Turning Frankenstein into Cinderella

-

@corlissmedia there's a guide to what you need to find out here:

https://docs.duet3d.com/User_manual/Overview/AdaptingThere's a guide to using the RepRapFirmware configuration tool:

https://docs.duet3d.com/en/How_to_guides/Configuring_firmwareThere's a couple of guides to converting an Ender 3 to Mini 5+, though the series isn't quite finished yet (ahem @Phaedrux !), but this covers the configuration:

https://docs.duet3d.com/How_to_guides/e3p_Mini5+_guide_part2_configurationA .bin file is a binary file. This is used to update the firmware on the Duet, for example. The configuration is done in text files, which are also Gcode files; they all end in .g. The RepRapFirmware Configuration Tool outputs a .zip file, which is just a compressed file. Within it are the .g files that make up the configuration. It's a bit of a headspin when coming from Marlin, but this page also explains it: https://docs.duet3d.com/User_manual/RepRapFirmware/RepRapFirmware_overview#firmware-differences-from-other-firmwares

Ian

-

@corlissmedia said in Turning Frankenstein into Cinderella:

Mystery Motors

Specifically about these: if possible measure the resistance of each phase (see https://docs.duet3d.com/User_manual/Connecting_hardware/Motors_connecting#identifying-the-stepper-motor-phases), measure the size (they are probably NEMA 17, but the length of the motor is directly proportional to how much torque it has/how much current it can take), and post a picture of (or write out) any markings or labels on the motor. This should give the forum sleuths some information to make a guess at some good motor settings. Though, realistically, setting the motor current to 1000mA is probably going to be fine on a Ender 3 clone.

Most other components are going to be pretty bog-standard. Thermistors will probably be typical NTC3950. Belts will be 2mm Gates. Pulleys will be 16 tooth or 20 tooth. But most of these things don't matter too much, as you can adjust it when commissioning the printer, and because it's RRF not Marlin, you don't have to reflash the firmware each time!

Ian

-

@droftarts thanks!

-

@droftarts that is really helpful!

-

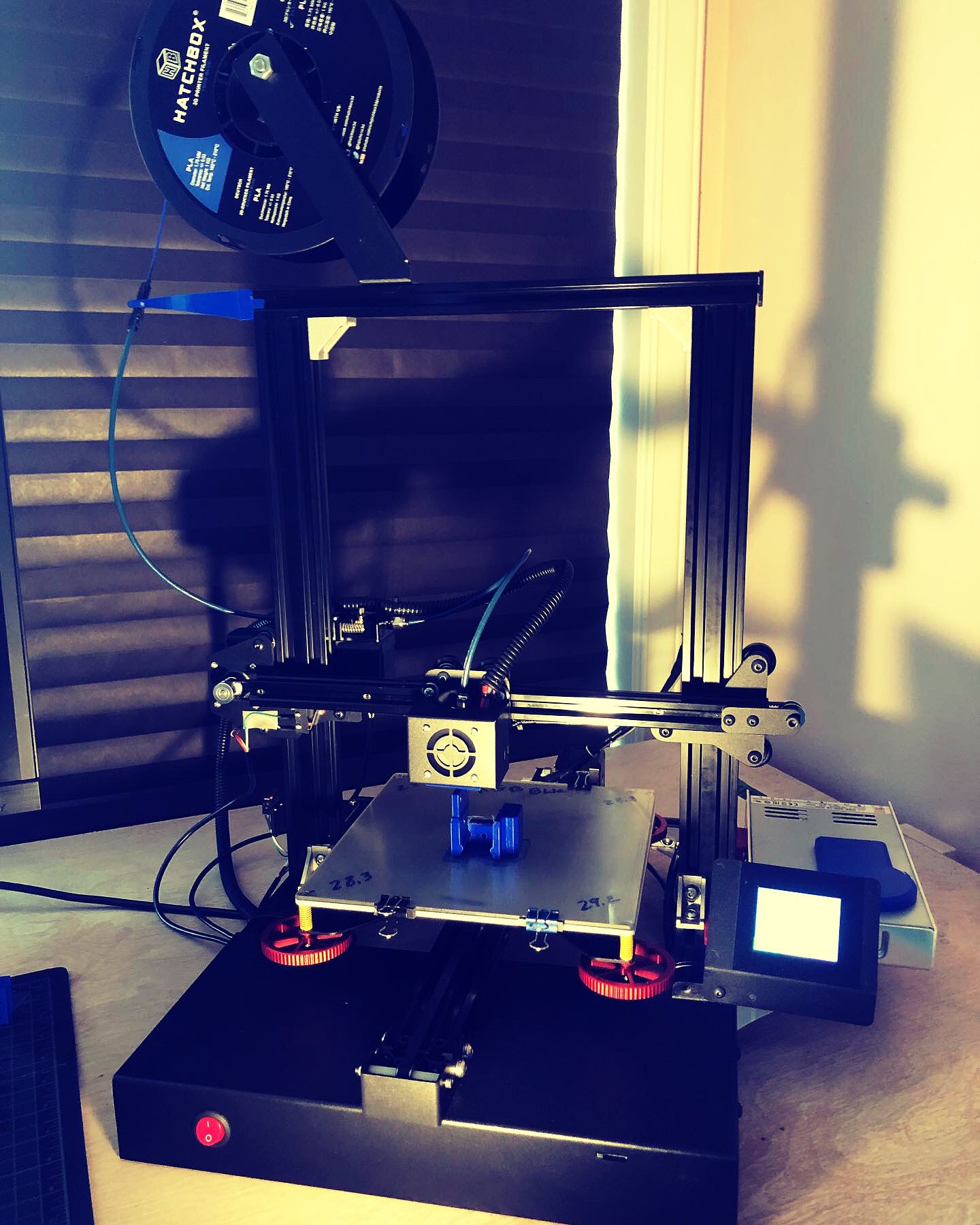

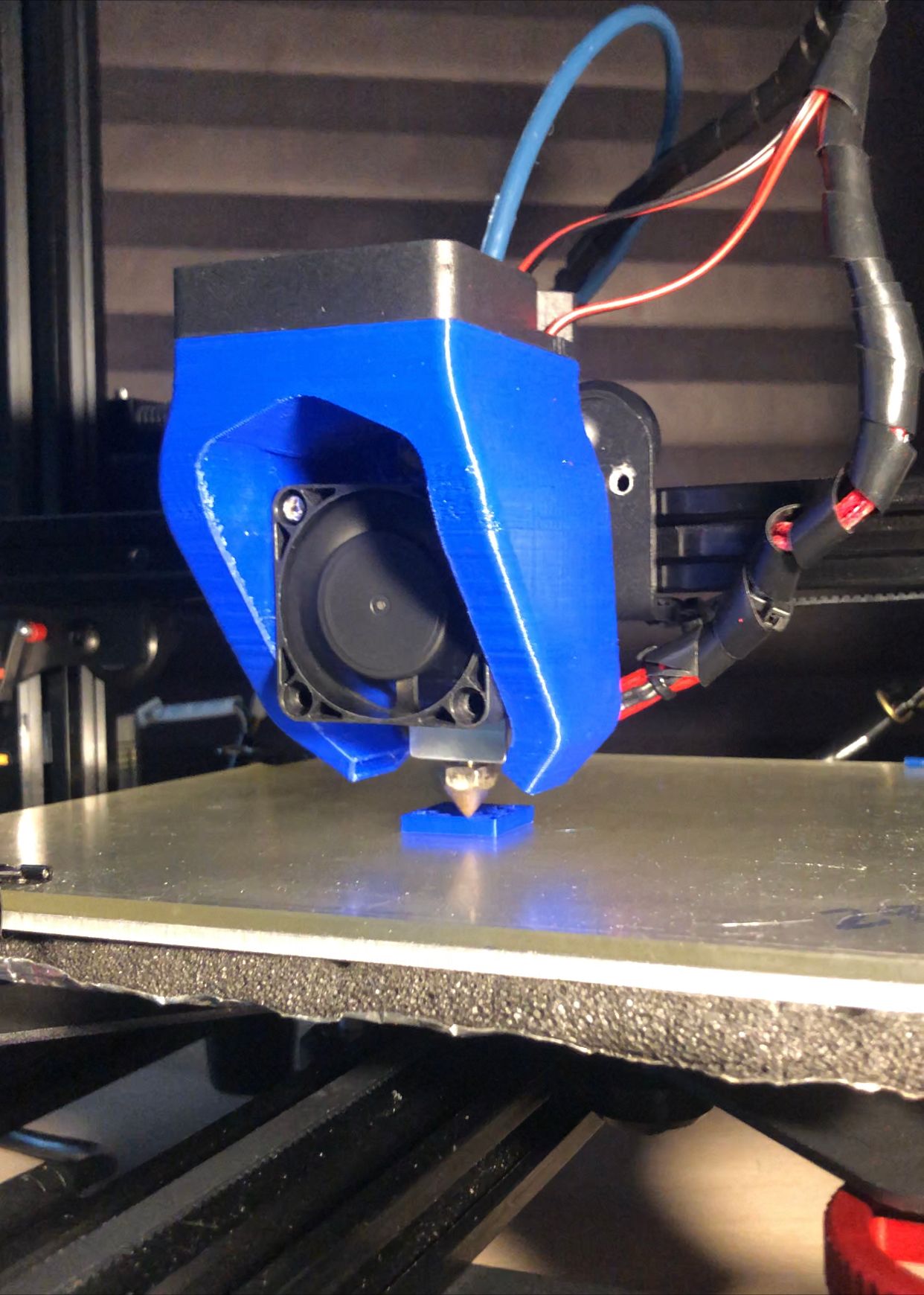

@droftarts I posted a series of pictures of my printer on Instagram. You can find me there @Corlissmedia2.0

-

@corlissmedia sorry, I don’t ‘do’ instagram! You can post images here, too, which would make it easier for people trying to help you.

Ian

-

@droftarts understood, so now I have to figure that out. Another learning experience!

-

Use the image upload function baked in to upload images to articles.

-

-

@oliof some of the tools are off the screen on my phone.

-

-

@corlissmedia

-

@corlissmedia thanks. Any labels on the motors? If you can still access the original electronics, you may be able to get some information off it. What is the exact manufacturer's name and model name/number? They may have their firmware on GitHub.

Ian

-

@droftarts This is the most information I've found so far: link text

Here's the info on the above page about the board: link text

There's no printed information on the motors, but here's what I can tell you: all of the mounting screws are 30mm apart, the bodies are 42 x42mm square, and 37.5mm deep.

This printer has a single lead screen (left side). That's where the X and filament drive motors are.

The bed's 220 by 220, and the possible vertical rise is 240.

I swapped out their 15amp power supply for a Meanwell 20amp supply when I installed a heated bed on this printer.

This man has a lot to say about the board in this printer: link text

There's a mention of Dlion as the manufacturer of the board.

Here's an interesting color drawing of the board, next to a shot of the board in the printer, what a rat's next! [link text](https://community.ultimaker.com/topic/33347-need-motherboard-for-my-xvico/

)

If I find any more cogent info, I'll let you know.

Mark