2 SD Cards - SBC - stop after pause.g 3.5beta2

-

Strange that I can still print with failed flashing, but my problem occured with a succesful flash.

Can you say what kind of error it is?

-

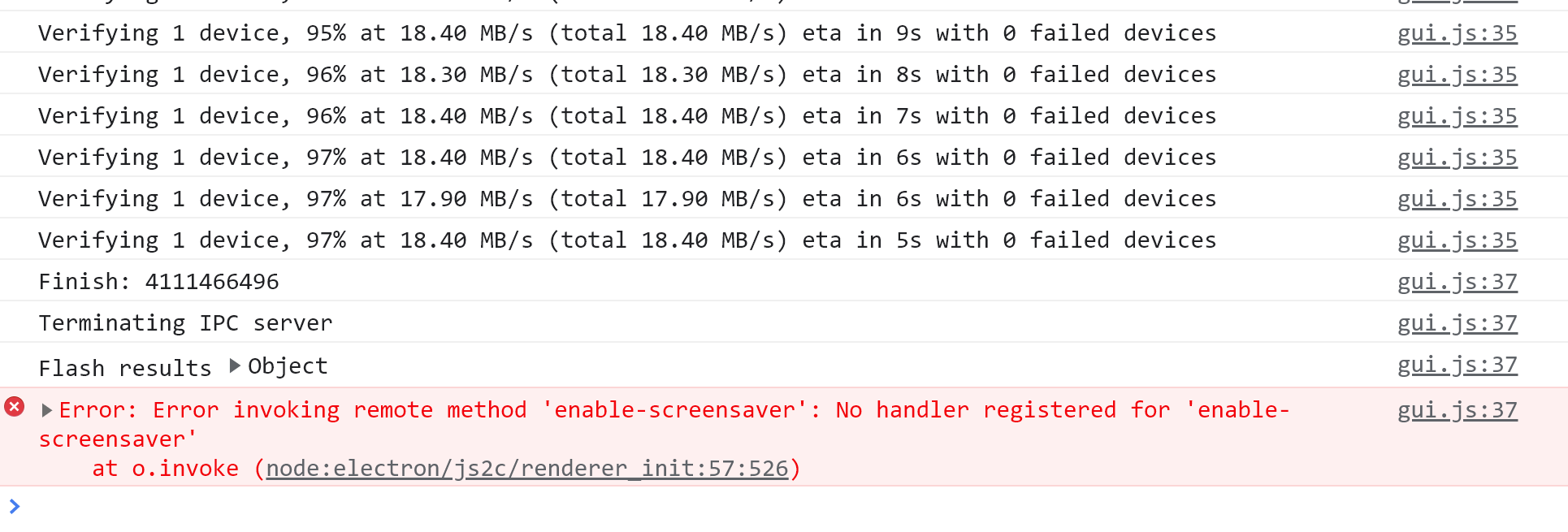

I don't know. But it looks like it failed on verify near the end with a strange error. Maybe try re-installing etcher with a fresh download. Or try a different SD card flasher.

Did you do a full format of the SD card? That's a good way to force it to remap any bad sectors and make sure it's entirely writable.

As for what is happening with the second SD card showing, perhaps @chrishamm knows.

-

@Phaedrux

Strangely flashing is failed earlier. Feels like the sd cards are more crazy with every step.

I'll buy new sd card, flash from different computer and use different raspberry.

I'll tell my experience later. -

@IndeX4D In SBC mode do NOT touch any files on the second SD card partition (which is

/booton the SBC system or the first FAT partition). This partition contains boot files for the SBC Linux system and several files for standalone mode, so if you delete arbitrary files from there, your SBC will not start any more.You can use the Raspberry Pi Imager if the other flash tools fail - just make sure you don't have read-only protection set on your SD adapter.

M122 P104is not supported in SBC mode, there are other Linux utilities for the same purpose. -

@chrishamm thanks for your answer

I´ll try everything again with completly new setup in a few minutes,

-

Is it ok to run sbc with ethernet not only temporary?

-

What do you mean?

-

@Phaedrux

Boot was successful. Can't connect WiFi.

But I could use ethernet cable to connect with my router? Is this also fine?Connected to WIFI!

New SD Card works fine.

SO, only to be sure. Now, I see DWC and have a terminal open to update. Should I upload my sy files in sys folder first, or should I update first?

thanks -

You can use wifi or ethernet on the SBC. That's up to you.

You can update the pi first and then upload your config files later through DWC.

-

So I don´t know whats wrong. Everything was working fine, but same problem happens. Press pause --> stuck

Interesting. First press pause was working fine with m226 in line in pause.g. But after resuming, it was printing slow till next zhop. then I executed pause again --> StuckI changed

-->

Computer to flash

NEW Sd card

Other raspberry

Software versions from 3.4.6 to 3.5 beta3.The last thing I do is to try it with a also complete new set up for another printer.

-

Please post your pause.g and resume.g files

-

@Phaedrux

resume.gG1 R1 X0 Y0 Z5 G1 E0.2 F3600 ; retract 10mm of filament G1 R1 X0 Y0 Z0 pause.g

; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Aug 02 2021 16:15:35 GMT+0200 (Mitteleuropäische Sommerzeit M83 ; relative extruder moves G1 E-0.2 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X200 Y200 F6000 ; go to X=0 Y=0 -

Ok after jumping through some hoops I think we've arrived at the actual issue.

There seems to be an issue with pause and resumed speeds when using closed loop steppers and 3.5 beta 2 and 3.

Can you make a video of what you see happening when you pause and resume?

-

@Phaedrux

yes I can do.

How can I share it?

mostly the size is to big.... give me a second.I have this only by using SBC mode.

Could be, that I had some slow down in standalone mode. No freezing. Im not sure, but this always disappeared after short a while.So no need to try at another printer?

-

Perhaps you can upload the video to dropbox or google drive or something like that and share a link here.

No I don't think we need to try and a completely different printer at this point.

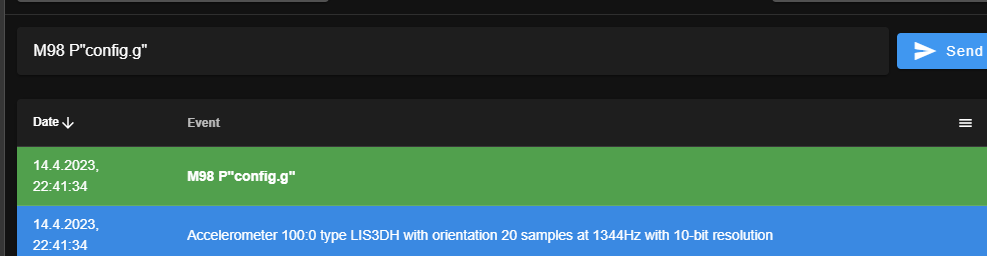

Can you send M122 on the current machine and share the results here?

Also please send M98 P"config.g" and share the results.

Also share your config.g as it currently is. -

@Phaedrux

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.5.0-beta.3 (2023-04-14 11:28:15) running on Duet 3 MB6HC v1.01 (SBC mode)

Board ID: 08DJM-956L2-G43S4-6J9D6-3S46P-KU42D

Used output buffers: 1 of 40 (17 max)

=== RTOS ===

Static ram: 154728

Dynamic ram: 85300 of which 0 recycled

Never used RAM 105580, free system stack 140 words

Tasks: SBC(ready,0.8%,402) HEAT(nWait,0.0%,326) Move(nWait,0.0%,243) CanReceiv(nWait,0.1%,770) CanSender(nWait,0.0%,334) CanClock(delaying,0.0%,341) TMC(nWait,7.2%,59) MAIN(running,91.8%,446) IDLE(ready,0.1%,30), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:44:20 ago, cause: software

Last software reset at 2023-04-14 20:56, reason: User, Gcodes spinning, available RAM 105884, slot 0

Software reset code 0x6003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

Error status: 0x00

MCU temperature: min 31.1, current 32.5, max 33.2

Supply voltage: min 22.9, current 23.6, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.0, max 12.1, under voltage events: 0

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0, mspos 353, reads 45215, writes 17 timeouts 0

Driver 1: standstill, SG min 0, mspos 253, reads 45215, writes 17 timeouts 0

Driver 2: standstill, SG min 0, mspos 345, reads 45215, writes 17 timeouts 0

Driver 3: standstill, SG min 0, mspos 629, reads 45215, writes 17 timeouts 0

Driver 4: standstill, SG min n/a, mspos 8, reads 45221, writes 11 timeouts 0

Driver 5: standstill, SG min 0, mspos 440, reads 45211, writes 21 timeouts 0

Date/time: 2023-04-14 21:40:25

Slowest loop: 77.94ms; fastest: 0.04ms

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 16, maxWait 2065783ms, bed compensation in use: mesh, comp offset 0.000

no step interrupt scheduled

=== DDARing 0 ===

Scheduled moves 151, completed 151, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 4], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue* is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x0000007

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== CAN ===

Messages queued 24248, received 213113, lost 0, boc 2

Longest wait 14ms for reply type 6018, peak Tx sync delay 33779, free buffers 50 (min 46), ts 13304/13302/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 36832/36832

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x26650

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.5.0-beta.3 (2023-04-14 15:12:26)

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 38.49, max time between full transfers: 122.2ms, max pin wait times: 50.7ms/4.1ms

Codes per second: 0.09

Maximum length of RX/TX data transfers: 4408/848both commands, no infos

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves; Drives ;closed loop

M569.1 P20.0 T2 C1000 E8:4 S200 R100 I0 D0.15 H60 ; Configure the 1HCL board at CAN address.20quadrature encoder 128 steps/motor full

M569.1 P21.0 T2 C1000 E8:4 S200 R100 I0 D0.15 H60 ; Configure the 1HCL board at CAN address.21quadrature encoder 128 steps/motor full step.

M569.1 P30.0 T2 C1000 E8:4 S200 R90 I0 D0.15 H60 ; Configure the 1HCL board at CAN address.21quadrature encoder 128 steps/motor full step.

M569 P20.0 D4 S0 ; Configure the motor on the 1HCL at can address 20 as being in closed-loop drive mode (D4) and not reversed (S1)

M569 P21.0 D4 S1 ; Configure the motor on the 1HCL at can address 21 as being in closed-loop drive mode (D4) and not reversed (S1)

M569 P30.0 D4 S1 ; Configure the motor on the 1HCL at can address 21 as being in closed-loop drive mode (D4) and not reversed (S1)Other drives; open loop;

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.2 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S1

M569 P0.5 S0

M569 P100.0 S0 ; physical drive 0.2 goes forwards

M569 P110.0 S0 ; physical drive 0.2 goes forwards

M584 X30.0 Y20.0:21.0 Z0.0:0.1:0.2:0.3 C0.5 E100.0:110.0 ; set drive mapping

M350 Z128 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z5120.00 C91.022 E400.00:690 ; set steps per mm

M566 X4000.00 Y4000.00 Z2000.00 C3000 E3000.00:3000.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z270.00 C10000 E24000.00:24000.00 ; set maximum speeds (mm/min)

M201 X3500.00 Y3000.00 Z2000.00 C400 E4000.00:4000.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z2300 C550 E800:1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S300 ; Set idle timeout

M671 X-100:-100:1180:1180 Y-100:1180:1180:-100 S20 ; leadscrews at front left1 and n´back2. back rigth3 and front4M915 P0.5 C S0 F0 R1

; Axis Limits

M208 X0 Y-100 Z0 S1 ; set axis minima

M208 X1000 Y1030 Z850 S0 ; set axis maxima; Endstops

M574 C1 S3

M574 X2 S1 P"^30.io1.in" ; configure active-high endstop for high end on X via pin ^io3.in

M574 Y2 S1 P"^20.io1.in+21.io1.in" ; configure active-high endstop for high end on Y via pin ^io1.in; Z probe

M558 P5 C"0.io1.in" H8 F2000 I0 T5000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X5 Y30 Z0 ; Set Z probe trigger value, offset and trigger height; Z probe

M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters

M557 X50:800 Y50:800 S37.5 ; define mesh grid; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M140 H0

M307 H0 R0.468 K0.275:0.000 D19.70 E1.35 S1.00 B0 ; disable bang-bang mode for the bed heater and set PWM limit

M143 H0 S120M308 S1 P"100.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as PT1000 on pin 121.temp0

M950 H1 C"100.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B1 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S260M308 S2 P"110.temp0" Y"pt1000" T100000 B4138 ; configure sensor 2 as PT1000 on pin 121.temp0

M950 H2 C"2.out0" T2 ; create nozzle heater output on out1 and map it to sensor 2

M307 H2 R2.655 K0.412:0.000 D6.50 E1.35 S1.00 B0 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S255 ; set temperature limit for heater 1 to 250C; Fans

M950 F0 C"100.out2" Q500 ; create fan 0 on pin 100.out1 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M563 P0 D0 H1 ; tool uses extruder 0, heater 1M950 F1 C"100.out1" Q500 ; create fan 1 on pin 100.out2 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M563 P0 D0 H1 F1 ; tool uses extruder 0, heater 1M950 F2 C"110.out2" Q500 ; create fan 2 on pin 101.out1 and set its frequency

M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off

M563 P1 D1 H2 ; tool uses extruder 0, heater 2M950 F3 C"110.out1" Q500 ; create fan 3 on pin 101.out2 and set its frequency

M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on

M563 P1 D1 H2 F2 ; tool uses extruder 1, heater 2; Magnete

M950 F8 C"20.out0" Q500 CMagnet0 ; create magnet 0 on pin out9 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F9 C"20.out1" Q500 CMagnet1 ; create magnet 0 on pin out9 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F10 C"21.out0" Q500 CMagnet2 ; create magnet 0 on pin out9 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F11 C"21.out1" Q500 CMagnet3 ; create magnet 0 on pin out9 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X-9 Y-39 Z-4.56 ; set initial tool 0 active and standby temperatures to 0C

G10 P0 R0 S0

M955 P100.00 I20M563 P1 D1 H2 F2 ; define tool 1 ; set initial tool 0 active and standby temperatures to 0C

G10 P1 X-76.9 Y-78.7 Z-21.8

G10 P1 R0 S0 -

undefined Phaedrux moved this topic from Firmware installation 14 Apr 2023, 20:55

-

Are you able to make it halt consistently with a pause/resume? Next time that happens can you send M122 from the gcode console? Or is DWC completely unresponsive as well?

-

@Phaedrux

DWC is completely unresponsive.

Mostly it´s freezing directly, sometimes it´s just slower after resume till next layer/wall.I can try it 3 more times.

this time it stopped with first pause.

see short video -

@Phaedrux WhatsApp Video 2023-04-14 at 22.59.46 (1).mp4

May the speed before decides the behaviour. I´ll test it.

-

Can you send M122 B# where # is the canbus address of each of your expansion boards and copy and paste the results from each here?