Extruder Concept . AM i mad

-

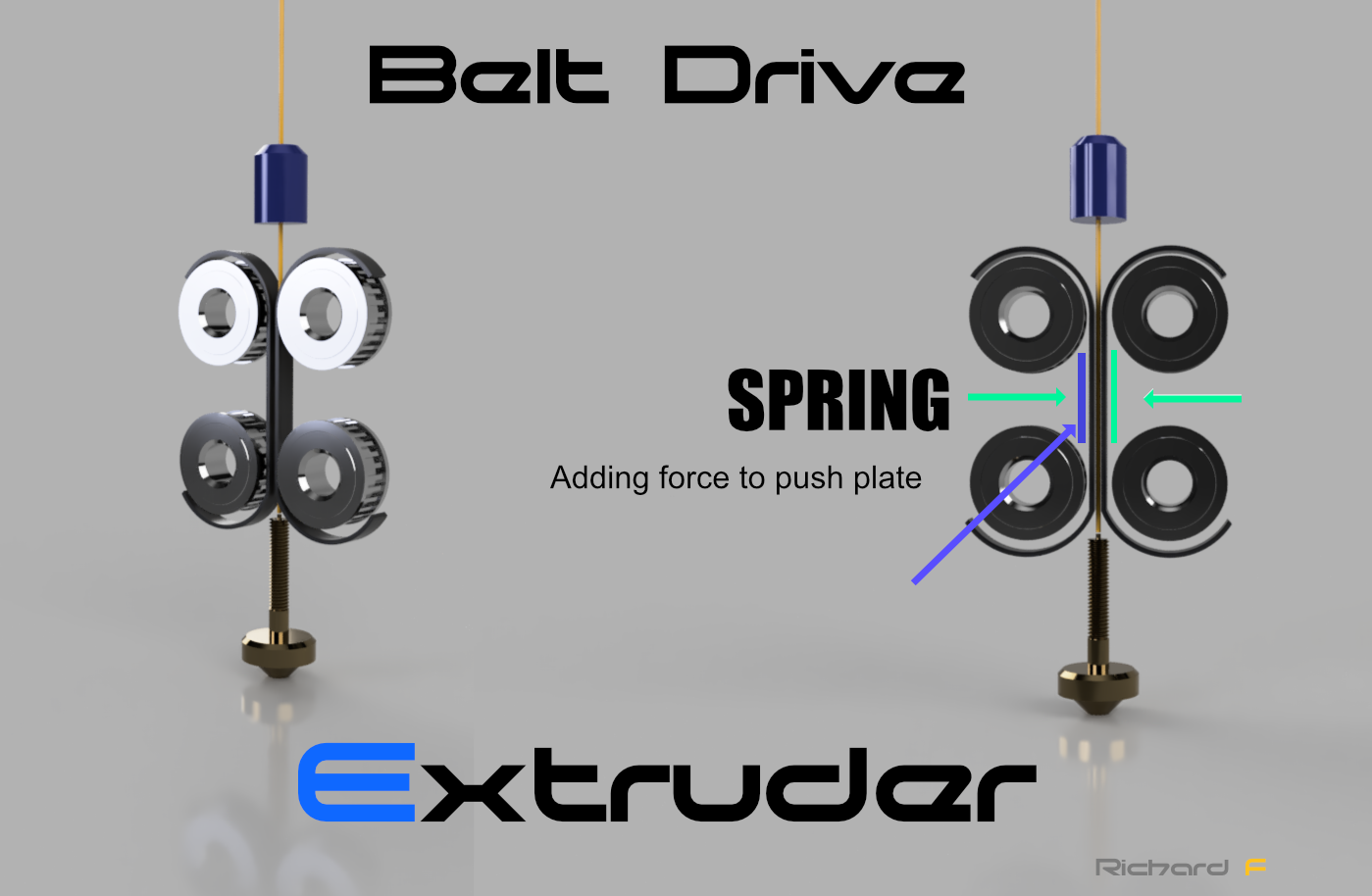

using gt2 belts to feed filament , like a tank track it has more traction , I'm not sure if someone has already tried this

just an idea -

@Richard-F Yes, that is an excellent idea. And it's one that has been had before. See the "Gunstruder" on thingiverse (https://www.thingiverse.com/thing:1247952) and a series of videos by "Proper Printing" ona different design (https://www.youtube.com/watch?v=-LdFmPYItb0)

-

@Richard-F I see two pinch-points where the belt has enough grip to feed. It's between the upper two pulleys and the lower two.

The area between the pulley pairs is more like a contact area. Not much grip to write home about...

Things can go wrong if the upper pair pushes on while for any reason the lower pair slips (say: temp rise from the hotend)

The filament would be pushed sideways out off the path.

Another possible failure is: the belts could deform at the pinch areas if the extruder is idle for too long. You'd have to release the pulley pressure between print jobs (say: over the weekend in a maker shop) -

@Richard-F have a look at the Papilio https://github.com/kevinakasam/Papilio-Belt-Extruder

-

I think belt-to-filament grip will be much less than toothed drive-to-filament, which positively cuts into the filament.

It's easy to demonstrate - if I take two bits of belt and pinch filament between them with my right hand, squeezing as hard as I can between finger and thumb of my right hand, I can pull the filament out with my left hand. If I do the same thing but use two toothed drives pinched on the filament my left hand doesn't stand a chance, even if I relax the grip with my right slightly.

-

Latest actual working version is the Papillon / Papilio Lite (I was a beta tester):

https://kevinakasam.com/papilio/

I previously ran the palatis fricex but that's too big to run as direct mounted option. Papilio is about the size of the Bondtech LGX Lite.

-

@o_lampe the filament is dragged along by friction between belts and filament. The pinch point issue isn't, and deformation of the belt during longer pauses isn't either (I am talking about weeks of idle).

-

@oliof said in Extruder Concept . AM i mad:

Latest actual working version is the Papillon / Papilio Lite (I was a beta tester):

https://kevinakasam.com/papilio/What is the intended advantage? The website says "With the belts there are no metal teeth damaging the filament, but soft rubber belts pressing against the filament guiding it all the way" but I don't understand what the perceived problem is with "the small bites on the filament when the metal gears grab the filament" - they get eliminated in the meltzone.

-

@achrn A number of issues with teeth:

a) they elongate the material so extrusion is somewhat uneven. With too much tension on an idler this can lead to visible defects.

b) the typical dual gear extruders suffer from gear meshing issues which lead to "wood grain texture" since the gear meshing translates directly to slight deviations in the extrusion.

Back when I tested the Palatis FricEx I was able to see the difference in surface quality between a genuine Bondtech BMG and the Palatis FricEx on vase mode prints (using the identical printer with identical filament and identical gcode), and it translated well to the Papilio Lite.

c) a number of dual gear extruders have further issues due to tolerances between gears, axles, and bearings which again translate directly into the depths of the bites which affect extrusion efficiency.

A friction drive does not suffer from these issues because the transmission is indirect rather than direct.

Further advantagea of the belt extruder are that it's easier to use for co-extrusion (which was Proper Printing's premier reason to develop a belt friction extruder) and that the abrasiveness of the filament itself does not affect the extruder since it only grabs it, but does not bite it.

There are some certain drawbacks as well: The four-gear arrangements puts a limit on how small you can make these extruders, you need to hit good tolerances to avoid belt rubbing and material deposition, and closed loop belts aren't that ubiquituous. Also, at least with the Papilio you cannot adjust tension or assumed diameter, so low quality filament with variable diameter or pultrusion filament which often ends up with a lower diameter may not work too well.

(and yes, the hollow shaft extruder we discussed a short while ago also suffers less from the things above due to the reduced amount of knife-edge-to-filament contact compared to a typical dual gear setup).

-

@o_lampe you could add a plate and spring to keep things even . i just didn't go mad with the design as i didn't know it had been tried before but a good obversion

-

@oliof just an idea

, ill have to watch those videos , i guess an idea is better than none

, ill have to watch those videos , i guess an idea is better than none -

@jay_s_uk

thanks

thanks -

@Richard-F But i know what the 3d market needs is cheap affordable servo drives , i know there is "0-drive "

but an add-on for duet would sell like hot cakes -

@MJLew said in Extruder Concept . AM i mad:

"Proper Printing"

i just watched the vid , wow he put a lot of work into it , it was cool just seeing the proof of concept work , i guess I'm not mad lol . But it made my post useless now.

-

@Richard-F said in Extruder Concept . AM i mad:

@Richard-F But i know what the 3d market needs is cheap affordable servo drives , i know there is "0-drive "

but an add-on for duet would sell like hot cakesThere is also simpleFOC-mini, which is running a BLDC motor with step/dir interface by RRF in my DD extruder.

It uses a GM3506 gimbal motor and upped the available torque a lot.An older version of O-drive can also be used (IIRC V3.6, before they went closed source) but that's hacker-talk, no mainstream stuff.

-

@o_lampe thanks