New heated enclosure printer

-

@phaedrux OK, got that taken care of. Was confused that the Modulation Pin needs to be not defined.

I installed AC power and powered it up. Nothing smoked, so that was a good step. I do of course have a couple of problems:

-1LC toolboard is not in CAN sync (fast blinking LED) tried reset to factory but no go. I'm pretty sure the wiring is correct. The extruder fan is on. Vin and 5V leds are lit. tried sending a query over the web interface with this response:

Error: M115: Response timeout: CAN addr 121, req type 6024, RID=14

-chamber temp sensor is reading at 2000C, but a multimeter reads 226kohm across the plug, which is two pt1000 sensors in series.

-when I go to home an axis I get a 'failed to enable endstops error'

Here's the config.g file:

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Apr 14 2022 23:52:03 GMT-0400 (Eastern Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"hyperprinter" ; set printer name

M669 K1 ; select CoreXY mode; Wait a moment for the CAN expansion boards to start

G4 S2; Network

M552 P192.168.2.1 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.2.20 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P121.0 S1 ; physical drive 121.0 goes forwards

M584 X0.1 Y0.2 Z0.0 E121.0 ; set drive mapping

M350 X32 Y32 Z8 E16 I1 ; configure microstepping with interpolation

M92 X56.14 Y56.14 Z320.00 E837.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z3000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X300 Y300 Z3900 E1500 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout; Axis Limits

M208 X-320 Y-290 Z0 S1 ; set axis minima

M208 X320 Y290 Z950 S0 ; set axis maxima; Endstops

M574 X1 S1 P"121.io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 121.io2.in

M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"121.io0.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X-300:300 Y-250:250 S100 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"pt1000" ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp2" Y"pt1000" ; configure sensor 1 as PT1000 on pin temp2

M950 H1 C"out1" T1 ; create chamber heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M141 H1 ; map chamber to heater 1

M143 H1 S150 ; set temperature limit for heater 1 to 150C

M308 S2 P"121.temp0" Y"pt1000" ; configure sensor 2 as PT1000 on pin 121.temp0

M950 H2 C"121.out0" T2 ; create nozzle heater output on 121.out0 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S320 ; set temperature limit for heater 2 to 320C; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off

M950 F2 C"121.out2" Q500 ; create fan 2 on pin 121.out2 and set its frequency

M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off; Tools

M563 P0 S"xyhead" D0 H2 F2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

M950 D1 C"spi.cs0+spi.cs2"Tha's it for now.

-

@coseng said in New heated enclosure printer:

a couple of problems:

-1LC toolboard is not in CAN sync (fast blinking LED) tried reset to factory but no go. I'm pretty sure the wiring is correct. The extruder fan is on. Vin and 5V leds are lit. tried sending a query over the web interface with this response:

Error: M115: Response timeout: CAN addr 121, req type 6024, RID=14That's almost certainly caused by a wiring error. Perhaps CANL and CANH are swapped betweeen the main board and the tool board. Can you post a photo of the CAN wiring?

-chamber temp sensor is reading at 2000C, but a multimeter reads 226kohm across the plug, which is two pt1000 sensors in series.

Did you mean two 100K thermistors in series?

-when I go to home an axis I get a 'failed to enable endstops error'

That's because the endstop is configured on the tool board and the main board failed to communicate with it.

-

@dc42 Here's a pic of both ends of the CAN line from the TDB to the 1LC. I used the provided RJ11 cable for the 6HC to the TDB.

The about 2m long purple cable is a CAN rated cable from McMaster, 8097T21. Connectors are 3M IDC style, 37304-3101-0P0FL-8P from Misumi. I checked continuity from end to end.

The temp chamber sensors are 2 PT1000 in series. They have the blue mesh wires and check out in a multimeter individually and wired together.

-

-

@coseng I suggest you use a multimeter to check for continuity between CANH on the 6HC and CANH on the tool board. Similarly for CANL.

Another test you can do is to measure the resistance between the 2 jumpers on an unused port on the distribution board. It should be 60 ohms if the connections are sound. But this doesn't check for CANL and CANH being swapped between the main board and the tool board.

Both tests with power off, of course.

-

@dc42 Thanks for responding on a holiday weekend. Traced it back and found that I somehow damaged the provided RJ11 cable. Swapped it out and now the CAN bus is synchronized and the nozzle temp is correct.

Chamber temp still reads 2000C and is two PT1000 sensors in series.

Now on to some motion problems. If I issue a M564 H0 and go to the 'move' page, Z moves without a problem but X and Y do not respond. If I then go back to the main page and try an individual axis home, z moves a little if any axis is pressed and a 'G0/G1: insufficient axes homed' error.

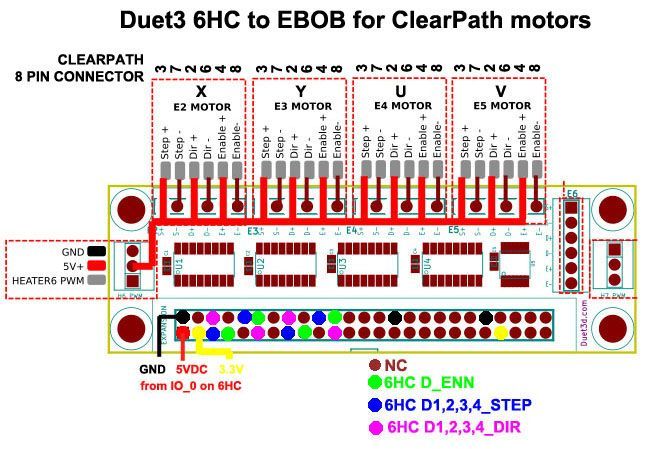

I'm pretty sure all the roach wires on the stepper signals are correct, and wired the BoB according to this image:

Only X and Y are connected.

-

OK, looking in the files and seeing that all the home moves move the Z axis first means that Z moving first when doing a x or y homing is not a problem. So now to figure out why the clearpath motors are not moving and the chamer temp is not reading correctly.

-

@coseng They are not moving because I have not turned the 5V output to it on! Is there a command to do this through the web control?

-

@dc42 To turn IO_3_out on to 5V, do I need to define it as a fan then turn the fan on at 100%?

-

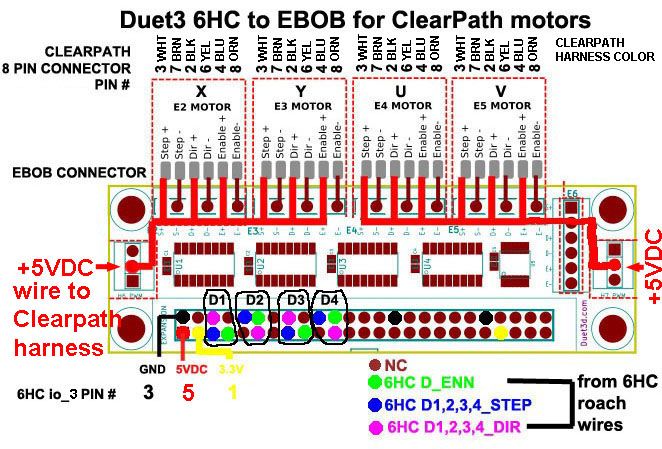

@dc42 I'm a stumped and at an impasse if you can spare a little time to help. Everything works but the chamber temp sensors (2 PT1000 in series) still reads 2000C and I can't get the X or Y motor (Driver 1/2) to move through my roach wired BOB arrangement. Z moves fine through Driver 0. I've triple checked the roach wiring and it matches this 'schematic':

I have the 5VDC to the ClearPath's (+) inputs wired externally to the connector thought the 5VDC pin on the 3 pin connector. This allowed me to test the polarity as you indicated in your previous post: 'If you are using single ended 5V drive, then connect ENA+ of your servo to +5V, and ENA- to either Enable+ or Enable- on the EBOB, whichever gives the correct polarity.' Enable- ended up working.

The motors are both enabled (a status LED on the motor body is in the 'enabled and waiting for a move command' state). But I can't get motion with the Clearpath's (-) step and direction lines connected to either BOB connector's polarity. See image.

I'm not sure if I should try swapping the clearpath lines around so +5V goes to brn/yel/ora instead of whi/blk/blu.

Any suggestions are appreciated. Here is the config.g file:

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Apr 14 2022 23:29:28 GMT-0400 (Eastern Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"hyperprinter" ; set printer name

M669 K1 ; select CoreXY mode

M564 H0 ; allow moves before homing; Wait a moment for the CAN expansion boards to start

G4 S2; Network

M552 P192.168.2.1 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.2.20 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P121.0 S1 ; physical drive 121.0 goes forwards

M584 X0.1 Y0.2 Z0.0 E121.0 ; set drive mapping

M350 X32 Y32 Z8 E16 I1 ; configure microstepping with interpolation

M92 X56.14 Y56.14 Z320.00 E837.00 ; set steps per mm

M566 X100.00 Y100.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X2000.00 Y2000.00 Z1000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X50.00 Y50.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X300 Y300 Z3900 E1500 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout; Axis Limits

M208 X-320 Y-290 Z0 S1 ; set axis minima

M208 X320 Y290 Z950 S0 ; set axis maxima; Endstops

M574 X1 S1 P"121.io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin 121.io2.in

M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"121.io0.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X-300:300 Y-250:250 S100 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"pt1000" ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"pt1000" ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create chamber heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit

M141 H1 ; map chamber to heater 1

M143 H1 S150 ; set temperature limit for heater 1 to 150C

M308 S2 P"121.temp0" Y"pt1000" ; configure sensor 2 as PT1000 on pin 121.temp0

M950 H2 C"121.out0" T2 ; create nozzle heater output on 121.out0 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S320 ; set temperature limit for heater 2 to 320C; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 C"Chamber 1" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 C"Chamber 2" S1 H-1 ; set fan 1 name and value. Thermostatic control is turned off

M950 F2 C"121.out2" Q500 ; create fan 2 on pin 121.out2 and set its frequency

M106 P2 C"XY Extruder" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"out7" Q500 ; create fan 3 on pin out7 and set its frequency

M106 P3 C"Water Cooler" S1 H-1 ; set fan 3 name and value. Thermostatic control is turned off; Tools

M563 P0 S"xyhead" D0 H2 F2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

M950 D1 C"spi.cs0+spi.cs2"Thanks.

-

@coseng you need to use M569 commands with T parameters to lengthen the step pulse timing for external drivers. See https://docs.duet3d.com/en/User_manual/Connecting_hardware/Motors_connecting_external#configuring-the-step-timing.

-

@dc42 Yes, that did it, thanks! The Clearpath say .750us step pulse width minimum, so I used a setting of T2 to be safe. Now I need to so some servo tuning with Tecnik then can start printing! Finally!

Thanks to the forum for all the help so far. And to the Duet3D crew for providing a great product and better customer support than most large companies do!

-

Progress! All the axes work and no more errors. And yes, thermistors for the chamber temp sensor. I have not done the thermal tuning for any of the heaters yet, but am expecting the chamber to take a while. Are there timeouts? I can't imagine the chamber coming up to temp quickly.

The from an aural perspective, the clearpath motors are light years ahead of steppers. Compared to the steppered Z axis, they are fast and quiet, and with the long belt runs (about 3ft.) there are no problems with belt span weirdness from really slow moves to nearly 2000ipm/0.9mps rapids. Yes, 2000ipm, that is not an extra zero. I know that it will never print at those speeds, but is nice to know that there is plenty of torque to spare and that the mechanical structure has the stiffness to deal with large acceleration forces. I was surprised that the bellows was not a limiting factor. I had Tom Tullar from Teknic remotely tune the motor parameters and he was very happy with the results, with a very small following error even during accelerations. The software is pretty awesome, their diagnostic oscilloscope feature is very useful and showed very good axis alignment by having a consistent torque requirement along the entire axis length.

Here's a short video of some motion:

https://youtube.com/shorts/0DkGP00Besg?feature=share

I am really impressed with the overall quality of entire the Duet ecosystem. The hardware,firmware, software, and user support were all top quality. It is not often that I can't find something that could be improved, but this is one of those times! It makes me want to build more stuff with it!

Now on to getting it hot and printing!

-

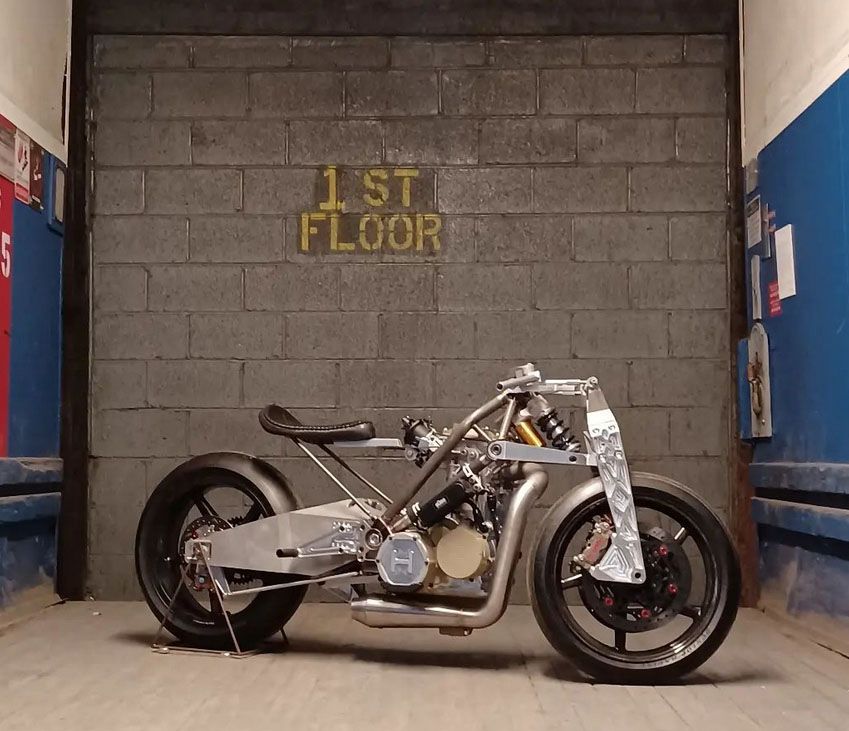

OK, sorry about the drop out there, but had to drive from NJ to Portland, OR to have the bike this is all about at a show, the One Moto show. The show was fun, the drive sucked, but for your viewing pleasure here's a shot of the bike, sans the bodywork that this printer will print.

Lots of other 3d printing in this baby. The first 8" of the exhaust was DMLS printed in 316 stainless steel. The swingarm was sand cast in A356 aluminum in a mold that was printed directly in sand by humtown.com. Same goes for the engine side covers and oil sump, but they are cast in magnesium. The steel chassis lugs were FDM printed in PolyCast filament then investment cast in 4130 steel. Last but not least, the oil cooler mounting brackets were printed on my Anycubic MonoX in Siraya's high temp white resin.

-

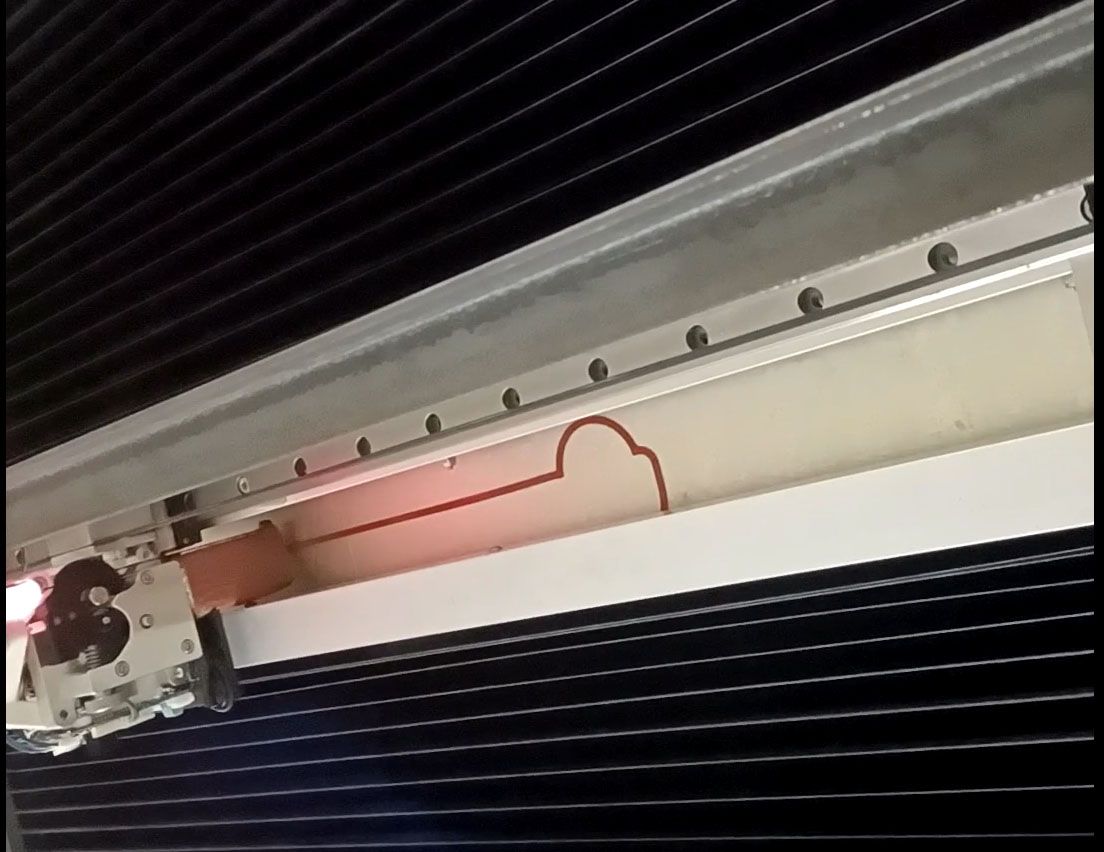

OK, plastic has been extruded! Got the alignment good enough, then did some thermal tuning, and got that good enough, then jumped right into printing and it printed! For a little while, at least.

After the first layer, the filament jammed at the spool. The feed entry from the spool dug into the spool and resulted in too much friction for the extruder to overcome.

and

The spool is mounted on bearings and on its own can turn very freely. Any suggestions on how to prevent this from happening? The printer could use an entire 10kg spool in one print, so these problams can waste a lot of time and material. Any suggestions are greatly appreciated!

-

Also, for a large, heated machine like this are there any hints for the heater tuning process?

The first run did them all individually with everything else at room temp.

After a full 25 or so runs and a couple of hours, the bed heater (600x700x8mm Al plate with 3000W 220VAC Keenovo heater) gave me an inconsistent heating warning, but the graph was a very regular sawtooth from 95-101C, so I ignored the error and used the settings.

The hot end (E3D aqua with supervolcano hot end, 24VDC/80W) tuning was pretty quick with no warnings.

The chamber heater had to be reworked a bit to double up on the number of heater coils (ended up with 3200W, two heater fans and two small always on chamber recirculating fans) as the temp rise was way too slow. I ended up with getting a decent response to 60C (at which point the bed temp sensor was reading 80C with the bed heater off) so called it a day and stored the values.

Since none of these heater systems will be working independently as these tuning procedures are run, is there a better way? Maybe set the bed temp to active then run the chamber tuning procedure, then do the reverse? The extruder is small enough mass and well thermally shielded that it may be mostly independent, but the chamber and bed systems seem highly coupled, which makes independent tuning less effective.

-

Also, I had some issues getting the BL touch bed scan to give consistent results, even cold. I did add a thin CF rod to the BL Touch bed probe to allow me to move the BL Touch sensor assembly away from the hot end. This extension adds about 2g to the stock one, so may be causing some problems. Are there parameters that can be tweaked for the BL Touch servo that I can try? I used a dial indicator to mechanically scan the bed and got less than .25mm TIR across the entire thing, so am pretty sure the problem is in the BL Touch mods and not actual bed alignment. The BL Touch was giving me nearly 2mm total variation.

But good progess!!!!

-

Some good successes today, even though the first print attempt ended quickly.

Since I was babysitting it, I saw the filament dig into the spool and jam, causing the failure. So first off, I need to make a spool advancer. Asking the extruder stepper to spin the 10kg spool and stuff filament into the hot end is too much. I saw a few examples online and will whip something up using a stepper and arduino with a slack arm and limit switches.

The second print worked by me sitting for the entire 2hr7min print time manually advancing the spool. I'm very happy with the initial results and welcome any critiques and advise on print settings. I used Cura 4.13 with only the most basic changes.

The part is about 2% undersized and was printed at 100% from the CAD output. Print settings were 60C chamber, 90C bed, 250C nozzle, 150mm/s print speed. 1mm nozzle, 0.8mm layer height. No supports. 4 pass brim. For some reason the non-print moves were at print speed, so a lot of time can be cut without messing with print settings, though I think there is more speed there too. The extruder stepper is the loudest part of the machine, the clearpath servos are silent. The extruder stepper was hot to the touch, but did not seem to stall at all. It has a heatsink and fan with a small air deflector shield on the back but is sitting on top of 6000W of heater.

There were some problem areas I'd like to eliminate: a few wiggles at the end of some ribs, not sure if they are g-code related, if something was hitting something else causing a wobble, or it just sagged from the heat.

And the outer surface had a lot of artifacts of rear side ribbing. I think this is a combination of over extruding and me not matching the CAD dimensions of the walls to the nozzle diameter. Cura was sticking some short infill print segments in the rib areas that was in addition to the perimeter paths. I'd like to make the geometry so that all of the part is made from perimeters.

Thanks to the forum and the Duet3D crew for all the help getting this far.

-

@coseng

Have you looked at Curate 5.0s variable line widths? That seems to be taking aim at your problem of the cad and the nozzle not being multiples. -

@baenwort Awesome! When I downloaded it last week, 4.13 was the latest, but I'll grab this and see what it can do. Sounds like it is exactly what is needed for this issue, thanks!

Now I just have to get this spool feeder working reliably. For some reason the stepper is randomly turning on and I can't trace the problem down. I don't want to come in in the morning and find a 10kg unspooled mess.