Fast Response Part cooling fan

-

I am finding with higher temperature chambers printing bridges with ABS is becoming difficult. Has anyone else experienced and solved this?? Is this just a inherent side effect?

Here's one thought: Slicers do a good job facilitating increased cooling settings for bridging features and ramps up the fan appropriately. HOWEVER, I believe often the printer part cooling fan cannot respond/spool up quick enough to fully utilise/capitalise on this control feature. This photo shows a part that used to have perfect bridges when the chamber was 55C, but now at 72C, bridges are poor. Can a closed loop controlled fan be employed to provide faster spooling up and therefore deliver cooling as soon as its needed?

What about the bird air cooling method? Would that be useful for this issue?

-

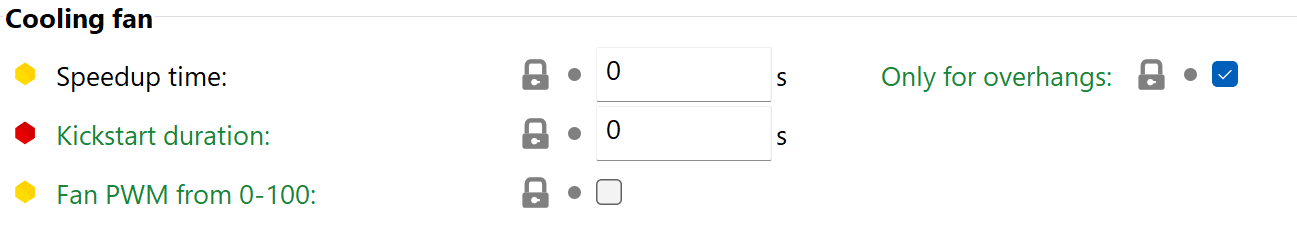

Are you already utilising the features available in some slicers specifically for managing fan ramp-up? ... eg superslicer:

-

@mintytrebor No, is this available in prusaslicer?

-

@bubblevisor Sorry I don't use it. But Superslicer is based on PrusaSlicer so maybe... Some-one else here will know I'm sure.

-

@mintytrebor The option for kickstarting the fan is not in prusaslicer, however I wonder is it already has been employed behind the scenes. Does superslicer have this feature enabled as a default?

-

@bubblevisor In SuperSlicer its available in Printer Settings - General (With Expert or Advanced view enabled). It is a default feature, but not enabled by default (defaults are zero).

I think printer profiles/configs are compatable between the two slicer skews, so you could always give Super Slicer a try as another option.

-

Yes it is an inherent side effect.

There are some options though.

a) let the heater blow constantly air at the printed layer (not easy do this consistent), I believe I saw one concept here in the forums but can't find it atm

b) berd air (this works but to get it 100% dialed in is not easy as you really need to aim the air just under the nozzle and make sure you do not cool other parts of the print as this will lead to thermal stress)

c) use support material (the better option), if you have 2 independent heads or a toolchanger you even have the option to print your support in another material (like pve or pla)

I print all my ABS prints with full supports and while it is a bit tedious to remove the support material, it simply delivers the best prints. -

The speedboaters found certain Sanyo Denki 4028 fans to be quite fast to react. Other fans in this form factors can take up to two seconds to get up to speed. So you may have some luck trying quality fans even in other form factors.

-

Do 3 wire fans (with RPM sense) provide a faster response and better RPM fidelity?

-

For ideal printing conditions you want a hot chamber but cold, focussed cooling air.

Perhaps I can use a low volume flowrate, tightly focussed, cold air source berd air setup. So the inlet is drawn from outside the chamber. Does anyone know the volume flowrate of and effective berd air system? I'm concerned it will overly cool my passively heated chamber.

-

@bubblevisor I thought about focused cooling at one point. Using compressed air (from an air compressor) and a solenoid seemed like it would be worth a try. If you already have a compressor its pretty simple from there.