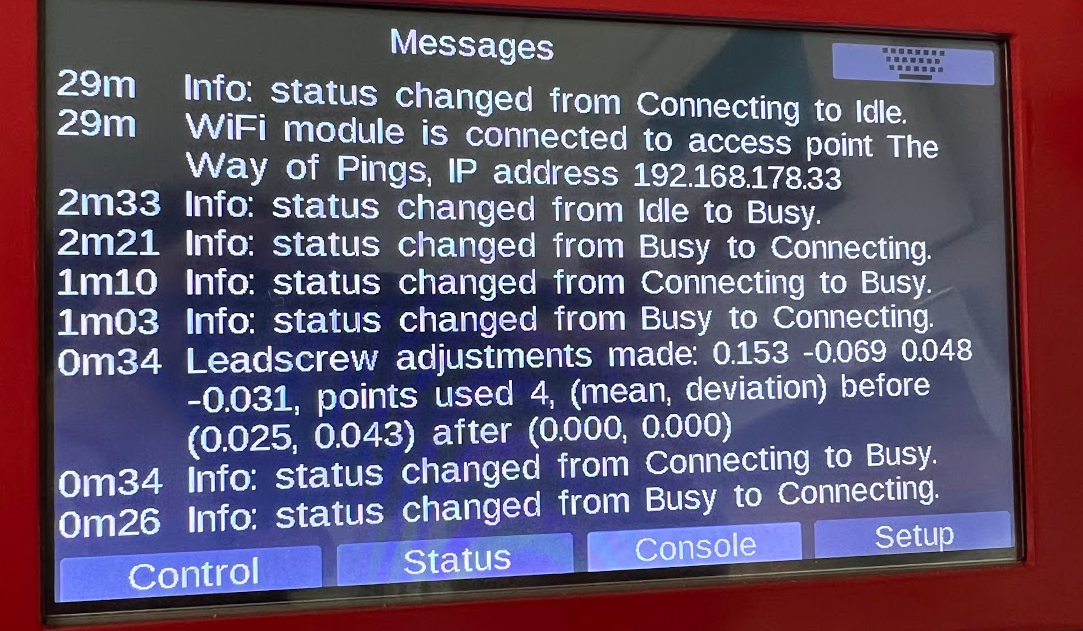

Paneldue getting frequent info popups, clogging the console

-

Having an interesting issue where the paneldue console is getting flooded by info status messages during a G32, reporting that status changed from connecting to busy, and then back from busy to connecting.

I suspect this may have to do with the processing required during the G32, as it uses gcode meta commands, but I don't see anything from the M122 that would indicate per-se that this is the case.

Is there anything that could be done to alleviate the frequent messages?

Firmware version: RepRapFirmware 3.4.2

Paneldue 3.4.1The M122 was executed during the G32 command

=== Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.2 (2022-09-13 15:11:16) running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DLM-996RU-N8PS4-6J9D0-3S86R-KAU3N Used output buffers: 1 of 26 (20 max) === RTOS === Static ram: 23860 Dynamic ram: 76640 of which 204 recycled Never used RAM 8376, free system stack 120 words Tasks: NETWORK(ready,13.9%,237) HEAT(notifyWait,0.0%,329) Move(notifyWait,0.0%,296) DUEX(notifyWait,0.0%,24) MAIN(running,86.0%,440) IDLE(ready,0.1%,30), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:29:57 ago, cause: power up Last software reset at 2022-09-21 18:37, reason: User, GCodes spinning, available RAM 8556, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,1,0 Step timer max interval 0 MCU temperature: min 13.8, current 23.7, max 24.0 Supply voltage: min 23.8, current 23.9, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/92/48, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0 Driver 1: standstill, SG min 0 Driver 2: standstill, SG min n/a Driver 3: standstill, SG min n/a Driver 4: standstill, SG min n/a Driver 5: ok, SG min 0 Driver 6: standstill, SG min 0 Driver 7: standstill, SG min 0 Driver 8: standstill, SG min 0 Driver 9: standstill, SG min 0 Driver 10: Driver 11: Date/time: 2022-09-23 10:57:41 Cache data hit count 4294967295 Slowest loop: 11.43ms; fastest: 0.16ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 8 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 3.6ms, write time 2.1ms, max retries 0 === Move === DMs created 83, segments created 6, maxWait 1619833ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 43, completed 42, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state 3 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by Aux HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 49 0 0, running macro Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0 sensor: no data received === DueX === Read count 1, 0.03 reads/min === Network === Slowest loop: 22.29ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 = WiFi = Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.27 WiFi MAC address ec:fa:bc:5b:3c:a9 WiFi Vcc 3.37, reset reason Turned on by main processor WiFi flash size 4194304, free heap 21256 WiFi IP address 192.168.178.33 WiFi signal strength -51dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0bed.g

M98 P"config_probe.g" ; insure probe is using most recent configuration values M280 P0 S60 I1 ; clear any probe errors G28 ; home all M280 P0 S60 I1 ; clear any probe errors G29 S2 ; cancel mesh bed compensation M290 R0 S0 ; cancel baby stepping G90 ; absolute moves G1 Z5 F99999 ; insure Z starting position is high enough to avoid probing errors G1 X{move.axes[0].min+2} Y{move.axes[1].min+2} F6000 ; move to front left G30 ; do single probe which sets Z to trigger height of Z probe ; --- level bed --- while true M280 P0 S60 I1 ; clear any probe errors G30 P0 X{move.axes[0].min + sensors.probes[0].offsets[0] + 2} Y{move.axes[1].min + sensors.probes[0].offsets[1] + 2} Z-99999 ; Probe near front left leadscrew M280 P0 S60 I1 ; clear any probe errors G30 P1 X{move.axes[0].max + sensors.probes[0].offsets[0] - 2} Y{move.axes[1].min + sensors.probes[0].offsets[1] + 2} Z-99999 ; Probe near front right leadscrew M280 P0 S60 I1 ; clear any probe errors G30 P2 X{move.axes[0].max + sensors.probes[0].offsets[0] - 2} Y{move.axes[1].max + sensors.probes[0].offsets[1] - 2} Z-99999 ; Probe near rear right leadscrew M280 P0 S60 I1 ; clear any probe errors G30 P3 X{move.axes[0].min + sensors.probes[0].offsets[0] + 2} Y{move.axes[1].max + sensors.probes[0].offsets[1] - 2} Z-99999 S4 ; Probe near rear left leadscrew if move.calibration.initial.deviation < 0.01 echo "Your bed is within 0.01 mm between the corners. The difference was " ^ move.calibration.initial.deviation ^ "mm. You can proceed to print" break ; check pass limit - abort if pass limit reached if iterations = 10 M291 P"Bed Leveling Aborted" R"Pass Limit Reached" abort "Bed Leveling Aborted - Pass Limit Reached" G1 X{move.axes[0].min+2} Y{move.axes[1].min+2} F6000 ; move to front left G30 ; do single probe which sets Z to trigger height of Z probeConfig.g

; General preferences_________________________________________________________ G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set output to look like Marlin M575 P1 B57600 S1 ; Set auxiliary serial port baud rate and require checksum (for PanelDue) ; Network_____________________________________________________________________ M550 P"Big 40" ; set printer name M552 S1 ; enable network ; Drives_________________________________________________________________________ ;Main board______________________________________________________________________ M569 P0 S0 ; Physical drive 0 . X1 M569 P1 S1 ; Physical drive 1 . X2 M569 P2 R-1 ; Physical drive 2 . Canceled M569 P3 S0 ; Physical drive 3 . Main Extruder M569 P4 S0 ; Physical drive 4 . Secondary Extruder ;Duex5 board_____________________________________________________________________ M569 P5 S0 ; Physical drive 5 . Y M569 P6 S0 ; Physical drive 6 . Z1 (0,400) M569 P7 S0 ; Physical drive 7 . Z2 (0,0) M569 P8 S0 ; Physical drive 8 . Z3 (400,0) M569 P9 S0 ; Physical drive 9 . Z4 (400,400) ;Settings_________________________________________________________ M584 X0:1 Y5 Z6:7:8:9 E3:4 P3 ; Driver mapping M671 X-185:-185:468:468 Y468:-46:-46:468 S30 ; Anticlockwise ;___________________________________________________________________ M350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation M92 X100 Y100 Z2000 E418.5:418.5 ; Set steps per mm M566 X360 Y360 Z120 E3600:3600 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X9000 Y9000 Z200 E12000:12000 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z120 E1000:1000 ; Set accelerations (mm/s^2) M204 P500 ; Set print and travel accelerations (mm/s^2) M906 X1800 Y1800 E1000:1000 I50 ; Set motor currents (mA) and motor idle factor in per cent M906 Z1800 I50 ; set Z motor currents M84 S100 ; Set idle timeout - 100 seconds ; Axis Limits M208 X0 Y0 Z-2 S1 ; set axis minima M208 X400 Y400 Z800 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop + e0stop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop ; Z-Probe M558 P9 C"zprobe.in" H5 F120 T6000 A1 R0.7 ; BLTouch probing settings M950 S0 C"duex.pwm5" ; sets the BLTouch probe M376 H100 ; Height (mm) over which to taper off the bed compensation G31 P500 X-25.5 Y26.9 ; BLTouch X and Y offset from nozzle M98 P"config_probe.g" M557 X{move.axes[0].min + sensors.probes[0].offsets[0] + 1, move.axes[0].max + sensors.probes[0].offsets[0] - 1} Y{move.axes[1].min + sensors.probes[0].offsets[1] + 1, move.axes[1].max + sensors.probes[0].offsets[1] - 1} P8:8 ; Heaters___________________________________________________________ M140 H-1 ; disable heated bed (overrides default heater mapping) ;E0_________________________________________________________________ ;M308 S0 P"e0temp" Y"thermistor" T100000 B4725 ; configure sensor 0 as thermistor on pin e0temp ;M308 S0 P"spi.cs1" Y"rtd-max31865" ; Configure sensor 0 as PT100 via the daughterboard M308 S0 P"e0temp" Y"pt1000" ; Configure sensor 0 as PT1000 on pin e0temp M950 H0 C"e0heat" T0 ; create nozzle heater output on e0heat and map it to sensor 0 M98 P"PID_tune_E0.g" R1 ; PID calibration M143 H0 S285 ; set temperature limit for heater 0 to 285C ; Fans______________________________________________________________ M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 C"Primary blower fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0 H-1 C"Secondary blower fan" ; set fan 1 value. Thermostatic control is turned on M950 F2 C"duex.fan7" Q500 ; create LED on pin fan2 and set its frequency M106 P2 S0 H-1 C"LED" ; Disable fan channel for LED M106 P2 S255 ; LED on by default M950 F3 C"duex.fan5" Q500 ; create fan 3 on pin fan1 and set its frequency M106 P3 S255 H0 T45 ; set fan 3 value. Thermostatic control is turned on M950 F4 C"duex.fan6" Q500 ; create fan 4 on pin fan1 and set its frequency M106 P4 S255 H1 T45 ; set fan 4 value. Thermostatic control is turned on ; Tools______________________________________________________________ ;T0_________________________________________________________________ M563 P0 S"E0 Primary" D0 H0 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S210 ; set initial tool 0 active and standby temperatures to 0C ; Automatic power saving____________________________________________ M911 S22.5 R29.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss. Power Failure Pause ; Primary hotend Clog detector__________________________________________________ M950 J0 C"duex.e2stop" ; create Input Pin 0 on pin E2 to for M581 Command. M581 T1 P0 S0 R1 ; Runout switch for E0 As External Trigger M591 D0 P7 C"e1stop" S1 L4.2 E10 R10:1000 ; Clog Detector E0 [Add-On] ; Crash detector__________________________________________________ M950 J2 C"duex.e4stop" ; create Input Pin 2 on pin E4 to for M581 Command. M581 P2 T0 S0 R0 ; Crash Detector [Add-On] ; Emergency stop button__________________________________________________ M950 J3 C"duex.e6stop" ; create Input Pin 2 on pin E4 to for M581 Command. ;M581 P3 T0 S1 R0 ; Emergency stop [Add-On] M581 P3 T1 S1 R1 ; Emergency stop, pause the print [Add-On] ;M581 P3 T1 S1 R0 ; Emergency stop, pause always [Add-On] ; Automatic Z Offset Calibration____________________________________ M574 Z1 S1 P"!zstop" ; configure switch-type for Automatic z-offset -

A message every minute is frequent? Not really.

-

How long is the cable run? Does it run near motor cables?

-

@phaedrux It's about 70cm, and does indeed run next to a motor cable, will need to test it seperated away

-

@phaedrux I've tested it by moving the cable away, so that it no longer runs near motor cables, but sadly the info messages remain.