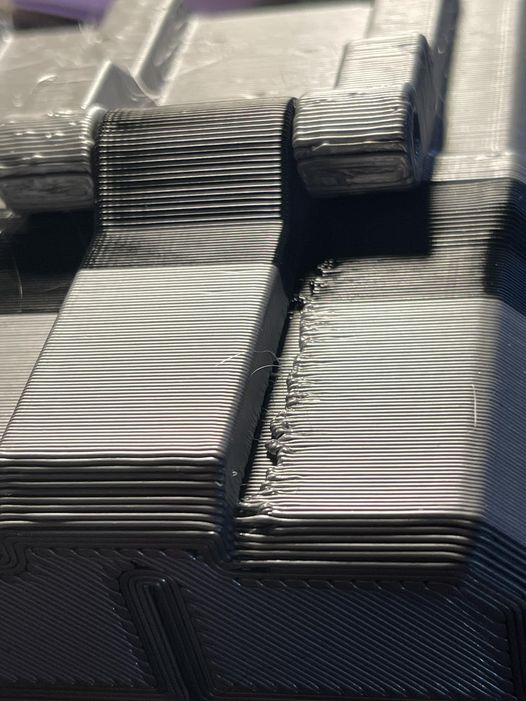

Large Seam Gap with thick nozzle

-

Printing petg thick, 0.8mm nozzle and 0.5mm layers, getting a large seam gap. Filament is dry. using prusaslicer need suggestions please

240 temp, 50mm/s, 500/s accel in slicer, 3k accel in firmware

1mm retraction, 0.1mm extra restart

-

@Adamfilip To figure out if it's pressure advance- or retraction-related you could tell slicer where to put the seam.

Don't put it in a corner for testing. -

@o_lampe during tuning. I ended up disabling pressure advance as it didnt seem to be making any improvements with a large nozzle

was previously at

;M572 D0 S0.025 -

@Adamfilip The cross sectional area of a 0.4mm nozzle is about 0.125mm^2. The area of a 0.8mm nozzle is about 0.5mm^2. Also, a 0.4mm nozzle would normally have a layer height of about 0.3mm whereas you are using 0.5mm with the 0.8mm nozzle. So the difference in cross sectional area x the extra layer height gives a volumetric flow rate of roughly 6.7 times more than 0.4mm nozzle. Your 50mm /sec print speed would translate to a print speed of about 330mm/sec with the 0.5 mm nozzle for the same volumetric flow rate. Are you able to print at that? If not, then I suggest you slow down the speed somewhat - somewhere about 1/6th or 1/5th of the print speed you use with a 0.4 or 0.5mm nozzle would seem to be appropriate. You are right that PA will probably have little to no effect because any pressure build up will be a lot less with a 0.8mm nozzle. You are likely to need much more retraction though, to help with the inherent "oozing" problems that large nozzles have.

-

I use big nozzles all the time up to 1.2mm. What does the part look like in your slicer? Thats what it looks like if you have thin walls or sharp corners. How thick is your wall? If the part wall is to thin it might not slice all the way to the end of your corner on your part.

Also use layer height at .4 for better prints. Raise your extruder temp as well because your prob printing faster than you can melt your plastic in the nozzle. I use 250c on a volcano with a 8mm nut extension and a cht nozzle.

My .8 nozzle settings.

extrusion width .96

retract 2mm

lift .8

retract speed 36000

coasting distance .8

wipe distance 5mm -

@deckingman im limiting max volumetric flow to 12 mm3/sec which isnt pushing the extruder too hard

-

@Adamfilip said in Large Seam Gap with thick nozzle:

@deckingman im limiting max volumetric flow to 12 mm3/sec which isnt pushing the extruder too hard

You didn't mention that in your OP - only that you were printing at 50mm/sec. So what is the head speed in reality with that volumetric extrusion limit applied?