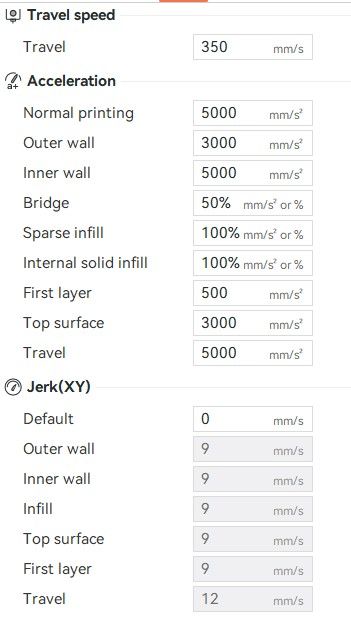

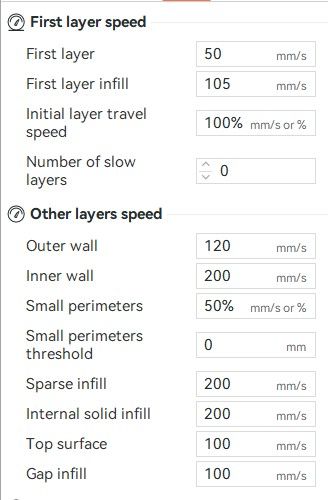

Fast print results, what can I improve?

-

Hi guys.

I am trying to psuh my homemade corexy 3d printer to limit.

What do you think I could improve?

I still have to configure pressure advance.Variabile speed form 120 to 200 mm/s

I

-

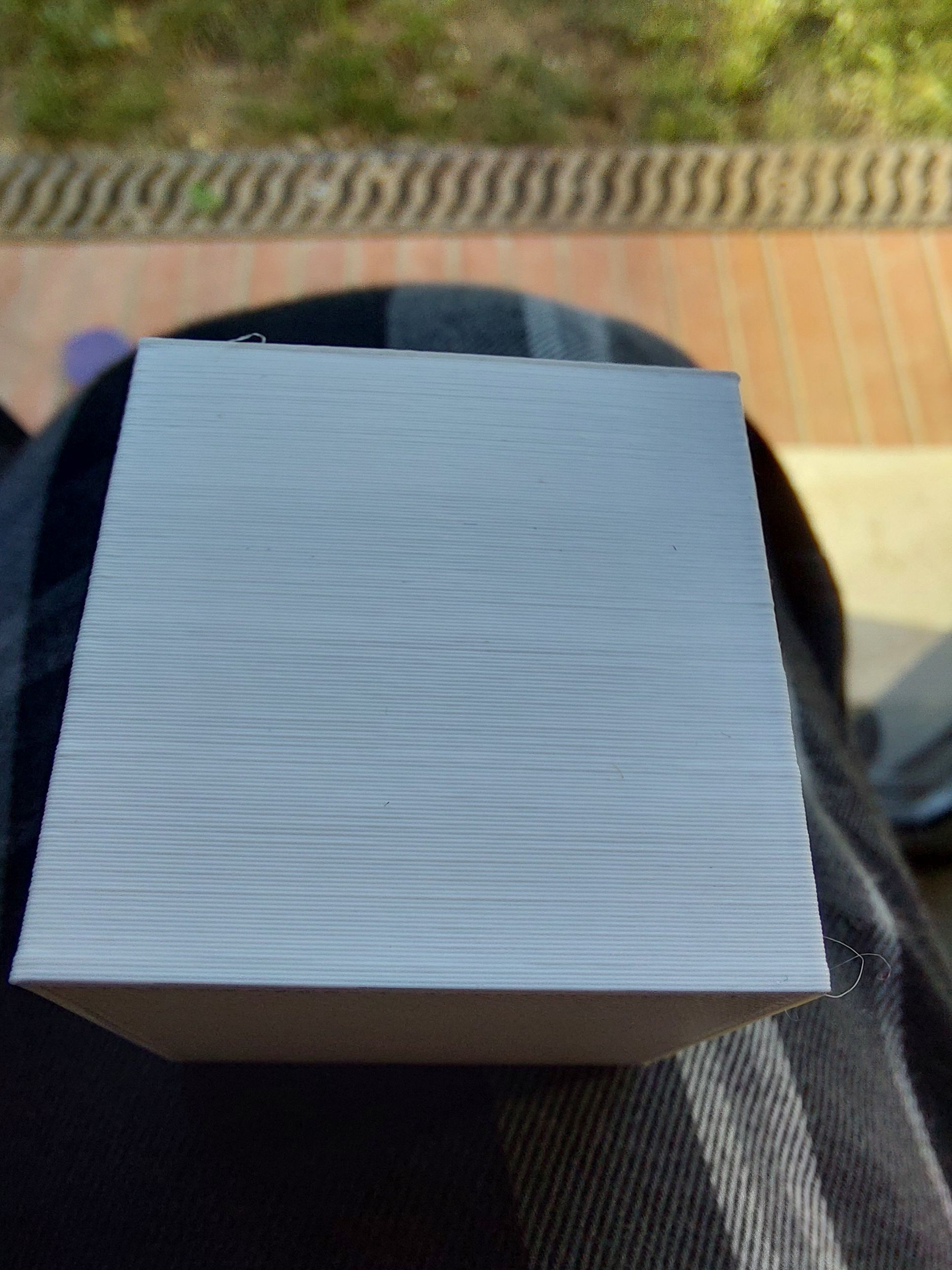

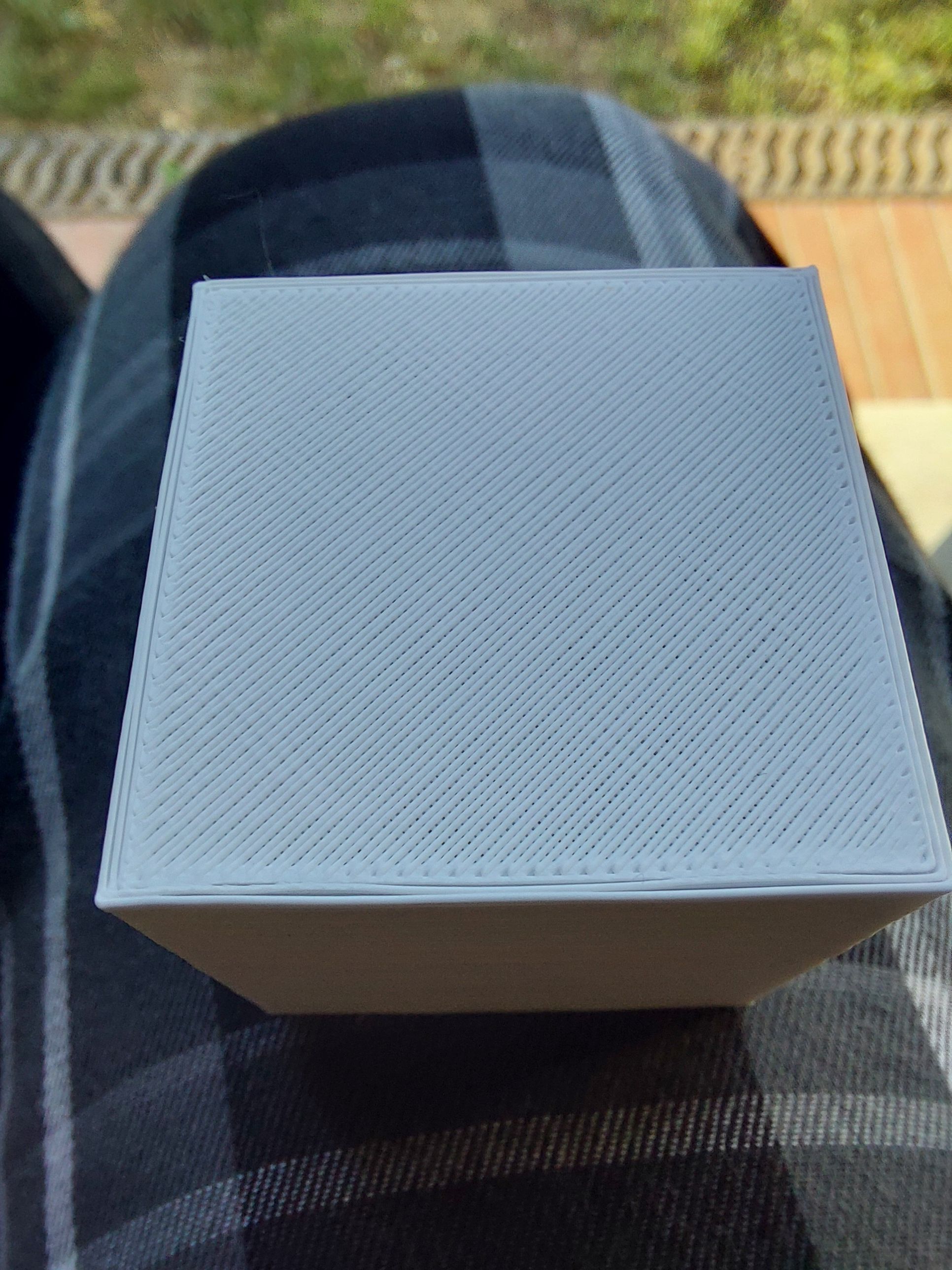

@claustro The top of the cube looks under-extruded. Notice the lines are in pairs with wider gaps between pairs than between the lines that make up the pairs. That indicates there is some backlash or other mechanical problem.

The side of the cube looks a little rough. That may be due to a dual drive extruder in which the drive gears don't mesh properly.

-

@mrehorstdmd Thank you very much for your suggestions.

Can you give me some hints on were to start to backtrace where the problem with under extrusion could be?

The extruder is a Titan extruder with a lot of print on the shoulder, maybe I could try to replace it but I don't know if replace it with another Titan or something else, I am tempted by BMG even If I have to design a new hot end carriage)Thank you

Andrea -

@claustro

Note the "wavy" inner wall. I think, this is the limit unless you make the system stiffer or the printhead lighter. -

@claustro I'd check the drive pulleys to make sure they're firmly screwed to the motor shafts and then grab the hot-end and try to wiggle it. I should be pretty solid- if it wiggles easily that may be the source of the line pairs. It could be the way the hot end is attached to the extruder or the way the extruder is mounted on the carriage, or the carriage bearings on the X axis guide rail.

Under extrusion can be just slicer settings, or it could be you're trying to print too fast for the hot-end to keep up. What's the hot-end heater power rating?

The wavy perimeter lines could be a symptom of the underextrusion problem or could indicate some mechanical issue.

-

@mrehorstdmd Thank you for your answer.

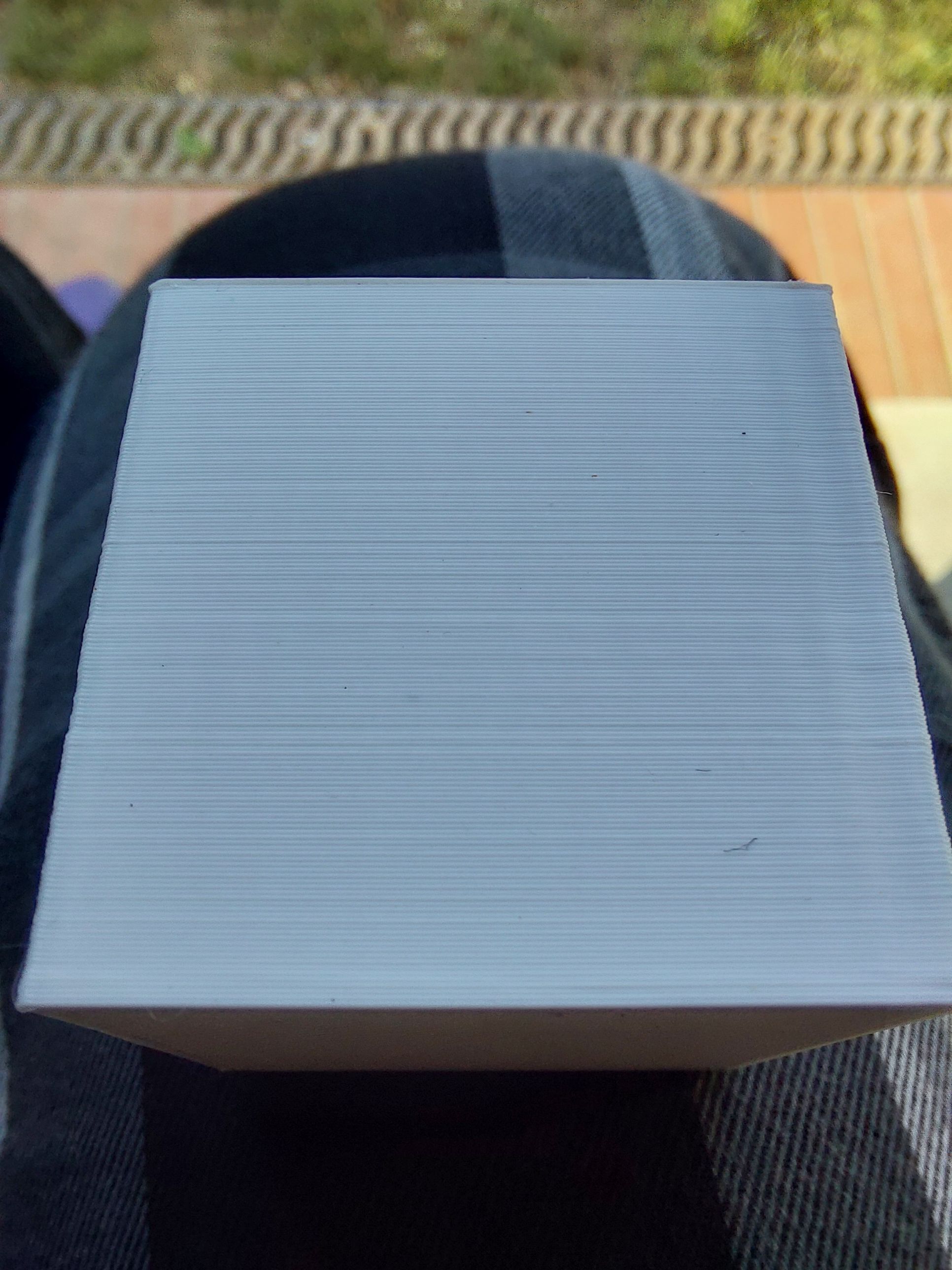

I made another test at the same speed with a triple-layer perimeter circular pattern.

My setup is a Revo Six hot end with a Titan extruder driven by a slightly underpowered Nema motor than the one suggested by E3D for Titan.The pulleys and belts are okay, and the hot end attachment seems rock solid. My concern lies with the mini V wheels or the wheel bearings, which could deteriorate over time. I am searching for a reliable European seller to buy good-quality V wheels.

This is the result of the print at 130 mm/s. During the print, I could hear a rhythmic noise pattern coming from the Y-axis. This is the reason I am considering a wheel problem.