Duet 2 v1.02 not responding

-

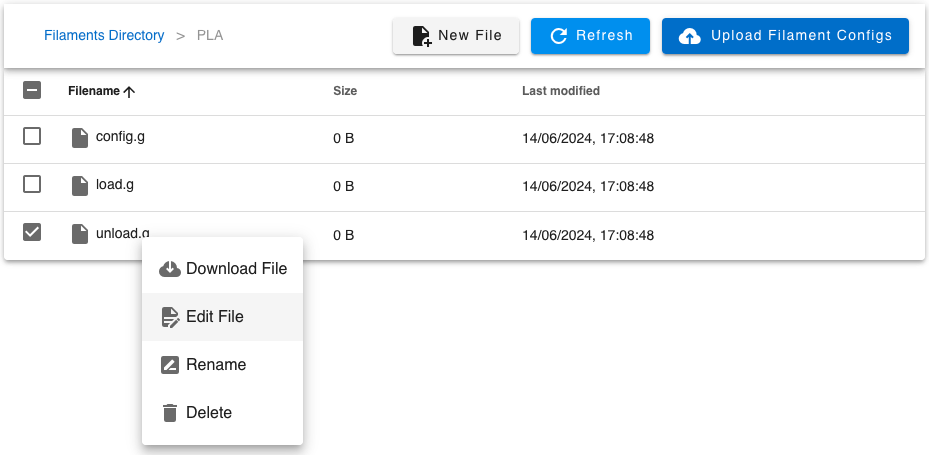

@droftarts It's also new to me to make configuration files for the filaments.

Do I need to make a directory /filaments and create this?

-

@thomasvanderwal You don't need to use the filament functionality of DWC/RRF. I don't! I just put the filament in that I'm going to use, and set up the slicer with the correct filament. It's up to you.

Creating a new filament should create the /filaments folder if there isn't one already. See https://docs.duet3d.com/en/User_manual/Reference/DWC_filaments

Ian

-

I changed S1 to S0 in M569. It went the wrong way.

Finally I wanted to print. But it "hit" the bottom. I thought I leveled the delta but. It says:

Error: G30: Probe was not triggered during probing move -

@thomasvanderwal said in Duet 2 v1.02 not responding:

extrude en retract seems to go the wrong way.

Change the M569 S parameter for the extruder. See "Reversing a stepper motor" in https://docs.duet3d.com/en/How_to_guides/Commissioning#h-10-check-stepper-motors

Also my PLA goos neary through the opening

I'm not sure what you mean.

But I don't know if the extrusion or retracting button on my duetPanel works also with this code.

Can you show a picture of what buttons you mean?

Ian

-

@droftarts I think I mad e some good changes due the PLA. My latest concern is the leveling

-

@thomasvanderwal said in Duet 2 v1.02 not responding:

My latest concern is the leveling

What's the problem? Most likely you need to do the bed calibration, for which you need the probe to work. Is the probe working now?

Also check that the motors move the effector the correct distance. See the "Check distance moved" section of https://docs.duet3d.com/en/How_to_guides/Commissioning#h-10-check-stepper-motors

For a delta printer, it's easiest to check movement in the Z axis, eg measure from bed to nozzle, move it down 50mm in DWC, then measure from bed to nozzle and check it moved 50mm.Ian

-

@droftarts Probe was said in an error statement.

I will manage the leveling. But The printer stood some time still. How can I clean a nozzle? I think its full or something. The tube (hot end?) before the nozzle is that also to clean?

-

@thomasvanderwal said in Duet 2 v1.02 not responding:

How can I clean a nozzle? I think its full or something. The tube (hot end?) before the nozzle is that also to clean?

Usually, if you heat up the nozzle to 200C, you can push out old filament with new filament. If it was printing a different material, eg ABS or Nylon, you may need higher temperatures, eg 230-240. Don't leave it at this temperature when the PLA goes through.

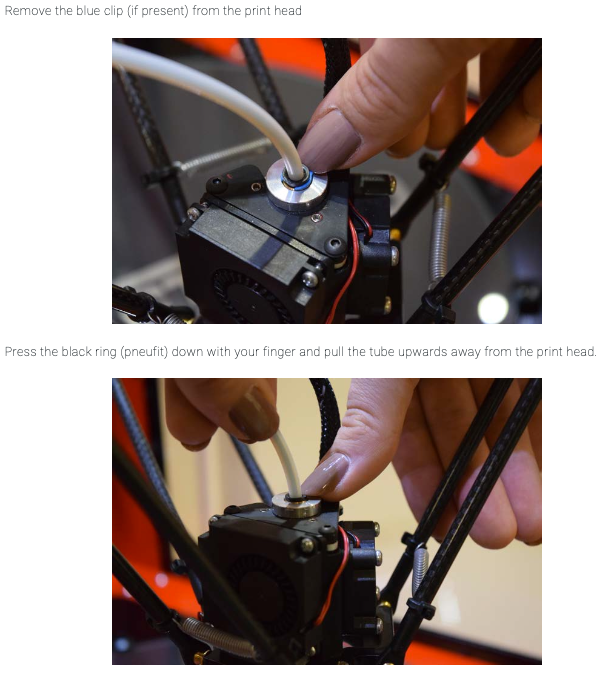

The feed tube may also have filament in it, it just means you have to push more filament through. Or you can detach the feed tube from the top of the nozzle, and pull the filament back out by hand. To take off the tube, shows this in the pdf manual.

If you can't push filament through at all, you may need to diassemble the hot end. Unfortunately the manual doesn't seem to cover this.

Ian

-

@droftarts Nozzle was defect. I changed it and now extruding works.

And I still confused about the leveling. Do I have a Z probe? Or did I configurated it as something else?

In web controller is the Z-probe 0 and goes to 1000 as you managed.

After pushing the button "Delta configuration". The nozzle hamers the bed. What do I need to do to get the leveling right?

The Commissioning document is very confusing. -

@droftarts

At Z=11 it touches the bed. I followed the steps for trigger height with g92/g30 . Then used G31 and put the z number (trigger height in config with G31 x0 y0 z-2.0 Is that right? -

@droftarts I am done. It will not work. After setting a z=0 (nozzle touches bed) delta calibration is not working proberly. The Z is suddenly 32. When calibrating the nozzle pushes the bed in 3 of the 6 down leveling. What I'm missing?

-

@dc42

Can you help me with bed leveling in my Tractus 3D t650P. After getting the firmware right and configuration my Z is off. When Z=11 then crashes the nozzle in the bed. I made may changes with G92 Z0 etc. G30 S-1->G31 and M500/M999. With G31 z-10.85 nozzle is still crashing with Z<11 -

Were you able to identify what kind of probe is actually being used? Can you point to a piece of hardware on the printer and say "this is the probe"?

-

@Phaedrux

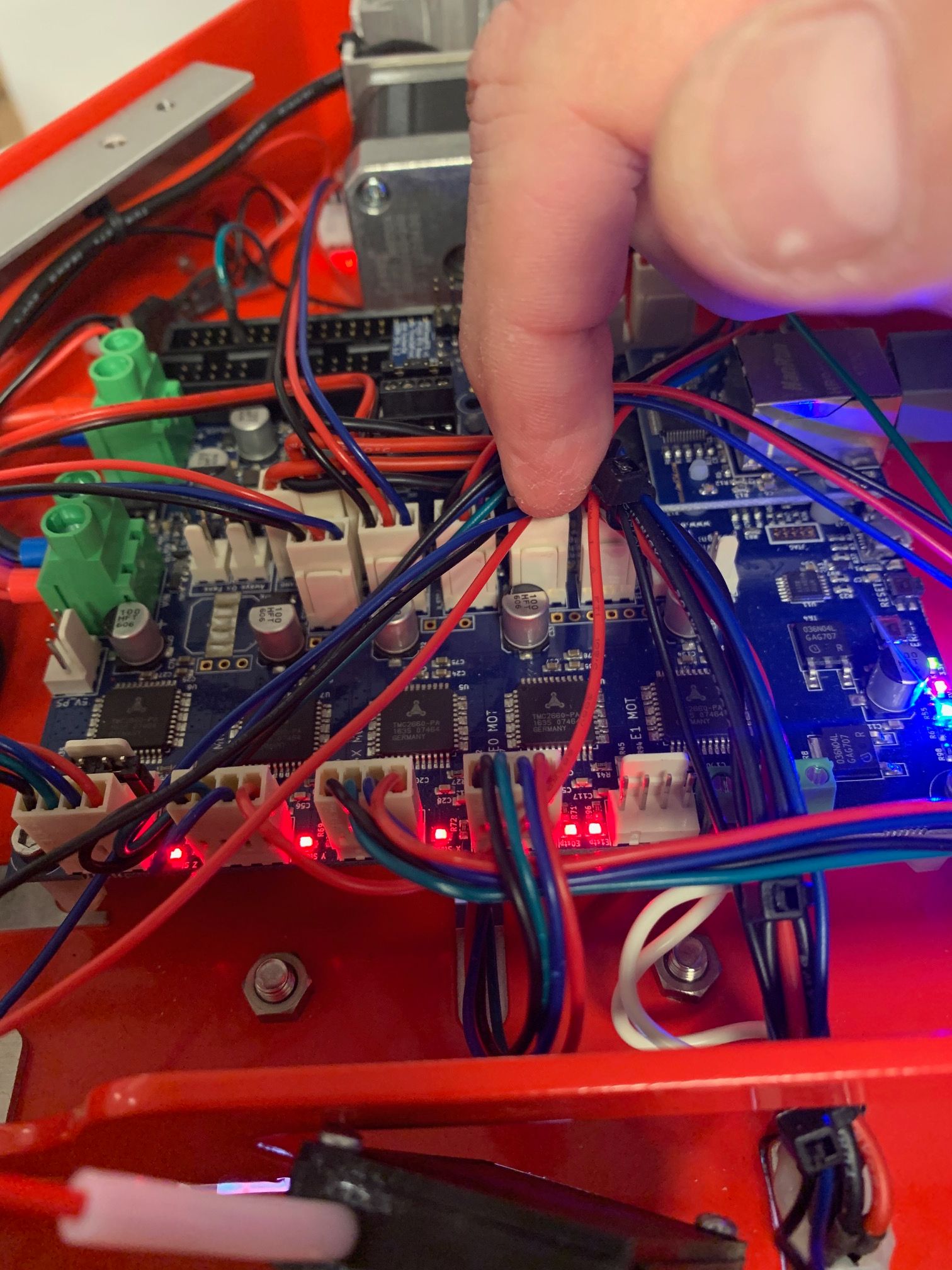

I Will dismantle the bottom to see.

I managed to print something unless the nozzle hitted the bed. But It was very small and didn’t make It as a benchy. Looked the size of 20% of the suppoost size. -

@Phaedrux @droftarts

you tell me haha

Do you know how I set this right in the config.g?

Please help me to get the calibration right. Every time I push "delta calibration" my previous (G92 Z0) is changed to something else (Z=0 but nozzle is about 6mm above bed). -

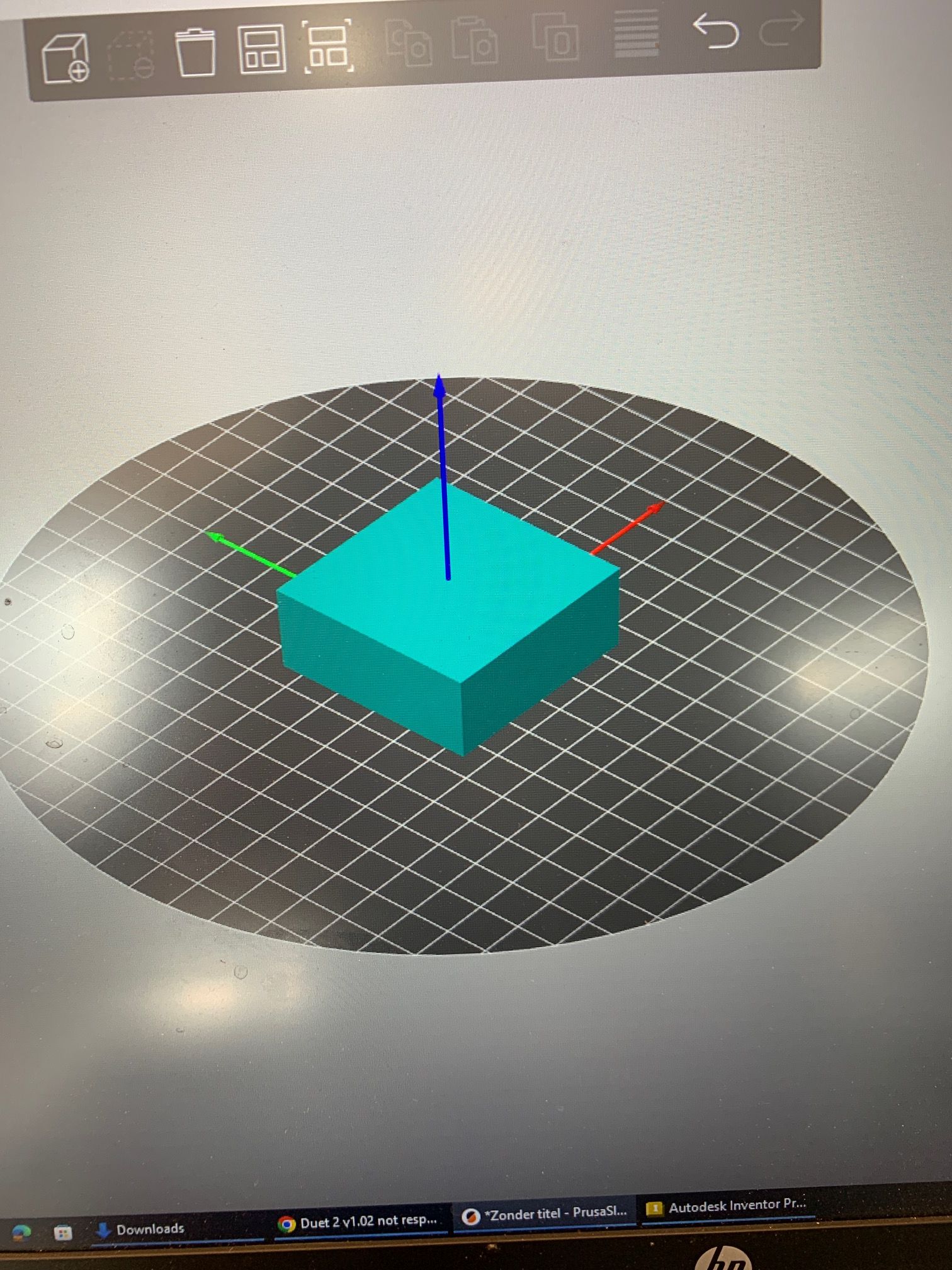

@droftarts

This is what is going wrong with printing. It had to be a sqaure 50mmx50mm h=20mm

Result 20mm x 15mm

-

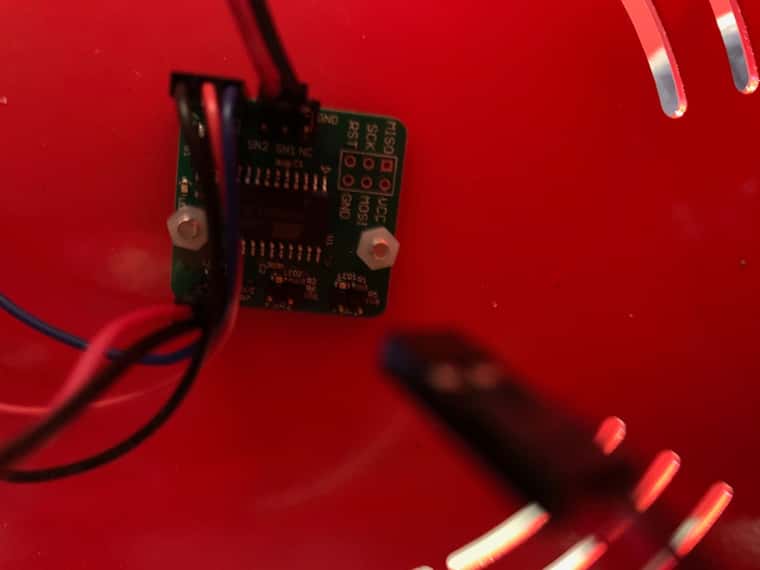

I think that's probably a bed attached piezo probe. It detects the nozzle contact tap.

You won't be able to print anything until you have the probe configured and are able to complete a delta calibration and bed mesh. Without an accurate mathematical model of your delta nozzle positioning won't be accurate enough.

Can you get a clearer shot of that little PCB? As well as a photo and description of where the wires from that PCB are connected to your Duet? With that information I can hopefully guide you in configuring it.

-

Also please share your entire current config.g and homedelta.g and bed.g

-

@thomasvanderwal sorry, I’m away on holiday this week.

Did you check that, from homing, when you move down 50mm in Z, it actually moves 50mm? Measure with a ruler. This is to check your steps per mm (M92).Ian

-

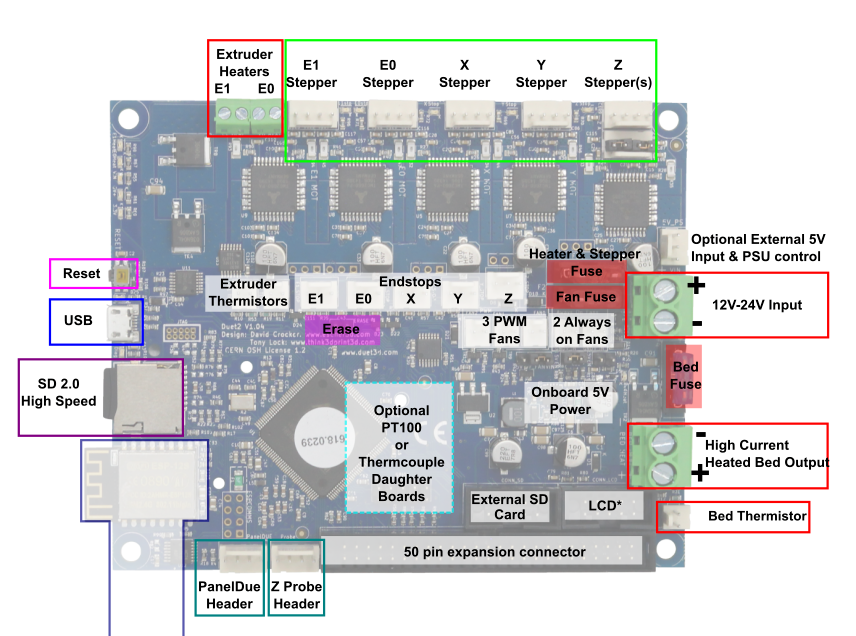

The 3 wires go to the E0 Endstop on the board.

The stepper for extrusion and retracting is attached to E0 Stepper