sensorless homing random wrong direction

-

Duet Web Control 3.4.1-rc1,Board: Duet 3 Mini 5+ (Mini5plus)

Firmware: RepRapFirmware for Duet 3 Mini 5+ 3.4.1rc1 (2022-05-03)

Duet WiFi Server Version: 1.25; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Valkyrie 3030 V002" ; set printer name M669 K1 ; core xy ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D2 ; physical drive 0 goes forwards M569 P0.1 S1 D2 ; physical drive 1 goes forwards M569 P0.2 S1 ; physical drive 2 goes forwards ( blown needs replacing) M569 P0.3 S0 ; physical drive 3 extruder M569 P0.4 S1 D2 ; physical drive 4 goes forwards D3=stealthchop M569 P0.5 S0 D2 ; physical drive 5 goes backwards M569 P0.6 S1 D2 ; physical drive 6 goes forwards M584 X1 Y0 E3 Z0.4:0.5:0.6 ; set drive mapping FL,FR,RC M350 X16 Y16 I1 ; configure microstepping with interpolation M350 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z320.00 E562.00 ; set steps per m M566 X700.00 Y700.00 Z100.00 E100.00 P1 ; set maximum instantaneous speed changes (mm/min) jerk M203 X24000.00 Y24000.00 Z4000.00 E400.00 ; set maximum speeds (mm/min) M201 X700.00 Y700.00 Z300.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z500 E800 I10 ; set motor currents (mA) and motor idle factor in per cent M84 S20 ; Set idle timeout ; Axis Limits M208 X-20 Y-11 Z0 S1 ; set axis minima "Travel Area" M208 X300 Y300 Z405 S0 ; set axis maxima "Travel area" ; Endstops M574 X1 S4 ; configure sensorless endstop, 1 = low end, 2 = high end. S4 multipule motors M574 Y2 S4 ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z2 S4 ; configure sensorless endstop for high end on Z, 1 = low end, 2 = high end. S4 multipule motors M671 X-20:300:150 Y0:0:280 S25 ; leadscrews at front left,front right, rear Center s= max correction factor must be in same order as M584 M558 P8 C"!io3.in" H10 F1000 T12000 R0 A4 S0.03 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 Z0.3 ; set Z probe trigger value, offset and trigger height bigger the posative number the closer to the bed G31 P500 X27 Y-11 ; set x,y trigger value, offset and trigger height M557 X10:290 Y10:290 S90 ; define mesh grid ; Heaters ;Bed M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed T °C" ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"out0" T0 Q10 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 R0.838 K0.331:0.000 D3.08 E1.35 S0.90 B0 ; PDI info for 8mm aluminium bed 700w Heater NTC 100K 3950 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ;extruder M308 S1 P"temp1" Y"pt1000" A"Extruder T °C" ; configure sensor 1 as thermistor on pin e0temp (104gt2) M950 H1 C"out1" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 R3.558 K0.357:0.000 D9.14 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ;Chamber M308 S2 P"temp2" Y"thermistor" T100000 B4267 A"Chamber T °C" ; configure sensor 2 as thermistor on pin temp2 M950 H2 C"out5" T2 ; create chamber heater output on 1.out0 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S100 ; set temperature limit for heater 2 to 280C M308 S10 Y"mcu-temp" A"MCU" ; defines sensor 10 as MCU temperature sensor M308 S11 Y"drivers" A"Duet stepper drivers" ; defines sensor 11 as stepper driver temperature sensor ; Fans M950 F0 C"out4" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 C"Part Fan" ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out3" Q250 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 C"Extruder Fan" ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; Custom settings are not defined M98 P"/macros/home_max_Z" ;External Buttons M950 J1 C"!io2.in" ;config input pin switch NO connected to io2 and Gnd M581 P1 T0 C0 ;T0 = emergency stop on trigger; T1 = pause print; T{N} = runs the macro "sys/trigger{N}.g", rising edge S1 falling edge S0 ;M581 P1 T4 c0 ;run a macro trigger4.g M582 T0 ; Check External Trigger; homex.g echo "start" M569 P0.0 ; Check status in console M569 P0.1 ; Check status in console G91 ; relative positioning M569 P0.0 S1 D3 V10 ; set to stelth chop M569 P0.1 S1 D3 V10 ; set to stelth chop M915 P0.0:0.1 S1 F0 R1 H200 ; Configure Z-Axis Stall Detection M906 X600 Y600 ; Lower motor current M574 X1 Y2 S4 ; Configure Z-Axis stall detection homing echo "after stall detection setup" M569 P0.0 ; Check status in console M569 P0.1 ; Check status in console G1 H1 X-0.2 F3000 ; move a little for cal of sensorless homing / not stalled G1 H1 Y-0.2 F3000 ; move a little for cal of sensorless homing / not stalled M400 ; make sure everything has stopped before we make changes echo "after stall detection Calibrate" M569 P0.0 ; Check status in console M569 P0.1 ; Check status in console G1 H1 X-350 ; Home Z-Axis actuators independently echo "check stall" M569 P0.0 ; Check status in console M569 P0.1 ; Check status in console G90 ; absolute positioning G1 X150 F6000 ; move to center of bed ;revert back M906 X1000 Y1000 ; Reset motor current M569 P0.0 S1 D2 ; reset motors back to spread cycle, M569 P0.1 S1 D2 ; reset motors back to spread cycle, echo "after revert back" M569 P0.0 ; Check status in console M569 P0.1 ; Check status in consoleso i have this issue where the X or Y axis will randomly go in the wrong direction when homing

so i have tried to capture the info on each drive after there has been a change made see config.g, the results below the only difference i can see when i have the error is that drive 1 pwmScaleAuto 0, when it should be pwmScaleAuto 1

G28 X start Drive 0 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 968 Drive 1 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x00053, toff 3, tblank 0, hstart/hend/hdec 5/0/0, pos 648 after stall detection setup Drive 0 runs forwards, active low enable, timing fast, mode stealthChop, ccr 0x00053, toff 3, tblank 0, tpwmthrs 10 (937.5 mm/sec), pwmScaleSum 2, pwmScaleAuto 0, pwmOfsAuto 66, pwmGradAuto 19, pos 968 Drive 1 runs forwards, active low enable, timing fast, mode stealthChop, ccr 0x00053, toff 3, tblank 0, tpwmthrs 10 (937.5 mm/sec), pwmScaleSum 2, pwmScaleAuto 0, pwmOfsAuto 76, pwmGradAuto 17, pos 648after stall detection Calibrate Drive 0 runs forwards, active low enable, timing fast, mode stealthChop, ccr 0x00053, toff 3, tblank 0, tpwmthrs 10 (937.5 mm/sec), pwmScaleSum 18, pwmScaleAuto 0, pwmOfsAuto 75, pwmGradAuto 19, pos 968 Drive 1 runs forwards, active low enable, timing fast, mode stealthChop, ccr 0x00053, toff 3, tblank 0, tpwmthrs 10 (937.5 mm/sec), pwmScaleSum 19, pwmScaleAuto 1, pwmOfsAuto 73, pwmGradAuto 17, pos 136check stall Drive 0 runs forwards, active low enable, timing fast, mode stealthChop, ccr 0x00053, toff 3, tblank 0, tpwmthrs 10 (937.5 mm/sec), pwmScaleSum 39, pwmScaleAuto 0, pwmOfsAuto 65, pwmGradAuto 17, pos 200 Drive 1 runs forwards, active low enable, timing fast, mode stealthChop, ccr 0x00053, toff 3, tblank 0, tpwmthrs 10 (937.5 mm/sec), pwmScaleSum 39, pwmScaleAuto 0, pwmOfsAuto 74, pwmGradAuto 16, pos 392 -

@moth4017 said in sensorless homing random wrong direction:

Are the motors moving the wrong way because it is wrongly detecting a stall and then moving 150mm (line 25 in your homex.g), or is it actually homing -350mm in the wrong direction (line 20)?

I don't think you are running the tuning move correctly. See: https://docs.duet3d.com/en/User_manual/Connecting_hardware/Motors_tuning#stealthchop-tuning (though this does need a little updating).

You must execute the proper tuning sequence after switching to stealthChop. This means: apply motor current, pause for more than 130ms, then execute a move at reasonable speed.

Rather than this (line 14-16 in homex.g):

G1 H1 X-0.2 F3000 ; move a little for cal of sensorless homing / not stalled G1 H1 Y-0.2 F3000 ; move a little for cal of sensorless homing / not stalled M400 ; make sure everything has stopped before we make changesM400 just waits for the current move to finish, so may not give a long enough pause. Use

M17 X Y Z ; enable XYZ motors G4 P150 ; wait 150msAfter this tuning needs a reasonable length move at reasonable speed to tune, ie a homing move. A 0.2mm move may not be long enough to tune stall detection.

Ian

-

X or Y axis will move the correct way when they do the stall detection calibration ,

but then randomly move in the opposite direction to home. -

@moth4017 said in sensorless homing random wrong direction:

X or Y axis will move the correct way when they do the stall detection calibration ,

but then randomly move in the opposite direction to home.It's unlikely to move 'randomly', unless there is an issue with wiring. In your homex.g, X and Y move -0.2mm, then homes X-350, then moves X+150. If the stall is detected without moving (the second X-350 move), it should move 150 in the other direction. Or does it try to move 350mm in the 'wrong' direction? Are subsequent moves in the 'wrong' direction?

Ian

-

@droftarts

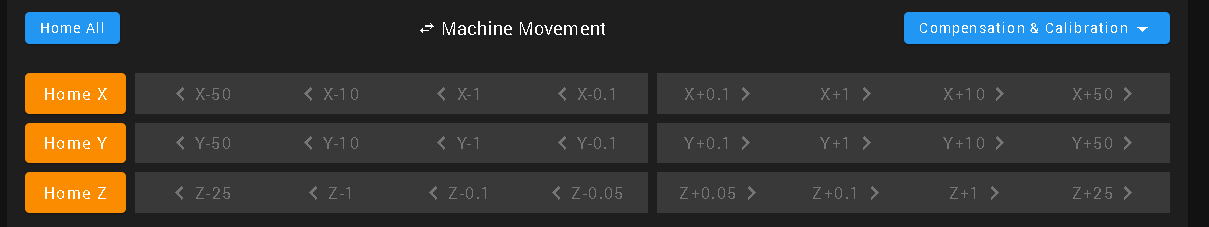

wiring ok , if i used the machine movement controls 100% perfect

just done a test it moves 150 in the wrong direction so it looks like its not doing the -350.

manual moves going in the correct way.

-

@moth4017 Okay, that means it is too sensitive to stalls. Either the tuning move is not working (did you do the change I suggested earlier?) or you need to revisit the sensitivity values.

Ian

-

also added the wait time now as suggested in the article and the move for calibration to 1.2mm but still the same issue

-

tried the following

S1 H200 works for end stops , does random wrong direction

S10 H200 works for end stops , does random wrong direction

S15 H200 works for end stops , does random wrong direction

S1 H400 crashies for end stops ,

S1 H300 crashies for end stops ,

S1 H250 crashies for end stops , -

@dc42

Hi , ive just done this in a 100% repeatablepress "emergency stop:

home X , homes in wrong directionpress "emergency stop:

home X , homes in correct directionpress "emergency stop:

home X , homes in wrong directionpress "emergency stop:

home X , homes in correct directionetc etc

-

@moth4017 Don't bother with a short tuning move. To tune stealthChop (which is what is being tuned, not stallGuard), you enable the motor, wait >130ms, then move a reasonable distance at a reasonable speed, ie the homing move. See the 2209 datasheet, page 35 (6.1 automatic tuning) https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC2209_Datasheet_V105.pdf

You are using 'S4' in your endstop configuration. This is for 'Multiple motor'. Change

M574 X1 S4andM574 Y1 S4to use S3 instead. Not sure of the effect of this if you are only using one motor. Using stall detection on Z is much more difficult, because of the torque on leadscrews.You are also dropping your motor current using M906 rather than M913. Not sure of the effect of that, either.

Finally, are you using 1.8 degree or 0.9 degree motors? This affects the H parameter in M915.

If the stealthChop tuning works correctly, all you should need to do is find a good value for M913.

Ian

-

@droftarts

my Z homing working perfectly 3 motors on gear boxes belt driven.Core XY configuration 1.8Deg Motors all round

the X and Y are the only ones playing up. i think i have been told to use S4 as its multiple motors driven at the same time, is this not correct? -

@moth4017 No, S4 is for multiple motors on the SAME axis, ie like your Z axis. Use S3 for X and Y. See https://docs.duet3d.com/User_manual/Reference/Gcodes/M574

Endstop type S4 means use motor stall detection (like S3) but if there are multiple motors, stop each one individually as it stalls. S3 means use motor stall detection but stop all relevant motors when the first one stalls.

If you're using 1.8 motors, H200 is correct.

Also see https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_stall_detection

Ian

-

im not sure why the emergency stop button is causing this , ive just tried it again and its very repeatable

press "emergency stop:

home X , homes in wrong directionpress "emergency stop:

home X , homes in correct directionpress "emergency stop:

home X , homes in wrong directionpress "emergency stop:

home X , homes in correct direction -

S3 same results

-

-

@droftarts @dc42

hi thanks for all the help , ive tried changing motor currents and many things over the past few weeks, i was waiting for the latest update to see if that had fixed it , but still in the same boat .. so i think this is a @dc42 one . -

@moth4017 said in sensorless homing random wrong direction:

M915 P0.0:0.1 S1 F0 R1 H200Looking back at your first post, you have the S parameter set to S1, which would typically make it more sensitive to stalls. You may want to try making it less sensitive, ie increase S. Try S3. You will need to balance this against motor current.

Ian

-

@droftarts

i have tried changing current with the"S" value , i can give that another go tomorrow , but the "emergency stop" button thing is bugging me why should that be so consist ant.

why should that be so consist ant.so in my stop.g macro i have

G28 X Y /macros/sensorless_Z;sensorless_z

M915 P0.4:0.5:0.6 S3 F0 R0 ; Configure Z-Axis Stall Detection

M906 Z300 ; Lower motor current

M574 Z2 S4 ; Configure Z-Axis stall detection homing

M400 -

@moth4017 said in sensorless homing random wrong direction:

G28 X Y /macros/sensorless_ZThat isn't a valid command, and the macro won't be running. If you want to run that macro after homing X and Y, you need

M98 P"/macros/sensorless_Z"Ian

-

@droftarts

i agree it looks invalid, but it runs.. changed it anywayStill made no difference

im still getting the

press "emergency stop:

home X , homes in wrong directionpress "emergency stop:

home X , homes in correct directionpress "emergency stop:

etc etc