I would like to say thank you to this forum and in particualr to @deckingman @mrehorstdmd @Phaedrux for the help in rebuilding my d-bot.

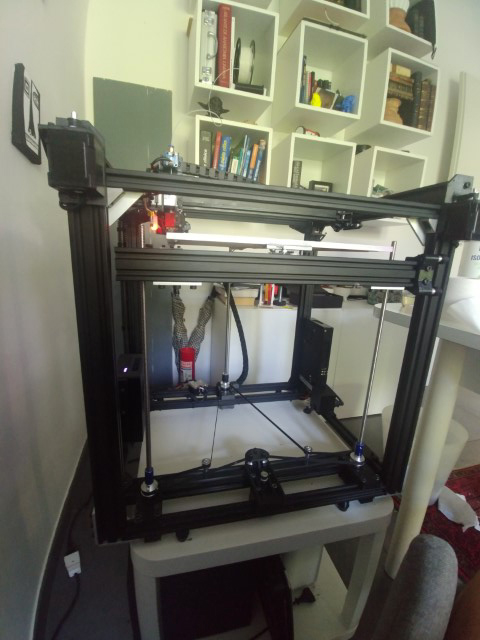

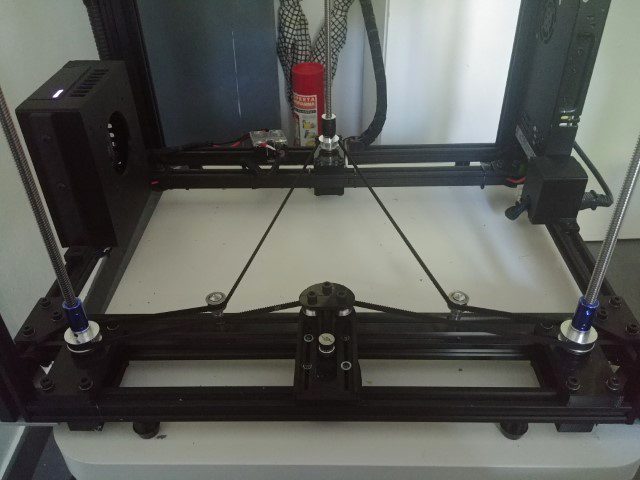

I switched to 3 lead screw using deckingam setup. The bed is guided by only two carts on opposite angles of the printer each cart is made of 3 wheels.

I choose to use a bed with 3 levelling screws ( in the future I would switch to levelling the bed by the lead screws) the levelling screws is mounted using mrehorstdmd setup .

The bed is a 330x340 die cast pei covered 8mm thick. I switched to a 220 volts heating element from Kenovo

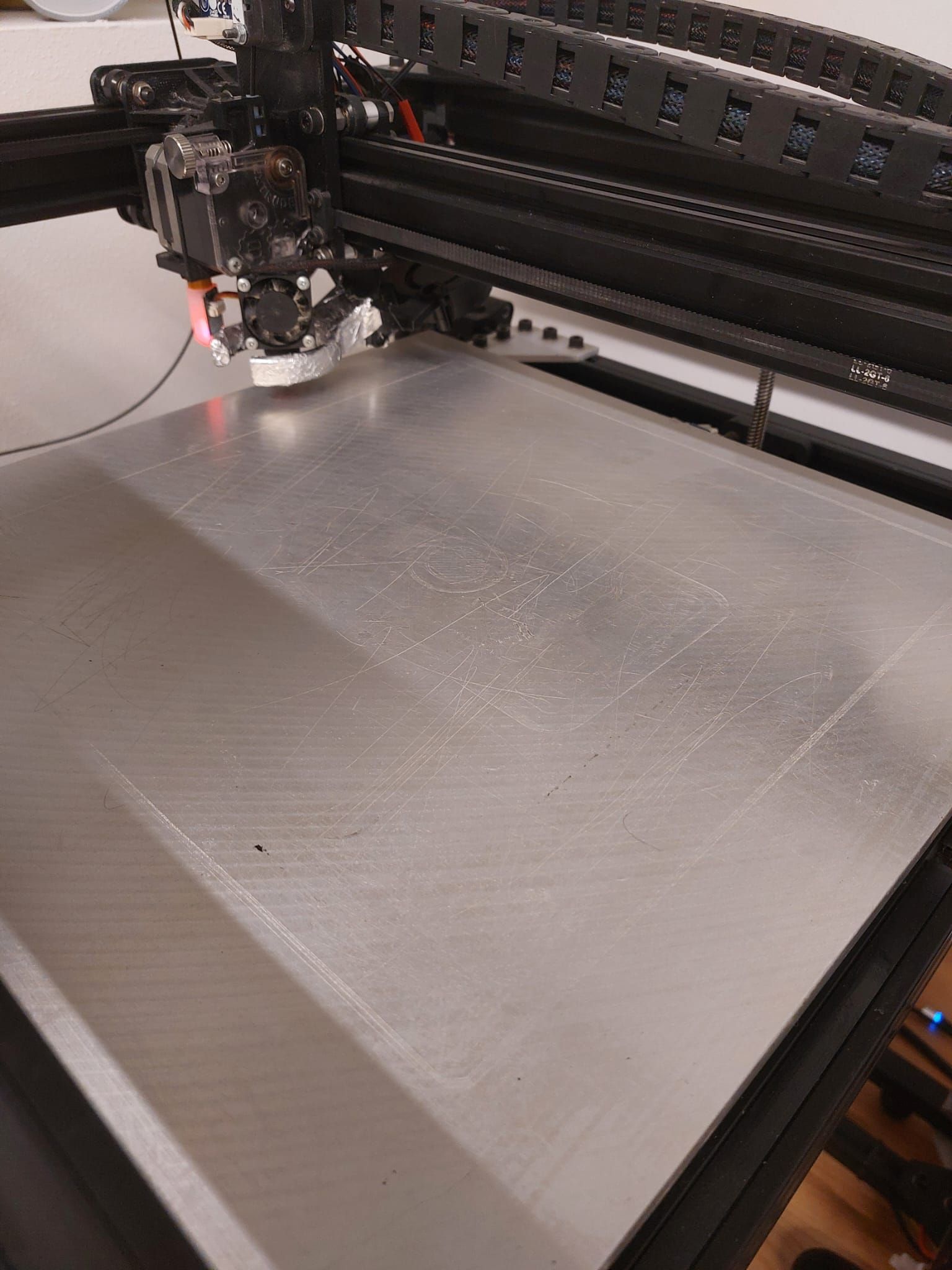

Now I cna print on 100% of the bed surface and I swithced off the

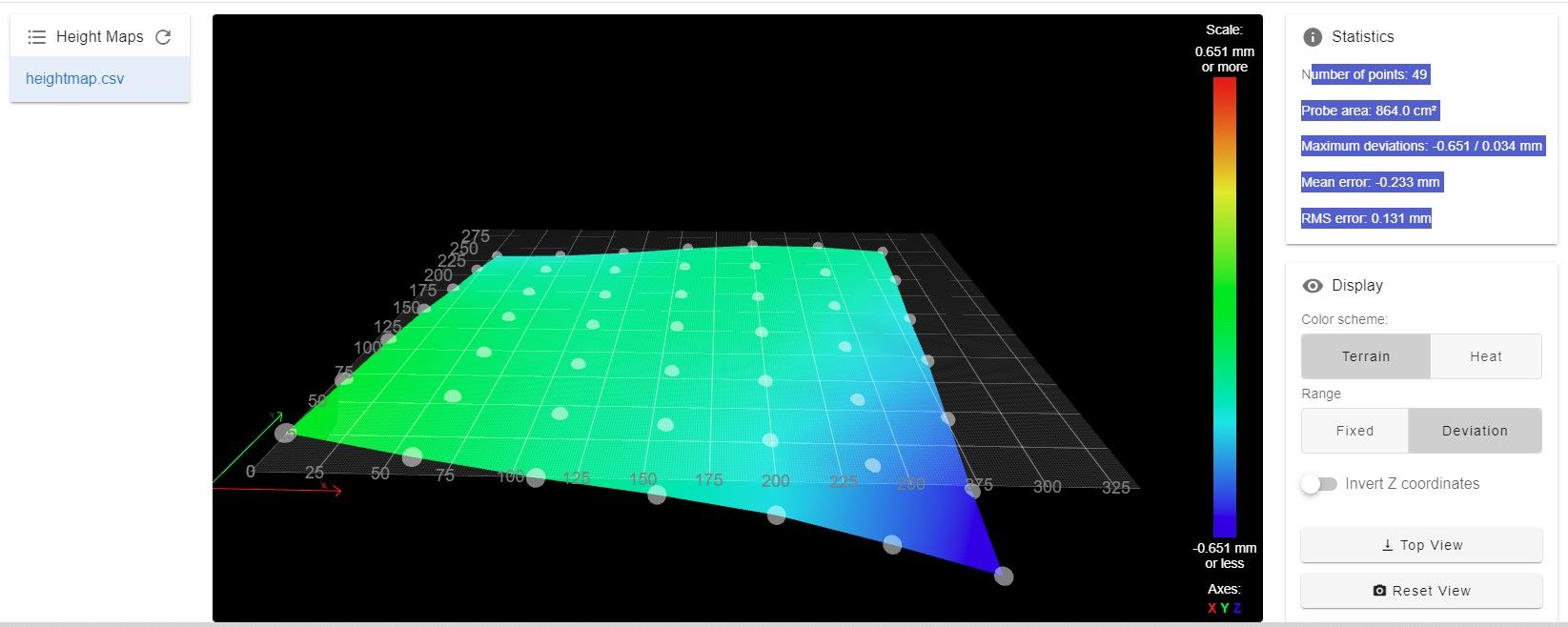

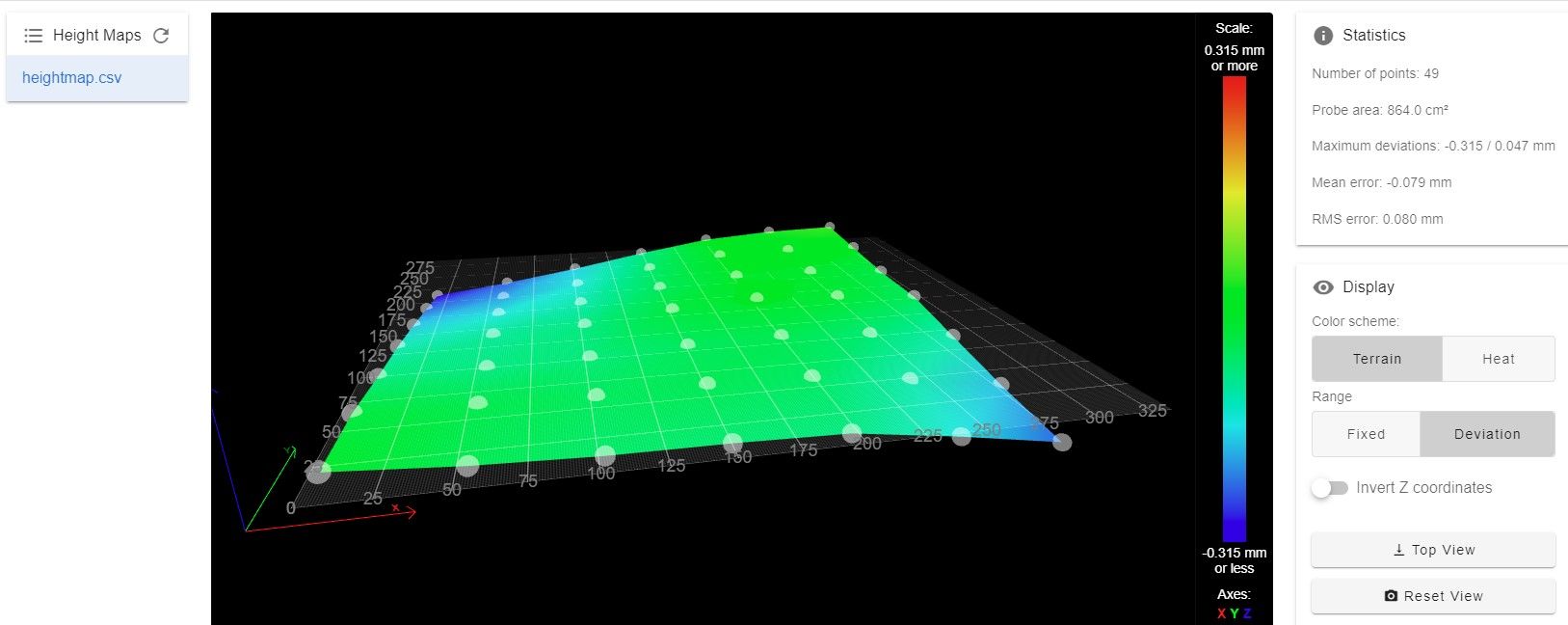

This is my first real print and I ma very happy with it I also disabled mesh grid compensation that for now seems useless

I still have to tweak a lot of stuff but the start seems promising!!