Optimizing Multi-Extruder 3D Printing by Preheating

-

Hello everyone,

I’m currently working on a multi-extruder 3D print, and I’ve encountered an issue with managing the non-active tool’s standby temperature. While keeping the inactive extruder at a lower temperature helps prevent oozing, it significantly increases the overall printing time because the extruder needs to reheat before it can be used again.

I’m looking for a solution to optimize this process. Specifically, is there a method to scan the G-code buffer and initiate the heating process shortly before the tool change occurs? This way, the next extruder would reach the required temperature just in time for its use, minimizing delays.

Any insights or suggestions would be greatly appreciated.

Thank you!

-

If you use PrusaSlicer this might be an option for you.

https://github.com/mkudzia84/toolchanger-pspp

It’s an older project, and may not work out of the box, or at all, but could be worth a try.

Beyond that, I wonder if Prusa has already implemented something like this for the Prusa XL?

-

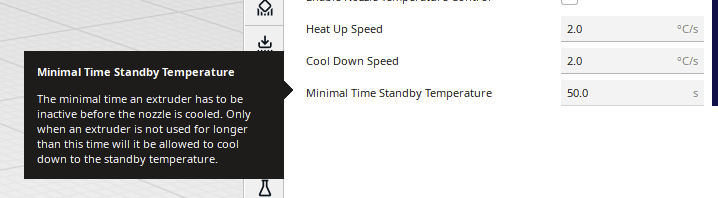

@SanderLPFRG Cura will inject temperature commands in such a way to ensure the next extruder is (nearly) at the printing temperature when called via the Tx command. This behavior can be further tuned via the 'Machine Settings' plugin, which allows you to specify the 'heat up' and 'cool down' rates of your tool. Also has a nice setting to configure the minimum stand by time (at print temperature).

-

@sebkritikel Yeahh that is exactly what I need, but then in Prusaslicer. I know the XL is doing it so I don't know why I cannot find the option in PS

-

@SanderLPFRG Hmm does require some programming but seems like it does the job

-

@SanderLPFRG what hot ends are you using? Modern hot ends such as Revo heat up much faster than older ones.