hope you all have a safe and happy holiday

from down under on a wet humid day , hope Santa delivers a filament dryer

Best posts made by moth4017

-

thanks everyone for the support and help this yearposted in General Discussion

-

for the DWC wish listposted in Duet Web Control wishlist

when you go to back up the Macros and system files it saves them as the name "download" would be nice if it was macros[date] and system[date]

Cheers

-

RE: G29 Mesh Level: Pass / Fail Toleranceposted in Gcode meta commands

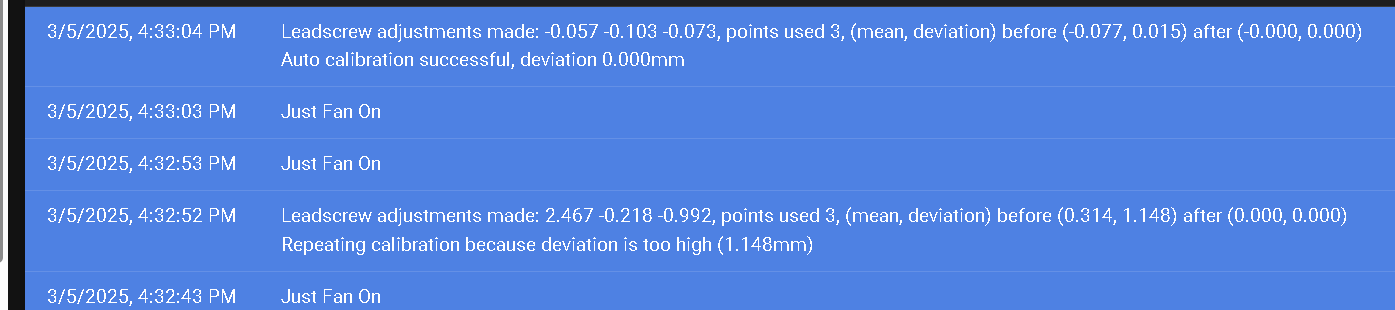

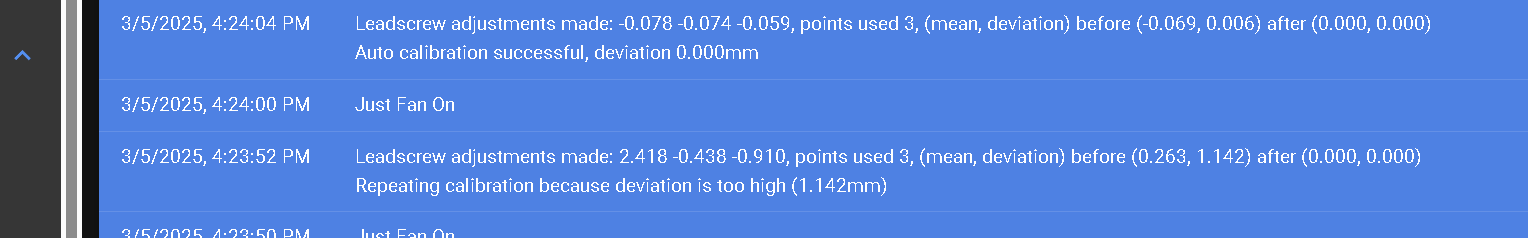

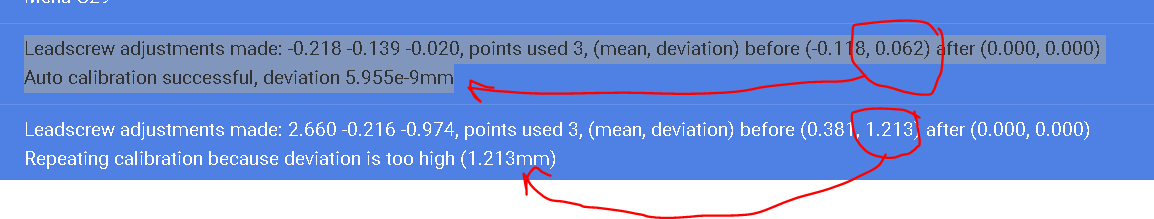

@CCS86 i do the deviation check in the bed.g G32

;G32 Auto calibration routine for large bed M561 ; clear any bed transform ; If the printer hasn't been homed, home it if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed G28 M98 P"/macros/ProbePickUp" ; probe pick up ; Probe the bed and do auto calibration ;G1 X149.5 Y179.5 Z30 F6000 ; go to just above the first probe point ;G30 P0 X152.5 Y152.5 S-2 G28 Z ;echo sensors.probes[0].lastStopHeight , "REF center probe" while true if iterations = 5 abort "Too many auto calibration attempts" G30 P0 X5 Y5 Z-99999 ; probe starboard bow echo sensors.probes[0].lastStopHeight, "P0" if result != 0 continue G30 P1 X305 Y5 Z-99999 ; probe port bow echo sensors.probes[0].lastStopHeight, "P1" if result != 0 continue ;G30 P2 X305 Y276 Z-99999 ; probe port stern ; echo sensors.probes[0].lastStopHeight, "P2" ;if result != 0 ; continue G30 P2 X152.5 Y276 Z-99999 s3 ; probe port bow echo sensors.probes[0].lastStopHeight, "P3" if result != 0 continue if move.calibration.initial.deviation <= 0.02 break echo "Repeating calibration because deviation is too high (" ^ move.calibration.initial.deviation ^ "mm)" ; end loop echo "Auto calibration successful, deviation", move.calibration.final.deviation ^ "mm" M558 F200 ;G1 F6000 X152.5 Y152.5 ; probe to center bed echo" center probe" ;G30 P0 X152.5 Y152.5 S-2 ;single probe ;echo sensors.probes[0].lastStopHeight G28 Z M98 P"/macros/ProbeDropOff" ; probe drop off M558 F600 G1 Z30 F10000 ; get the head out of the wayand just use the mesh.g file G29 for fine tuning

-

RE: Write a plugin for DWC- solved using BtnCmd.posted in Duet Web Control

@jay_s_uk

Hi yes it will be all shared , plus we will also put in the acknowledgements and web links etc to all the other contributors -

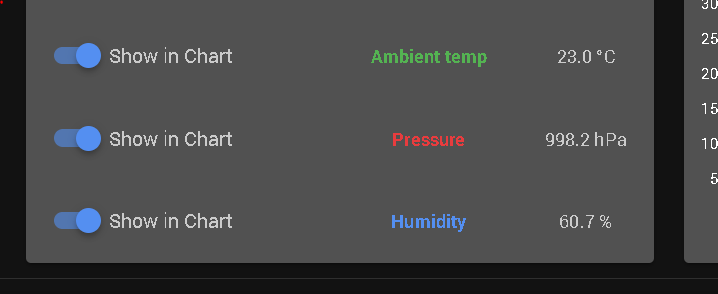

RE: M308 add a new sensorposted in Duet Hardware and wiring

BME connected and working , i have used spi.cs2

M308 s11 y"bme280" p"spi.cs2" A"Ambient temp"

M308 s12 y"bmepressure" p"s11.1" A"Pressure[hPa]"

M308 s13 y"bmehumidity" p"s11.2" A"Humidity[%]"

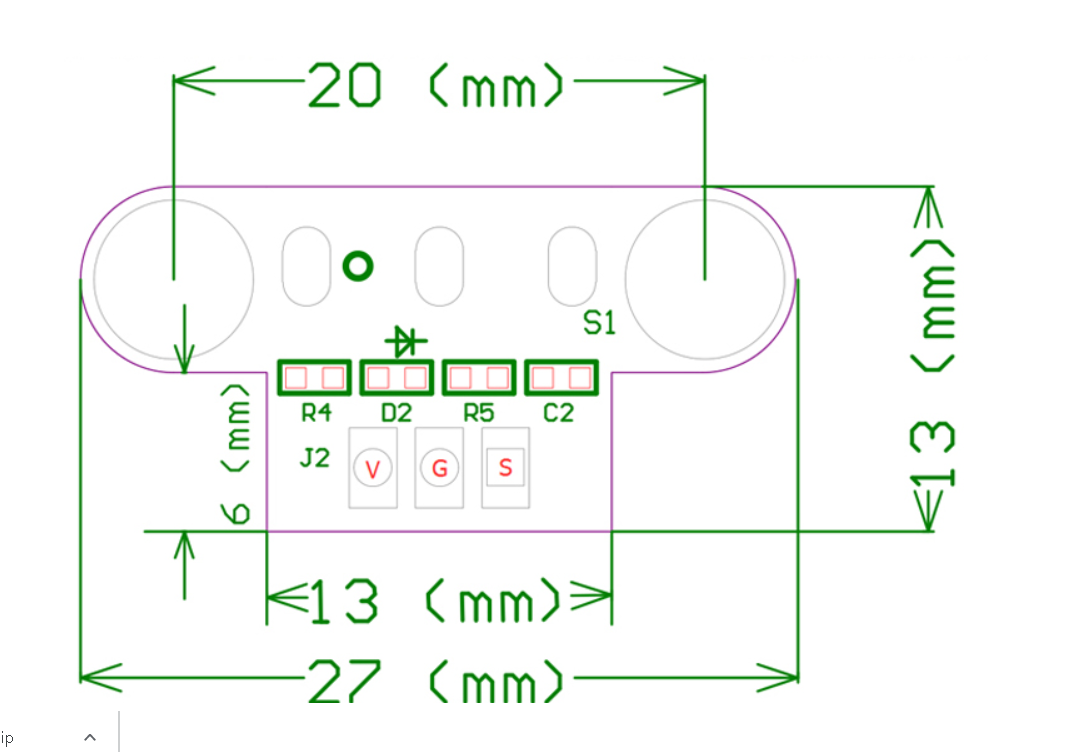

A bit of info as the Pin out description on the BME not the same as Duet board

Duet Temp Daughter Board to BME 280

pin 1 .................................................. CSB

pin2 ................................................... GND

pin3

pin4.................................................... SCL

pin5 ................................................... SDA

pin6.................................................... SDO

pin7

pin8................................................... VCC

pin9

pin10 -

backing up with zip filesposted in Duet Web Control

Backing up the system/macros files and folders , if you select all the files and folders in either system or macros it wont let you save to a zip file until you unselect the folders , can this be changed so everything can be zipped?

-

RE: end gcode causes bed to raiseposted in General Discussion

you have a G28 in you end code, and in your start code you can do G32 for your beg.g file

-

RE: beta 3.5b2 no wifi re connection after emergency stopposted in Beta Firmware

Also i have noticed that i cannot connect to the printer, if the printer is on before the PC which i use to connect to the printer . pressing the reset button on the printer then gets a connection .

-

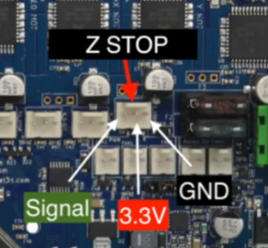

RE: Endstop Wiringposted in Duet Hardware and wiring

@SonnyD1 said in Endstop Wiring:

The back is completely blank. Here is the link: https://www.amazon.com/HUAREW-Vertical-Mechanical-3018-PROVer-3018-MX3/dp/B0B38X86NY/ref=sr_1_2_sspa?crid=2N8YX15627OFR&keywords=huarew+vertical+limit+switch&qid=1675344329&s=industrial&sprefix=huarew+vertical+limit+switch%2Cindustrial%2C117&sr=1-2-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyRTVWT1lPWTdDRldVJmVuY3J5cHRlZElkPUEwOTUxMjk5MUdQWVAzNjA4S01YTCZlbmNyeXB0ZWRBZElkPUEwNzcwNzk1UzRRRzA2TDlJMEtSJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ== .

Says its contact type : Normally Open

Sorry, steppers I'm good at but as simple as they are, I suck at endstops.

-

RE: DWC Duet Web Control 3.4.0-rc2 no extrude or retractposted in Duet Web Control

Ok even though the firmware new that the tool T0 was selected adding T0 to the config seems to have fixed this issue.

Latest posts made by moth4017

-

RE: 3.6.0rc1 DWC baby stepping values incorrect value displayedposted in Beta Firmware

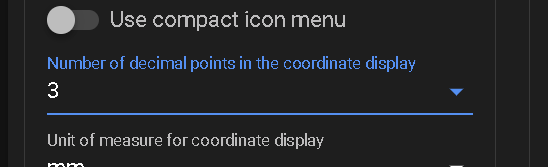

@chrishamm thanks i missed that on that general page

-

RE: 3.6.0B4 object model calibration final deviation valueposted in Beta Firmware

@dc42 Why would i use more then points than lead screws to tram the bed ?

-

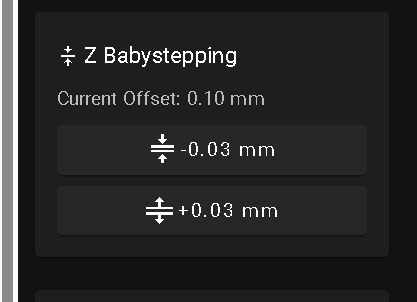

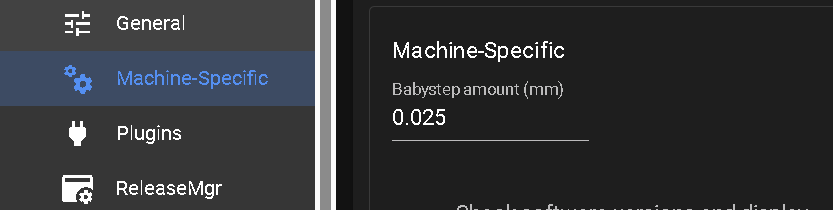

3.6.0rc1 DWC baby stepping values incorrect value displayedposted in Beta Firmware

in the DWC status window , displayes 0.03mm

but in the machine specific its set up as

-

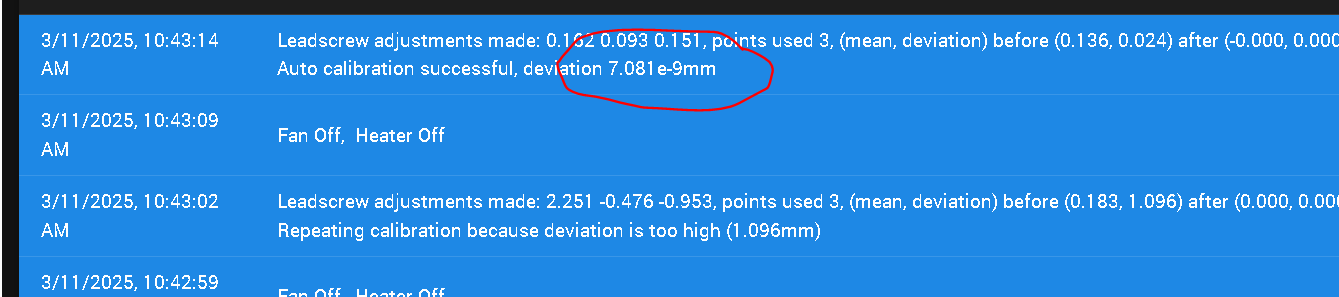

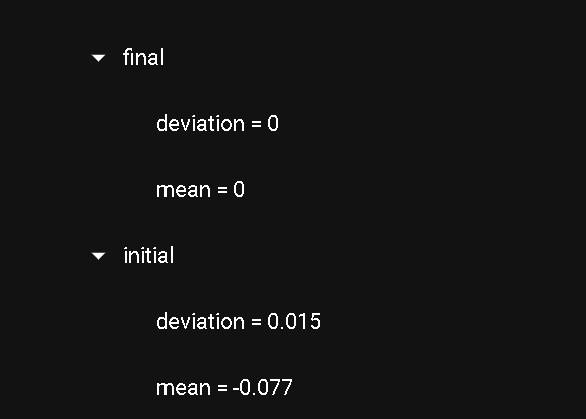

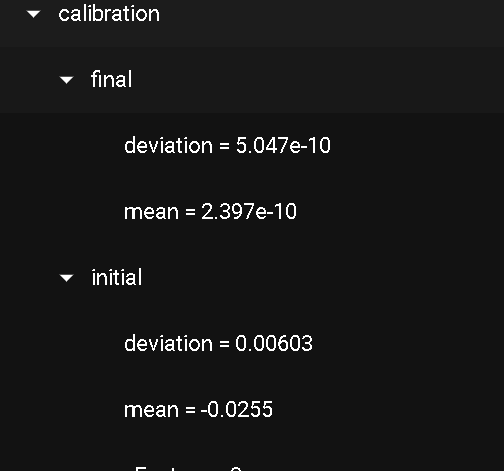

3.6.0B4 object model calibration final deviation valueposted in Beta Firmware

in the new beta versions v6.3.0 the value displaying the final deviation value has changed from mm rounded to 3 decimal places to a scientific notation format , will it be like this in the future or is this a mistake?

v3.5.3

v3.60b2

v3.6.0b4

it would be nice to select the number of decimal places , but as it was was ok

-

RE: M950 to add servo controlposted in Firmware wishlist

@T3P3Tony i still need to control a vent/solenoid / servo as my chamber is sealed , i just thought it would be away to kill 2 birds one stone

-

RE: M950 to add servo controlposted in Firmware wishlist

@jay_s_uk @T3P3Tony I have 2 applications for this cooling and venting, I sometimes need to vent the printer chamber through a carbon filter because of the fumes ,but can only do this when the chamber is cool enough for the activated carbon, I'm sure there will be other uses, as always I

-

RE: M950 to add servo controlposted in Firmware wishlist

@jay_s_uk

so M950 set min & max angel

and

M106 still be 0 to 100% -

RE: M950 to add servo controlposted in Firmware wishlist

@T3P3Tony

cpap/fan , controlled via A fan output,

servo Controlled via A fan output

Flap homing via digital inputrequired 2 fan outputs and 1 input in total