Duet3 Mini5+ Ethernet Nozzle Distance to PEI sheet is too large

-

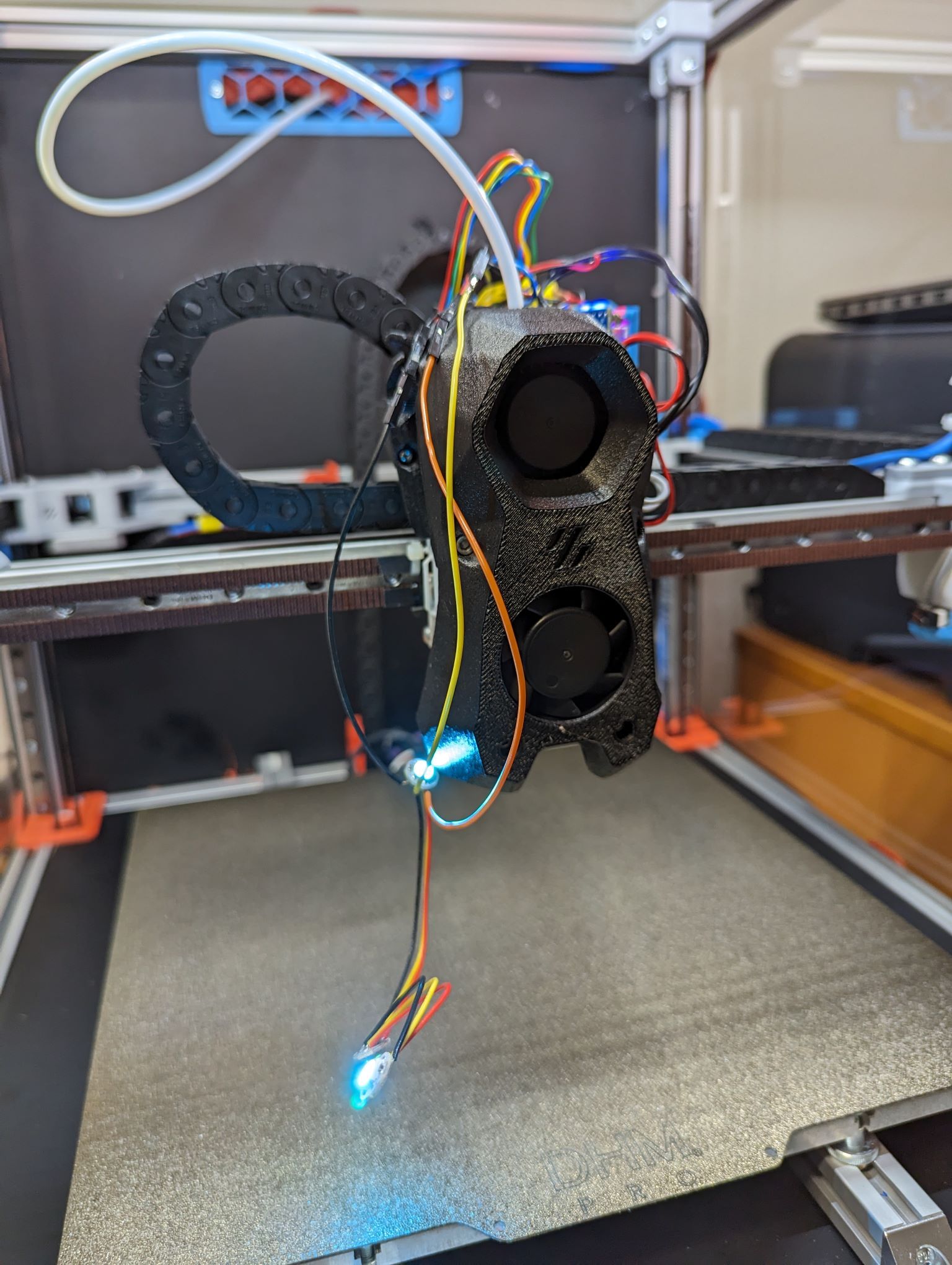

@droftarts Good morning Ian, the printer is running again with the 0.6 nozzle. I'm currently printing a large part as an endurance test, see photo. Do you see anything unusual in the photo?

When I started the Prusa Slicer, I entered the following codes and commented out the one from Prusa:

;print_start EXTRUDER=[first_layer_temperature[initial_tool]] BED=[first_layer_bed_temperature]

G32

G29

This also works well, only after the mesh, the nozzle temperature is set to 0. This means that the first few cm don't stick because the temperature drops quickly. The plate temperature is maintained.

Which code do I have to enter where so that this doesn't happen?

When I start the machine, I would like the printer to automatically reference its axes immediately. Where do I have to enter something in config.g?

Thank you for your competent help and I wish you a nice weekend, greetings

wolfgang

-

@Wobi while you can put movement commands in config.g, generally we don’t recommend automatic homing, heating or movement to be put in config.g, mainly because the state of the machine may be unknown at power on. What if there has been a power cut during print, or you did an emergency stop (effectively a reset) because of a problem?

For the temperature setting problem, I expect Prusa slicer is putting in the temperature that you have set for the filament, which may be 0C. Post the first 50 or so lines of a GCode file, up to where the G1 move commands start, so we can see what it is doing.

I successfully connected 7 RGB LEDs to my Mini 5+, using the ‘led’ header and pin name. I connected 5V and ground to an IO header, as these were quite low power LEDs (30mA each, so about 0.2A, within the 5V regulator’s capability). Please check your firmware version by sending M115 and post the result. Also post a link to the LEDs you are using (same as my link earlier?) and post a picture of how they are wired, and finally post the M950 code you’re using to configure them and M150 code to turn them on. Also send M98 P"config.g" in the console, and see if it produces any errors.

Ian

-

@droftarts

Thank you for your quick and competent answer.

Your arguments are convincing, thank you, I'll leave it that way.

I can't say which LEDs are installed, they are not specified in the invoice, but they are RGBW LEDs that were completely soldered and all lines have continuity to all three LEDs, but I was only able to measure the data line up to the first LED.

I will deliver everything else when the printer has hopefully completed its print job tomorrow morning without any errors. -

@Wobi Change the Q parameter in this line:

M950 E0 C"led" T2 Q800000back to Q3000000. I've found that my LEDs don't work correctly with Q800000. I mistakenly thought Q was the bits per second rate, but it is the SPI clock frequency, which is 4x the bit rate, hence 800000 x 4 is 3200000. 3000000 is just below this, and has been check that it works fine on most LEDs.

For reference, I use:

M950 E1 C"led" T1 Q3200000 M150 E1 R255 S3 F0 ; sets first 3 LEDs to redIan

-

@droftarts

Hello Ian,

Thanks, I can't try that until tomorrow.

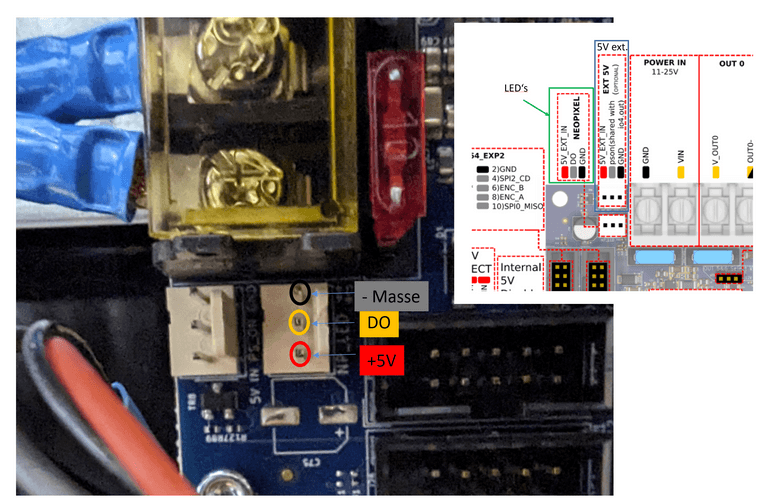

To which pins did you connect the LEDS, to the Neopixel pins (do) directly next to the power connection of the Mini5 or directly to the 1LC and where exactly?

And have you connected an external power supply and if so where? Everything please, please with a photo.

I have attached a shortened G-code file of the Prusa Slicer.

Thank you for your patience and perseverance.wolfgang

Grundplatte_teil2_02.gcode -

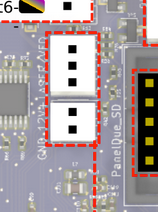

@Wobi I’ll wire up 3 RGBW lights tonight. This is how I wired up the RGB leads:

The strips have 3 connections; 5V, data and GND. I connected 5V and GND to the 5V and GND on IO_4. I connected data to the led pin on the LED connector by power in. I don’t have anything connected to 5V_EXT, and no jumpers on the 5V_Select or internal_5V_disable pins. So the LEDs are powered from the internal 5V regulator, which can supply 1A. 3 LEDs should pull maximum 0.24A, so unless you’re running something else on 5V (PanelDue and 12864 screen etc) as well (I ran a PanelDue on mine as well, no problem), this should be fine. You can also just turn on LEDs at low brightness, to reduce current usage.

Make sure the data line connects to Di (data in) on the first LED, not Do (data out). If you can post a picture, that would help.

Ian

-

@droftarts said in Duet3 Mini5+ Ethernet Nozzle Distance to PEI sheet is too large:

12864

I have a 12864 display

-

@Wobi

Good morning Ian,

I've now measured again and I couldn't measure any voltage, the voltmeter shows 0 volts at the pins.

To be on the safe side, I also measured with the display disconnected, still 0 volts on + and -.

An external power supply was also unsuccessful, regardless of whether I supplied the board with 5 volts using the pin next to it or applied the 5 volts directly to the LEDs.

It seems like the DO pin is not outputting a signal.

Did I even use the correct pins for the Stealthburner LEDs or do I have to connect them somewhere completely different?Printing now works fine and fairly quickly. That's actually the main thing.

The cause of the crash was probably a larger blob on which the nozzle got stuck, it only has an M5 thread and is hollow inside, so not very stable.Another request, by repeatedly unplugging and plugging in the fan plug on the 1LC board, the cables broke off and now I also ran out of small pins to re-crimp.

Could you please tell me the exact name of the small pins so that I can get some?Thank you, Wolfgang

-

@Wobi I've now got RGB and RGBW LEDs working on Mini 5+, 6HC and Duet 2 WiFi, on both the dedicated 5V signalling 'led' pin, as well as 3.3V signalling pins like io_#.out. It should really not be difficult!

First, please send

M115in the terminal so I can check you are using the correct firmware; I know you said you updated, but please send this to check.On the Mini 5+, the NEOPIXEL header is only powered by External 5V; you can't power your LEDs from that header. However, the DO pin is active, and provides a 5V signal (not constant, only when you send an M150 command). So you need to connect the +5V and GND of the LEDs to somewhere else. If you only have 3 LEDs, you should be okay to use 5V from the Duet itself. I don't think the 12864 display draws that much current, so you should be okay to leave that connected.

So connect the LED +5V and GND to an IO header, or anywhere else that has a 5V pin and GND. Then connect the data wire to DO pin on the NEOPIXEL header. If you have a LED string configured for the 12864, make sure you're using different M950 E# numbers for each.

Let me know if that helps. If not, I'll take a picture of my setup. Also, please post a picture of your LEDs.

Ian

-

@droftarts

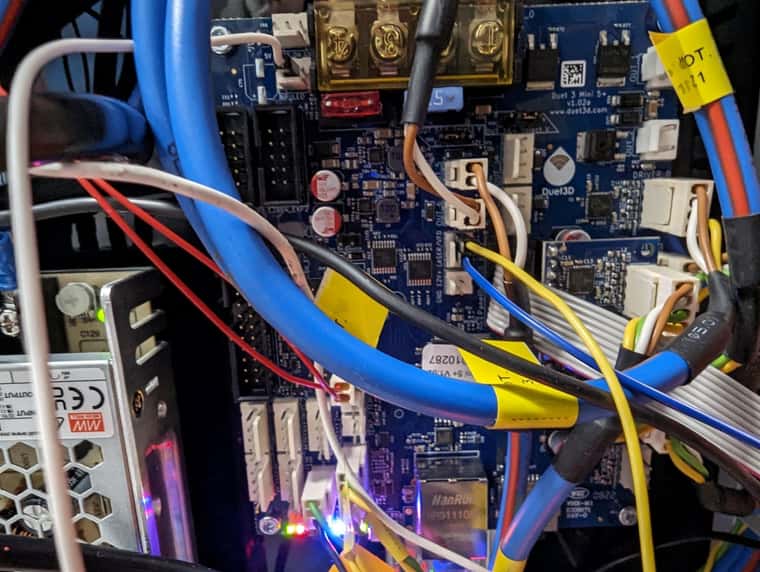

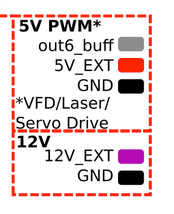

Good morning Ian, the ones that were already installed still don't work, they are probably defective. I have now temporarily connected a new 2 euro set and after entering your GCodes the first one lights up red, the second green and the third doesn't light up at all. Power supply via the 5v PWM+, see photo. However, I only measure 3.6 volts on the third LED and after the ground PIN of the LEDs is broken, both of them continue to light up and I measure 5 volts on all LEDs again. So I will use an external power supply.

Which LEDs should I order or can I use the 2 euros?

And please, where can I order connectors for the 1LC board?

Thanks Ian

wolfgang

-

@Wobi Are the 5V power and GND the Blue and Yellow wires? If so, you've plugged 5V (blue) into 5V_EXT (which should be okay), but the yellow GND wire into 'out6_buff', not GND!

Move the yellow wire to a proper GND pin.

Ian

-

@Wobi said in Duet3 Mini5+ Ethernet Nozzle Distance to PEI sheet is too large:

And please, where can I order connectors for the 1LC board?

What connectors you need depend on which version of the toolboard you have.

See https://docs.duet3d.com/en/User_manual/Troubleshooting/Parts#connectors-used-on-duet-3-toolboard-1lc

and https://docs.duet3d.com/Duet3D_hardware/Duet_3_family/Duet_3_Toolboard_1LC#description-of-connections

Most likely it is a 3- or 4- pin JST PH. You can find pre-wired ones on eBay that you can solder your wires to, or the crimps and headers ready for crimping.Ian

-

@droftarts

yes, it's true that it still worked.

Thanks for the links, that helps me.

greeting

wolfgang -

@Wobi

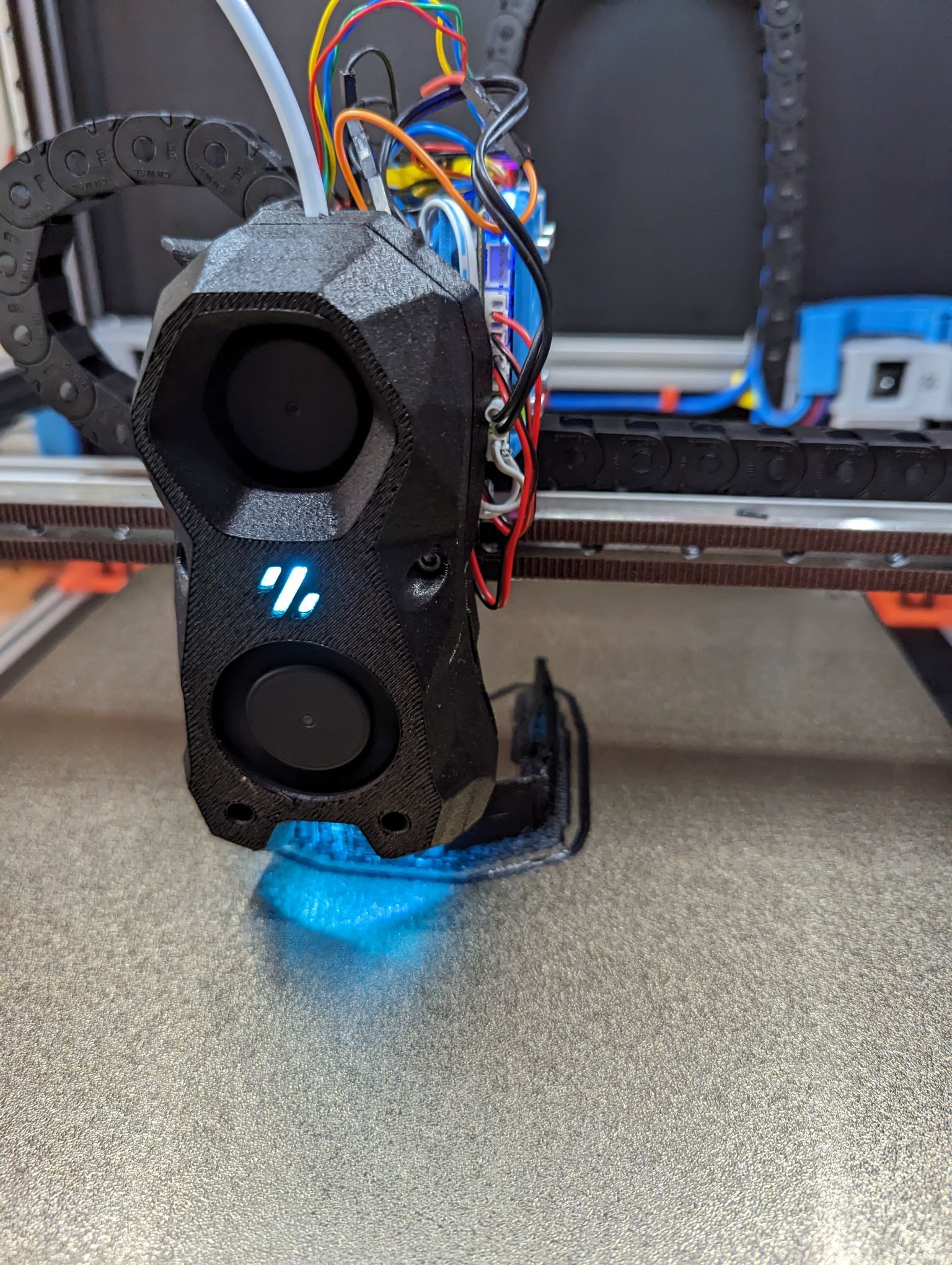

Hello Ian, thanks to your instructions and tips, I have now connected correctly and all three of the connected LEDs work perfectly. The built-in ones are probably broken.

I have to wait until I have the JST PH connectors to install it.This solved my problem, thank you very much.

Greetings Wolfgang

-

@Wobi Great! Glad you got it fixed in the end. Are the LEDs wired to the toolboard, or do the wires run back to the Mini 5+?

Ian

-

@droftarts

The LEDs are connected to the Mini5 as described above -

@Wobi Okay. I'll try them on a 1LC when I get a chance, but I think the LEDs will need a level shifter, or 'hack' (I'm waiting for some diodes to be delivered to try this hack) to accept the 3.3V signal they will get from a 1LC io.out pin.

I haven't tested it, but I think the out6_buff pin (pin name

out6) should also be able to drive the LEDs as the data line, instead of DO on the NEOPIXEL header, as it is a 5V PWM pin. If you have wired 5V and GND to that header, it may be convenient for you to connect the LED data line there, too.Ian

-

@droftarts

Good morning Ian, yes that would be an advantage as only one plug is needed.

But at the moment the LEDs are working perfectly, so there is no need to change them.

Now I need a hood to hide the tangled cables.

greeting

W olfgang

olfgang -

@Wobi

This thread can be marked as solved, thanks -

undefined droftarts marked this topic as a question

undefined droftarts marked this topic as a question

-

undefined droftarts has marked this topic as solved

undefined droftarts has marked this topic as solved

-

@Wobi Hello, may I ask you what mount you are using for the 1LC tool board? If you have a link that would be great. Thanks