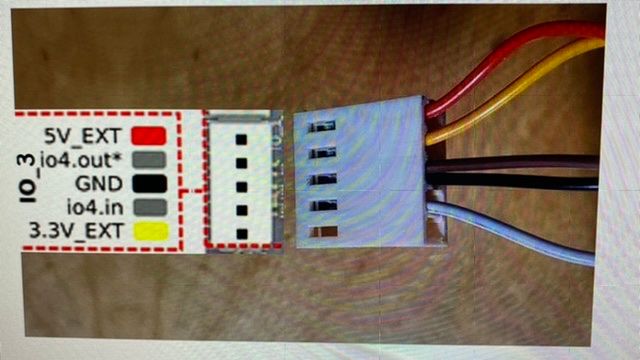

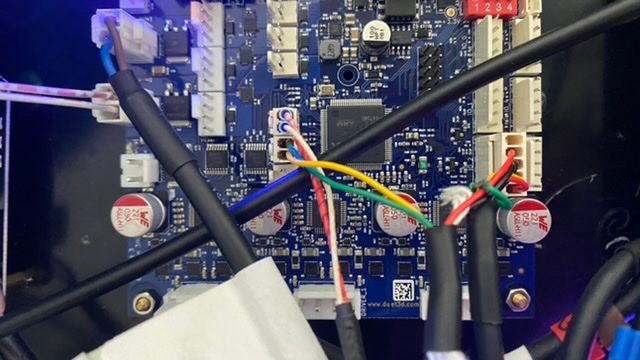

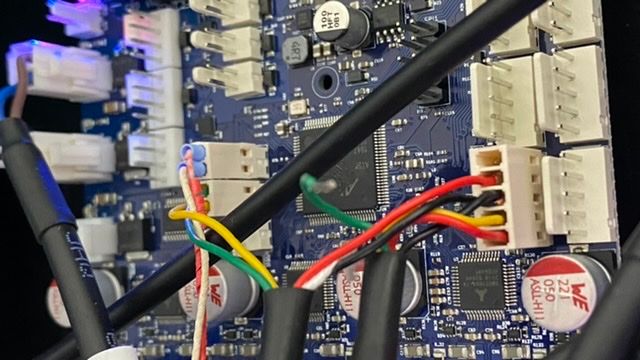

I’m sorry it’s a bit of a fudge but I have only been able to get the 3D touch wired up (I hope correctly) with the 3HC, IO_2

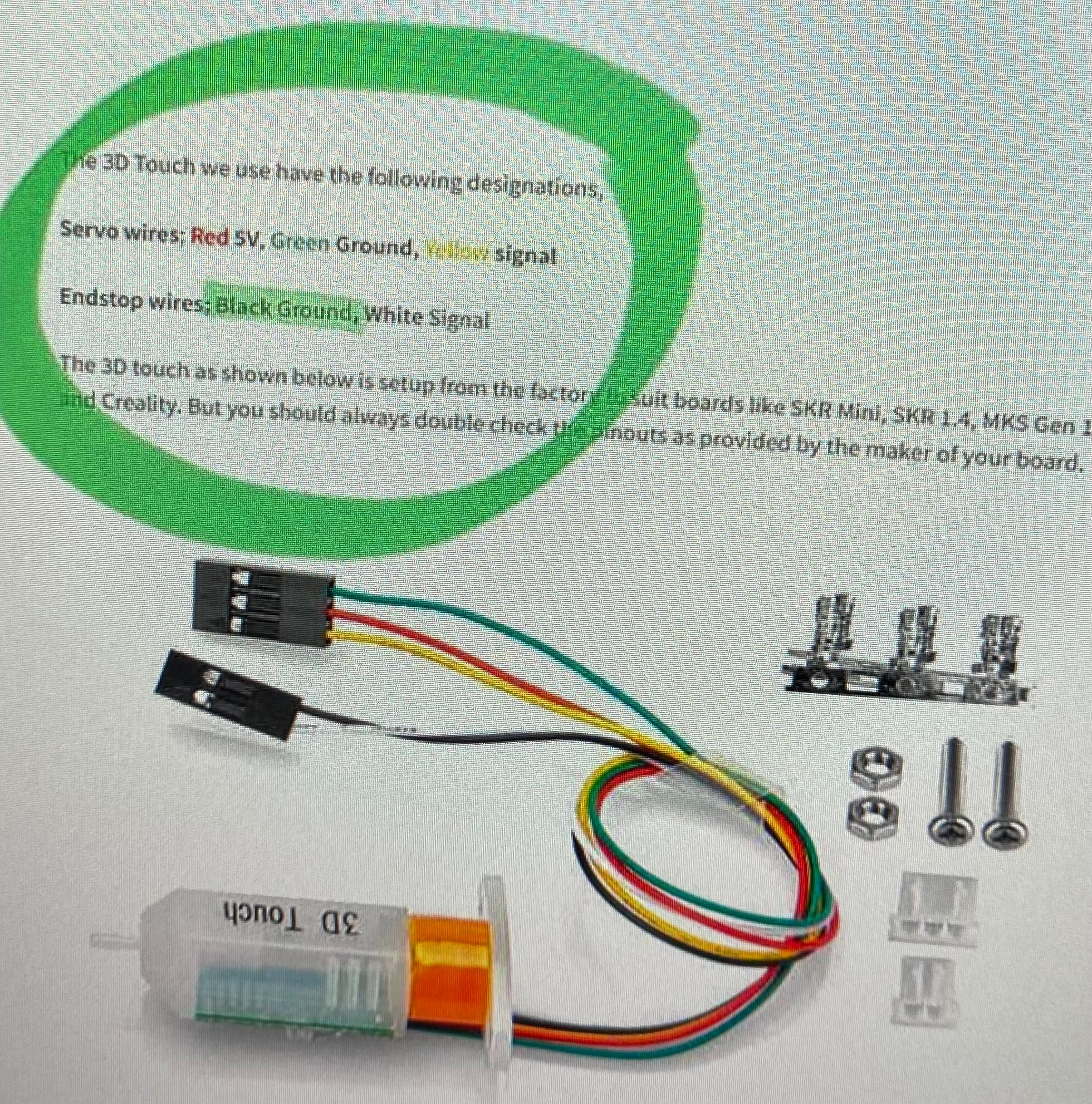

Here is what the wiring from the touch is supposed to be:

But the 3D touch I have does not have a white wire, it has a blue wire though so I am guessing that’s the only difference.

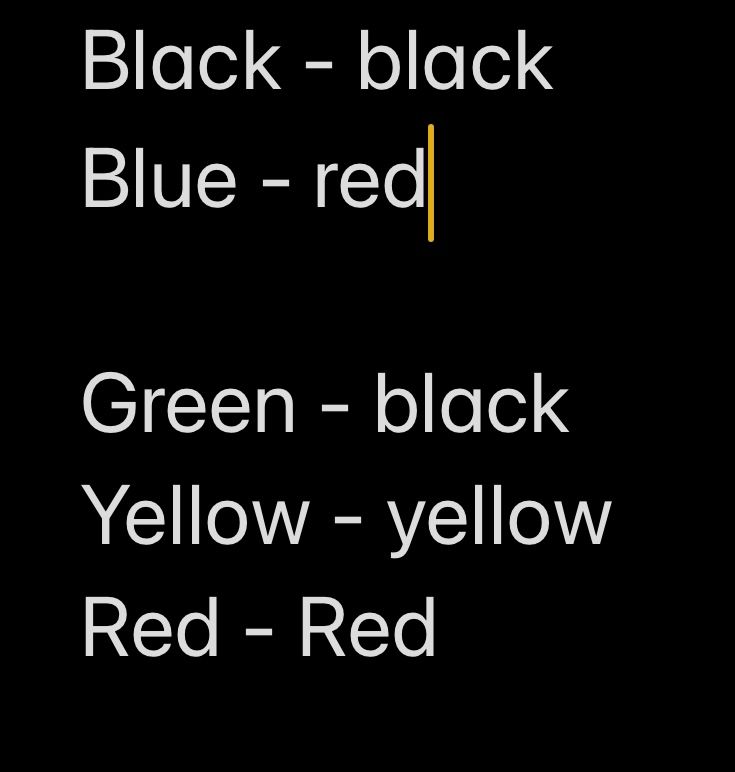

I have to connect the BL touch to two different cables, each with four wires in them to reach the board at the other end of the printer. In one of the cables, two of the wires are already used by the NTC thermistor so it looks like this:

Then I can only reach IO_2 on the 3H with all that following this diagram:

Which looks like this:

I hope that’s correct! I’ll try to change the code and hope it works!

-

WOAH! All I did was change the IO_1 to IO_2 in the config file and now so many errors and the heaters missing and things:

Configuration file for Duet 3 (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.3 on Fri Oct 01 2021 16:59:54 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ; Wait a moment for the CAN expansion boards to start G4 S2 ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes forwards M569 P0.4 S0 ; physical drive 0.4 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M569 P1.0 S1 ; physical drive 1.0 goes forwards M584 X0.0 Y0.1 Z0.2:0.4:0.5:0.3 E1.0 M350 X16 Y128 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y1280.00 Z1926.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z500.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X2800 Y2800 Z1200 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X1200 Y2000 Z1600 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure active-high endstop for low end on X via pin io1.in M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin io2.in M574 Z1 S1 P"io0.in" ; Z-Probe M558 P9 C"^1.io2.in" H100 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"1.temp0" Y"PT1000" M950 H0 C"1.out0" T0 M307 H0 B1 R0.138 C790.6 D13.87 S1.00 V24.0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S80 ; set temperature limit for heater 0 to 80C M308 S1 P"1.temp1" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"1.out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 R1.465 C296.7:296.7 D8.30 S1.00 V24.0 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 H1 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"lily" D0 H1 F1 G10 P0 X100 Y100 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined03/11/2021, 17:00:56 Error: M143: Heater 1 does not exist 03/11/2021, 17:00:56 Error: M307: Heater 1 not found 03/11/2021, 17:00:56 Error: M307: Heater 1 not found 03/11/2021, 17:00:56 Error: M950: Response timeout: CAN addr 1, req type 6026, RID=12 03/11/2021, 17:00:53 Error: M308: Response timeout: CAN addr 1, req type 6031, RID=10 03/11/2021, 17:00:51 Error: M307: Heater 0 not found 03/11/2021, 17:00:51 Error: M143: Heater 0 does not exist 03/11/2021, 17:00:51 Error: M950: Response timeout: CAN addr 1, req type 6026, RID=8 03/11/2021, 17:00:50 Error: M308: Response timeout: CAN addr 1, req type 6031, RID=6 03/11/2021, 17:00:47 Error: G31: Invalid Z probe index 03/11/2021, 17:00:47 Error: M558: Response timeout: CAN addr 1, req type 6036, RID=5 03/11/2021, 17:00:46 Error: Invalid remote handle 03/11/2021, 17:00:46 Error: M906: Response timeout: CAN addr 1, req type 6043, RID=4 03/11/2021, 17:00:45 Error: M92: Response timeout: CAN addr 1, req type 6042, RID=3 03/11/2021, 17:00:45 Error: M350: Response timeout: CAN addr 1, req type 6042, RID=2 03/11/2021, 17:00:45 Error: M584: Response timeout: CAN addr 1, req type 6042, RID=1 03/11/2021, 17:00:44 Error: M569: Response timeout: CAN addr 1, req type 6018, RID=0 03/11/2021, 17:00:39 Connection established 03/11/2021, 17:00:32 Connection interrupted, attempting to reconnect... 03/11/2021, 17:00:30 Emergency stop, attemping to reconnect... 03/11/2021, 16:58:33 Error: M307: Heater 1 not found 03/11/2021, 16:58:33 Error: M143: Heater 1 does not exist 03/11/2021, 16:58:33 Error: M307: Heater 1 not found 03/11/2021, 16:58:33 Error: M950: Response timeout: CAN addr 1, req type 6026, RID=12 03/11/2021, 16:58:30 Error: M308: Response timeout: CAN addr 1, req type 6031, RID=10 03/11/2021, 16:58:28 Error: M143: Heater 0 does not exist 03/11/2021, 16:58:28 Error: M307: Heater 0 not found 03/11/2021, 16:58:28 Error: M950: Response timeout: CAN addr 1, req type 6026, RID=8 03/11/2021, 16:58:26 Error: M308: Response timeout: CAN addr 1, req type 6031, RID=6 03/11/2021, 16:58:24 Error: G31: Invalid Z probe index 03/11/2021, 16:58:24 Error: M558: Response timeout: CAN addr 1, req type 6036, RID=5 03/11/2021, 16:58:23 Error: Invalid remote handle 03/11/2021, 16:58:23 Error: M906: Response timeout: CAN addr 1, req type 6043, RID=4 03/11/2021, 16:58:21 Error: M92: Response timeout: CAN addr 1, req type 6042, RID=3 03/11/2021, 16:58:20 Error: M350: Response timeout: CAN addr 1, req type 6042, RID=2 03/11/2021, 16:58:19 Error: M584: Response timeout: CAN addr 1, req type 6042, RID=1 03/11/2021, 16:58:18 Error: M569: Response timeout: CAN addr 1, req type 6018, RID=0 03/11/2021, 16:58:16 Connection established -

The 3HC is not being seen any more. It no longer flashes the amber light in time with the 6HC

When I send M115 B1 it just spins forever

-