The Mean Machine

-

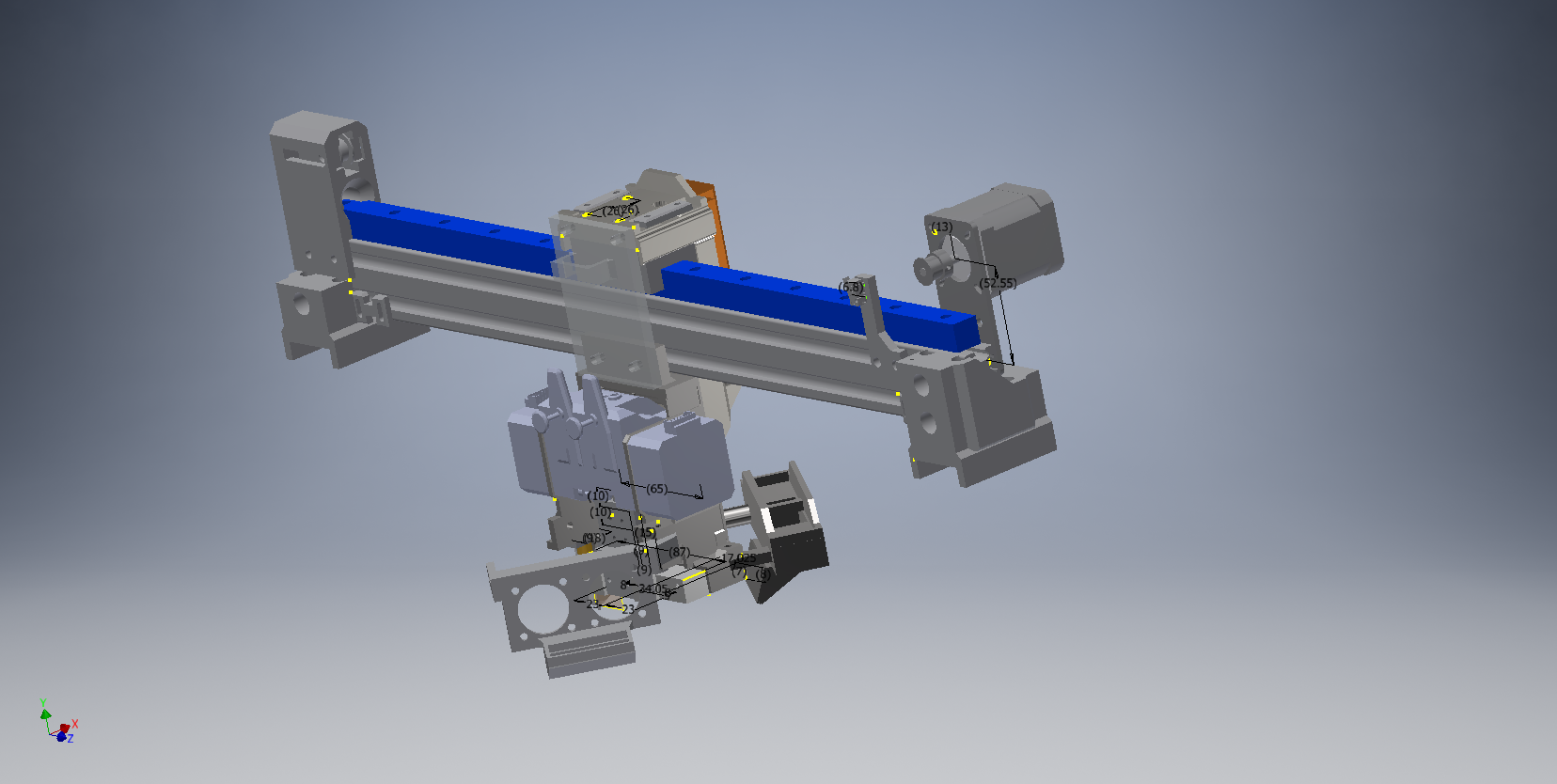

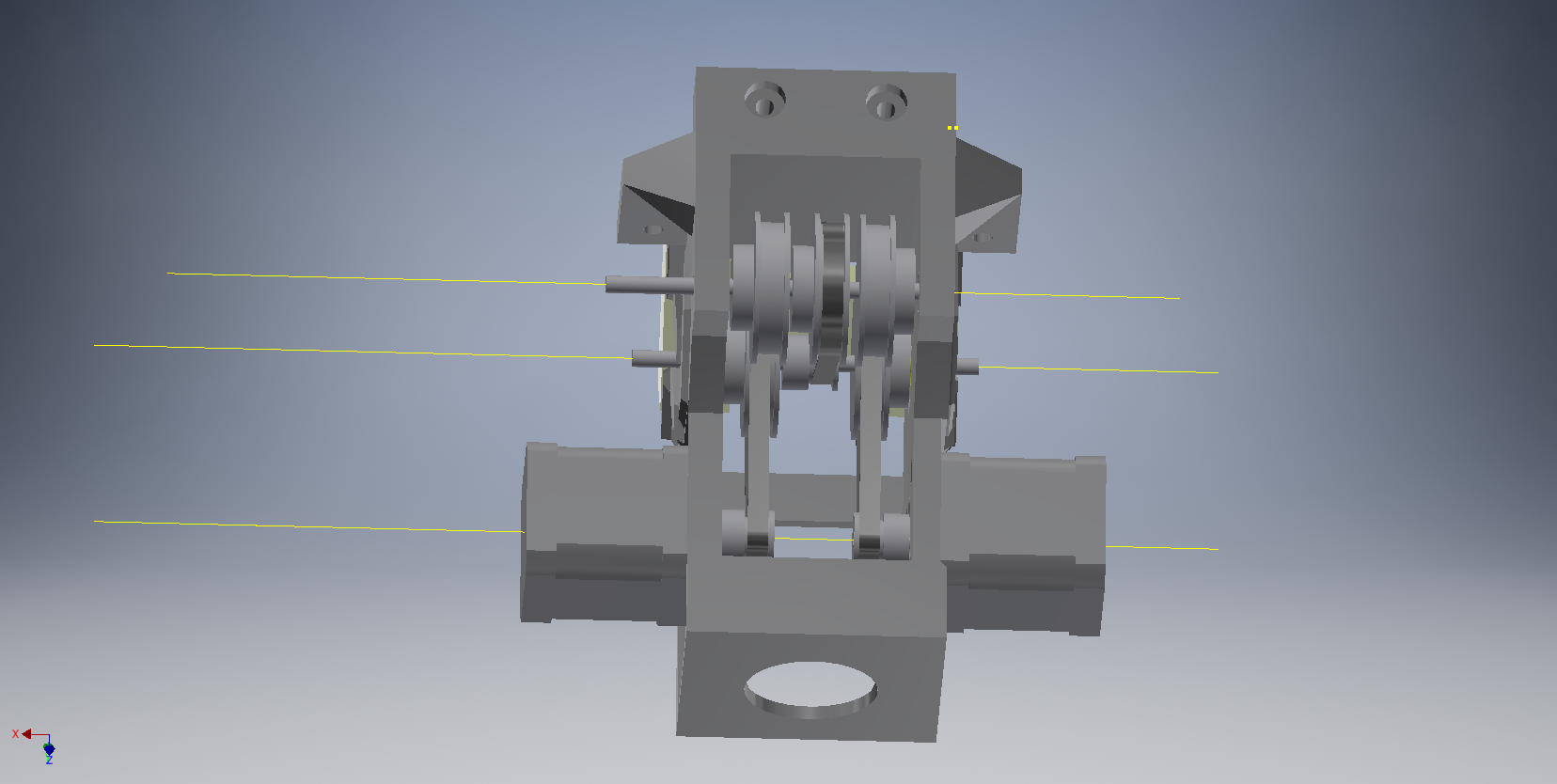

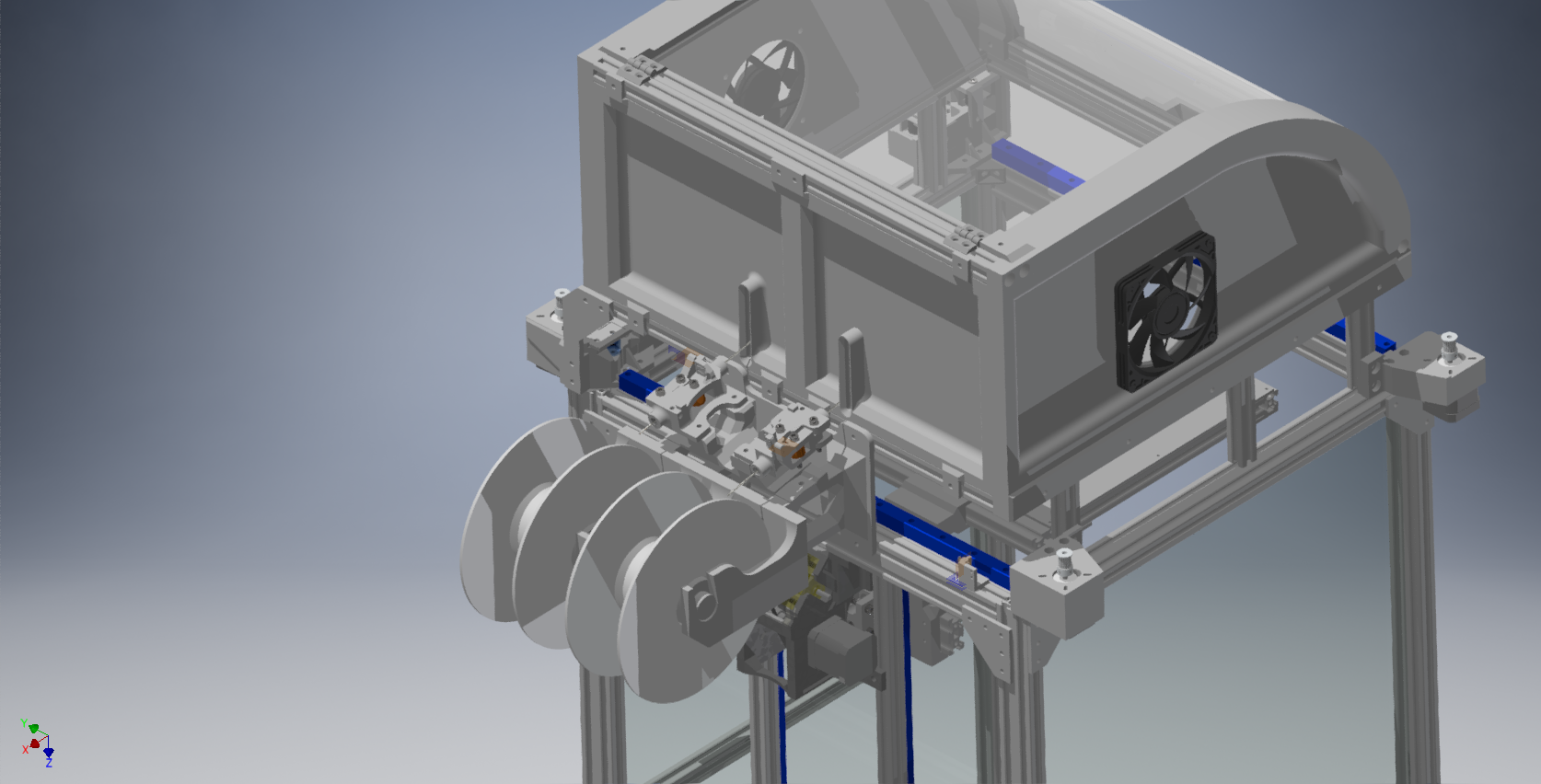

Here another update , i have ordered a duet 3 expansion board so i could mount a second motor facing the other one in the Pulley box for the Z , with the addition of this i will be able to get rid of the temporary counter weight . my Z will be powered by 2x60mm .09 stepper motor now. i as well redesigned a bit the carriage for a more better look and functionality .

Added as well pivot area now for the cooling fan in the front and back just need to remove a screw and they will pivot so that they wont be suspending in the air , less chance of breaking those tiny wire and faster access if i have to.Since my printer is on the big side , i will be adding a few shelf on the right side so i can put the multiple box of material giving me extra weight on the machine so probably less vibration as well.

-

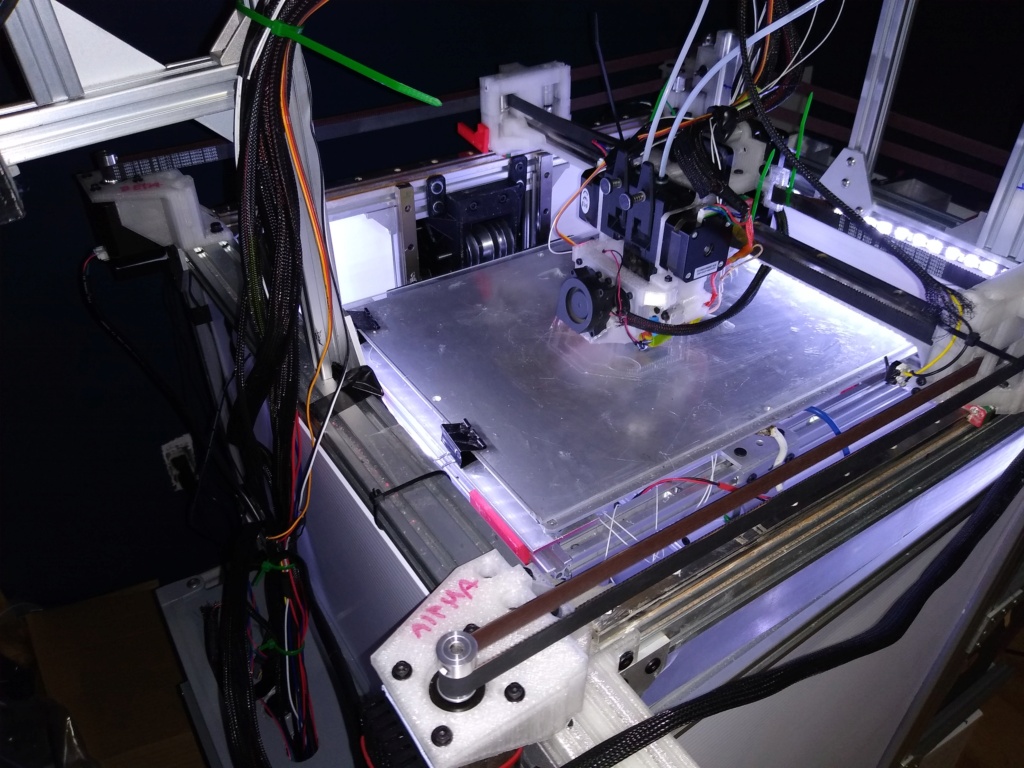

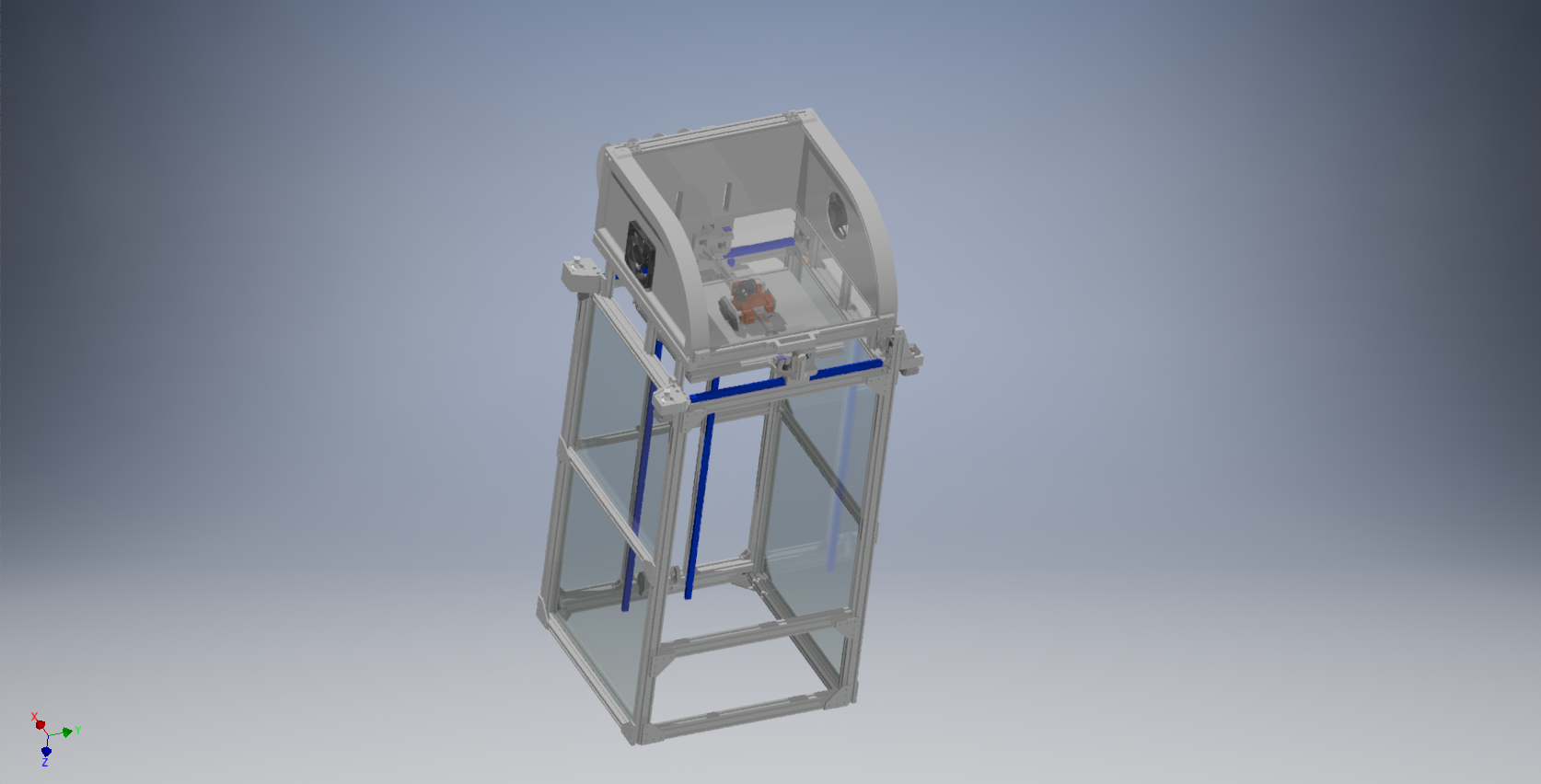

got most of my part today unfortunately i was missing some 2040 for the shelf so him missing one shelf right now , got rid of my counter weight , added the second 60mm nema 17 in the pulley box . the 3hc is wired and installed and everything seem to work good . Only things left now is to reprint the 2 main part for the head , and figure a way to close the front half on top . Getting close of completion on this project which ive started around a year ago now

-

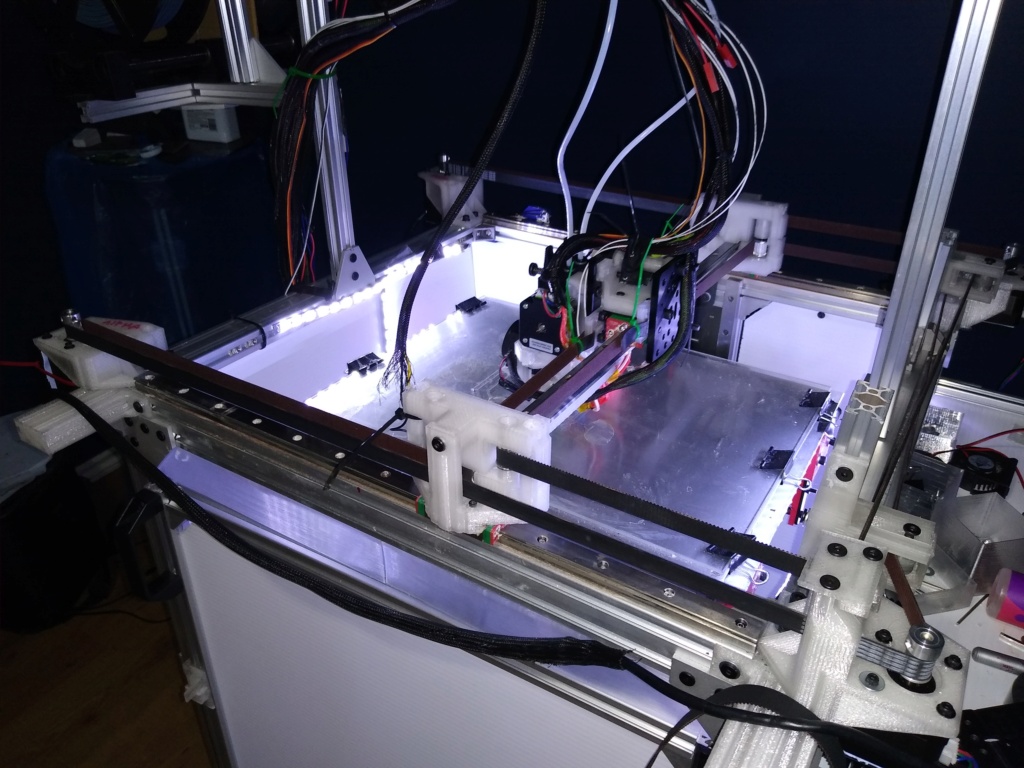

Swaped out many of my part on the Y axis for what i had redesigned , print are coming better it seem so far , added the last shelf as well , that give a lot more weight to the printer , the whiole machine doesnt move as much as it used to now , vibration should be lower as well. still figuring out how i will finish the enclosure as well got a few idea just cant make my mind lol !

-

Looks good! I like the electronics enclosure box.

-

Well after multiple TEST and print , i wasn't happy with the current speed and result it was still better than my old rostock max v2 but i wanted more. this build has been a good learning experience with multiple challenge for the last year, yep one year of tweaking reprinting piece , changing them , upgrading again lol

Well from a cartesian style printer i present you the next evolution of my printer . it is now a corexy . Learning from some of my mistake i redesigned the Y axis way lighter and the head as well . eliminated a lot of pieces as well i would say . since i had the hardware and spare motor i went with something a little more complex . 2 motor per axis so total of 4 motor moving the gantry . i figure out that since most people only have a single extruder while i have a dual i would need some more torque so adding a extra motor per axis should help preventing losing step.

I still need to reprint the Y gantry for a few minor tweak . it seem that for once now i will be able to achieve my goal of a constant print speed of 50-60mm/sec minimum . Before the redesign my acceleration for x-y axis were around 400 since the switch i have been able to test up to 1750 and believe the final number will be higher . Switched to 12mm gates belt and pulley as well from 6mm . That 12mm belt was expensive, the printer use around 4.5m of it .

-

Well here another update on my printer , replaced the 6mm belt for the Z axis for some 12mm , and changed the pulley as well to 20 teeth from 60 and had to readjust my e-step seem i gain around 3X the step now , when machine is off my bed doesnt go down anymore with the switch to smaller pulley there enough torque now . next step is to finish the top once i get more extrusion and reprinting my motor mount making them beefier. then it should be fun printing time !

-

So finally got the aluminum extrusion I was waiting for , next step is to redesign my spool holder and position , than rework my cable to tidy the whole things . Plus a few minor tweak here and there . I think overall no further major change and finishing my enclosure

So finally got the aluminum extrusion I was waiting for , next step is to redesign my spool holder and position , than rework my cable to tidy the whole things . Plus a few minor tweak here and there . I think overall no further major change and finishing my enclosure -

!

!Got some time to work on the printer , partially completed my enclosure , moved my spool behind the machine now

-

Well haven't updated this thread in a long time , thinking of finally get rid of the double extruder and go to a single extruder , always seem to have issue with the double extruder lately as well , by getting rid of it i would cut the weight by more than half , seem like the consensus is the orbiter 2.0 is the best extruder for this next step with a mosquito .

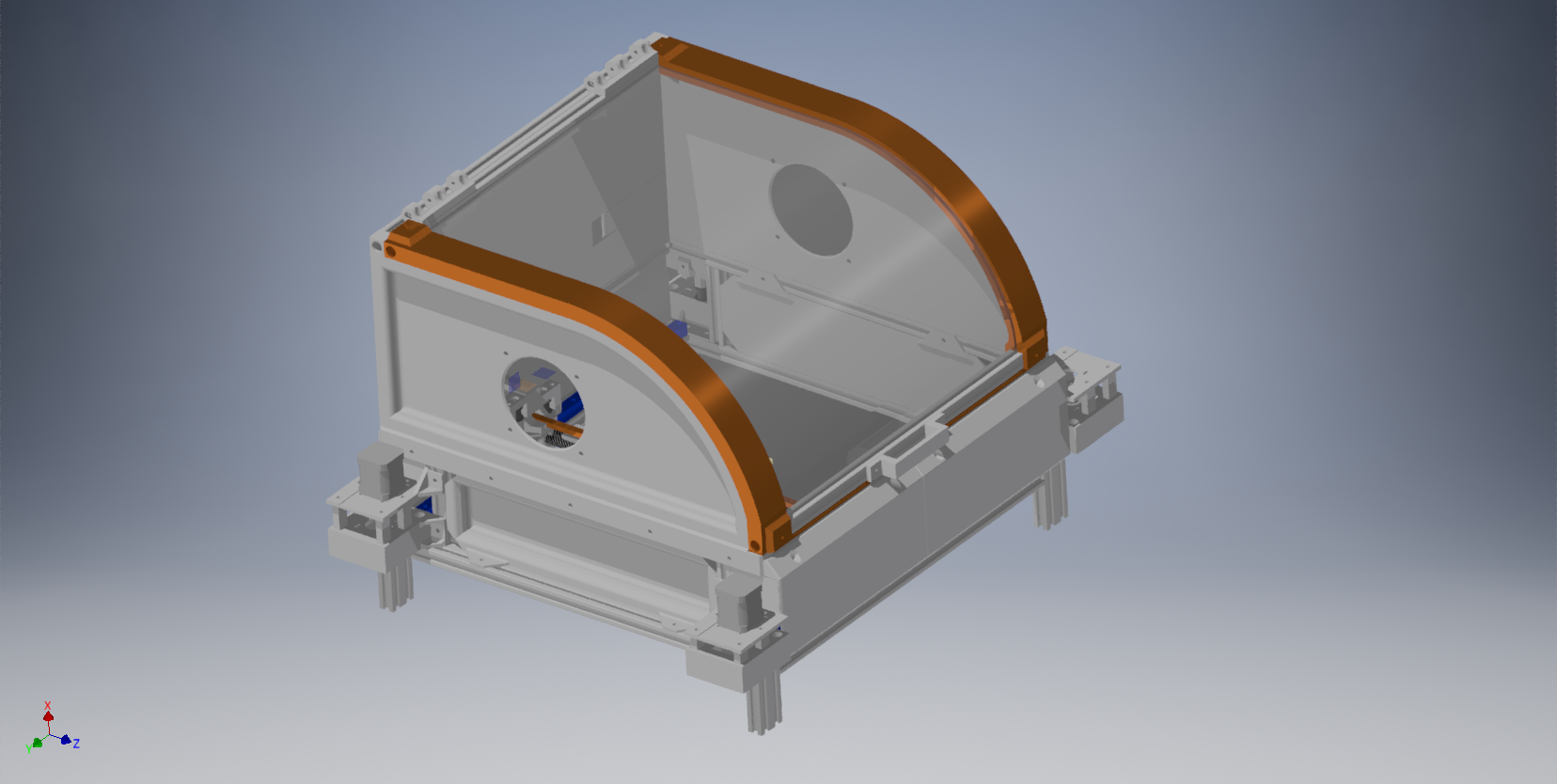

ive been working on my top a bit lately still printing a bunch of part .

here a quick look at the next evolution of this project .

-

here a small update , got a few things printed and mounted has well , got more part to print still and waiting for part to come from the mail as well , had to change the spool setup since i decided i was going to install the double extruder in the back as a feeder magazine for the orbiter mosquito combo , just need to make Y filaments guide and a bit of tinkering so i can still have dual material abilities. Spool now sit vertically at the top in the back of the printer , with filaments switch udner it doing a nice curve to the dual extruder than to the orbiter .

-

early mount for orbiter/mosquito

-

undefined Dad003 referenced this topic

undefined Dad003 referenced this topic

-

Did the swap over , using the bmgx2 has Feeder magazine heading to a y adapter , to the orbiter , only did a few test but everything seem to work as intended . I accidentally burn one of the fan mosfet , error in config , I just moved it to another pin my fault on that one . Just need to tweak and make some duck fory cooling fan.

I think I can call this v3 of my printer

-

fully enclosed top once i swap the Y gantry for the lighter version . Need to work something better for my fan duct as well , i have an idea .

-

New fan duct and lift support installed for top

-

Well I have ordered the last few things I need to make the lighter y carriage going in , all the side panel to enclose the top have been printed as well , him now printing the new motor mount , so once I receive those carbon fiber tubing I can swap the whole things and test again . When with a hiwin mgn9 rail with short block . Decide to go with quality components over cheaper one

-

Well new y gantry and axis is nearly done building got a few more part to print to be able to swap over , everything is printed in nylon pa6 cf , overall weight savings on moving axis will be from 500g to 1000g at least , I shrinked a few part as well for more weight savings. Hgr 15 weight 750g for 500mm new mgn9 with rail, block and carbon fiber tubing is like 280g .

-

@Dad003 nice! hope you will have an accelerometer on the print head for testing.

-

@T3P3Tony i do , i just need to make a new connector for it

-

@Dad003 Well ive installed the new rail this week but found that i messed up the heigh of my motor mount unfortunately lol , had made a mistake on some part when i drawn then on my cad software so about 12mm too high, so i had to put some spacer to lift up the rail higher . so got the corrected motor mount reprinted and did a few tweak as well , waiting for more brass heat set insert to swap over again.

so far printing look very good on new motor mount , i think it an improvement from 1-1.5lbs lighter at least than last iteration , ordered 4 more stepper motor with different spec which i think will help me achieve the acceleration and speed him looking . him definitively getting closer to the end of this build i think . Speed an quality.

-

Here a few updates after I swapped my y axis , it working good , still need to modify my motor mount

a

a