BLtouch not deploying / PID auto tune issues

-

@gloomyandy

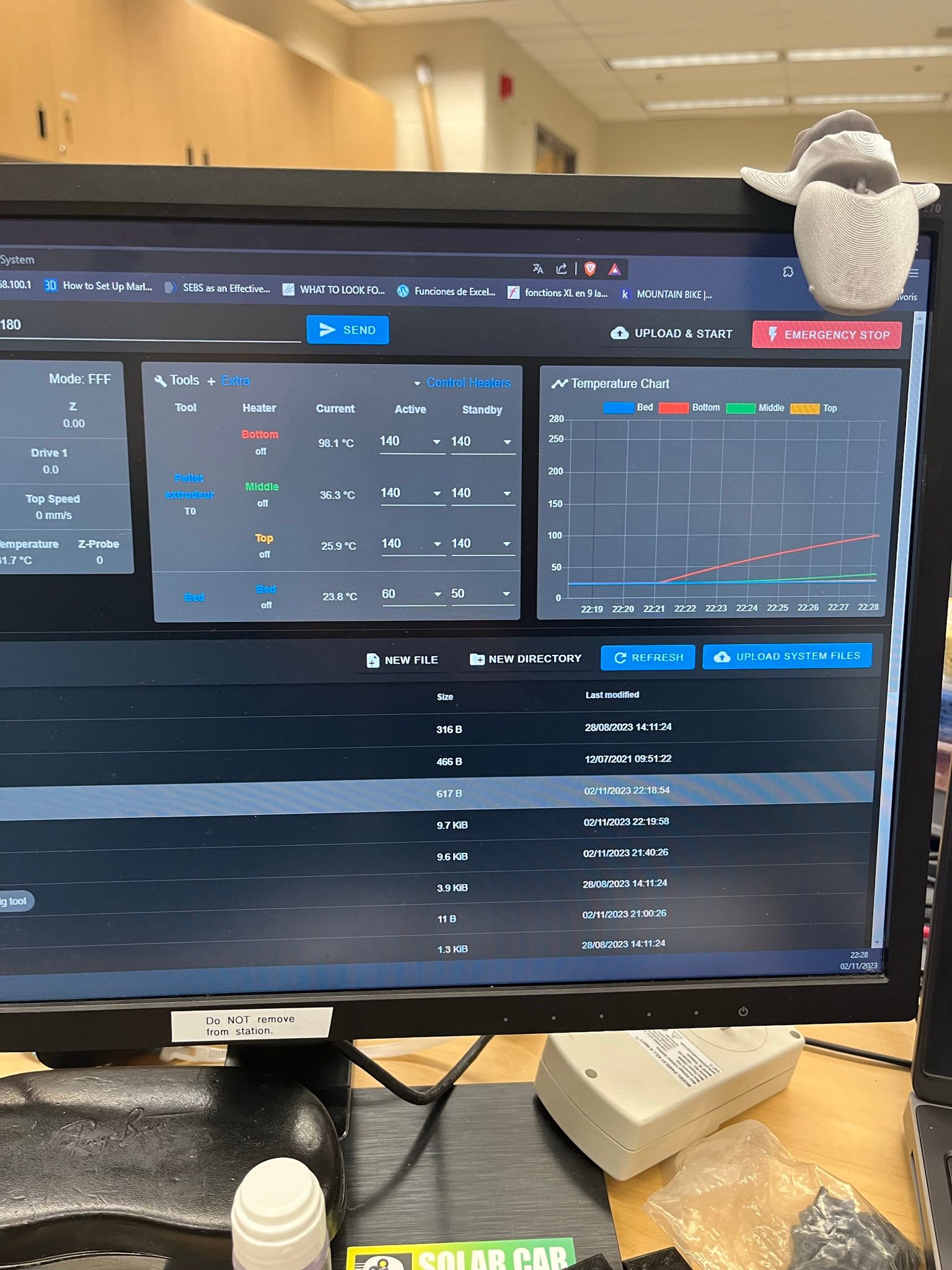

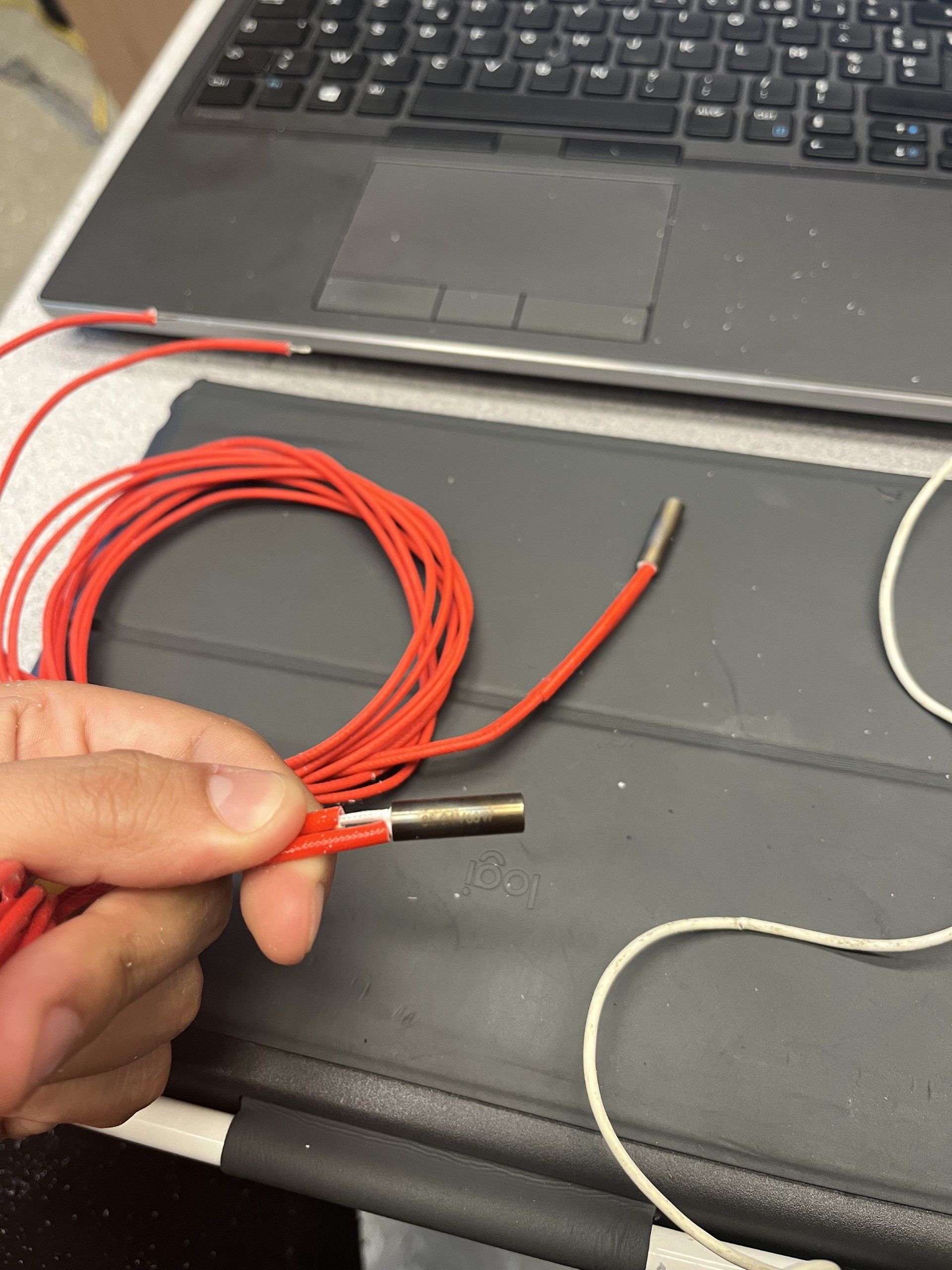

Hello!!The machine in question is a Pellet extruder, which incorporates three barrels within the extruder assembly. Each of these barrels is equipped with a heating system. Two of them are fitted with 24V 80W heaters (as shown in Figure 1), while the remaining one is equipped with a 24V 60W heater (depicted in Figure 2).

During the tuning process, I observed that all of them ceased functioning after precisely 7 minutes had elapsed. You can find visual representations of the diagrams below for reference.

Tunning Heater 1

Commencing at an initial temperature of 23°C (ambient)

It stopped at 98°C after 7 min

Tunning Heater 2

Commencing at an initial temperature of 86°C, (achieved through induction heating, I aimed to verify whether the elapsed time was consistent across all). The process halted at a temperature of 158°C.

Tunning Heater 3

Commencing at an initial temperature of 27°C

It stopped at 113°C after 7 min

Figure 1

Figure 2

confg.g

M291 P "Welcome to your experence using the GigabotX_ Western_University" S1 T0

; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Gigabot X UWO edition" ; set printer name; Network

M552 P192.168.100.8 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.100.254 ; set gateway

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S0 ; disable Telnet; Drivers

M569 P0.0 S2 ; physical drive 0.0 goes forwards X

M569 P0.1 S1 ; physical drive 0.0 goes forwards YR

M569 P0.2 S0 ; physical drive 0.0 goes Backwards YL

M569 P0.3 S1 ; physical drive 0.3 goes forwards ZR n ZL

M569 P0.4 S1 ; physical drive 0.4 goes forwards Extruder

M569 P0.5 S1 ; physical drive 0.4 goes forwards Crammer

M584 X0.0 Y0.1:0.2 Z0.3 E0.4:0.5 ; set drive mapping

M350 X16 Y16:16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X53.335 Y59.26:59.26 Z2015.75 E 26.00:34.00 ; set steps per mm E extruder:crammer

M201 X500.00 Y500.00 Z20.00 E900.00 ; TEST set accelerations (mm/s^2)

M203 X10740.00 Y6810.00 Z480.00 E3600.00 ; TEST set maximum speeds (mm/min)

M566 X900.00 Y900.00 Z60.00 E500.00 ; TEST set maximum instantaneous speed changes (mm/min)

M204 P5100 T20000 ; set printing and travel accelerations (mm/s^2)

M906 X2800 Y2000:2000 Z2000 E850:2000 I30 ; set motor currents (mA) and motor idle factor in per cent

M572 D1 S0.03 ; Set extruder pressure advance

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X600 Y760 Z890 S0 ; set axis maximaEndstops

M574 X1 S1 P"!io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io1.in

M574 Y1 S1 P"!io3.in+!io2.in" ; configure switch-type (e.g. microswitch) endstop for High end on YR and YL via pin io3.in + io2.in

;M574 Z1 S1 P"!io4.in" ; configure switch-type (e.g. microswitch) endstop for High end on ZR and ZL via pin io4.in;Z-probe

M950 S0 C"io7.out" ; configure BLtouch Z in pin io7.in

M558 P9 C"io7.in" H10 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

;M558 P5 C"!io5.in" H10 F120 T6000 ; configure switch-type (e.g. microswitch) endstop for High end on ZR and ZL via pin io5.in

G31 X20 Y-10 Z0 P100

M557 X50:600 Y50:754.5 S80 ; define mesh gridHeaters

M308 S0 P"spi.cs0" Y"thermocouple-max31856" A"Bed" T "k" F 60 ; configure sensor 0 as thermocouple via CS pin spi.cs0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 R0.367 C336.3 D2.47 S1.00 V23.2 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M140 S60 R50 ; heated bed "S" active temp "R" standby temp

M140 S-273.1 ; switch off bed heater

M143 H0 S110 ; Heated Bed Max temp

M308 S1 P"spi.cs1" Y"thermocouple-max31856" A"Bottom" ;T "k" F 60 ; configure sensor 1 as thermocouple via CS pin spi.cs1

M950 H1 C"out1" T1 ; create nozzle heater output on out0 and map it to sensor 1

;M301 P32.00 I4.00 D74.00

M307 H1 B0 R0.575 C791.0 D20.76 S1.00 V23.9 ; disable bang-bang mode for heater and set PWM limit

;M307 H1 B0 R0.16 C3600 D60 S1.00 V23.9

M143 H1 S280 ; set temperature limit for heater 1 to 300C

M308 S2 P"spi.cs2" Y"thermocouple-max31856" A"Middle" T "k" F 60 ; configure sensor 2 as thermocouple via CS pin spi.cs2

M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 2

;M301 P32.00 I4.00 D74.00

M307 H2 B0 R0.768 C389.3 D15.78 S1.00 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 1 to 280C

M308 S3 P"spi.cs3" Y"thermocouple-max31856" A"Top" T "k" F 60 ; configure sensor 3 as thermocouple via CS pin spi.cs3

M950 H3 C"out3" T3 ; create nozzle heater output on out2 and map it to sensor 3

;M301 P32.00 I4.00 D74.00

M307 H3 B0 R0.533 C588.3 D18.57 S1.00 V23.9 ; disable bang-bang mode for heater and set PWM limit

M143 H3 S280 ; set temperature limit for heater 3 to 280C; Fans

M950 F0 C"out9" Q30 ;"Refroidissement de couche" create fan 0 on pin out5 and set its frequency

M106 P2 S255 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out8" Q500 ; create fan 1 on pin out3 and set its frequency

M106 P1 S255 H-1 ; set fan 1 value. Thermostatic control is turned off

;M950 F2 C"1.out4" Q20 ; create fan 2 "vibrateur Motor" on pin out4 and set its frequency

;M106 P3 S1 H-1 ; set fan 2 value. Thermostatic control is turned off; Tools

M563 P0 S"Pellet extrudeur" D 0:1 H1:2:3 F0 ; define tool 0

M567 P0 E1:1

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R140,0: 140,0 S140,0:140,0:140 ; set initial tool 0 active and standby temperatures to 0C; Miscellaneous

M501 ; load saved parameters from non-volatile memory

;Automatic power saving

M911 S20 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

Conf-override.g

; config-override.g file generated in response to M500 at 2023-10-12 20:12

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 R0.367 C336.291:336.291 D2.47 S1.00 V23.2 B0 I0

M307 H1 B0 R0.575 C791.0 D20.76 S1.00 V23.9

M307 H2 B0 R0.768 C389.3 D15.78 S1.00 V23.9

M307 H3 B0 R0.533 C588.3 D18.57 S1.00 V23.9

; Workplace coordinates

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00

-

@gloomyandy Hello!!

I have updated the information and I still having the same issue

Could you please help me? -

@Casugo Sorry I've really no idea, those heating rates seem very slow for the type of heater you are using, but they are not as slow as some bed heaters. Are you sure that they can ever reach the target temperatures you are trying to use? So for instance if you simply connect the heater cartridge directly to 24V and monitor the temperature using DWC how long does it take to reach your target temperature? Obviously make sure you do not leave this test set up running unattended!

-

Yes, the heaters are capable of reaching the desired temperature as when I heat them they do it without problem. However, I am encountering difficulties with PID tuning. Also, when I attempt to initiate a print, the heaters initially reach the target temperature, but at the moment it start the printing process, they suddenly shut off, and all temperature readings show 2000. I'm uncertain whether this issue is pobably related to incomplete reception of the 24V power supply or if there's interference between the thermocouples and the stepper motors causing this problem.

-

@Casugo Can you post a screenshot of the temperature graph when heating "normally" so that we can see how the temperature rises and how long it takes to reach your target temperature of 180.

-

Update:

I simultaneously heated all three heaters, and the following are the results:

Heater 3 displayed an error: "T0 Error: Heater 3 fault: temperature rising much more slowly than the expected 0.5°C/sec" (Fig 1).

While the other heaters continued to heat up, they reached the desired temperature after approximately 14 minutes for heater 1 (Fig 2) and 13 minutes for heater 2 (Fig 3)."

Fig 1

Fig 2

Fig 3

-

@Casugo When you are tuning I assume you are just using a single heater? If so, could you just run a single heater in "normal" mode and post the graph from that.

-

I heated the first heater, and it took approximately 20 minutes to reach the desired temperature.

-

@Casugo I've checked the code and it looks like RRF only allows a maximum time of 7 minutes for a hotend heater to reach the target temperature. It allows 30 minutes for a bed or heated chamber. So unfortunately it looks like your heater is too slow to be PID tuned as a hotend. You may be able to get it to tune by temporarily configuring it as a bed or chamber heater and getting the PID settings that way? If that does not work then I think you may have to set the heater parameters by hand, or ask DC42 to make changes to allow a longer heat up period.

The code in question is here: https://github.com/Duet3D/RepRapFirmware/blob/3.4-dev/src/Heating/LocalHeater.cpp#L677

-

@gloomyandy

Thank you so much!!!

I'll try to do it in that way.I have another question.

I sent a test print, and although the heaters reached the desired temperature, once the temperature was reached and it was about to start printing, the print job paused, and all temperature indicators suddenly showed 2000 (fig 1). Additionally, an error appeared in the console:

Error: Temperature reading fault on heater 1: sensor short to other wiring

Error: Temperature reading fault on heater 2: sensor short to other wiring

Error: Temperature reading fault on heater 3: sensor short to other wiring

Resume state savedfig1

Is the issue you mentioned related to this error as well?

Thanks.

-

@Casugo That issue looks more like some sort of wiring issue to me, I don't think it can be caused by any sort of firmware problem.

-

Okay, I'll check on the wiring and the tuning in heater chamber mode :).

Thank you and have a good day :D.

-

@gloomyandy

Hello!!I configurated each heater as a heated chamber and I was able to do the tunning.

Thank you a lot