wifi 2 Board skipping steps

-

Hi,

I've been asked by support to post here.

I have a duet wifi 2 board installed just a few months. It's on a large format printer but I confirmed with Duet sales/ support for suitability of the board before purchase. Purchased via E3D uk.

Setup was excellent via the Duet3D guidance. I am a 3D printing engineer and we fix printers as part our business so everything was straightforward.

Printer has worked excellently and as expected for a few months now with no issues other than the pathetic wifi onboard - connection is weak and unstable for loading up files despite a pro access point only a couple of metres from the machine in our workshop.

However just the past couple of weeks have suddenly had skipping steps issues mainly on the one Y axis. It was a repeated file gcode had been printing fine and then suddenly wouldn't print without skips in the layers.

It's actually configured 2 stepper motors on the Y axis and each with a separate stepper driver channel. All worked perfectly up until last week.

Initial thought was possible stepper motor issue so swapped out the steppers with 2 x brand new e3d high torque motors. Movement is fine with the new motors but the random skipping steps has continued.

Since then tried reducing motor current - 85% of rated value as suggested so currently 1.4A per channel on this axis, similar or lower on the other channels.

Also tried slowing the print speeds and reducing jerk. We are talking 60mm/s or slower and jerk 13 print / 18 travel.

However the printer continues to skip steps.

Checked the Y axis belt tension and movement, all is as should be.

16x microstepping and around 120 steps per mm on the Y axis so nothing excessive there. The new motors are not getting especially warm around 45 degrees C tops during a print.

Seems to me that there's a weakness occurred somehow on the duet board and that's causing the skipping steps. I'd like to try a replacement board but preferably upgrade either to the board with the wifi antenna to strengthen the signal or trying a larger board if the experts recommend. However the current number of channels are perfectly adequate and everything seems well within capacity of the current board.

Appreciate your response and assistance as this is a business machine and would like to get the issue resolved as soon as possible.

kind regards,

Julian

-

@juls can you post your config and firmware version?

-

Hi yes RepRapFirmware for Duet Wifi/Ethernet version 3.4.6 running on Duet WiFi 1.02 or later

config.g

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.4.1 on Tue Mar 12 2024 18:27:32 GMT+0000 (Greenwich Mean Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"*****" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P3 S0 ; physical drive 3 goes backwards (y axis)

M569 P0 S0 ; physical drive 0 goes backwards (extruder)

M569 P2 S1 ; physical drive 2 goes forwards (z axis)

M569 P4 S1 ; physical drive 4 goes forwards (y axis)

M569 P1 S0 ; physical drive 1 goes backwards (x axis)M584 X1 Y3:4 Z2 E0 ; set drive mapping

M350 X16 Y16:16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X59.26 Y118.52:118.52 Z2015.75 E820.5 ; set steps per mm

M566 X600.00 Y600.00:600.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X7200.00 Y7200.00:7200.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X5000.00 Y5000.00:5000.00 Z100.00 E250.00 ; set accelerations (mm/s^2)

M906 X1400 Y1400:1400 Z1400 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeoutM591 D0 L26 P3 C"e1_stop" S1 ; filament monitor connected to E1_stop

M591 D0 ; display filament sensor parameters for extruder drive 0

; Axis Limits

M208 X-5 Y-15 Z0 S1 ; set axis minima

M208 X601 Y601 Z602 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X0 Y0 Z2.4 ; set Z probe trigger value, offset and trigger height

M557 X15:565 Y15:565 S68.75 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R0.099 K0.262:0.000 D11.40 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.506 K0.331:0.000 D5.33 E1.35 S1.00 B0 V24.1; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M570 H0 P60 T15; Fans

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S0 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

M563 P0 S"Extruder" D0 F0 H1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R100 S190 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M501 -

@juls said in wifi 2 Board skipping steps:

For all of these lines in your config.g, remove the second Y value:

M350 X16 Y16:16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X59.26 Y118.52:118.52 Z2015.75 E820.5 ; set steps per mm

M566 X600.00 Y600.00:600.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X7200.00 Y7200.00:7200.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X5000.00 Y5000.00:5000.00 Z100.00 E250.00 ; set accelerations (mm/s^2)

M906 X1400 Y1400:1400 Z1400 E1000 I30 ; set motor currents (mA) and motor idle factor in per centie should look like this:

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X59.26 Y118.52 Z2015.75 E820.5 ; set steps per mm M566 X600.00 Y600.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X7200.00 Y7200.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z100.00 E250.00 ; set accelerations (mm/s^2) M906 X1400 Y1400 Z1400 E1000 I30 ; set motor currents (mA) and motor idle factor in per centI'd say the jerk setting (M566) is fine, but your maximum speed (M203) and acceleration (M201) are quite high, particularly if the hot end/extruder are heavy. That may lead to skipping, particularly if there is a bit more resistance to movement on the axes than there was initially (worn linear bearings, dirty rails, grease solidifying in bearings over time etc.)

I think it very unlikely that "a weakness occurred" with the stepper drivers unless you've replaced the power supply for a lower voltage one. It's possible they have been overheating in the past, but the drivers will cut out before damage is done. Running at 1.4A, cooling shouldn't really be necessary unless the board is in a particularly confined space. Sending M122 while printing will show the board temperature.

Note that slicers have a bad habit of overriding configuration settings. Check that the Gcode files you are uploading are not trying to go even faster than the configuration limits in config.g. If you upload, or post the first couple of hundred lines of, a Gcode file that exhibits the problem, we can check if that's causing the issue.

For the WiFi issue, yes, the internal WiFi aerial isn't great if you put it in a metal box! We have boards that have external aerials, and generally connectivity is more robust with them.

Ian

-

Hi Ian,

the 2nd Y value is inserted because there are 2 steppers on the Y axis controlled by 2 separate stepper drivers as previously explained. Unless you are telling me that it's only necessary to specify the one setting as it will be automatically applied across both channels? Any way the current config g has not caused any issues and everything has worked as expected.

For your information I have already changed every single bearing in the Y axis arrangement and checked every moving part of it - it is smooth as silk and 100% clean there are no 'dirty rails, worn bearings, grease solidifying'.

The board is not in a confined space, it's in a very large metal box but with the door open and external fans circulating air across it. There is no obvious sign of overheating.

We have not replaced the power supply.

I can reduce the maximum speed and acceleration but it was working perfectly up until a couple of weeks ago.

This is 1st 200 lines of most recent gcode file below, the file printed perfectly apart from one dramatic layer shift (around 0.5mm+) right in the middle of it half way up.

Speed settings were in mm/s:

Infill 50

outer wall 45

inner wall 5

Top/bottom speed 45

Initial layer 35

print jerk 15

travel jerk 20We have already reduced those speeds down from the files that were faster but working 100% with no issues and despite this we are still getting issues that are ruining our prints.

We are at a loss what to do here - the only remaining option is a new board. We are happy to return you the board and you can test it as you wish - we are happy to pay the difference to get the version with the antenna but we need to do something as this is commercial machine. Ok I might expect this to happen on some random board I get from the net but I thought that purchasing a relatively more expensive Duet3D option would at least give us more than a few months of use.

Basically the support verdict is you 'think it's very unlikely' that your board has failed.. but in the absence of any other options we are going to have to purchase another board at our own cost?

;FLAVOR:RepRap ;TIME:17006 ;Filament used: 60.5575m ;Layer height: 0.3 ;MINX:192.102 ;MINY:240.102 ;MINZ:0.35 ;MAXX:397.898 ;MAXY:344.898 ;MAXZ:59.15 ;Generated with Cura_SteamEngine 4.13.2 T0 M190 S60 M104 S200 M109 S200 M82 ;absolute extrusion mode G28 ;Home G29 S1; G1 Z15.0 F6000 ;Move the platform down 15mm ;Prime the extruder G29 S1 ;load bed compensation mesh G92 E0 G1 E75 F200 G92 E0 M83 ;relative extrusion mode G1 F2400 E-2.5 ;LAYER_COUNT:197 ;LAYER:0 M107 M566 X1200 Y1200 G0 F2800 X193.51 Y240.788 Z0.35 M566 X900 Y900 ;TYPE:SKIRT G1 F2400 E2.5 G1 F2100 X193.952 Y240.513 E0.0606 G1 X194.432 Y240.309 E0.06071 G1 X194.937 Y240.18 E0.06067 G1 X195.449 Y240.13 E0.05989 G1 X196.444 Y240.109 E0.11585 G1 X198.693 Y240.103 E0.26181 G1 X205.669 Y240.106 E0.81208 G1 X389.908 Y240.106 E21.44735 G1 X391.319 Y240.102 E0.16426 G1 X393.87 Y240.11 E0.29696 G1 X394.528 Y240.121 E0.07661 G1 X395.047 Y240.17 E0.06069 G1 X395.552 Y240.297 E0.06062 G1 X396.032 Y240.501 E0.06071 G1 X396.475 Y240.775 E0.06064 G1 X396.871 Y241.113 E0.06061 G1 X397.211 Y241.508 E0.06067 G1 X397.487 Y241.951 E0.06076 G1 X397.691 Y242.43 E0.06061 G1 X397.82 Y242.935 E0.06067 G1 X397.87 Y243.447 E0.05989 G1 X397.891 Y244.435 E0.11504 G1 X397.897 Y246.674 E0.26064 G1 X397.894 Y253.613 E0.80777 G1 X397.894 Y336.945 E9.70072 G1 X397.898 Y338.172 E0.14284 G1 X397.89 Y340.781 E0.30372 G1 X397.878 Y341.526 E0.08674 G1 X397.829 Y342.045 E0.06069 G1 X397.702 Y342.55 E0.06062 G1 X397.499 Y343.03 E0.06067 G1 X397.226 Y343.474 E0.06067 G1 X396.887 Y343.87 E0.06068 G1 X396.492 Y344.21 E0.06067 G1 X396.05 Y344.486 E0.06066 G1 X395.571 Y344.691 E0.06065 G1 X395.066 Y344.82 E0.06067 G1 X394.551 Y344.87 E0.06023 G1 X393.557 Y344.891 E0.11574 G1 X391.278 Y344.897 E0.2653 G1 X384.248 Y344.894 E0.81837 G1 X373.859 Y344.894 E1.20939 G1 X372.18 Y344.87 E0.19547 G1 X371.385 Y344.847 E0.09259 G1 X368.646 Y344.844 E0.31885 G1 X367.074 Y344.878 E0.18304 G1 X366.568 Y344.893 E0.05893 G1 X200.075 Y344.894 E19.38153 G1 X198.668 Y344.898 E0.16379 G1 X196.128 Y344.89 E0.29568 G1 X195.473 Y344.879 E0.07626 G1 X194.954 Y344.83 E0.06069 G1 X194.449 Y344.702 E0.06065 G1 X193.969 Y344.499 E0.06067 G1 X193.525 Y344.225 E0.06074 G1 X193.129 Y343.887 E0.06061 G1 X192.79 Y343.491 E0.06068 G1 X192.514 Y343.049 E0.06066 G1 X192.31 Y342.57 E0.06061 G1 X192.181 Y342.065 E0.06067 G1 X192.131 Y341.553 E0.05989 G1 X192.109 Y340.519 E0.1204 G1 X192.103 Y338.326 E0.25529 G1 X192.106 Y331.387 E0.80777 G1 X192.106 Y248.055 E9.70072 G1 X192.102 Y246.829 E0.14272 G1 X192.11 Y244.179 E0.30849 G1 X192.122 Y243.471 E0.08243 G1 X192.171 Y242.953 E0.06057 G1 X192.299 Y242.447 E0.06076 G1 X192.502 Y241.967 E0.06067 G1 X192.776 Y241.524 E0.06064 G1 X193.115 Y241.128 E0.06068 G1 X193.51 Y240.788 E0.06067 M566 X1200 Y1200 G1 F2400 E-2.5 ;MESH:brick base_3_Carrick.stl G0 F2800 X193.509 Y240.478 G0 X219.828 Y275.328 G0 X215.769 Y271.05 G0 X216.411 Y272.162 G1 F2400 E2.5 G0 F2800 X216.499 Y272.208 M566 X900 Y900 ;TYPE:WALL-OUTER G1 F2400 X216.607 Y272.503 E0.03657 G1 X216.566 Y273.358 E0.09965 G1 X216.244 Y274.319 E0.11798 G1 X216.316 Y274.925 E0.07104 G1 X216.518 Y275.8 E0.10454 G1 X216.559 Y276.519 E0.08384 G1 X216.616 Y277.151 E0.07387 G1 X216.421 Y278.13 E0.1162 G1 X216.433 Y279.013 E0.1028 G1 X216.575 Y279.649 E0.07586 G1 X216.563 Y280.367 E0.08359 G1 X216.381 Y280.995 E0.07611 G1 X216.163 Y281.772 E0.09394 G1 X216.544 Y282.463 E0.09186 G1 X216.24 Y283.458 E0.12111 G1 X216.307 Y284.359 E0.10518 G1 X216.364 Y285.191 E0.09708 G1 X216.225 Y285.971 E0.09223 G1 X216.516 Y286.878 E0.11089 G1 X216.381 Y287.552 E0.08002 G1 X216.624 Y288.542 E0.11867 G1 X216.349 Y289.183 E0.0812 G1 X216.61 Y290.112 E0.11233 G1 X216.428 Y290.886 E0.09256 G1 X216.511 Y291.877 E0.11577 G1 X216.41 Y292.664 E0.09237 G1 X216.207 Y293.303 E0.07805 G1 X216.437 Y294.156 E0.10284 G1 X216.597 Y295.037 E0.10424 G1 X216.524 Y295.842 E0.09409 G1 X216.205 Y296.521 E0.08733 G1 X216.632 Y297.26 E0.09936 G1 X216.617 Y298.258 E0.11619 G1 X216.585 Y298.897 E0.07448 G1 X216.107 Y299.518 E0.09123 G1 X216.578 Y300.344 E0.11069 G1 X216.472 Y301.182 E0.09833 G1 X216.301 Y301.963 E0.09307 G1 X216.209 Y302.741 E0.0912 G1 X216.157 Y303.564 E0.096 G1 X216.257 Y304.198 E0.07472 G1 X216.398 Y304.947 E0.08872 G1 X216.598 Y305.854 E0.10812 G1 X216.213 Y306.795 E0.11836 G1 X216.409 Y307.741 E0.11246 G1 X216.287 Y308.578 E0.09847 G1 X216.684 Y309.378 E0.10396 G1 X216.138 Y310.068 E0.10243 G1 X216.374 Y310.803 E0.08986 G1 X216.623 Y311.613 E0.09865 G1 X216.24 Y312.395 E0.10136 G1 X216.456 Y312.733 E0.04669 G1 X216.708 Y313.001 E0.04282 G1 X216.93 Y313.105 E0.02854 G1 X217.804 Y313.063 E0.10186 G1 X218.726 Y313.195 E0.10842 G1 X219.492 Y312.96 E0.09327 G1 X220.13 Y313.388 E0.08943 G1 X220.941 Y312.845 E0.11362 G1 X221.808 Y312.825 E0.10095 G1 X222.475 Y313.389 E0.10168 G1 X223.217 Y313.263 E0.08761 G1 X224.164 Y313.302 E0.11033 G1 X224.781 Y312.899 E0.08579 G1 X225.604 Y313.226 E0.10309 G1 X226.207 Y312.848 E0.08285 G1 X227.058 Y313.17 E0.10592 G1 X227.894 Y313.258 E0.09786 G1 X228.861 Y312.856 E0.12191 G1 X229.666 Y312.931 E0.09412 G1 X230.628 Y313.219 E0.1169 G1 X231.603 Y313.156 E0.11374 G1 X232.534 Y313.095 E0.10861 G1 X233.178 Y313.391 E0.08251 G1 X233.781 Y313.188 E0.07407 G1 X234.496 Y313.05 E0.08477 G1 X235.415 Y313.072 E0.10701 G1 X236.206 Y313.383 E0.09894 G1 X236.939 Y313.375 E0.08533 -

@juls I am coming to this a bit late but have you tried swapping the Y axis drivers for X and Z , that should help determine if its a stepper driver issue.

To do that swap the connectors from Y1 to Z and Y2 to X, then update the configuration (M584 command and M569 commands to match).

The reason we find it unlikely to be the stepper drivers failing is the way that they typically fail is not with a "reduced power" mode but more definitively (i.e. they wont work at all). Skipping steps could also be driver thermal shutdown, so there could be some other issue or change in your electronics enclosure that is making the board a lot hotter than it was before, leading to thermal shutdown.

-

@juls said in wifi 2 Board skipping steps:

Your gcode is changing the M566 setting, which is 'jerk' or 'maximum instantaneous speed changes'. This is how fast it will change between one speed and another instantaneously. eg:

;LAYER_COUNT:197 ;LAYER:0 M107 M566 X1200 Y1200 G0 F2800 X193.51 Y240.788 Z0.35 M566 X900 Y900 ;TYPE:SKIRTM566 X1200 Y1200 is double the jerk setting in config.g of M566 X600 Y600. Your motors may not have enough torque to do this move in certain situation, eg a change of direction.

Some slicers use 'adaptive jerk', and change M566 during the print. What slicer are you using? Possibly Orcaslicer? If you updated the slicer in the last couple of weeks, this may have been turned on. Is the gcode you posted newly created, or did this exact code print correctly a couple of weeks ago?

@juls said in wifi 2 Board skipping steps:

the 2nd Y value is inserted because there are 2 steppers on the Y axis controlled by 2 separate stepper drivers as previously explained. Unless you are telling me that it's only necessary to specify the one setting as it will be automatically applied across both channels?

Yes. In the past this has been known to cause issues. RepRapFirmware does not support individual motor settings where an axis has multiple motors connected to different stepper drivers. The first parameter specified will be used for all motors on the axis. You should use identical motors on any axis that has more than one motor to avoid unexpected behaviour. Each extruder axis is counted as a separate axis, so you only specify extra values if you have multiple extruders.

Ian

-

Hi Tony, appreciate your trying to help resolve

I have already tried swapping the axis drivers.. strangely the issue did not move but remained. That would of course make you think the axis is the issue but the axis and motors have been completely refurbed checked and all bearings and motors renewed. The layer shift is still occurring, it has reduced, mainly with slowing everything down but I'm still getting around 1-5 skips occurring per print. If there was any axis or motor issue (which I'm not convinced there was) then it's gone now anyway.

But none of this gets away from the fact the the identical prints were working perfectly with zero skips and much faster speeds and identical setup.. we are talking 20 or more of the same print, all completely successful! It just feels like the whole system has lost power somehow.

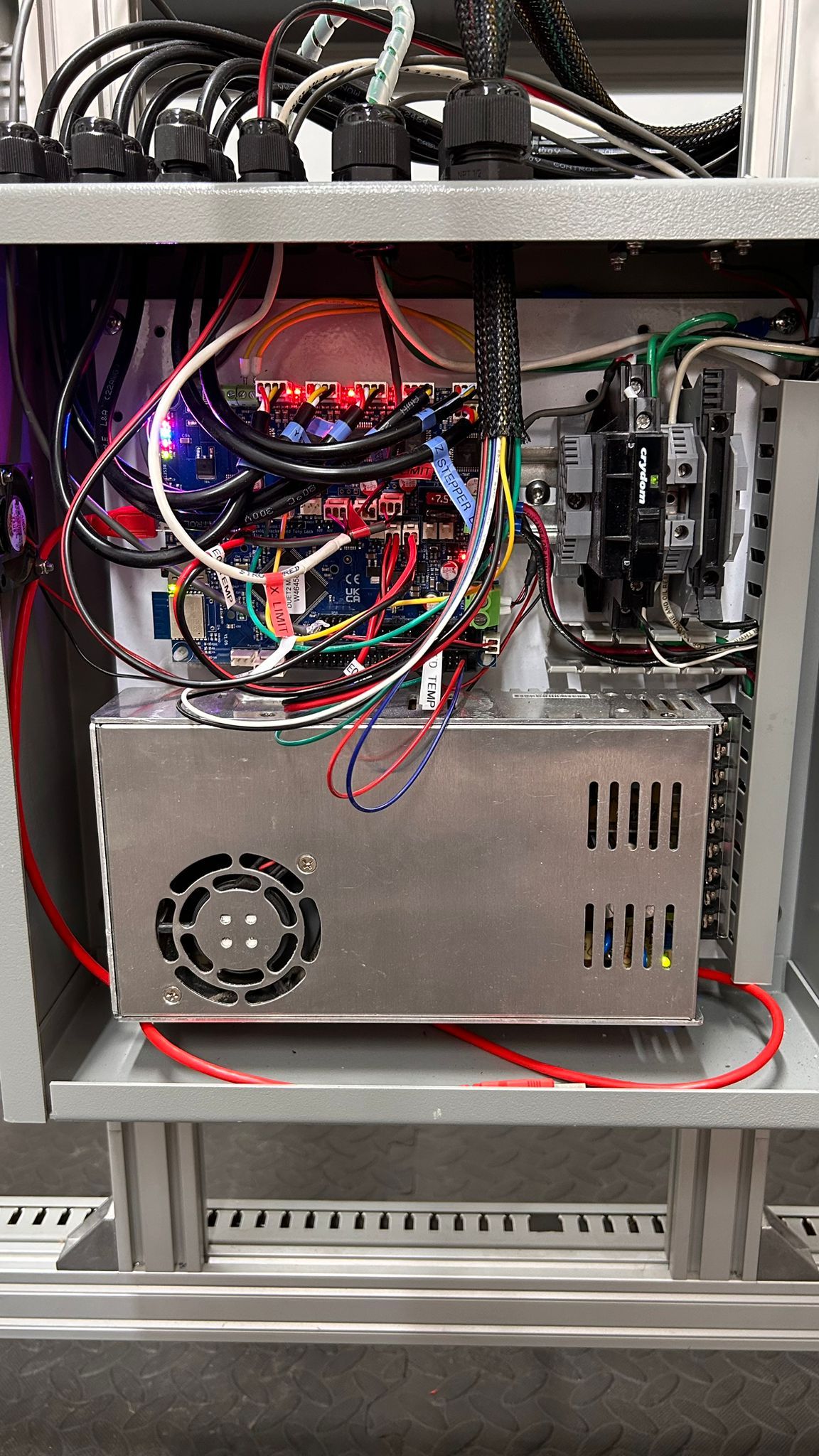

I've not made any change in the electronics enclosure but I have included a picture here so you can see it's not cramped in any way. I've already been running temp checks with an infra red thermometer and nothing on the board seems to be reading over 30 degrees which is consistent with M122 which is giving a max MCU temp of 27.8

The only other thing I can think of is that between the successful prints mentioned above and the current skipping steps scenario we completed a number of very large ABS prints, high temperatures, extruder 250 bed 80 across multiple days. The prints completed successfully, ie without any layer shifting issues however I'm wondering if the stress on the board has caused a power failure somewhere. It's odd that the problem has occurred since those prints.

-

Hi Ian,

so I've taken out the second parameter in config.g as suggested, thanks for explaining.

the slicer is CURA (which is actually written in the code)

the M566 changes you have noted are turned on/off via 'Jerk control'

However I've checked back through the gcodes and the layer skipping ones to start with all had jerk control turned off, ie no M566 changes in the gcode.

I've actually enabled that to try to cure the issue, it's certainly not made it worse, if anything it has improved it but we need prints without any layer skips at all obviously..

A recent gcode file that I ran I had the M566 turned down to X780 Y780 and it still had layer skips.

I'm currently running a file with the config change and M203 set at 5000, M201 set at 3000

However none of this still gets away from the fact that all was working perfectly at the faster settings and config so I feel issue lies elsewhere.

-

@juls thanks for the update.

There is no reason the higher ABS temperatures would have stressed the control board significantly unless the electronics enclosure is heated by the bed in some way so the internal temperature of the enclosure was higher.

What does occur to me is its worth confirming the power supply is not the issue, depending on how your bed and extruder are powered (I assume bed is AC given the printer size, extruder is DC)

Is the powersupply still providing the correct voltage and do you see any drop in power supply voltage when heating the extruder from cold?

Another point you mentioned:

@juls said in wifi 2 Board skipping steps:

Since then tried reducing motor current - 85% of rated value as suggested so currently 1.4A per channel on this axis, similar or lower on the other channels.

Have you subsequently restored the motor current to what is was when it was working perfectly? If not please do that.

-

@juls Please can you send M122 in the DWC console, and post the response. There's some diagnostics that may help.

If you have moved the stepper motors to different drivers and experienced the same issue on the same axis, I'd have to say this is:

- either a settings issue (I'd revert to not using 'Jerk control' in Cura), ie trying to run the motors faster than they were previously when it was working fine,

- or a power issue, ie the motors are trying to pull more or the same voltage (stepper drivers always supply the same current, but voltage changes as required to move the motor) but are not getting the required voltage supply. That makes be think the PSU or power wiring may be an issue. Please check all wiring is firmly seated (ie the power screw terminals on the Duet), and the PSU is supplying the correct voltage under load. The M122 report may show such voltage drops.

Edit: sorry, I see @T3P3Tony has replied with much the same thing.

Ian

-

the electronics enclosure isn't heated by the bed in any way. The bed is above the enclosure so no risk of that.

I've not noticed any issue with power supply or heating from cold, as you can see the bed is indeed powered via a relay so not directly heated by the board supply. All of the stepping issues seem to appear later in the printing anyway not at the start.

M122 reads supply voltage min 23.8 current 24 max 24.5, under voltage events: 0, over voltage events: 0, power good: yes

Yes already thought of that with regards to the motor current. I've actually been increasing it gradually again as it does of course reduce issues to have more current available. Current on the Y axis is 1600 at the moment - but the motors are only sitting around 50 degrees C during printing so still very comfortable.

-

as requested - wiring all looks good and has been checked, it was all replaced and rebuilt only a few months ago. I've just checked the voltage manually during the print and its reading just over 24v

Only slightly interesting thing is that 1 stepper motor on the Y axis is consistently reading about 2 degrees hotter than the other which is a bit odd since they are identical brand new motors and both sides of the axis are loaded identically. Either way max temp of the stepper is still only around 49.5 degrees.

m122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.6 (2023-07-21 14:08:28) running on Duet WiFi 1.02 or later

Board ID: 0JD0M-9P6B2-NJ4S4-6JKF2-3SD6P-KU1QL

Used output buffers: 1 of 26 (25 max)

=== RTOS ===

Static ram: 23896

Dynamic ram: 75612 of which 12 recycled

Never used RAM 9272, free system stack 104 words

Tasks: NETWORK(ready,14.4%,229) HEAT(notifyWait,0.0%,308) Move(notifyWait,2.5%,300) MAIN(running,83.0%,456) IDLE(ready,0.0%,30), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 02:07:08 ago, cause: software

Last software reset time unknown, reason: User, GCodes spinning, available RAM 9128, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 0

MCU temperature: min 27.2, current 27.7, max 28.7

Supply voltage: min 23.8, current 24.0, max 24.5, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/28/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: ok, SG min 0

Driver 1: stalled, SG min 0

Driver 2: ok, SG min 0

Driver 3: ok, SG min 0

Driver 4: ok, SG min 0

Driver 5:

Driver 6:

Driver 7:

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Date/time: 2024-06-28 12:02:12

Cache data hit count 4294967295

Slowest loop: 9.39ms; fastest: 0.19ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 9

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 1.3ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 18, maxWait 3211ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 99844, completed 99814, hiccups 0, stepErrors 0, LaErrors 2, Underruns [0, 0, 0], CDDA state 3

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.3

Heater 1 is on, I-accum = 0.8

=== GCodes ===

Segments left: 1

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is doing "G0 X351.317 Y341.779" in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Filament sensors ===

Extruder 0: pos 73.83, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

=== Network ===

Slowest loop: 100.48ms; fastest: 0.07ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

= WiFi =

Interface state: active

Module is connected to access point

Failed messages: pending 0, notready 0, noresp 4

WiFi firmware version 1.27

WiFi MAC address a4:e5:7c:03:db:6c

WiFi Vcc 3.44, reset reason Power up

WiFi flash size 2097152, free heap 25840

WiFi IP address 192.168.0.21

WiFi signal strength -45dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0 -

@droftarts @T3P3Tony @jay_s_uk

So after following the previous advices given there were 2 successful prints, then the 3rd print and most recent print failed again - a big layer shift ruining the print about 3/4 the way up.

I've checked M122 following the print and there were no undervoltage issues reported and also no temperature issues.

-

@juls Was it the same Gcode file three times, or three different Gcodes files? Newly sliced or old files that have printed successfully or failed before? Can you post the Gcode file that failed?

Ian

-

So just to update you that all subsequent prints (about 3 since last report) have all continued to have stepping issues. All the prints have been a variation of the same file and sliced with the same settings, slowed down considerably from the original 20 or so prints that were all successful and with the tweaks that have been suggested above implemented. No jerk control, config corrected, overall speeds and acceleration reduced dramatically.

We can't post the full gcode for legal reasons but the lines as compared with the previous code show you that the M566 command has gone:

;FLAVOR:RepRap ;TIME:17378 ;Filament used: 61.718m ;Layer height: 0.3 ;MINX:192.102 ;MINY:237.71 ;MINZ:0.35 ;MAXX:397.898 ;MAXY:347.29 ;MAXZ:59.15 ;Generated with Cura_SteamEngine 4.13.2 T0 M190 S60 M104 S200 M109 S200 M82 ;absolute extrusion mode G28 ;Home G29 S1; G1 Z15.0 F6000 ;Move the platform down 15mm ;Prime the extruder G29 S1 ;load bed compensation mesh G92 E0 G1 E75 F200 G92 E0 M83 ;relative extrusion mode G1 F2400 E-2.5 ;LAYER_COUNT:197 ;LAYER:0 M107 G0 F2800 X193.512 Y239.036 Z0.35 ;TYPE:SKIRT G1 F2400 E2.5 G1 F2100 X193.955 Y238.762 E0.06064 G1 X194.435 Y238.558 E0.06071 G1 X194.94 Y238.429 E0.06067 G1 X195.445 Y238.38 E0.05906 G1 X196.398 Y238.359 E0.11097 G1 X198.693 Y238.353 E0.26716 G1 X205.669 Y238.356 E0.81208 G1 X389.908 Y238.356 E21.44735 G1 X391.319 Y238.352 E0.16426 G1 X393.87 Y238.36 E0.29696 G1 X394.528 Y238.371 E0.07661 G1 X395.047 Y238.42 E0.06069 G1 X395.552 Y238.547 E0.06062 G1 X396.032 Y238.751 E0.06071 G1 X396.475 Y239.025 E0.06064 G1 X396.871 Y239.363 E0.06061 G1 X397.211 Y239.758 E0.06067 G1 X397.487 Y240.201 E0.06076 G1 X397.691 Y240.68 E0.06061 G1 X397.82 Y241.185 E0.06067 G1 X397.87 Y241.698 E0.06 G1 X397.891 Y242.692 E0.11574 G1 X397.897 Y244.849 E0.2511 G1 X397.894 Y251.648 E0.79147 G1 X397.894 Y338.804 E10.14587 G1 X397.898 Y340.002 E0.13946 G1 X397.89 Y342.557 E0.29743 G1 X397.878 Y343.278 E0.08394 G1 X397.829 Y343.796 E0.06057 G1 X397.702 Y344.302 E0.06073 G1 X397.499 Y344.782 E0.06067 G1 X397.225 Y345.225 E0.06064 G1 X396.886 Y345.621 E0.06068 G1 X396.491 Y345.961 E0.06067 G1 X396.048 Y346.237 E0.06076 G1 X395.569 Y346.441 E0.06061 G1 X395.064 Y346.57 E0.06067 G1 X394.555 Y346.62 E0.05954 G1 X393.6 Y346.641 E0.1112 G1 X391.365 Y346.647 E0.26018 G1 X384.498 Y346.644 E0.79939 G1 X374.178 Y346.644 E1.20136 G1 X372.67 Y346.622 E0.17557 G1 X371.37 Y346.586 E0.15139 G1 X368.637 Y346.586 E0.31815 G1 X367.656 Y346.616 E0.11425 G1 X365.793 Y346.644 E0.2169 G1 X200.06 Y346.644 E19.29306 G1 X198.822 Y346.648 E0.14412 G1 X196.212 Y346.64 E0.30383 G1 X195.474 Y346.628 E0.08592 G1 X194.955 Y346.579 E0.06069 G1 X194.449 Y346.452 E0.06073 G1 X193.969 Y346.249 E0.06067 G1 X193.526 Y345.975 E0.06064 G1 X193.13 Y345.637 E0.06061 G1 X192.79 Y345.242 E0.06067 G1 X192.514 Y344.8 E0.06066 G1 X192.309 Y344.32 E0.06076 G1 X192.18 Y343.815 E0.06067 G1 X192.13 Y343.302 E0.06 G1 X192.109 Y342.315 E0.11492 G1 X192.103 Y340.151 E0.25191 G1 X192.106 Y333.352 E0.79147 G1 X192.106 Y246.196 E10.14587 G1 X192.102 Y244.998 E0.13946 G1 X192.111 Y242.391 E0.30348 G1 X192.123 Y241.718 E0.07836 G1 X192.172 Y241.2 E0.06057 G1 X192.3 Y240.694 E0.06076 G1 X192.503 Y240.215 E0.06056 G1 X192.778 Y239.772 E0.0607 G1 X193.117 Y239.376 E0.06068 G1 X193.512 Y239.036 E0.06067 G1 F2400 E-2.5The printer has not been turned off and I've been keeping an eye on diagnostics - this is the latest and as you can see still no particular issues reported in 72 hours

m122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.6 (2023-07-21 14:08:28) running on Duet WiFi 1.02 or later Board ID: 0JD0M-9P6B2-NJ4S4-6JKF2-3SD6P-KU1QL Used output buffers: 1 of 26 (25 max) === RTOS === Static ram: 23896 Dynamic ram: 75684 of which 12 recycled Never used RAM 9104, free system stack 92 words Tasks: NETWORK(notifyWait,23.4%,211) HEAT(notifyWait,0.5%,308) Move(notifyWait,15.2%,294) MAIN(running,60.8%,456) IDLE(ready,0.1%,30), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 71:35:32 ago, cause: software Last software reset time unknown, reason: User, GCodes spinning, available RAM 9128, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Step timer max interval 0 MCU temperature: min 24.4, current 24.9, max 29.1 Supply voltage: min 23.7, current 24.1, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/186/186, gc cycles 0 Events: 1 queued, 1 completed Driver 0: standstill, SG min 0 Driver 1: standstill, SG min 0 Driver 2: standstill, SG min 0 Driver 3: standstill, SG min 0 Driver 4: standstill, SG min 0 Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: Date/time: 2024-07-01 09:30:36 Cache data hit count 4294967295 Slowest loop: 118.65ms; fastest: 0.15ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 7.3ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 22, maxWait 25669423ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 353169, completed 353169, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.3 Heater 1 is on, I-accum = 0.7 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0: pos 331.17, errs: frame 7 parity 0 ovrun 0 pol 4 ovdue 0 === Network === Slowest loop: 109.93ms; fastest: 0.07ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Interface state: active Module is connected to access point Failed messages: pending 0, notready 0, noresp 18 WiFi firmware version 1.27 WiFi MAC address a4:e5:7c:03:db:6c WiFi Vcc 3.44, reset reason Power up WiFi flash size 2097152, free heap 25840 WiFi IP address 192.168.0.21 WiFi signal strength -48dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 -

@juls Thanks for the information. I can't see anything in the Gcode that would cause a skip, and the M122 report doesn't show any skips (assuming this M122 was from after a print that skipped - some data in M122 resets after each M122 command). There are some errors in the Filament sensors section that I'm just checking with @dc42.

I think this is a regular cartesian machine, rather than CoreXY? Is it always the Y axis that skips, any skips on X? When you replaced the motors, did you replace the wiring to the motors? Please check all wiring and crimps from board to motor. I still find it difficult to rationalise that there is a problem with the drivers on the board, as you say you swapped which driver controlled which axis.

Ian

-

Hi Ian, it's a regular cartesian machine not core XY. Generally yes the skips appear to have been only on the Y, however it's the only axis with independent channels for the 2 motors - possibly that's the aspect the board is struggling with for some reason. I have checked the wiring to the motors on the axis and yes in fact ALL the wiring in the entire printer was replaced as part of the refurbishment with brand new cables. But I have rechecked just recently the specific wiring on the Y, everything is perfect.

I would agree with what you are saying however I feel having ruled out every other possibility the only option left to try is replacing the board. If the issue goes away then we know that there was a problem somewhere on the board. If changing the board doesn't solve the issue I'm willing to return you the replacement board.

-

@juls said in wifi 2 Board skipping steps:

RepRapFirmware for Duet Wifi/Ethernet version 3.4.6

Have you tried updating firmware to 3.5.2 yet?

If the issues stays with the Y axis itself regardless of drivers than it makes me think it's a mechanical binding issue. How heavy is the Y axis?