Duet 3 mini 5+/FYSETC Big Dipper on FFCP/Flashforge Creator Pro

-

I started the print, it looks promising, 25% done

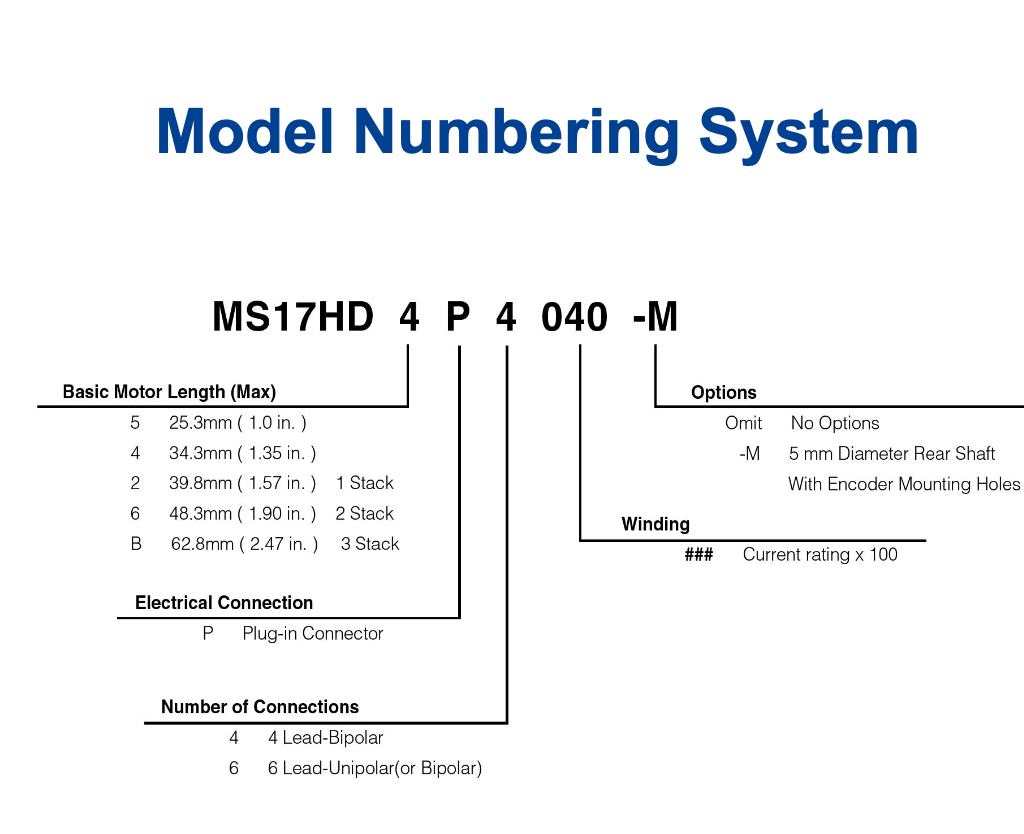

Now I googled the datasheet for moons stepper motors (17HD4063-06N) that are installed on my FFCP, and as far as I understand they have a rated current of 630 mA, so I should change my config.

063 / 100 = 0.63 A for the Y axis at least

and for the extruders my FFCP has two 0.8 A rated 42HB34F08AB-22

-

I am pretty sure that I connected the PSU cables the way they were before upgrade, because I have a photo.

Sorry, I haven’t. That’s why I asked for additional information:

"Is the power outlet you use protected by an earth leakage circuit breaker? Is there any one of these installed in your house? Which country are you located in?"My own decision was to connect a screw of the board to the PSU ground, that is where the black cable with blue ring connector is going

That’s fine.

I didn't intentionally connect GND and V-, although I saw some guys do that on the internet.

Thankfully, @droftarts stepped in to clarify this one and some related topics.

I forgot to mention, that the PSU keeps running always. It is the board that shuts down.

From your photo, I can’t figure out how the board is switched off. As a side note: When electricity in your part of the world is not particularly cheap, it might be a good idea to cut power on the AC side. Thinking of safety reasons, this idea even looks better

Ok I found an accidental connection between the right extruder pin and the ground

Glad you spotted this one. Keep reporting on how it works.

Also the resistance between the ground and PSU 24+ is about 1500 om

That value alone isn’t really telling. To check if some component inadvertently bridges to GND (instead of to V-), you’d have to disconnect any and all connections. Then, check the resistance, reconnect a single component, measure again. Repeat this procedure until all connections are back in place. Well, better try to avoid this tedious process - maybe the right extruder turns out to have been the real culprit.

Now I googled the datasheet for moons stepper motors (17HD4063-06N) that are installed on my FFCP, and as far as I understand they have a rated current of 630 mA, so I should change my config.

Don’t know how the steppers are currently configured. The section Stetting motor currents in the support document Configuring stepper motors provides detailed infos - I think even more than you ever wanted to know.

-

Ok, yesterday the printer was working for hour and a half until I turned it off. The motors were about 50 degrees celsius and I guess that's why the layers shifted. The current was set to 850 ma for xy and 400 for z, and 900 for extruders

Today I changed the config but the print failed with the HardFault

m122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.3 (2024-09-18 11:25:48) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: RHYS5-6J9MK-K65J0-40TK2-JRW2Z-ZLX8A Used output buffers: 3 of 40 (18 max) === RTOS === Static ram: 103368 Dynamic ram: 121908 of which 12 recycled Never used RAM 16460, free system stack 206 words Tasks: NETWORK(2,nWait 7,14.4%,217) HEAT(3,nWait 6,0.0%,325) Move(4,nWait 6,0.0%,355) CanReceiv(6,nWait 1,0.0%,939) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,334) TMC(4,nWait 6,1.4%,110) MAIN(1,running,83.4%,665) IDLE(0,ready,0.0%,29) AIN(4,delaying,0.8%,264), total 100.0% Owned mutexes: === Platform === Last reset 00:16:28 ago, cause: software Last software reset at 2024-10-12 09:04, reason: HardFault invState, Gcodes spinning, available RAM 13464, slot 0 Software reset code 0x4063 HFSR 0x40000000 CFSR 0x00020000 ICSR 0x00489803 BFAR 0xe000ed38 SP 0x20012008 Task NETW Freestk 482 ok Stack: 0000017d 00000002 200014e4 00000000 20032fe9 000a0f9f 00000000 600f0000 00000000 00000000 00000000 00000000 20031e34 00000800 2002c640 2002c640 00000001 2002c496 2001882c 2001ea80 00030523 00000000 00000000 00000000 200120b8 00000014 b5dd500a Error status: 0x00 MCU revision 3, ADC conversions started 741990, completed 741988, timed out 0, errs 0 MCU temperature: min 29.1, current 31.6, max 31.8 Supply voltage: min 24.0, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 38, read errors 0, write errors 1, ifcnt 36, reads 24344, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 6, read errors 0, write errors 1, ifcnt 36, reads 24343, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 1, ifcnt 35, reads 24343, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 32, reads 24343, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 32, reads 24344, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 5: standstill, SG min 0, read errors 0, write errors 1, ifcnt 33, reads 24343, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 1, ifcnt 32, reads 24343, writes 10, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2024-10-12 09:20:57 Cache data hit count 1872586024 Slowest loop: 7.85ms; fastest: 0.16ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 1.4ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 8900, received 0, lost 0, errs 4675536, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 26 (min 26), ts 4945/0/0 Tx timeouts 0,0,4944,0,0,3954 last cancelled message type 4514 dest 127 === Network === Slowest loop: 5.85ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.1.0 MAC address 08:3a:8d:eb:24:44 Module reset reason: Power up, Vcc 3.38, flash size 2097152, free heap 42932 WiFi IP address 192.168.1.69 Signal strength -48dBm, channel 7, mode 802.11n, reconnections 0 Clock register 00002001 Socket states: 0 0 0 0 0 0 0 0 m122p106 Platform 2001d138-2001e737 SbcInterface 2001e740-2001ea70 Network 2001ea80-2001eb67 GCodes 2001eb70-2001ff6f Move 20023ff8-20024d33 Heat 20025110-20025237 PrintMonitor 20025240-2002544f FansManager 20025458-200254d7 PortControl 200254e0-2002550f Display 20025518-20025533 ExpansionManager 20025540-200282f7 m122p1007 a{0x2001ea80+8} 2001ea88: 2002c420 m122p1007 a{0x2002c420+136} 2002c4a8: 20032e60 -

@Inlinebrother Hm… Looks like as soon as you happen to touch one problem, a bunch of others surface seemingly out of nowhere. You'd need an octopus to handle all of these at once - in other words: your way to approach the issues with your printer has, IMHO, some potential to be optimised. You see, from a distance, members on this forum have to rely on your reportings, we can only guess what could possibly be the root cause of a symptom you describe.

Following this long thread, I have difficulties to find a single issue being properly resolved - when I still try to wrap my head around some of your wiring issues, I’m left with open queries and … steppers. Well ok, why not steppers for lunch, today? I even figured out that eventually, these things from the moon are rated at 1.5 A, not at 630 mA. Quite a difference, but in the meantime, you have already changed the config (interestingly, none of us has any idea of what’s in there) and moved to the next problem, a hard fault. Sure, that’s a serious one and has to be dealt with, so please understand that I don’t intend to offend you.

Instead, I propose to concentrate on a single issue at a time. That’s easier said than done, but the newly reported layer shifts are a perfect candidate for a separate thread - after the PSU- and cabling issues have been resolved. I assure you that, in this forthcoming thread, the steppers as well as the config.g will be dealt with in detail. I think you perfectly understand what I mean: You already joined the appropriate thread to report your HardFault. Others may have a different view, in my eyes, thats the perfect place to go with that.

So sorry for this rant. It’s just that we are no octopussies (as a non-native speaker, I know there’s 'something' wrong with that expression, but I have no clue what exactly

). Regarding the power issues and related phenomenons, please keep us informed. As 3D printer enthusiasts, we are only satisfied at a point when your FFSC works as intended - we want to hear success stories.

). Regarding the power issues and related phenomenons, please keep us informed. As 3D printer enthusiasts, we are only satisfied at a point when your FFSC works as intended - we want to hear success stories. -

Is the power outlet you use protected by an earth leakage circuit breaker? Is there any one of these installed in your house?

I guess so

I can’t figure out how the board is switched off

It is the Flashforge Creator Pro and it has a button behind it to turn off the power that goes to the PSU

Glad you spotted this one. Keep reporting on how it works.

Now I finally can focus on configuring other params because it works fine. I had two hard faults though.

To check if some component inadvertently bridges to GND

Before I started printing I checked once again, and ground wasn't connected to other pins.

Don’t know how the steppers are currently configured. The section Stetting motor currents in the support document

Configuring stepper motors provides detailed infos - I think even more than you ever wanted to know.As fas as currents are concerned I think I'll monitor motors temperature, for now they are not even 50 degrees hot and they say that's fine

I found macros for tuning the speeds, jerk and acceleration here https://forum.duet3d.com/topic/6181/tuning-macros-menus-accel-jerk-retraction-pressure-advance

And that's what I am going to focus on now

Finishing the test print without defects

One of the main problems for me is the layer shifting for the y axis

-

Looks like as soon as you happen to touch one problem, a bunch of others surface seemingly out of nowhere

Yeah, sorry, it might look that way. But really the biggest concern was the restarts. And here is your portion of success story, after I removed the screw I am able to print.

Hard faults don't bother me too much.

Layer shifting does, so that's my next problem

I even figured out that eventually, these things from the moon are rated at 1.5 A

That's great. I wonder how you did that?

-

That's my config right now that produced the best results.

; Configuration file for RepRapFirmware on Duet 3 Mini 5+ WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.0 on Sun Jun 02 2024 14:45:59 GMT+0300 (Moscow Standard Time) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"Flashforge Creator Pro" ; set hostname M911 S19.8 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss M122 P500 S0 ;enabled debug ; Network M551 P"" ; set machine password M552 S1 ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; Smart Drivers M569 P0.0 S0 D3 ; driver 0.0 goes forwards (X axis) M569 P0.1 S0 D3; driver 0.1 goes forwards (Y axis) M569 P0.2 S1 D3 ; driver 0.2 goes forwards (Z axis) M569 P0.5 S0 D3 ; driver 0.3 goes forwards (extruder 0) M569 P0.6 S0 D3 ; driver 0.4 goes forwards (extruder 1) ; Axes M584 X0.0 Y0.1 Z0.2 ; set axis drives mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M906 X700 Y700 Z350 M92 X94.12 Y94.12 Z400.00 ; configure steps per mm M208 X0:225 Y0:145 Z0:150 ; set minimum and maximum axis limits M566 X60 Y60 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X4800 Y4800 Z300; set maximum speeds (mm/min) M201 X120 Y120 Z80 ; set accelerations (mm/s^2) ; Extruders M584 E0.5:0.6 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E700:700 ; set extruder driver currents M92 E96.2752:96.2752 ; configure steps per mm M566 E12000:12000 ; set maximum instantaneous speed changes (mm/min) M203 E4800:4800 ; set maximum speeds (mm/min) M201 E1000:1000 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; Endstops M574 X1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin !io2.in M574 Y1 S1 P"!io3.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin !io3.in M574 Z1 S1 P"!io4.in" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin !io4.in ;Sensors M308 S0 P"temp0" Y"thermistor" T100000 B4066 ; configure sensor 0 as thermistor on pin temp0 M308 S1 P"temp1" Y"thermistor" A"RE thermistor" T100000 B4981 C1.632834e-7 ; configure sensor #1 M308 S2 P"temp2" Y"thermistor" A"LE thermistor" T100000 B4981 C1.632834e-7 ; configure sensor #1 ; Heaters M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.290 K0.260:0.000 D1.86 E1.35 S0.85 B0 M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2 M307 H2 R1.920 K0.483:0.000 D5.98 E1.35 S1.00 B0 M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"out6" ; create fan #0 M106 P0 C"Board Fan" S1 L0 X1 B0.1 ; configure fan #0 M950 F1 C"out4" ; create fan #1 M106 P1 C"Extruder 0 Fan" S1 B0.1 H1 T45 ; configure fan #1 M950 F2 C"out3" ; create fan #2 M106 P2 C"Extruder 1 Fan" S1 B0.1 H2 T45 ; configure fan #2 M950 F3 C"out5" ; create fan #3 M106 P3 C"Cooling Fan" S0 L0 X1 B0.1 ; configure fan #3 ; Tools M563 P0 S"EXTRUDER RIGHT" D0 H1 F0 ; define tool 0 G10 P0 X-34.04514634972721 Y0.29743029572304586 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"EXTRUDER LEFT" D1 H2 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 0 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CAt these jerk and acceleration for axes I have no layer shifting. There are some underextrusions though

Slicer: Cura

layer size: 0.3 -

I wonder how you did that?

We all live on the same internet, have access to identical or similar sources. The problem was to interpret the results: These moonish things seem to have been discontinued, the specs I stumbled upon on second sources for your specific steppers had been carelessly slapped together. So from the various data offered, I picked just the most plausible value. Given the size (especially: height) of your steppers, 1.5A will be not too far from the truth. Take this to calculate the values for your

M906as described here: Stetting motor currents.From my search, I got the impression that these steppers are not particularly powerful, in the realms of speed and accel, I suggest you to stay on the conservative side.

-

@Inlinebrother

Leakage circuit breaker installed?:I guess so

Let's leave it at that as long as the PSU issues seem to have vanished.

Mains power switch:

It is the Flashforge Creator Pro and it has a button behind it to turn off the power that goes to the PSU

But didn't you tell me that the PSU never turns off? Or did I misunderstand something? In this context, you also mentioned some LEDs never going off …

Config, print quality, tuning:

I found macros for tuning the speeds, jerk and acceleration here

These are really great. But, before you start tuning the printer, you should take two separate steps:

- Go through your config.g, some motor settings are off the rails. I'll get back to this in a separate post.

- Learn where to draw the line between RRF and Cura: Some print (and printer) parameters can both be defined in Cura and RRF, some settings will be overridden by values from the other side of the fence. I tend to lean more towards the RRF side, because the various slicers are difficult to manage due to a plethoria of settings, but in the end, you must simply know what GCodes your slicer generates in his start section - and, which of these might interfere with your definitions in config.g and the Macro start.g (on the RRF side of the fence).

Generally, stick to the same rules as for hardware debugging: One step at a time. So, don't change multiple parameters in either Cura or RRF (and never in both of them in the same test cycle). If you don't know what you do, learn it. To understand the effect of a certain setting to the print result you get, you must be able to identify the culprit. If you are faced with multiple suspects, chances are high that the real culprit stays unidentified.

Enough said. In the meantime, I have to take care of my dog and some other stuff, but then, we'll deal with your config.g. CU

-

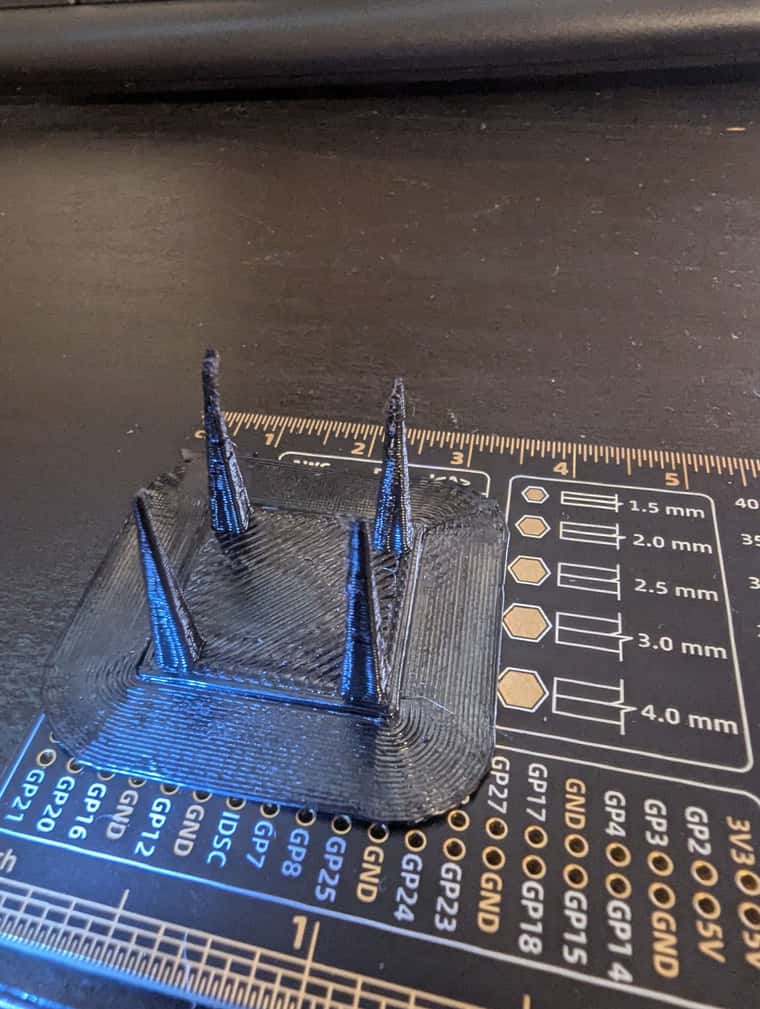

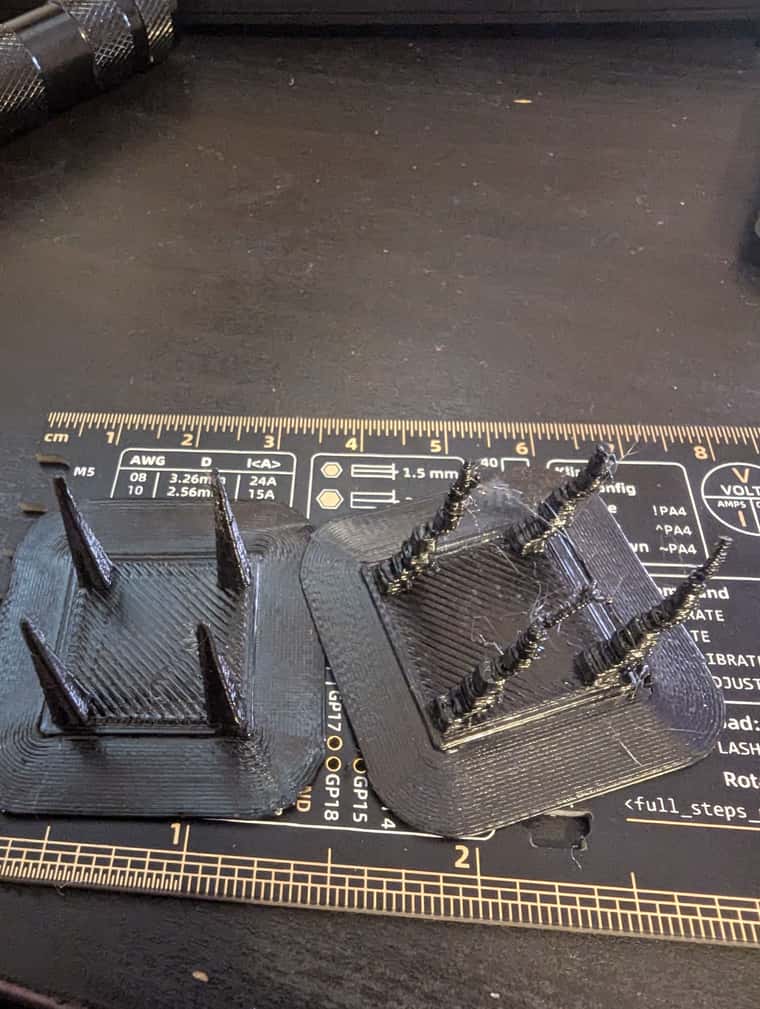

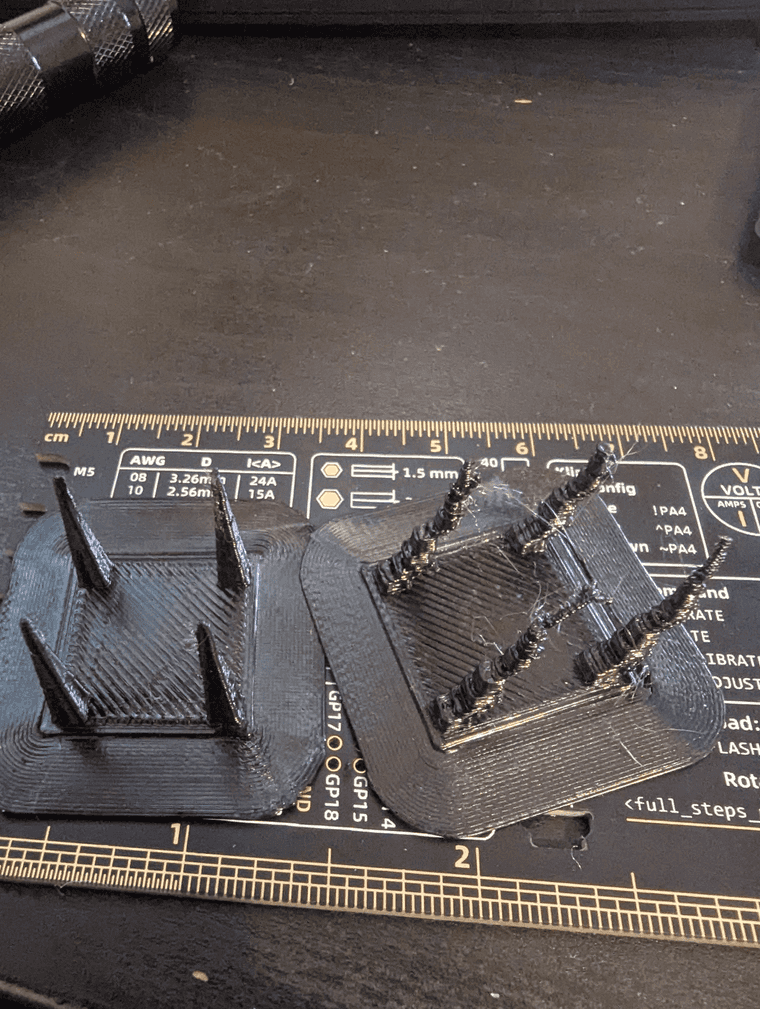

The left print is a good start, but how can you explain the failure on the right? Which parameters or settings were wrong? And please, don’t simply guess what might have gone wrong.

What I intend to say: You must be in control of the printing conditions all the time. Furthermore, remote observers need to know what exactly you intended to test, and, which parameters you changed in order to cause such a poor quality output as on the right. At least, you should remember the settings for the left print: it’s a good start, revert to them.

-

@Inlinebrother OK. Just to be clear about today’s topic: It’s your config.g, motor section.

Firstly, an admission: For me, GCodes are hard to decipher, I can neither read nor spell GCodes by heart, I have to look them up here. Sure, I’ve prominently bookmarked the GCode dictionary, but even to understand my own config.g, I have to go through it line by line. Chaps like @Phaedrux (that’s the one who wrote the tuning macros) and @droftarts (the one who contributed most of the valuable hints to your thread) eat GCodes for breakfast (Sorry guys, didn’t want to trigger you - but if you are willing to scan @inlinebrother’s config,g, you’re welcome: I won’t catch everything).

M566 X60 Y60 Z12 ; set maximum instantaneous speed changes (mm/min)These values are an order of magnitude off. To understand what you do, PLEASE look up

M566in the dictionary. The example depicts conservative values, start with these for X, Y and Z. Note that E is missing from your line: That’s because your setup follows a different pattern, it provides a secondM566in the ”Extruders” section.Let’s take a break and look at the details: Comparing the values for X/Y/Z to E, the difference is stunning. All units are mm/min, so why should Z be limited to 12 mm per minute(!), whereas E can take 12000 mm in the same time? Sincerely: 1000 times more than the 12 on Z? This pattern stinks, it is illogical. Well, that’s a good reason for yet another break: Where do these figures come from?

My claim: Oral tradition (or a digital variant of that). Someone had these numbers in his config, some values were lost in translation, someone ignored the decimal point, another one omitted a trailing zero, and finally, you have to observe the units to deal with: RRF uses millimetres per minute, other firmwares (and slicers like Cura) prefer to use millimetres per second - what a difference!

Sorry for the rant. My point is just this:

- Always have a close look at the units involved

- Never copy the templates from others blindly, better think twice

- Analyse every line of GCode, use the dictionary (and your brain)

OK, three points. But you get the idea. Anybody on this forum cries for templates of a config for his specific printer. If you followed me up to here, you now understand why that’s a questionable idea - too much can go wrong (and has almost certainly gone wrong with your config).

———

Next:

M203. This line carries no comment, it defines the max. speed per axis, again, in mm/min. Add a comment to make its meaning explicit. Again, the extruder has it’s ownM203. Comparing your settings to those for my poor old bedslinger, there is some room for optimization. But, first things first: cross-check your RRF settings with what you command in Cura:M203imposes absolute limits, regardless of what you tell your slicer. And always remember: RRF is mm/min, Cura is mm/sec.———

Finally,

M201(Accellerations). Again, you have separate entries for axes and extruders. IMO, the values are leaning to the conservative side, so there’s a potential for optimization. Keep this in mind, add the topic to your list of items to be tuned. -

But didn't you tell me that the PSU never turns off? Or did I misunderstand something? In this context, you also mentioned some LEDs never going off …

I meant that when there was a shutdown, nothing happened to the PSU, it was the board that stopped working

At first, before I grounded the board, I witnessed the board shutdown and turn off wifi. The lights near 5v switch were blinking with no pattern. But the 24v power LEDs didn't show any signs of trouble.

All that is in the past now, after I removed the screw

Learn where to draw the line between RRF and Cura:

That's actually a nice thing to mention. I think that the Printer Settings plugin makes things a bit more difficult)

I'll have to check what it does, besides the setting that I set for firmware rectraction when I explored tuning tutorial yesterdayI have to take care of my dog and some other stuff, but then, we'll deal with your config.g. CU

Nice of you to put so much energy into helping me, but please keep balance and take care of your dog)

-

but how can you explain the failure on the right?

The config I posted is for the left print

The fact is that low jerk and acceleration settings helped achieve a good result -

@infiniteloop Thank you for your thoughts, I think that I use all of your advice, but I lack experience, so I can't be as good as you before I get some experience)

My strategy is "try and fail, but do not stop".

I've learnt a lot about my printer in a month) If I were too afraid to change the config or hardware I would do nothing and just throw my printer away.The thing that I lack about the DWC is git.

It would be great to have a VCS for configs.

But I can always create a repository myselfWhere do these figures come from?

Here is the tuning discussion, I used this number for E jerk on purpose

https://forum.duet3d.com/topic/6181/tuning-macros-menus-accel-jerk-retraction-pressure-advance/18?_=1728802639093guys are saying that E jerk should be high enough so that it doesn't "cap the X and Y jerk values for a print move"

All units are mm/min, so why should Z be limited to 12 mm per minute(!)

That comes from the config generator, I didn't change that because Z axis seem fine.

This line carries no comment,

The one for the Extruders has it. I lost the one for axes when copied the config here

separate entries for axes and extruders.

that is also how the generator creates a config today

-

@Inlinebrother

Mains power switch:At first, before I grounded the board, I witnessed the board shutdown and turn off wifi. The lights near 5v switch were blinking with no pattern. But the 24v power LEDs didn't show any signs of trouble.

Got it.

RRF vs Cura:

I think that the [Cura’s] Printer Settings plugin makes things a bit more difficult.

You nail it. But it depends on your personal preferences. For my part, I feel uncomfortable with the idea of having crucial firmware settings embodied in every print object - when I improve my configuration over time, I’d have to re-slice every single design, I.e. all over the place, instead of doing it once and for all. And, of course, I am nailed to one slicer, can’t switch to another one or even run .gcode files from other sources.

There’s already a lot of settings in the .gcode files: print speeds, temperatures, layer heights… BUT: except of the layer heights, I can adjust all of this in DWC on the fly. With this approach, I could already save numerous prints, while my older designs automatically inherit all benefits from tuning measures I made over time - in RRF, that is.

-

The config I posted is for the left print

So start your journey from here.

The fact is that low jerk and acceleration settings helped achieve a good result

I agree. A second thing to have in mind is print speeds. Most of the basic settings can be better explored at moderate speeds. At high speed, you introduce a whole zoo of mechanical effects from your printer’s hardware to the equation. Everybody want’s to print fast, but I feel more comfortable with the idea to take this challenge in a second step.

-

I think that I use all of your advice, but I lack experience, so I can't be as good as you before I get some experience

Holy cow! If you knew how many of my prints I still ruin today, you would speak differently.

Here is the tuning discussion, I used this number for E jerk on purpose

guys are saying that E jerk should be high enough so that it doesn't "cap the X and Y jerk values for a print move"I am no tuning expert. Despite of my long bowden, I don't even use PA. I'm just printing slowly. But, with respect to your stepper settings, it might be helpful if @Phaedrux could have a quick look. He has a "feeling" (or call it "intuition") for suitable values that I completely lack.

My strategy is "try and fail, but do not stop".

That’s the way! With a caveat: to learn from a fail, you must be able to localise its cause. If you operate too many handles at once, this may be difficult (remember the ”octopussy syndrome“?

That’s the way! With a caveat: to learn from a fail, you must be able to localise its cause. If you operate too many handles at once, this may be difficult (remember the ”octopussy syndrome“?  ).

).The thing that I lack about the DWC is git.

It would be great to have a VCS for configs.This was my very first thought when I updated my printer with a Duet and converted to RRF. In fact, I grabbed some config.g for my type of printer from the Web. To start with, it didn’t even match my RRF version. In the end, I had to spell every single line of it (by the help of the GCode dictionary - that’s how I learnt GCode the hard way. Most of the template’s entries were either idiotic or faulty. It took me three months until I had a functional machine again. TBH, I’m still working on that project - after years. The fun never stops, my journey continues.

In my eyes, it is better to use the RepRapFirmware Configuration Tool as a starting point - see: Configuring RepRapFirmware for your machine. It has some flaws (see your Z values), but IMO it’s arguably better than some template ”from hearsay” which could easily turn out to be ”from hell”.

that is also how the generator creates a config today

I’m perfectly fine with separate entries for axes and extruders, I just noted that it is different from my settings.

-

Hi, want to share some news

I changed my PSU to Meanwell LRS 450w - it fits (35 mm height is good for FFCP)

I installed creality 40w 24v heater catridges

And I still had vdd brownouts after that. Though the board restarted and showed the error every time. So it was another issue.Recently I got used to checking all the cables. And I had a guess that something is wrong with my extruder motors. Because it was only during the print that a printer would give a vdd brownout error and restart. So I checked my stepper motors cables and it turned out all that time I also had loose connections on my stepper drivers

So I recrimped them. And that time I also had a "pull test" of my cables while holding multimeter and checking the resistance.

So I recrimped them. And that time I also had a "pull test" of my cables while holding multimeter and checking the resistance.I hope now I'll be able to continue refining my config and help dc42 with debugging

-

But that was not the end of the story...

Spoiler: I fixed it

So I noticed several things about my printer and here is the list of what I noticed and done to my printer

- First of all, my SD card was corrupted several times. And I ordered an industrial SD card as it is recommended in the docs. It works fine. I had no issues with that.

- I noticed that my extruder fan is too loud and I thought it might help to replace it. It did help to reduce the noise though.

- I had to replace my new thermistors because I had a clog and I damaged them while removing the clog

- While removing the clog I noticed that my grounding cable was loose and I fixed it better

- Then I thought something is wrong with my stepper motors config and I found out a lot about their tuning process. And in the process I even made my printer work without bed heating and low motor currents. I also found out that I like how silent is the stealthchop, especially for Z axis.

- I measured the current of my bed with a clamp meter and it is about 8-9 A, so it's 200w

- I found the config here for duet 2 wifi config

- I found out why I might have problems with my stepper motors. Because there is only one man who tried using duet 3 mini 5+ on this forum that I know of. And TMC2209 have to be configured.

- I noticed that z axis motor is producing a very loud hissing sound in standstill spreadcycle mode

- I removed another loose grounding cable near the sd card.

And after all that I was lost. The only thing I had in mind was to replace the board.

- while setting up a new board I had to reflash the firmware several times, because it was always busy with something. So if I closed up the connection and had to change something in it again it won't connect to my mac until I push the reset button two times and upload the .uf file to the bootloader

And changing the board helped. I might have damaged the old one with a short.

I also took a precaution and removed another screw that was underneath the board.The one thing that I noticed right away is that the voltage shown by the new board is higher

And I also had some hard faults on the way, but for now I just want to rest a bit)I'll post my config some time in the future when I am sure it produces the best results, but for the most part I use the one mentioned earlier from github + my settings to enable spreadCycle almost for every move except standstill.

-

An update about hardware:

- The old board was damaged for sure. I don't know how it's called, but something is wrong with how the 5v power is interpreted. When I connect it to USB it shows 1.1v. I use a replacement now.

- I installed the bltouch and it's working perfectly fine. Though I was concerned that it is glowing red and not violet

- I had to reconfigure my thermistors using multimeter, because the resistance values from the docs were wrong. And I was overheating my hotend. It was 270 instead of 230

- ordered an accelerometer supported by duet, will have to design a holder and set it up if I have the time and energy to do that)

Some words about 3d printing troubles)

- Had a lot of trouble printing PETG. Reassembled extruders and changed nozzles several times.

- For now printing 40mms but maybe later I'll try to use input shaping and pressure advance, though on small parts I am not sure that my printer can accelerate faster

- Had holes in my prints. I blame clogs and a bad petf tube. Also 60mms seems to be too high for small models

As for petg it seems that I need to lower flow value in cura. Standard esun petg profile is not working. Thought it might be moisture, bought a dryer, but it didn't help for PETG. Lowering line width and flow seems to help a bit.

I am glad I did that upgrade. Learnt a lot about printing and electronics. And the printer is silent enough that I am sure no neighbor hears it.

Auto bed levelling is a miracle

Wifi interface is a miracle. I need only to push one button to turn my printer on and then I can just sit and control it from distance.

This upgrade made my printer usable at home and a lot more convenient to use.

I learnt a lot and I am in total control of my printer now

Thanks for your help and attention)