How do I Do Anything?

-

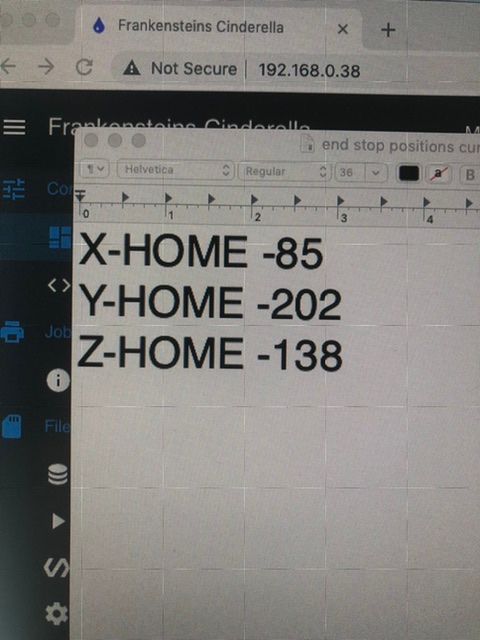

I sent M564 H0 S0 to my Duet Mini 5+. When I manually homed the three axis to the endstops this is what I saw in Status Display.

I’m thinking it was a mistake to buy this board. It’s not like the boards I’ve used before. I’ve skimmed a lot of the documentation. It’s describing what the board is, but so far I haven’t found something that says HOW to get my printer, which I’ve worked very hard to get to this point, and spent more than and Ender 3 on, to do anything.

The Duet3D mini 5+ is advertised as a 3D Printer Control Board. And it can do that, it appears, if you know g-code, and are willing to stand there and tell it what to do. That’s what I’m experiencing. With all of its built-in power, it doesn’t seem to be built for doing anything on its own. That is what distinguishes it for other 3D printing control boards, but I don’t think it’s for people like me, who want to print things without having to tell the printer what to do all the time.

Sucked in by YouTubers that gushed about what a great board it is.

I’ve talked to a lot of great people on here. I’ve seen the amazing machines they operate. I know this board can control wild things. But sending an STL file to it, and watching it print that file occasionally, that’s not what this board is for. That’s not what Duet3D is about.

It’s a full time job. That’s what they’ve created. It’s an interface that cost me $165, plus $54 for new motors. And I still can’t get it to home. It still doesn’t know where the endstops are. Because it doesn’t know what to do on its own. It’s waiting for me to tell it, constantly, what to do.

This board, this forum, all these wonder people with all of their amazing skills, can’t help me because the board doesn’t do what I thought it would. That’s what I think now. That’s the feeling I’m getting from this forum.

If I’m wrong, and this board can print like all the other boards out there that call themselves 3D printing control boards, please, comment. If I’m right, no one will say anything.

Thank you.

Mac

-

@mac From a personal point of view, it's difficult to know what more I could do. Your other thread has around 700 posts and many of the most knowledgeable people have tried to help and explained things in various ways. How does anyone answer the question "How do I do things" ? All I can say is that you send it gcodes and it the printer will "do" what the gcode tells it to do. To send it a gcode, you can either use the jog buttons in DWC to move axes around or you can enter gcode commands in the box at the top of DWC.

-

@mac when you turn the printer on, it has no idea where each of the axes are. It has to ‘home’ each axis to a switch, which gives it a position. Usually (but doesn’t have to be) this is zero when the switch is activated. RepRapFirmware only sees the switch and sets zero when a specific type of move is sent; G1 H1. This tells the machine to move, stop when the endstop is triggered, and set the axis position to the limit defined by M208, ie the axis limits.

I think what you have done is move the axes from the start point, possibly just jogging them, until they touch the endstop. This is not a homing move. The numbers you have recorded are just how far each axis moved from where it started from.

I think your motors and endstops are working correctly now? Turn the machine on and send:

G1 H1 X-250 F1000

This should send the X axis to the endstop, stop it when it activates the endstop, and set the X axis to its reference position, ie zero. The axis can then be moved within the limits defined by M208. The firmware will not allow it to go below zero, or above the axis maximum.Ian

-

@droftarts thank you, that is what I’ve been looking for. Will that same code work for Y and Z? Or will a variation work for them?

Is there a code I can put at the beginning of the config.g that will make it home the printhead? There must be, right? Where are all those sub-routines, I’ll call them?

But here I go again, trying to make this expensive board act like all the other control boards out there. Which it is not, correct?

Mac

-

@deckingman thanks, you’ve confirmed my suspicion. This board is not for 3D printing like a board that runs Marlin is. I wish it was advertised as such.

Mac.

-

@mac said in How do I Do Anything?:

@deckingman thanks, you’ve confirmed my suspicion. This board is not for 3D printing like a board that runs Marlin is. I wish it was advertised as such.

Mac.

Really? You think that some other board running Marlin would be easier? That it would "just work" without you configuring it for your printer? That it would "just do stuff" without you telling it what to do?

-

@mac said in How do I Do Anything?:

Will that same code work for Y and Z? Or will a variation work for them?

Yes. One extra detail... it's best to home axes using relative movements, rather than absolute movements. So you say 'move this far' (relative move), rather than saying 'go to this point' (absolute move). So:

G91(Set to Relative Positioning)

G1 H1 X-300 Y-300 F1000(Home X and Y axes at the same time)

G1 H1 Z-300 F100(Home Z axis)

G90(Set to Relative Positioning)Following these commands, you can move the nozzle anywhere you want within the limits. Don't use H1 though. eg

G1 Z10 F100(Move Z up 10)

G1 X100 Y100(Move X and Y to centre of bed)Is there a code I can put at the beginning of the config.g that will make it home the printhead?

You don't want the printer to move as soon as power is applied, it is dangerous, and if you have turned off power to the printer as an emergency stop, having it move as soon as power is applied could be disastrous.

There must be, right? Where are all those sub-routines, I’ll call them?

All the Gcodes for homing are in the homing files in the /sys folder: homex.g, homey.g, homez.g and homeall.g files. They are called when you press the 'Home' buttons in DWC, or send the Gcode G28 (send G28 on its own to home all axes, or G28 X to just home X). We went through all this in the long thread, a number of times.

And @deckingman is correct. If you think RRF is difficult because of all the Gcodes, Marlin and Klipper are worse; you will still have to configure them for your machine. The only 'preconfigured' way of doing this is to revert to the original board. However, a lot of your problems have been caused by bad wiring. Stick with it a bit longer.

Ian

-

@mac said in How do I Do Anything?:

This board, this forum, all these wonder people with all of their amazing skills, can’t help me because the board doesn’t do what I thought it would. That’s what I think now. That’s the feeling I’m getting from this forum.

Your Duet board fully supports 3D printers.

Just to give you some context of mine, I bought a Duet3 MB6HC for my three-axis CNC machine, and started exactly where you have - with no knowledge. I asked quite a few questions (though not anywhere near as many as you), and was embarrassed to do so, particularly when the answer was so simple I should have known the answer before I asked it, because it's quite easy to get in to "the moment"!

It's taken me almost three months to get to where I have a functioning machine, where all I need to do is tweak things sto my liking, i.e. x, y abd z probing, and tool changes (cutters, not actual tools!), but there are three very important lessons I learnt the hard way - in amongst the guidance and support from the helpful people on here:

Lesson 1 - READ THE CONSTRUCTION GUIDE, then take things one step at a time. It's too easy to get tangled up with what if scenarios. Just plan how you want the machine to be, then get the machine built, with all the parts in place, then sit back and have a cup of coffee. Get to know what each component does, and what you're expectations of that componenet are.

Lesson 2 - READ THE GUIDANCE PAGES, then read them again. The Duet is the brains of the system, but it will only do what you tell it to do. If it does something wrong, it's probably your fault.

Lesson 3 - READ THE FORUMS, then search for topics and read them again! Just be aware that no-one on here can read your mind, nor are they in your 'space' so they can't see what you see, feel what you feel, or hear what you hear.

One last thought: Building your own machine from scratch (as is the case with most hobby machines) to undertake 3D printing, laser etching and/or CNC work is not for everyone. Sometimes it's easier to buy a ready-built machine or rethink any hobby ambitions and take up something else. My wife likes knitting, for example.

So, in answer to your question "How do I do anything?", whatever you choose to do, it's you choosing to do it.

Good luck!

-

It appears that @mac has deleted his account and 'left the building'. I'm locking this thread and his others.

Ian

-

undefined droftarts locked this topic

undefined droftarts locked this topic