Delta bedlevelling

-

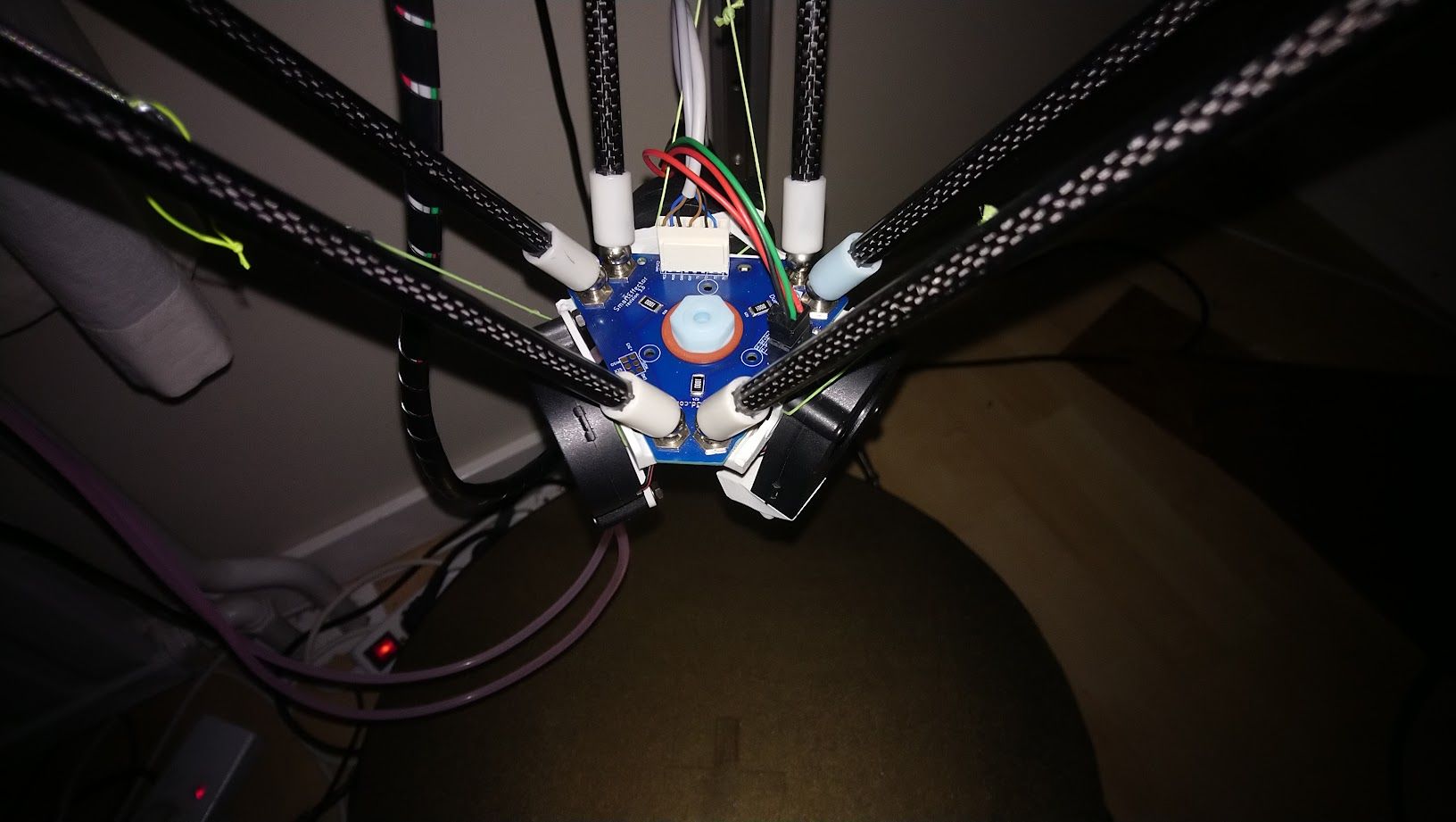

It has only 3 contact points + the E3DV6 style thread

-

Seems to be a hot potatoe as nobody cares to answer the range of functional mesh compensation.

-

@tecno The mesh compensation can probably account for the bed deviation (from memory there isn't any practical limit), but what is the reason the bed is deformed? Most likely is effector tilt. Have a look at http://boim.com/DeltaUtil/CalDoc/Calibration.html and see if any of those examples match your bed shape. I assume you have been through this page too: https://docs.duet3d.com/en/User_manual/Tuning/Delta_calibration

Any reason you're using a square mesh, rather than a round one? If you have a round bed (and you may have a square one) your M557 should have an R parameter rather than X and Y, eg

M557 R130 S20

See https://docs.duet3d.com/User_manual/Connecting_hardware/Z_probe_mesh_bed#define-the-mesh-size-and-spacingIan

-

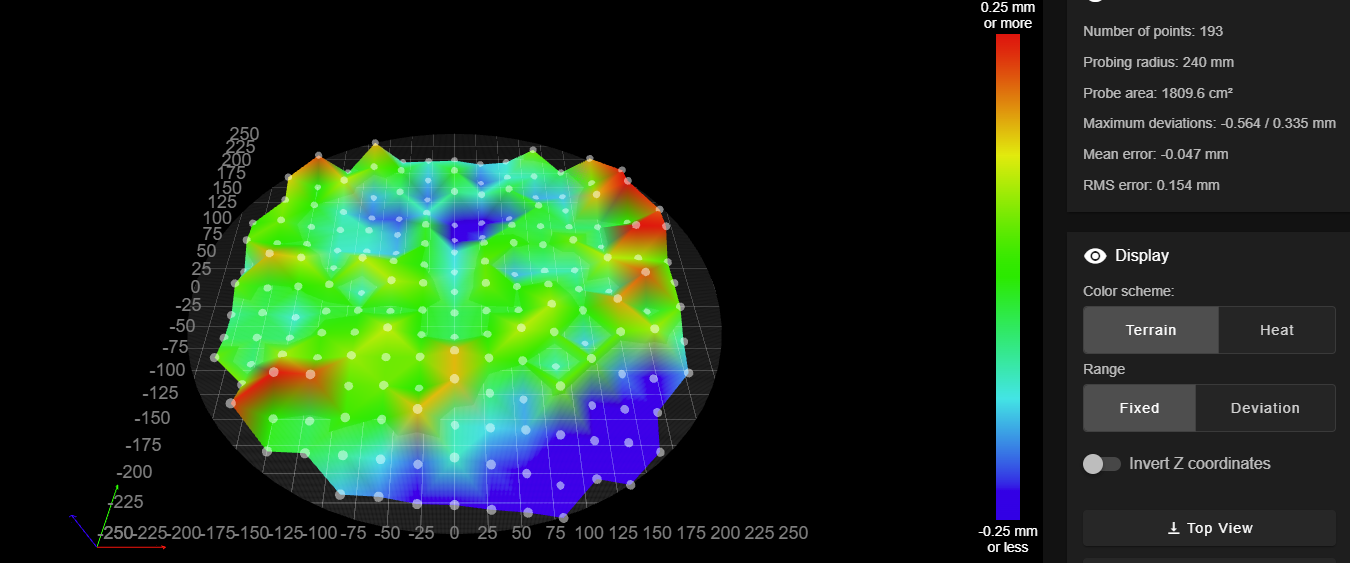

- M557 R240 S80 and it gives the result as seen in pictures

-

@tecno Can you post your config.g? And M115 response.

Ian

-

@droftarts

M115

FIRMWARE_NAME: RepRapFirmware for Duet 3 Mini 5+ FIRMWARE_VERSION: 3.4.5 ELECTRONICS: Duet 3 Mini5plus Ethernet FIRMWARE_DATE: 2022-11-30 19:41:164f0dead3-6363-4140-b2fe-e93db7c36ceb-config.g

1930649a-c3ad-4e83-8a70-1498e7f0b954-config-override.g -

@tecno said in Delta bedlevelling:

M557 R240 S80 and it gives the result as seen in pictures

Actually, it's the probe spacing S80 (ie 80mm) that is causing it to be square. It can't get into the edges with that value.

Ian

-

M557 R240 S30

-

@tecno There definitely seems to be a lot of variation in the measurements. Your current probe setup is:

M558 P8 R0.4 C"io3.in+io4.out" H50 F1200See M558 in the Gcode dictionary.

I'd say reduce the probe feed speed (F) down to something slower (my delta probes at 120, but it isn't a smart effector)(see following post). You can always have a fast travel speed (T, which is missing from yours). Reduce the dive height (H) to speed up probing, doesn't need to lift 50mm each time. And you can probe multiple times (A) to improve accuracy based on tolerance (S). I'd try something like:M558 P8 R0.4 C"io3.in+io4.out" H10 F1200 T6000 A5Use that and see if you get a smoother mesh. It's difficult to tell what else is going on otherwise.

Ian

-

@tecno Sorry, the docs say to use F1200, so keep that for now. If the bed mesh doesn't improve with the other settings, try varying this speed, as it is possible the weight of the extruder makes a difference.

Ian

-

@droftarts

I can not run A in M558 errors out in

M140 P0 S0

Error: Z probe readings not consistentSensitivity is set like this after a lot of testing.

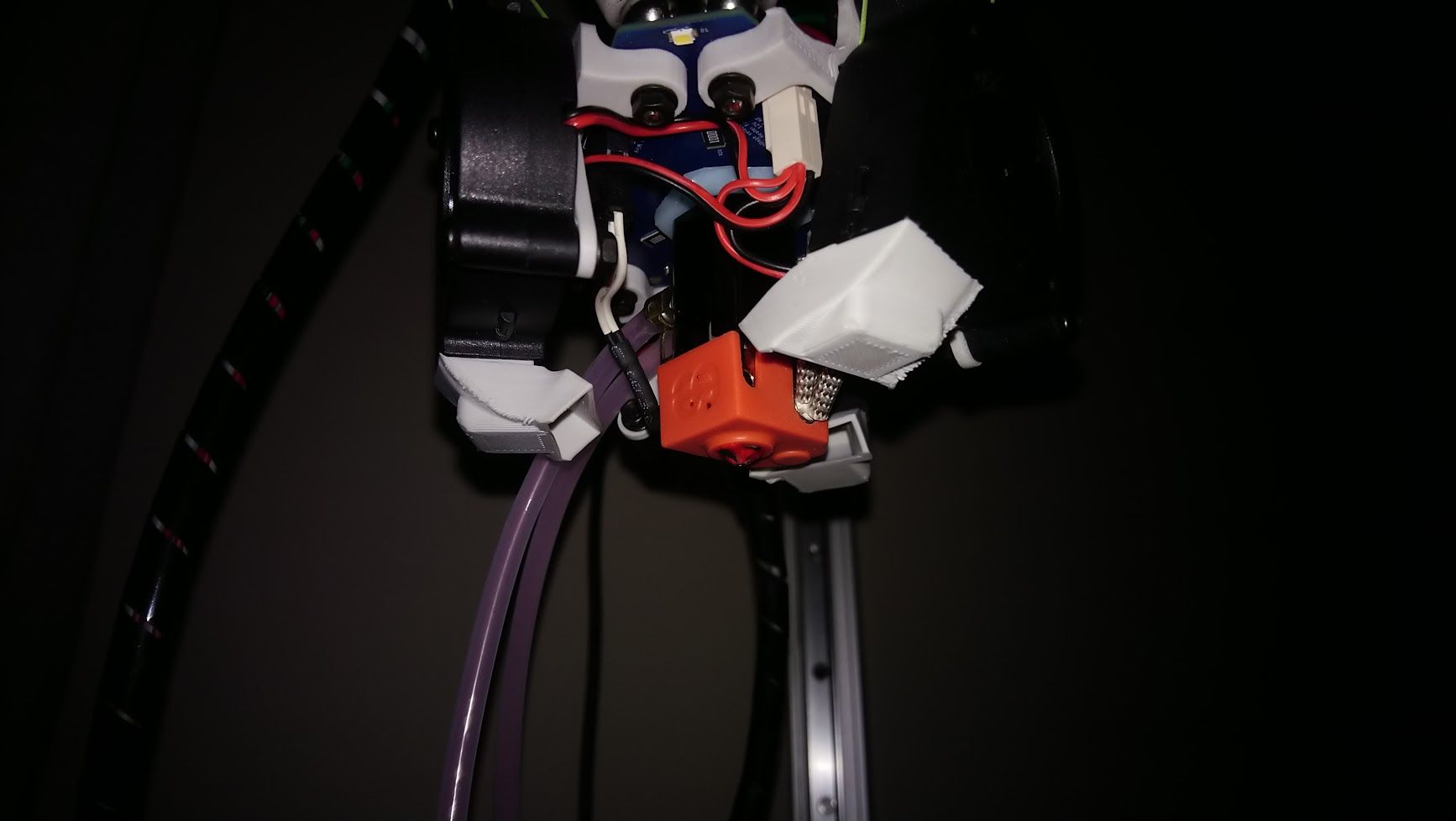

m672 s105:039:216So I think that no extruder is working directly on the effector

-

I have now tried to get the Smart Effector to work properly but no.

M672 is now set to 10:245 and still I do not get all points probed.

Only my Phaetus Dragon water cooled is mounted on the board.

So I want to get this board replaced.

-

@tecno when and where did you purchase it?

-

@dc42

Trying to PM youWAC-UYIQAQU look tru all details!

-

Please send an email to warranty@duet3d.com and CC your reseller. Include a link to this forum thread and the details of your original purchase. You'll receive a reply with a form to fill out.