Should I pull apart my light preload linear rail?

-

Hi all,

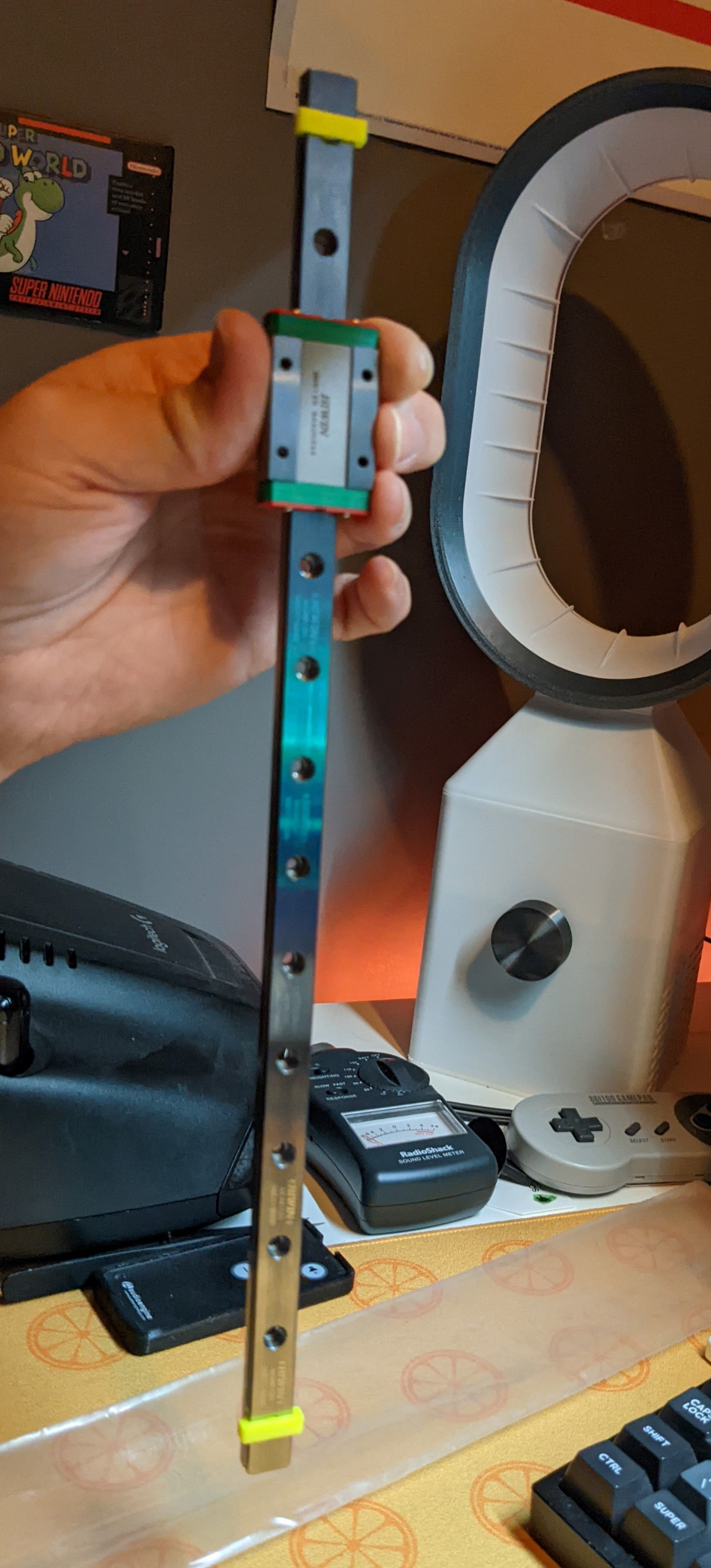

I'm working on a few upgrades for my Voron 2.4, including installing a Hiwin MGN12 with Z1 preload and "high precision" on the X axis.

I've only experienced more affordable MGN9 rails with clearance (ZF), rather than pre-load. I expected more resistance when sliding but what I didn't expect was how much it will stick in certain positions at low speeds.

I tried running enough EP2 grease through them that they overflow a lot, while sliding them up and down the rail to try to dislodge any dust/dirt that might be in there. As well as cleaning the rails. But that hasn't changed anything.

I see a lot of product pages that say not to remove the carriage from the rail, but I'm not sure why this would be a problem if one is careful enough.

I'm very tempted to take everything apart, clean it all thoroughly with my watch servicing fluids before inspecting every bearing and the rail under a microscope and with a micrometer, before reassembly and lubrication.

I'm pretty comfortable dealing with small parts since I service my own watches sometimes.

I have read that they match the rails to the carriages, but I'm not sure what exactly that entails. Do they have slightly different sized bearings and match them to the rail after manufacture? Will all the bearings be "exactly" the same size? It might be a problem if the bearings on one side are a few microns bigger than the other!

It might not make any difference, but it would make me feel better to know all the bearings are flawless. What do you guys think?

-

As an example, surely this shouldn't be possible? It's rare that is will stick this much but still...

-

@threepwood I disassembled a number of linear rails including MGN12's. I don't see a specific reason to not do it appart from that it can be tedious. Once the rail is out of the cariage, there isn't much keeping the balls in check (the little metal bar inside is far from 100%) and boy do they like to go everywhere if they get a chance to bounce. My advice would be to disassemble them inside or over a container so you don't lose any balls. Also getting the cariage back on the rail can a hassle for the same reason.

I have not worked with the MGN9 size personaly but I imagine it is idential, perhaps with even smaller balls.

-

@nxt-1 One thing I didn't mention is that I took all my cheap MGN9 rails apart and cleaned and re-lubed them before use. Just wondered if there was some reason it was a bad idea with a better quality/potentially matched rail and block with preload.

-

@threepwood If your rail is out of spec and a genuine part you can always contact the supplier. That being said, if it were my rail I would not mind taking it appart and reassembling it ¯_(ツ)_/¯.

-

@nxt-1 I think I'd rather take it apart. There's some mention in the Hiwin documentation that says you are likely to have more "stiction" with pre-loaded rails, so I'm not sure it's out of spec. Also the small UK retailer I bought from sent me an MGN9 at first and was happy to send me an MGN12 and packing label overnight before returning the MGN9. Which I think is pretty excelent customer service! I don't want to bother him again!

-

I've "reballed" many balls screws and linear guides and it's sooo much fun. The result, that is not so much the process. Cleaning them shouldn't help much unless they already have way too much grease. If you have an accurate

or at least repeatable micrometer you can measure your existing balls. If they are right on nominal, like 2mm for example you can buy a couple hundred grade 25 chrome steel balls from ebay and sort them. They usually fluctuate + 0 above nominal and 3-5 microns or more below. Try finding a set that are 6 microns small (about .0002") and load them. You can also alternate 1 smaller and 1 larger ball. Unfortunatly it does take some time but details are what make a difference. Keep in mind the temperature of the micrometer can have a measurable effect especially if going from an airconditioned room to a warm shop. -

@nxt-1 @Threepwood I find when I strip my carriages its much easier to mount the carriage on a magnet it stops the bearings flying everywhere

-

@jumpedwithbothfeet said in Should I pull apart my light preload linear rail?:

@nxt-1 @Threepwood I find when I strip my carriages its much easier to mount the carriage on a magnet it stops the bearings flying everywhere

That might be a bad idea. Magnetising the bearings and block will likely cause extra wear because of the tendency for the bearings to align with the magnetism. It might be a good idea to buy a cheap de-magnetiser!

I just finished re-assembling and lubing the rail. It might be slightly better, but not by much! I do feel better now I've checked over everything though.

Ignore the cat hair. I made sure everything was spotless as I put it back together. I don't know how it gets everywhere! I only had it uncovered for a short time.

-

@threepwood so your saying the carriage stays magnetised once the magnet is removed? I suppose you mean like making a compass out of a needle, I will check next strip down

but I`ve not had any issues yet and it does make life easier lol

but I`ve not had any issues yet and it does make life easier lol -

If that's a real HiWin rail, I wouldn't take it apart. Preload is accomplished by selecting balls within a specific narrow diameter range. You can clean and relube all you want but it won't change the diameter of the balls. If the thing is too tight for your application, get a different rail or get more torque from your motors.

-

@mrehorstdmd I wouldn't recommend it unless you're like me and just enjoy taking things apart and are confident doing it. After using it as a fidget toy for a while, it's now much smoother than before. It might help that I haven't overlubed them this time.

I bought a high preload MGN12 for my X rail to replace my MGN9s, because the only obvious flex in my Voron is the X carriage being able to be twisted up and down. I think this is more due to the printed parts flexing on the small MGN9 carriage, the wider MGN12 should improve things a bit but I've also ordered a aluminium machined parts that sit between the MGN12 carriage and printed hot end and extruder parts.

I think it would have been better to incorporate wider MGN12 carriages for the Voron for this reason, but they may be harder to source at a reasonable price.

I'm using E3D "Super Whopper" motors, and they give me more torque than I will ever need!