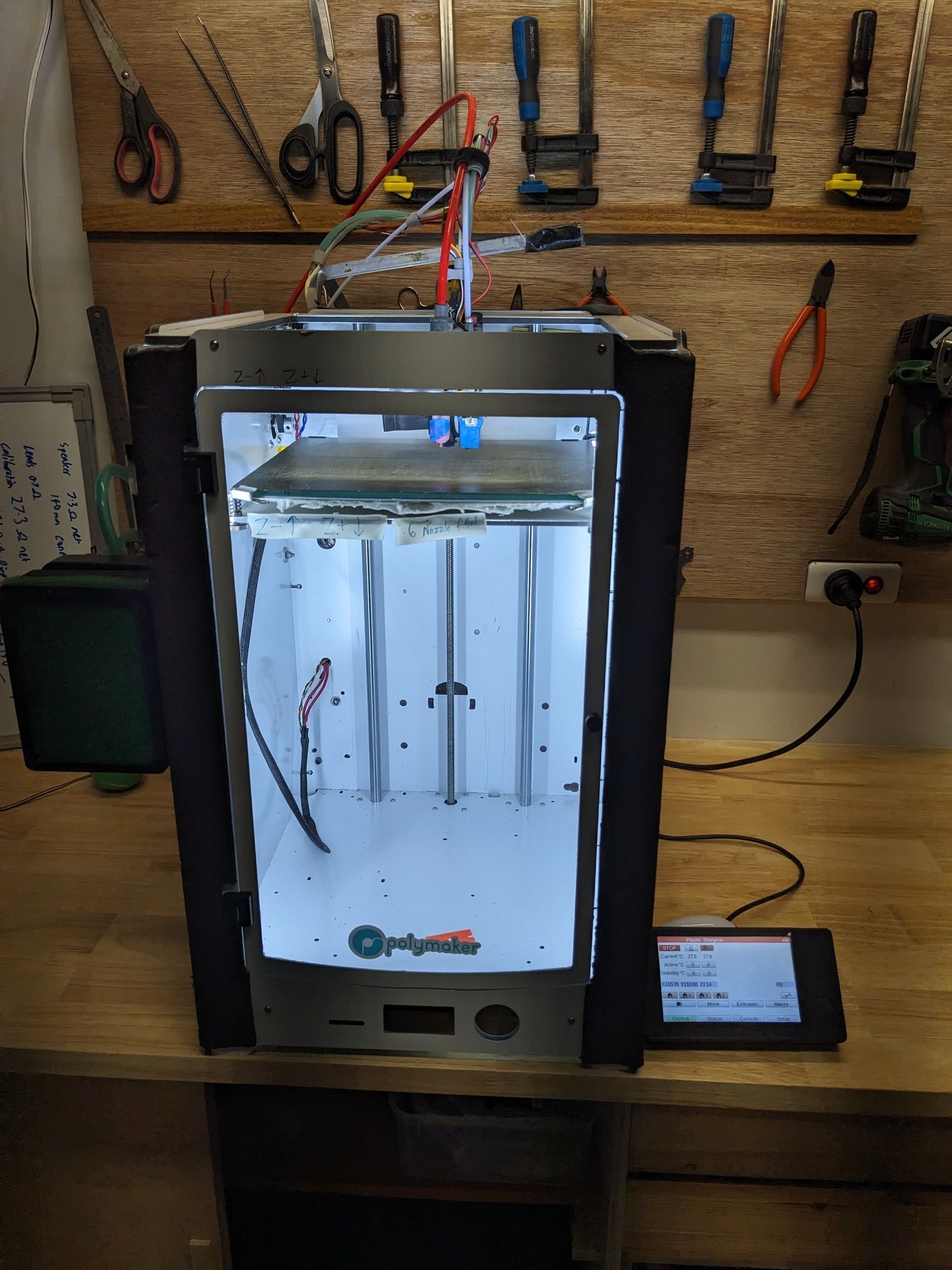

The Plastic Sturgeon (Watercooled franken printer)

-

Hi All,

I'm now in the tuning phase of my inherited 3d printer.

It hadn't been updated since 2019 and i think hadn't been used in a few years.

I'm new at 3d printers but old at electronics and noodling.

So i spent the last few days and (with your help) got it printing ok.

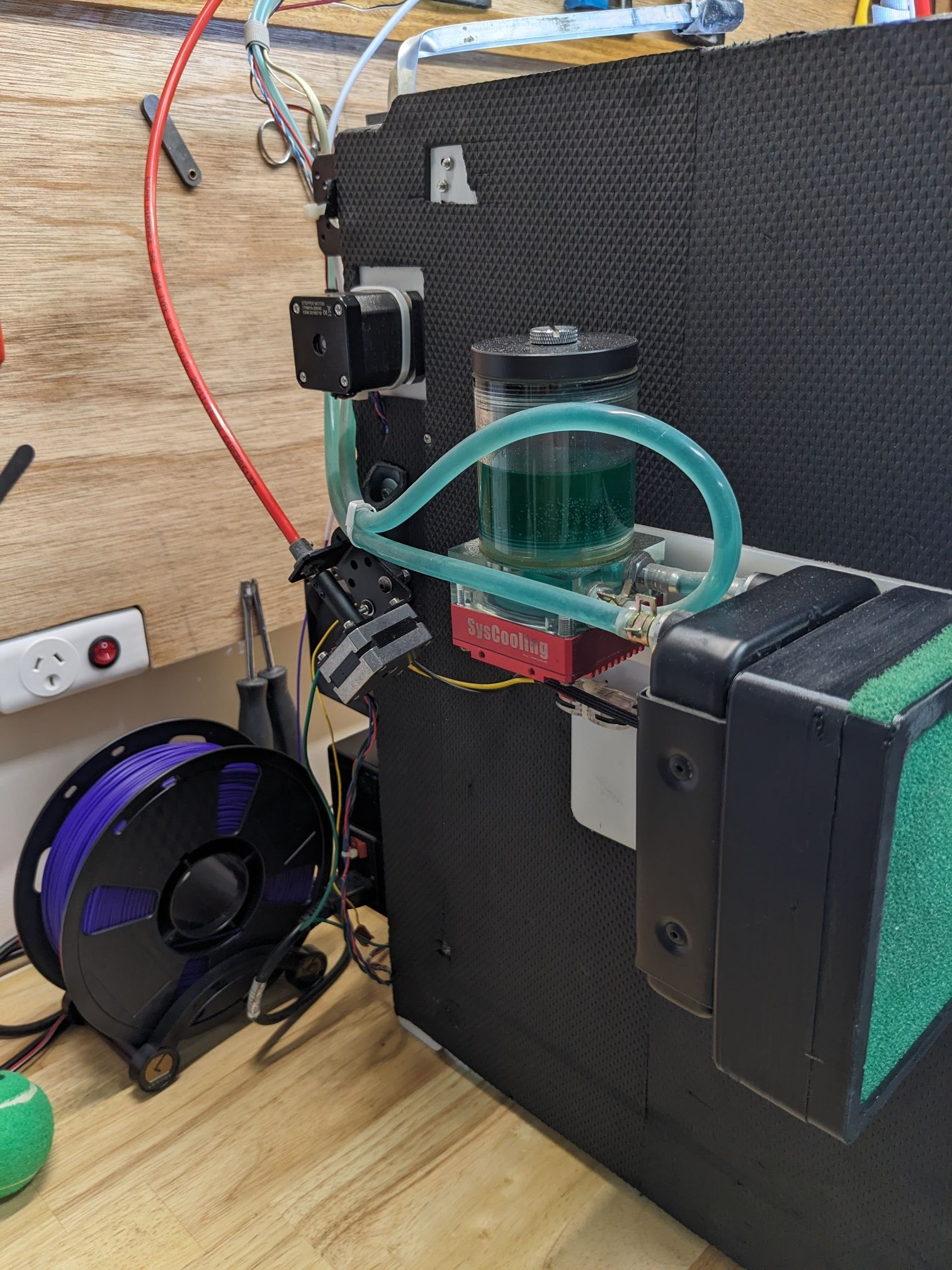

I'm now trying to make it fasterHere are some pictures, i think it's a fairly unusual printer because of the water cooling and the extruder drive system.

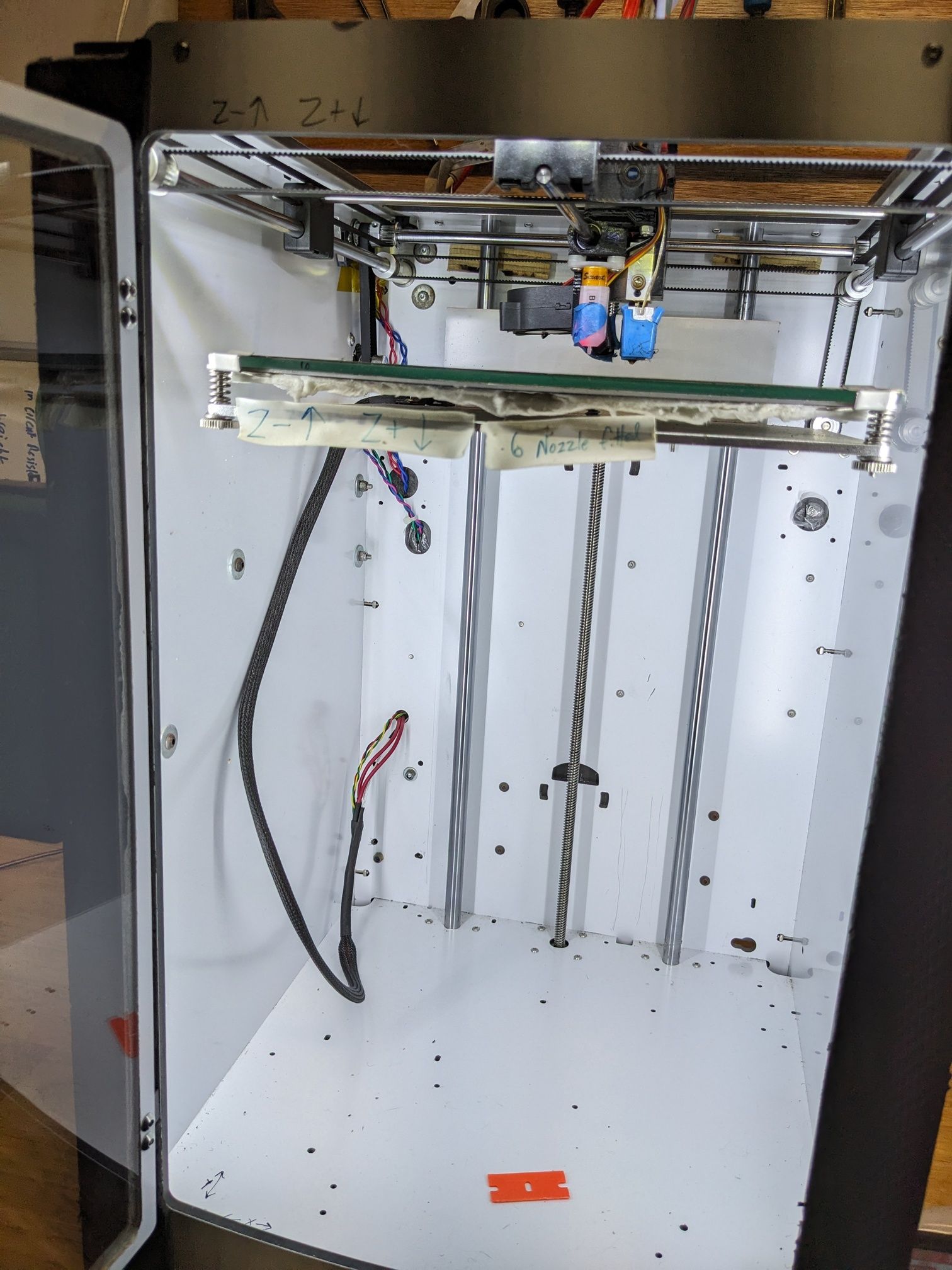

I think it uses an ulitmaker 3 enclosure.

It has a build space of 200x200 and at least 300 (probably more).

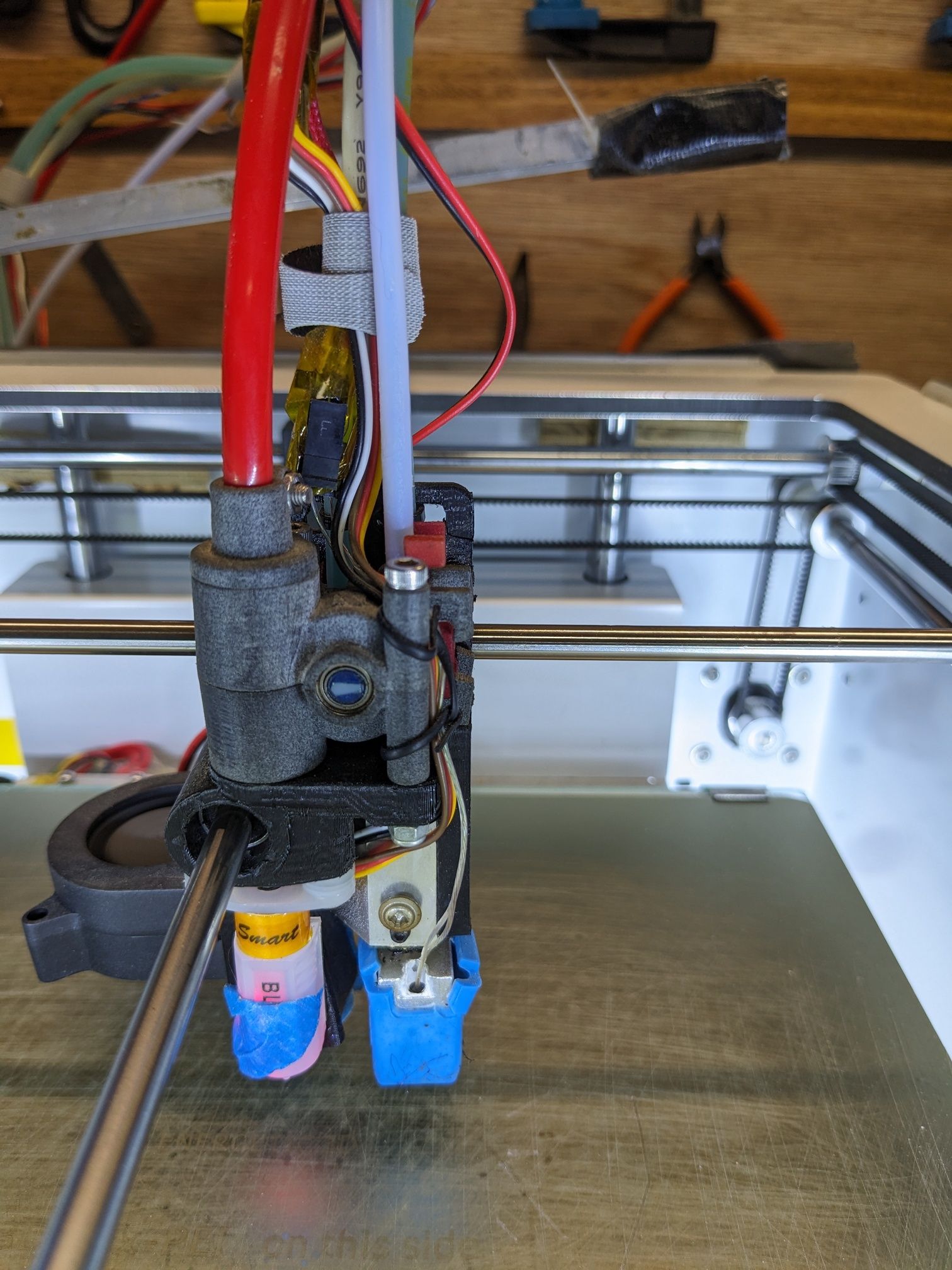

It has a watercooled head

it has a remote flex drive extruder called a Zesty Nimble by Zesty Tech (no longer around)

no idea what head it has, it has a .6 nozzle allegedly.and PEI plate on the heated bed.

-

@magnets99 Nice! Looks like an Ultimaker 2 or 3 extended frame, but the XY motors have been moved outside the chamber. I’d guess the intention was to do higher temperature materials, except with the BLTouch in there you’re limited to 80C ambient. I think the hot end is an E3D Volcano or similar, so it’s probably meant to print fast. However, the Zesty may be the limiting factor, as the cable drive can wind up and fail if there’s too much extrusion pressure. Swapping the extruder for one of the modern, light, direct drive options would probably make it reliable.

Ian

-

@droftarts

Ooo thanks for the info, yes I think the previous owner was printing nylon a fair bit.I'm quite new to this so how fast is fast?

I ran a benchy on it and it took 2hours and 10mins.My speeds are based on the original config.g I found on the SD card so i have no idea if they are super conservative or if that's a typical benchy print?

-

@magnets99 that’s pretty slow, but as ever, it’s more dependent on your slicer settings.

Printing speed is generally related to how fast your hotend can melt filament, which is expressed in cubic mm a second (mm^3). You can calculate this from layer height, wall width and speed, eg printing at 0.3mm layer height at 0.6mm wall width (ie nozzle width) at 100mm/s is 0.3 x 0.6 x 100 =18mm^3/s. A normal E3D V6 nozzle can extrude at about 10mm^3/s, a Volcano should be able to do 25mm^3/s. It’s also dependent on what material you’re printing, and the set temperature. Most hot end manufacturers have a rough figure for the throughput of their hot ends, and there are online reviews too. Some slicers also have built in flow testing you can run. RRF has also recently introduced heater temperature feed forward, which increases hot end temperature as speed increases.

Non-printing speeds (eg travel moves) can generally be faster, and are only limited by the speed the motors can cope with. Tuning speeds, accelerations and jerk will show the maximum that can be achieved.

That’s a very brief outline to the many happy hours of tuning you have ahead of you!

Ian

-

@droftarts

Thanks for the info Ian,

That's really helpful stuff.

I'm using orca slicer as reddit feels it give the best results and i liked the interface.

i'm working my way through these

https://teachingtechyt.github.io/calibration.html#flow

calibration settings, though my partner made a very good point, i could shave 30 minutes off the print time, but if it wasn't a good result or failed 3 in 10 i'd be just as efficient leaving it at 2 hours print time.I'm looking forward to playing with the feed forward, and i'm going to buy an accelerometer. a bit frustrating that i have a box of ADXL345's but it doesn't support that one. Still it's a very awesome OSS project!

-

@magnets99 said in The Plastic Sturgeon (Watercooled franken printer):

I'm using orca slicer

Yes, I've pretty much switched from Prusaslicer to OrcaSlicer. OrcaSlicer also has some built-in calibration tests, but I haven't tried them myself. I also recommend the 'Califlower' test by Vector3D, though unfortunately it'd gone up in price recently with a new version.

a bit frustrating that i have a box of ADXL345's but it doesn't support that one.

The accelerometers supported by RRF are the LIS2DW12, LIS3DH and LIS3DSH. They have a fast readout mode, which allows us to read the acceleration data without getting the artefacts in it that we saw with the ADXL345 in testing (Klipper also suffers from this).

Ian

-

@droftarts

I did buy the Califlower, it's printed out really well. Thought my calipers only go to one decimal place, i'm pretty happy that that values are the same in each direction though,

it recommended m556 s100 x-0.033

which i'll test again after i've finished the other tunings. before adding it. -

@magnets99 The gantry is pretty interesting: They use the smooth rods for linear motion and as rotating shaft.

I wonder how well that works with these linear ball bearings? Especially on pure X or Y moves (i.e. homing) they will suffer.

I'd replace them with IGUS bearings if they seem to be worn out.