Crying stepper motors

-

Hello!

I have connected stepper motors, but they "cry" when I start them up on the Duet3Mini5+. Is there a solution for this? -

@jason0607 usually this means that you have set a combination of acceleration too high, steps/mm too high, max movement speed too high, or motor current too low. If you post your config.g file and tell us what motors you are using, we can help further.

-

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 P169.254.179.25 S1 ; enable network and set IP address

M553 P255.255.0.0 ; set netmask

M554 P192.168.150.1 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X1000.00 Y1000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X200.00 Y200.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X200 Y200 Z200 E200 I60 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z200 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io1.in

M574 Y2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

;M950 S0 C"io3.out" ; create servo pin 0 for BLTouch

;M558 P9 C"temp2" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

;G31 P500 X25 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

;M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"spi.cs1" Y"thermocouple-max31856" A"Thermocouple" K"K" F50 ; configure sensor 0 as typ k thermocouple on pin spi.cs1 (TC0)

M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S280 ; set temperature limit for heater 0 to 280C

;M308 S1 P"1.spi.cs1" Y"thermocouple-max31856" K"S"; define temperature sensor number 1 as a Type thermocouple on the first port of a temperature daughter board plugged into the expansion board with CAN bus address 3.

;M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;M143 H1 S280;Fans

M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

;M563 P0 D0 H1 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool; Configuring steps and speeds

M584 X0 Y1 Z2:3 E4:5 ; set drive mappingM350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm;Setting motor speeds and accelerations

M584 X0 Y1 Z2:3 E4:5 ; set drive mappingM566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X500.00 Y500.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X69000.00 Y69000.00 Z20.00 E250.00:250 ; set accelerations (mm/s^2);Setting motor currents

;M584 X0 Y1 Z2:3 E4:5 ; set drive mapping

;M906 X400 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent -

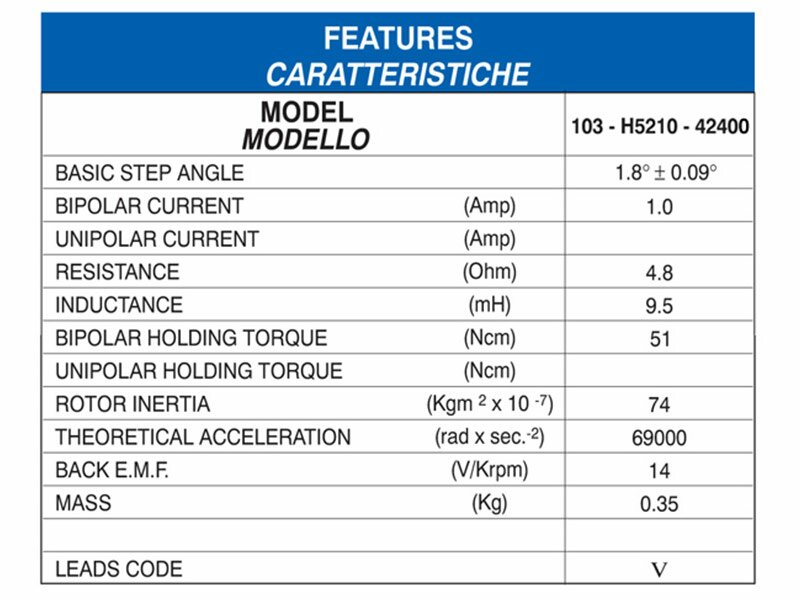

Motor: / 103-H5210-4240 / NEMA17 / Flansch 42mm / 1A / 51 Ncm

-

This post is deleted! -

-

@jason0607 I would say your motor current is to low. 200mA, for a 1A motor. Try increasing those to say 800mA.

-

@jason0607 you also have multiples of some commands acceleration, feedrate etc. Some are commented out but not all.

This for example is at the bottom of your config,

M201 X69000.00 Y69000.00 Z20.00 E250.00:250 ; set accelerations (mm/s^2)While you have another at the top,

M201 X200.00 Y200.00 Z20.00 E250.00 ; set accelerations (mm/s^2)The one at the bottom is way to high and getting used as it's called last.

-

@Rushmere3D

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name; Network

M552 P169.254.179.25 S1 ; enable network and set IP address

M553 P255.255.0.0 ; set netmask

M554 P192.168.150.1 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X1000.00 Y1000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X200.00 Y200.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I60 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z200 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io1.in

M574 Y2 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

;M950 S0 C"io3.out" ; create servo pin 0 for BLTouch

;M558 P9 C"temp2" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

;G31 P500 X25 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

;M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"spi.cs1" Y"thermocouple-max31856" A"Thermocouple" K"K" F50 ; configure sensor 0 as typ k thermocouple on pin spi.cs1 (TC0)

M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S280 ; set temperature limit for heater 0 to 280C

;M308 S1 P"1.spi.cs1" Y"thermocouple-max31856" K"S"; define temperature sensor number 1 as a Type thermocouple on the first port of a temperature daughter board plugged into the expansion board with CAN bus address 3.

;M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

;M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;M143 H1 S280;Fans

M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

;M563 P0 D0 H1 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool; Configuring steps and speeds

;M584 X0 Y1 Z2:3 E4:5 ; set drive mapping;M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

;M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm;Setting motor speeds and accelerations

;M584 X0 Y1 Z2:3 E4:5 ; set drive mapping;M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

;M203 X500.00 Y500.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

;M201 X69000.00 Y69000.00 Z20.00 E250.00:250 ; set accelerations (mm/s^2);Setting motor currents

;M584 X0 Y1 Z2:3 E4:5 ; set drive mapping

;M906 X400 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent -

@jason0607 Yeah better, you will need to maybe adjust some of your settings but that should work.

You have commented out you Tool settings.

-

@Rushmere3D

Now the motor is just as loud but moves slower -

@jason0607 Are the phases of the stepper motors connected correctly?

Is this a new build?

Your config has multiple M584 commands make sure you have the correct one in use. -

@jason0607 Yes they are connected correctly

-

@jason0607 I would say these settings need, tweaking.

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X1000.00 Y1000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X200.00 Y200.00 Z20.00 E250.00 ; set accelerations (mm/s^2)Something like this maybe? BUT you need to adjust based on your machine, these are based on one of my printers.

M566 X300.00 Y300.00 Z60.00 E420.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z360.00 E1500.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z300.00 E10000.00 ; set accelerations (mm/s^2) -

Would also be a good idea to share the results of m122 and M98 P"config.g" please?

-

@rushmere3d

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.4.1 (2022-06-01 21:06:56) running on Duet 3 Mini5plus Ethernet (standalone mode)

Board ID: 0KSJD-0296U-D65J0-40KMS-K803Z-H4BUF

Used output buffers: 3 of 40 (14 max)

=== RTOS ===

Static ram: 103684

Dynamic ram: 104352 of which 100 recycled

Never used RAM 33504, free system stack 182 words

Tasks: NETWORK(ready,25.6%,244) ETHERNET(notifyWait,0.2%,576) HEAT(notifyWait,0.0%,374) Move(notifyWait,0.0%,290) CanReceiv(notifyWait,0.0%,942) CanSender(notifyWait,0.0%,372) CanClock(delaying,0.0%,339) TMC(notifyWait,0.7%,81) MAIN(running,71.8%,510) IDLE(ready,1.0%,29) AIN(delaying,0.8%,264), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:00:56 ago, cause: software

Last software reset at 2022-08-16 09:30, reason: User, GCodes spinning, available RAM 33520, slot 1

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

MCU revision 3, ADC conversions started 56285, completed 56285, timed out 0, errs 0

Step timer max interval 1487

MCU temperature: min 23.9, current 24.8, max 24.8

Supply voltage: min 24.0, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 2 queued, 2 completed

Driver 0: standstill, SG min 0, read errors 0, write errors 1, ifcnt 21, reads 2937, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 1: standstill, SG min 0, read errors 0, write errors 1, ifcnt 27, reads 2935, writes 13, timeouts 0, DMA errors 0, CC errors 0

Driver 2: standstill, SG min 0, read errors 0, write errors 1, ifcnt 27, reads 2934, writes 13, timeouts 0, DMA errors 0, CC errors 0

Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 21, reads 2936, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 19, reads 2939, writes 9, timeouts 0, DMA errors 0, CC errors 0

Driver 5: not present

Driver 6: not present

Date/time: 2022-08-16 09:31:34

Cache data hit count 97077235

Slowest loop: 299.88ms; fastest: 0.13ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 22.5MBytes/sec

SD card longest read time 3.4ms, write time 11.7ms, max retries 0

=== Move ===

DMs created 83, segments created 3, maxWait 40644ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 6, completed 6, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== CAN ===

Messages queued 282, received 0, lost 0, boc 0

Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 282/0/0

Tx timeouts 0,0,281,0,0,0 last cancelled message type 30 dest 127

=== Network ===

Slowest loop: 101.62ms; fastest: 0.03ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- Ethernet -

State: active

Error counts: 0 0 0 0 0

Socket states: 5 2 2 2 2 0 0 0

- Ethernet -

-

@rushmere3d Error: M98: control character in string

-

M98 P"config.g"Didn't work?

I'm out of ideas if your still having issues I'm sorry to say.

-

@Rushmere3D What would be the settings for my motor?

-

@rushmere3d M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: Failed to initialise thermocouple: bad response from sensor

Warning: Sensor number 0 has not been defined