strange over/under extrusion

-

I seem to suddenly be having a strange under/over extrusion issue. Prints are coming out terrible and were fine yesterday.

I'm not really sure if this is a slicer, firmware or hardware issue, but old gcode files that previously printed fine are coming out bad.

; Configuration file for Duet 3 Mini 5+ (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Jul 01 2021 17:21:30 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"BLV MGN Cube" ; set printer name M669 K1 ; select CoreXY mode M80 C"nil" ; ATX PS_ON on ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S0 ; disable Telnet G4 S1 ;wait for expansion boards to start ; Drives M569 P0.0 S0 D2 ; X motor runs forwards M569 P0.1 S1 D2 ; Y motor runs forwards M569 P0.2 S1 D2 ; physical drive 0.2 goes backwards M569 P0.3 S1 D2 ; physical drive 0.2 goes backwards M569 P0.4 S1 D2 ; physical drive 0.2 goes backwards M569 P121.0 S1 D2 ; physical drive 121.0 goes backwards M584 X0.0 Y0.1 Z0.2:0.3:0.4 E121.0 ; set drive mapping M671 X0:290:290 Y155:62:255 S3 ; leadscrews at rear left, front middle and rear right M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M350 E16 I0 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z3200.00 E947.00 ; set steps per mm M566 X2000.00 Y2000.00 Z150.00 E4000.00 ; set maximum instantaneous speed changes (mm/min) (Jerk) M203 X30000.00 Y30000.00 Z300.00 E2000.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z200.00 E5000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Pressure advance M572 D0 S0.7 ; Axis Limits M208 X-20 Y-20 Z0 S1 ; set axis minima M208 X305 Y295 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io1.in" ; configure active-high endstop for low end on X via pin io0.in M574 Y2 S1 P"io6.in" ; configure active-high endstop for low end on Y via pin io1.in M564 H0 ; allow jog without homing ;M591 D0 P7 C"io5.in" ; filament sensor ; Z-Probe M950 S0 C"^121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H3 F120 T10000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y66 Z0.40 ; set Z probe trigger value, offset and trigger height M557 X-10:293 Y65:300 P8 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.291 C1127.4 D26.90 S1.00 ; Set PID for bed values M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 R3.089 C258.2:154.4 D5.95 S1.00 V23.7 ; Set PID for hotend values M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"121.out2" Q80 ; create part cooling fan 0 on pin toolboard out1 and set its frequency M106 P0 S0 H-1 B1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out1" Q100 ; create hotend fan 1 on pin toolboard out1 and set its frequency M106 P1 S0.8 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Accel M955 P0 C"io3.out+io3.in" ; Screen M575 P1 B57600 S1The retraction looks and sounds a bit unusual so I've turned off all retraction in the slicer and pressure advance in firmware, yet the extruder still seems to be retracting.

-

@nick9one1 said in strange over/under extrusion:

Prints are coming out terrible and were fine yesterday.

What changes did you make since yesterday?

-

@alankilian nothing (intentional)

-

@nick9one1 said in strange over/under extrusion:

I'm not really sure if this is a slicer, firmware or hardware issue, but

... old gcode files that previously printed fine are coming out bad.

That eliminates slicer and firmware as a suspect.

- Does the temperature graph look stable during printing?

- Does your extruder make any funny noises?

- Does your Vin look stable on the DWC page during printing?

- What printer, firmware version, hardware do you have?

- Same filament?

- Did the humidity or room temp change since yesterday?

-

@nick9one1 If files that previously printed OK but now do not, that rules out the slicer. If you haven't made any changes to the firmware, that rules out the firmware. If you haven't made any changes to the configuration, that rules settings. Which only leaves hardware. If the extruder looks and sounds unusual, that would point to either the extruder itself or possibly a fault with the hot end.

-

thanks. I'm leaning towards it being the extruder too.

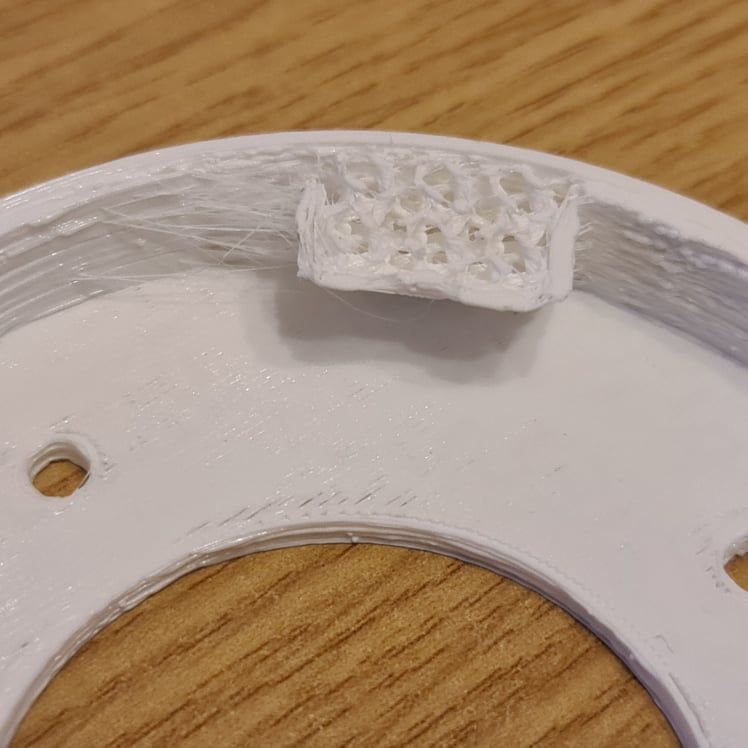

What's strange is it seems to make large retractions at ends of lines, when I have retraction set to zero. This is supposed to be a base layer of a solid cube.

Everything points to a hardware fault, but I cant think how a hardware fault would cause retractions to be too large like that.

-

@nick9one1 Post some GCODE.

-

-

@nick9one1 Yeah, I don't see any retractions in the GCODE at all.

What's with "Firmware retraction"?

I've heard it mentioned, but I don't know what revision it came into being or how to control it. -

@alankilian That's commented out. I use superslicer which usually has new features like that quite early.

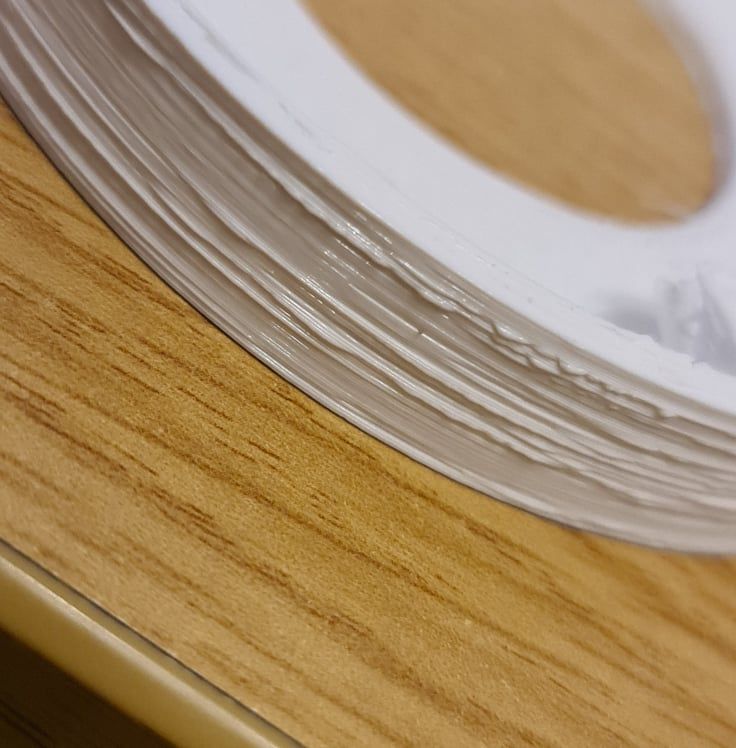

I thought it would be a good idea to print a cylinder in vase mode to see if its the retractions that are causing issues...

looks perfect to me;

and the same cylinder set to 2 walls and vase turned off.

-

@nick9one1 The only thing that I can think of which will cause what looks like retractions to happen when retractions are set to zero, is pressure advance. You do have a very high value of 0.7. That would also make the extruders look and sound unusual. And pressure advance may not get applied in vase mode because essentially it's one continuous move with no obvious start and end point where PA could be applied (but I'm not sure how the algorithm deals with that so I might be wrong).

Suggest you try disabling pressure advance by setting it to 0 (M572) or at least to a much lower value. The only thing that puzzles me is that you say you haven't made any changes.

EdIt. According to your first post, you say that you turned PA off. Yet it's there in the config.g file you posted.

-

@deckingman

Thanks. You're right. I had turned it off (I'm sure I did!) But will double check and reprint. -

it's always something simple.

Pressure advance should be 0.07 not 0.7!

Thank you !!

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved

-

@nick9one1 said in strange over/under extrusion:

Prints are coming out terrible and were fine yesterday.

@nick9one1 said in strange over/under extrusion:

Pressure advance should be 0.07 not 0.7!

So you changed pressure advance this morning and that was it?