Duet 3 current hardware config for Railcore II?

-

Hello

I am just finishing my build of a RailCore II 300ZLT ( that I started in 2020). This is a personal Machine at my home. My printer build is mostly metal.

I have built up the mechanics with a NEMA 23 Halo and I am starting to look at the controls.

The kit was originally supplied with a Duet 2 combo, but I like the look of your DUET 3 board in combination with your NEMA 23 smart motors and the Duet 3 Toolboard as well as your scanning Z probe all on CAN bus.

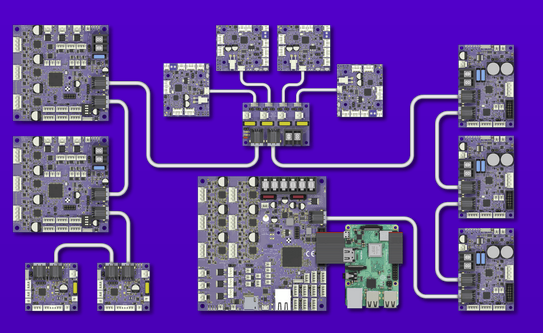

I was hoping to keep and use the Bondtech BMG and Mosquito combo printhead, but I am open to changing the printhead if you feel there is major advantage to using your Duet 3 Roto toolboard with the E3D Roto extruder.Do you have any example system configuration drawings (block diagrams?) vaguely like this –

using these latest Duet controls and their suggested interconnections that would suit my printer?

Regards

Frank Howard

Sr. Automation/Application Engineer

Addup Inc.

Cincinnati, Ohio, USA -

Have you been to the Railcore discord?

-

@Phaedrux , yes I have. There is some discussion of Duet 3 hardware, but not of wiring and configuring a total system of Duet 3 including the motors and other CAN I/O that I noticed.

-

@FrankHowardNUSA Railcore Discord is the place to ask those questions, not enough people here familiar with Railcore. There are stock configs posted for Duet 3 on a Railcore. You'd want to use a 6HC (and a 1LC if you want a CAN-connected toolboard).

-

@FrankHowardNUSA Stock Railcores use a Duet 2 or 3 mainboard only, no additional CAN connected boards, as far as I can see. Anything beyond that is a 'custom' setup, and is going to require you to configure and maintain the setup yourself.

However, this forum (and the Railcore Discord for more Railcore-specific questions) is here to support you, and the latest version of the configuration tool should get you most of the way in setting up the machine; see https://configtool.reprapfirmware.org/

For your actual choice of boards, as the mainboard is only running the Z axis, if you are using the LDO-42STH40-1684MAC NEMA 17 motors (1.6A), a Duet 3 Mini 5+ would be plenty for them.

For the X and Y motors, a NEMA 17 motor (the same as Z) is specified in the BOM; is there a mod for NEMA 23 motors? 2 x Duet 3 M23CL closed loop motors can be used if so. The 6HC and Mini 5+ support them.

For the toolboard, as you want a scanning Z probe, you may as well use the new Roto toolboard. It would be capable of driving your Bondtech BMG and Mosquito, as well as having the SZP (and accelerometer) built in. You may have to create a custom mount for it on the toolhead, though.For CAN connection advice and cabling, see https://docs.duet3d.com/en/User_manual/Machine_configuration/CAN_connection

Ian

-

@droftarts - I am planning to finish my railcore build over Christmas this year. I have decided to use my previously purchased standard stepper motors on X and Y instead of the CAN connected M23CL's in the near term for simplicity sake. They consume 2.8Amps (Stepperonline pn 23HM22-2804S). The 3each Z-axis NEMA 17 motors (LDO pn LDO-42STH40-1684MAC) consume 1.68Amps. It looks like the the Duet 3 Mini 5+ is a little light on current for the X&Y so I am planning to purchase the Duet 3 Main Board 6HC to drive the 5 total X, Y and 3-Z steppers. Earlier you mentioned using the Duet 3 Roto Toolboard with my Bondtech BMG and Mosquito.

Is this a better solution than the Duet 3 Tool Board 1LC since the Roto Toolboard includes the accelerometer and Scanning Z-probe?

Are the connectors for the Roto Toolboard available easily or as a kit?

(I will look further into the docs)

Thanks for your help with this!

Frank Howard

Electrical Controls Engineer

Mitutoyo America Corp

Duet3D hat howardautomation dhot com -

@FrankHowardNUSA yes the 6HC is a better choice for those motors than the Duet 3 Mini.

The Roto Tool board has the advantage of a more powerful processor and built-in scanning Z probe. However, as you noticed it has connectors designed to for those supplied with the Revo Roto hot end. See https://docs.duet3d.com/en/User_manual/Troubleshooting/Parts#connectors-used-on-duet-3-roto-toolboard for the connector types. Also check whether the current needed by your extruder motor is within the rating of the Roto Tool board.

We also sell a version of our magnetic filament monitor that fits on the Revo Roto.

If you choose the TOOL1LC then since version 1.1 the accelerometer is included.

-

@dc42 - The NEMA 17 stepper on my Bondtech extruder is p/n LDO-42STH25-1404MAC

The data sheet is specing' - " DC 1.4A /Phase ". (I can't post links in this forum yet)It looks like the Duet 3 Roto Toolboard has a stepper driver current limit of 1.0Amps due to

thermal constraints. The TMC2240 stepper driver chip can Drive -

" Current Ratings per H-Bridge (Typical at 25°C):

* IMAX = 5.0A (Bridge Peak Current)

* IRMS = 2.1ARMS (3A Sine Wave Peak) "

Note 1 in the Duet 3 Roto Toolboard web data sheet states -

*1 Note further thermal testing may allow higher extruder current for Extruders other than the Revo Roto which should not exceed 600mA current.So, do you think this would be a good combination for "further thermal testing" or is it bound to fail?

-

@FrankHowardNUSA if you run stepper motors at their full rated current they get very hot. It's normal to run them at 60 to 80% of that current. So 1A should be enough anyway.

Sadly it's not possible to get anywhere close to the maximum figures headlined by Trinamic, especially when space is constrained. The headline figures are for intermittent operation with a very large PCB area for heatsinking. However, we should be able to increase the maximum current of the Roto Tool board somewhat.