Odrive and Duet

-

@carlitototo I would say yes if it uses step/direction signals and doesn't consume a massive amount of processing speed

-

Isn't the diamond hotend working with one heater cartridge ? like, what do you mean by heated chamber ? I thought it worked by putting one filament, do it's thing and after retract it to let place to another one

@3DPMicro, hope you're right ! i don't kno about the precessing speed needed...

merci :3

-

@carlitototo said in Odrive and Duet:

Isn't the diamond hotend working with one heater cartridge ? like, what do you mean by heated chamber ? I thought it worked by putting one filament, do it's thing and after retract it to let place to another one

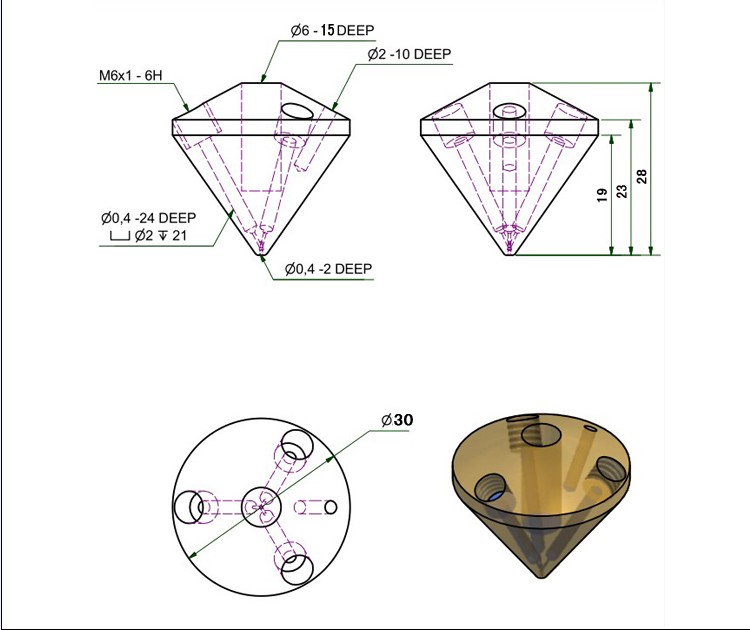

Yes, the Diamond has a single heater but it's not heater power that determines the melt rate. It's contact area of the filament with the hot surface, plus the time that the filament is in contact with that hot surface. Think cookery. If you tried to fry a very large steak in a very small pan, and parts of the steak were outside the pan, then only the part inside the pan will get cooked. Here is a schematic of the 3 colour Diamond nozzle.

The heater cartridge sits in the centre of the brass cone with the 3 melt chambers around it.

No, it doesn't use one filament, do it's thing, then switch to another filament (although it can do but without retracting any filament). Filaments are loaded into all the inputs so by mixing them, you can have say 2-% of one filament and 80% of another. That's how I print things like this scaled up Julia Vase by Virtox.

That was done by mixing filaments in 1% increments.

Now, if instead of using different colours you use the same colour in all 3 inputs, set the mixing ration to 0.33:0.33:0.34, you now employ all 3 mixing chambers in equal proportions to melt the filament. So you have 3 times the surface area (a much bigger frying pan), plus each filament moves at only 1/3rd the speed of a single filament in single melt chamber, so spends more time in contact with the hot surface giving a higher melt rate than a single melt chamber.

That's the theory but for a better explanation and some practical test results, see my blog here

https://somei3deas.wordpress.com/2017/06/22/exploration-of-print-speeds-with-a-diamond-hot-end/ -

Oh I see now, thanks for the explaination !

So now I need to choose a hotend with a super long hot zone !

The diamon looks nice, but you need to put in 3 spools, kinda tidious, I also believe you can print only with filaments that have the same melt temperature ?

Research are being conducted to learn more about the best hotend for my case

-

! Forgot to say : WOW super duper ultra mega cool vase ! Also, nice blog, little question : why cold coffe and the title ?

-

The "Super Volcano" hot end that E3D is developing may also be part of the solution to fast printing, if they get it working well enough. Last time I spoke to them, they said that the limiting factor for it was heating power.

-

@carlitototo said in Odrive and Duet:

,,,,,,,,,,,,,,,,,,,, little question : why cold coffe and the title ?It's just a little catch phrase. I often make myself a coffee but then get distracted by what I'm doing, so when I get around to drinking it, the coffee is cold. It's a bit of standing joke in our household. As for title it's a kind of amalgam of "3D" and "Ideas" so I3deas. A bit lame but the best I could come up with.

-

Can't you just put a heater element with more watts ? I think the one they are using is 30W, could you replace it with, let's say a 50 or 60W one ? I'm almost shure the answer is no because it would bring issues, but, never know :3

@deckingman , :'), this explains it all ! You should put your mug on a heated bed

-

I think it's a little more complicated than just upping the wattage on the heater. It takes time for the heat to penetrate the filament evenly enough to make it molten. Then you also have the non-newtonian fluid dynamics of the plastic to deal with. The harder you push it the more back pressure you get. Using filament as the medium is likely a limiting factor because of that. You are using the stiffness of the unmelted plastic to push the molten plastic and eventually the back pressure overcomes the pressure you have to push with and the it strips or motors skips.

The largest printer I have seen in person was the size of a room. It was being used to print a towable trailer. It used a specially made pellet extruder. It didn't move very fast but when you are laying down a 1.8mm bead at 1mm layer height you make up for movement speed with volumetric flow. They estimated they could do an entire trailer in about 24 hours. This was using PETG pellets.

So there's definitely room for development in the space and it's likely not going to follow along with the current filament based ecosystem.

The one thing that will matter most is having a clear idea of what your end result is going to be. Then designing a printer that can achieve that is just a matter of engineering.

-

Mmmmmhhhhh, seems difficult ! maybe use an even thiner filament than 1.75 would help penetration and also upping the temperatures to make it more liquid would overcome the problem ? ( again, it's a noob speaking ^^ )

For now I guess I'm gonna need to "prendre mon mal en patience" as we say in france !I read an article about this printer, isn't in a fablab cafe of some sort in Canada ?

I knowperfectly what I want, has you said, just matter of engineering ! It's going to be interesting to do

-

@carlitototo said in Odrive and Duet:

I read an article about this printer, isn't in a fablab cafe of some sort in Canada ?

Indeed it is. Create Cafe in Saskatoon.

-

On their 900MC Stratasys uses an approximately 75mm long tube with the nozzle on the end and has a huge heater block clamped to it yielding about a 60mm long hot zone and no heat break.Probably mainly to deal with the high performance materials like Ultem but it does push ASA through the same set up. Looks like it prints fast to me

Back to the ODrive. That set up looks to have a lot of potential for the price especially if high speeds are desired for printing or non printing moves -

On the subject of heater wattage, the Diamond 5 colour ships with a massive 80 watt heater cartridge. When I tested one, it was uncontrollable and impossible to maintain a stable temperature. Long story short but I replaced it with a more standard 40 watt version which proved to be more than adequate to melt 5 filaments concurrently. I read somewhere that it only takes single digit watts to melt filament. Time is an important factor because filament itself is a poor conductor of heat.

-

I stumbled in to this article

Fast Desktop-Scale Extrusion Additive Manufacturing by MIT

https://arxiv.org/ftp/arxiv/papers/1709/1709.05918.pdfThey used a 50 W Laser Assisted Heater Cartridge.