Berd-Air pump configuration notes for Duet users

-

I'm a bit confused about PWM. I have a Berd-Air pump on fan 0 through an e-switch mosfet.

If I add an F25500 parameter to the M106 I have very little control over fan speed.

If I leave off the F parameter I can vary pump speed from 0 to full speed. It seems that the higher the PWM frequency the less control over fan speed.When you run with a high PWM frequency are you still going through an e-switch?

-

@davea said in Berd-Air pump configuration notes for Duet users:

I'm a bit confused about PWM. I have a Berd-Air pump on fan 0 through an e-switch mosfet.

If I add an F25500 parameter to the M106 I have very little control over fan speed.

If I leave off the F parameter I can vary pump speed from 0 to full speed. It seems that the higher the PWM frequency the less control over fan speed.When you run with a high PWM frequency are you still going through an e-switch?

I was not. I still have my e-switch lying around and I may get a chance to test that later tonight or tomorrow and let you know my results. It is very possible that the e-switch may not respond to high PWM values as well as the pump does directly. If that is the case I have a DC-DC SSR lying around and I may give that a shot to see if it makes a difference.

-

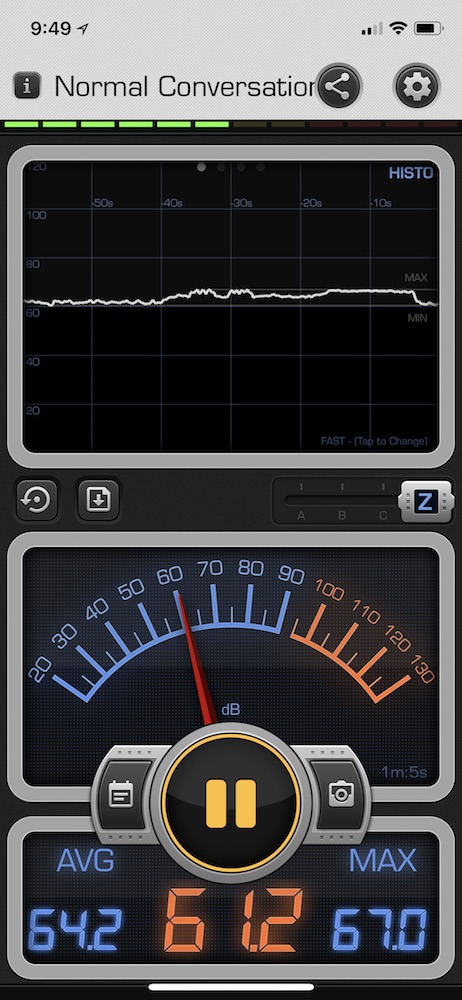

For reference here is a DB monitor of the pump running at very near full speed during a print. This is with the phone about 1" from the pump.

-

Brushless?

-

@klcjr89 said in Berd-Air pump configuration notes for Duet users:

Brushless?

This was actually the brushed version. I will put up something with the brushless in a day or so.

-

@msquared About the flayback diode, your link points to a 1N4007.

I have first tried this one, but it got pretty hot.

After some googling I think the reason is that the diode is just too slow for a high frequency of 25kHz (reverse recovery time of 30us).

I have replaced it by a schottky diode that doesn't get warm.And I would like to know what motors temperatures you observed with the standard pump?

For example, mine has reached about 50°C after a while running at 50%... I don't know if this is good or not... -

If you are using a high PWM frequency (you mentioned 25kHz), please check also that the mosfet isn't getting hot.

-

I've been using:

- The flyback diode provided with the eSwitch kit, sans the rest of the kit.

- The current limiting thermistor DC42 linked to.

I'm getting great results at 25kHz freqency. Prior to changing the frequency, my minimum operating range was about 25%. I'm now able to operate at 20%, and my understanding is the current limiting thermistor is dropping voltage a touch based on the ~30 Ohm resistance I measured when checking my circuit.

-

@dc42 Yeah, the mosfet gets indeed a bit hot.

Hard to measure that tiny thing with a thermometer, but from touching it, I would say roughly around 60°C as I can still touch it for at least a couple of seconds. -

Duet boards with PCB revision 1.02 and later have flyback diodes already included on all fan outputs.

-

So you've set M106 with F25500 as PWM frequency parameter? I've got the same configuration and mofset is well cooled, just asking before changing the configuration.

-

@hergonoway said in Berd-Air pump configuration notes for Duet users:

So you've set M106 with F25500 as PWM frequency parameter? I've got the same configuration and mofset is well cooled, just asking before changing the configuration.

Correct, I'm using F25500 on a 24V (1.03 Duet Wifi) and 12V (0.85 Duet) without issue. I've got a flyback on both. The 0.85 needs the external flyback, but the 1.03 does not. I am not using the eSwitch module.

-

@MSquared Any progress with the brushless pump?

-

Ive got 2 Berd air systems that only need to be at 25% or so to give great part cooling. The sound of air whoosing out is louder than the pump. I am using a brass tube that is 3.75 mm outside diameter with a flattened tip and is positioned to point at the tip of the extruder. This size tube and opening is less restrictive on the pump than the supplied 2.4 mm tube so it runs quieter and supplies more air. Initial positioning of the tube took some trial and error (was quite fiddly as some would say), but once you've got it the results are impressive. My Duets are 0.85 and Wifi 1.0 or 1.01 and both are on 12v. I am not willing to risk running the Berd air pumps on my Duets without the eswitch and hope that no one who does regrets it.

-

Thinking about getting a bigger tube, for the same obvious reasons, air flow. 3,75mm is kind of uncommon did you have to flattened the tube (I think of using 1/8" because 4mm seems to big) ? And did you use a jig to bend the "circle" part?

-

@hergonoway 1/8" is an improvement to the stock tube and is close to 3.75 (3.18). I flattened the tube by stripping a length of #12 AWG stranded and inserting as many wires as possible into one end. I flattened the end with a small hammer and pulled out each wire with pliers afterward. I am not using a circle, only the flattened tip.

-

@hergonoway said in Berd-Air pump configuration notes for Duet users:

@ayudtee

And did you use a jig to bend the "circle" part?One way to bend soft tubing is to fill it with salt (table salt) and tape the ends shut. Pack it pretty tight and then you can bend it to as tight a circle as you need.

Then remove the tape and tap it until all the salt comes out. I blow air thru it as well afterwards.

-

@ayudtee said in Berd-Air pump configuration notes for Duet users:

@hergonoway 1/8" is an improvement to the stock tube and is close to 3.75 (3.18). I flattened the tube by stripping a length of #12 AWG stranded and inserting as many wires as possible into one end. I flattened the end with a small hammer and pulled out each wire with pliers afterward. I am not using a circle, only the flattened tip.

@timcurtis67 said in Berd-Air pump configuration notes for Duet users:

@hergonoway said in Berd-Air pump configuration notes for Duet users:

@ayudtee

And did you use a jig to bend the "circle" part?One way to bend soft tubing is to fill it with salt (table salt) and tape the ends shut. Pack it pretty tight and then you can bend it to as tight a circle as you need.

Then remove the tape and tap it until all the salt comes out. I blow air thru it as well afterwards.

Thanks I'll give a shot then !

One last question, did you choose a specific angle for the holes ? some people keep the same 90° angle but others use a 45° angle toward the hotend, is there really a benefit from one to another ? the current problem I have with Berdair are on overhang, I've gain airflow by directly connecting the 1/8" tube to the aluminium tube, and I'll certainly gain more air flow by increasing the metal tube, but does orientation in this little space will change anything, I don't know.

-

@hergonoway My 2 printers are using an E3D V6 and an Ormerod Quickset II hotend. I do not have enough room under either hotend to use a larger tube that is bent in the stock ring configuration. A larger tube would not fit under either hotend after if it was bent into a circle.

-

@ayudtee Standard E3D nozzle has a clearance of 5mm between the tip and the heatbock. I suppose your using these ones.

In my case I'm currently using tungsten MakerBot type of nozzle which have ~8 mm of clearance, so 1/8" should work with a E3D sock, at least I hope from my test on fusion 360.

I'll post pictures if it works #FingerCrossed