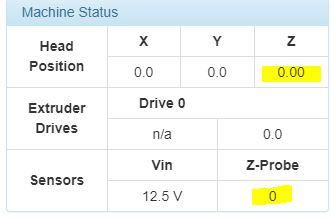

Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Is this related to why the "G30 S-1" command to bury the nozzle hard into the bed (when it shouldn't move the Z position)?

Very likely.

-

@mindbender9

I see your M558 H parameter is still set to 5. Change it to 30mm as suggested by dc42 a few weeks back. I crashed my probe into the bed a few times over before i found that post. I believe that H parameter sets the height the probe moves to before actually doing any probing. If 5mm takes the probe below the bed before probing starts, it will crash every time.

Have you tried doing a manual calibration without a probe again, just to eliminate any fussiness with probes for now? I gave up using my probe as it wasn't consistent enough, probably a result of the frequent bed crashes. Manual calibration was quick, easy and accurate enough. -

All -

I've made the two changes as instructed:

M558 P1 X0 Y0 Z0 H30 F1000 T5000 G1 S1 X400 Y400 Z400Progress so far:

-

The auto probe calibration works with the Z probe except for the far XY edge where it drags along the bed (the IR sensor is positioned off the side of the bed - it sees nothing so the nozzle eats the bed). This is amazing progress, though. Because reterminating the IR Z probe connectors got it to work (in theory).

-

However, it looks like the printer still thinks that Z=5.3 is the same thing as Z=0. When I try to print something like the XYZ calibration cube, the nozzle drops down to Z5.30 (5.3mm above the bed) and spews filament onto the bed. Recalibrating (and entering M500 to save settings) doesn't resolve the issue. What might be causing this stubborn behavior in the printer?

Here are my config files:

config.g:

; Configuration file for Duet WiFi (firmware version 1.20 or newer) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P1 ; Set firmware compatibility to look like RepRapFirmare ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 R134 L270 B85 H285 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 Pduettest M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Z-Probe M558 P1 X0 Y0 Z0 H30 F1000 T5000 ;I1 ; Set Z probe type to DC42 and the dive height + speeds G31 X0 Y0 Z2.02 P500 ; Set Z probe trigger value, offset and trigger height M557 R130 S20 ; Define mesh grid ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z80 E96 ; Set steps per mm M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Set active high endstops ; Heaters M305 P0 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M305 P1 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S275 ; Set temperature limit for heater 1 to 275C ; Fans M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled M501 ; Custom settings are not configuredconfig-override.g:

; This is a system-generated file - do not edit ; Delta parameters M665 L270.000 R134.000 H285.000 B85.0 X0.000 Y0.000 Z0.000 M666 X0.000 Y0.000 Z0.000 A0.00 B0.00 ; Heater model parameters M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1 M307 H1 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0bed.g:

; bed.g ; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 M561 ; clear any bed transform G31 X0 Y0 ; don't want any probe offset for this - ADDED 5/21/2018 G28 ; home the printer M401 ; deploy the Z probe ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 10 points, 6 factors, probing radius: 105, probe offset (0, 0) ;M98 Pdeployprobe.g G30 P0 X0.00 Y105.00 Z-99999 H0 G30 P1 X90.93 Y52.50 Z-99999 H0 G30 P2 X90.93 Y-52.50 Z-99999 H0 G30 P3 X0.00 Y-105.00 Z-99999 H0 G30 P4 X-90.93 Y-52.50 Z-99999 H0 G30 P5 X-90.93 Y52.50 Z-99999 H0 G30 P6 X0.00 Y52.50 Z-99999 H0 G30 P7 X45.47 Y-26.25 Z-99999 H0 G30 P8 X-45.47 Y-26.25 Z-99999 H0 G30 P9 X0 Y0 Z-99999 S6 ;M98 Pretractprobe.g ; DEFAULT SETTINGS - Set by the RepRapFirmware Wizard ; Probe the bed at 3 peripheral and 0 halfway points, and perform 3-factor auto compensation ; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g. ;G30 P0 X0 Y84.9 H0 Z-99999 ;G30 P1 X73.53 Y-42.45 H0 Z-99999 ;G30 P2 X-73.53 Y-42.45 H0 Z-99999 ;G30 P3 X0 Y0 Z-99999 S3 ;H0 M402 ; retract the Z probe G1 X0 Y0 Z150 F15000 ; get the head out of the way of the bedhomedelta.g

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 G91 ; relative positioning G1 S1 X400 Y400 Z400 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 X-5 Y-5 Z-5 F1800 S2 ; go down a few mm G1 S1 X10 Y10 Z10 F360 ; move all towers up once more (second pass) G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning ;G1 X0 Y0 F6000 ; move X+Y to the centreAny suggestions? Thanks!

-

-

The probe is going off the side of the bed because your offset from the probe to the nozzle is set to zero.

In bed.g:

G31 X0 Y0 ; don't want any probe offset for this - ADDED 5/21/2018and in config.g:

G31 X0 Y0 Z2.02 P500The X and Y in G31 should accurately describe the distance from the probe to the nozzle.

-

As for Z 5.3, etc.

What is the physical offset of the probe to the nozzle in the Z direction?

G31 is telling the printer this is 2.02. Is it really? At the moment the probe triggers (like with your finger), what is the EXACT Z dimension to the tip of the nozzle, as compared to the probe?

-

Sorry for the delay, as I’ve been away for work.

You’ve asked “What is the physical offset of the probe to the nozzle in the Z direction?” Do you mean that I should measure the distance between the Z-probe edge and the nozzle tip?

Thanks

-

@mindbender9 no the way to measure this is to move the probe towards the bed until the probe triggers. Then move the Z axis down further until the nozzle is just touching the bed (measure using a piece of paper as feeler gauge). Then you have the difference between the probe trigger point and Z0. The probe Z offset.

-

Ok, I'm getting confused about what values to put in the G31 line.

G31 X0 Y32.82 Z0 P500-

I measured the distance from the tip of the nozzle/hot-end to the circuit board of the dc42 IR probe, which came out to 32.82mm. I believe that the IR probe is off to the side of the nozzle along its Y-axis, because when I click on "Y-10", it moves in the direction of the mounted IR probe. Therefore, I'm entering "Y32.82".

-

For the X-value, I'm not sure if the probe is offset along the X-axis. From what I can see, the probe lines up directly in the path of the IR probe. So I'm going to make a guess and leave the X value of G31 as 0.

-

For the Z-value, there's a problem (of course). As I lower the nozzle to the bed, it stops at Z=0 and won't go any lower - but the nozzle's position is roughly 8-10mm above the bed - it won't drop any further. The IR Probe also is at zero at this same point, but will register "465" if I slide a single page of paper under it.

Why is the Z-axis stopping at 8-10mm off of the bed?

Here are the current config files:

config.g

; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P1 ; Set firmware compatibility to look like RepRapFirmare ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 R134 L270 B85 H285 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 Pduettest M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Z-Probe M558 P1 X0 Y0 Z0 H30 F1000 T5000 ;I1 ; Set Z probe type to DC42 and the dive height + speeds ; M558 P0 X0 Y0 Z1 H5 F1000 T5000 ;I1 ; Set Z probe type to MANUAL and the dive height + speeds G31 X0 Y32.82 Z0 P500 ; Set Z probe trigger value, offset and trigger height ;G31 X0 Y0 Z1.0 P500 ; Set Z probe trigger value, offset and trigger height M557 R130 S20 ; Define mesh grid ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z80 E96 ; Set steps per mm M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Set active high endstops ; Heaters M305 P0 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M305 P1 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S275 ; Set temperature limit for heater 1 to 275C ; Fans M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled M501 ; Custom settings are not configuredbed.g:

M561 ; clear any bed transform ;G31 X0 Y0 ; don't want any probe offset for this - ADDED 5/21/2018 G28 ; home the printer M401 ; deploy the Z probe ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 10 points, 6 factors, probing radius: 105, probe offset (0, 0) ;M98 Pdeployprobe.g G30 P0 X0.00 Y105.00 Z-99999 H0 G30 P1 X90.93 Y52.50 Z-99999 H0 G30 P2 X90.93 Y-52.50 Z-99999 H0 G30 P3 X0.00 Y-105.00 Z-99999 H0 G30 P4 X-90.93 Y-52.50 Z-99999 H0 G30 P5 X-90.93 Y52.50 Z-99999 H0 G30 P6 X0.00 Y52.50 Z-99999 H0 G30 P7 X45.47 Y-26.25 Z-99999 H0 G30 P8 X-45.47 Y-26.25 Z-99999 H0 G30 P9 X0 Y0 Z-99999 S6 ;M98 Pretractprobe.g ; DEFAULT SETTINGS - Set by the RepRapFirmware Wizard ; Probe the bed at 3 peripheral and 0 halfway points, and perform 3-factor auto compensation ; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g. ;G30 P0 X0 Y84.9 H0 Z-99999 ;G30 P1 X73.53 Y-42.45 H0 Z-99999 ;G30 P2 X-73.53 Y-42.45 H0 Z-99999 ;G30 P3 X0 Y0 Z-99999 S3 ;H0 M402 ; retract the Z probe G1 X0 Y0 Z150 F15000 ; get the head out of the way of the bedhomedelta.g:

; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 G91 ; relative positioning G1 S1 X400 Y400 Z400 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 X-5 Y-5 Z-5 F1800 S2 ; go down a few mm G1 S1 X10 Y10 Z10 F360 ; move all towers up once more (second pass) G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning ;G1 X0 Y0 F6000 ; move X+Y to the centre -

-

If you have mounted the IR sensor with the bottom edge of the board 1 to 3mm above the top of the nozzle as recommended, then it should not be triggering when the nozzle is 8-10mm above the bed. Please ask your supplier to replace the IR sensor. -

@dc42 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

If you have mounted the IR sensor with the bottom edge of the board 1 to 3mm above the top of the nozzle as recommended, then it should not be triggering when the nozzle is 8-10mm above the bed. Please ask your supplier to replace the IR sensor.

David:

From his screenshots, I don't believe the probe is triggering.Mindbender9:

You MAY need to up the M665 H parameter, and then allow auto calibration to give you a real value. H is currently 285, try 300.

Finger on the power button!! Stop it if it drives into the bed.

-

Good point, I didn't read his post properly. Yes, it looks like the H parameter may need to be increased.

-

I increased the M665 H parameter to 300, and then changed the bed.g G31 line to: G31 X0 Y32.82 to account for the IR probe distance from the nozzle. I then ran auto-calibrate.

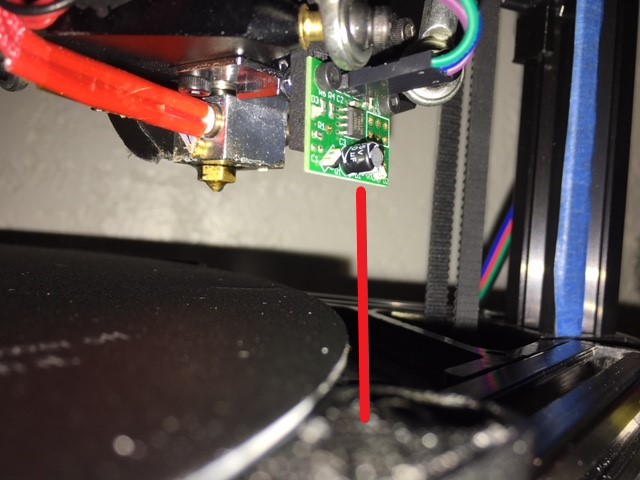

While the nozzle didn't bury itself, it did move outside the bed on the third survey while auto-calibrating. Here's a picture to show what I'm describing:

Both the IR Probe and the nozzle are outside the circular bed/printable area. I stopped the auto-calibration at this point.

Any idea how to correct this? I think we're getting close.

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Are you sure that the offset for the probe is in the +Y direction only? Looking at your pictures compared to how my effector is installed (as by the anycubic manual) the probe may need offsetting on both axis. Can you post a picture of your effector from the front (between x and y motors) of the machine so we can see it relative to the bed?

I also noticed that the config-override.g file you posted has no updated parameters in it. When you do get the probe measuring all areas of the bed properly and you do an M500 to save the settings, double check that the override file has been updated.

Oh, and since you've been having lots of crashes when attempting to print, before you start printing anything next time, manually lower the nozzle to different points on the bed to make sure that "zero" isn't above or below the bed.

-

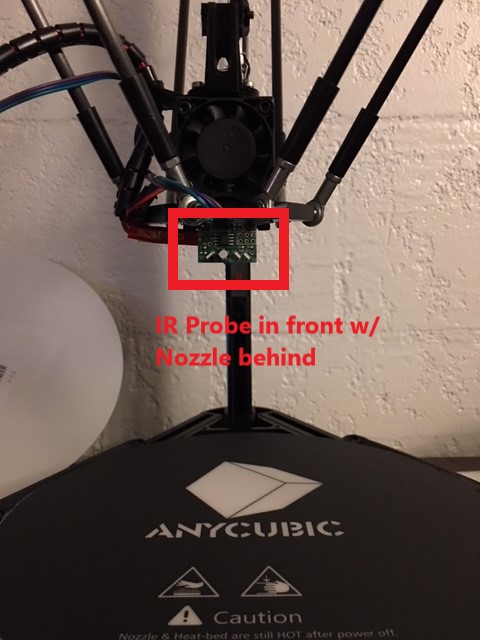

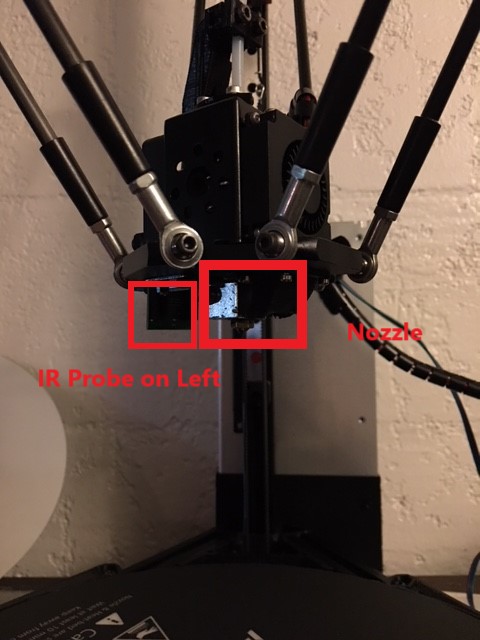

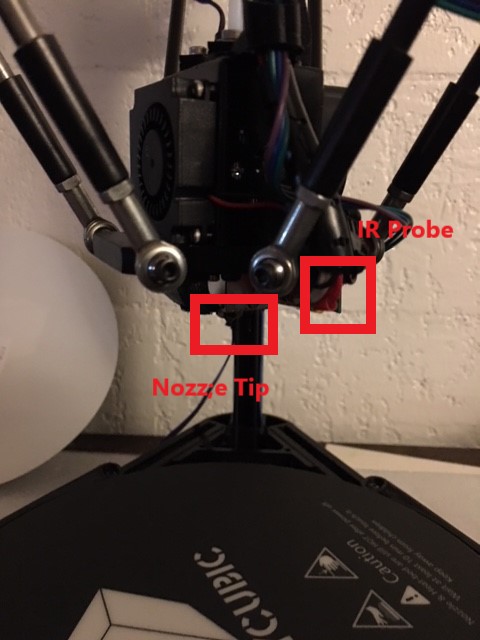

Hopefully, you'll be able to recognize something from these pictures.

View from front between X and Y motors:

View from right side between Y and Z motors:

View from left side between X and Z motors:

-

M557 R130 S20seems wrong for a printer with a 230 diameter bed. Radius of 130 would be diameter of 260. This will move the nozzle off the bed.Try a radius of 105, for diameter of 210, to keep things well away from the edges. If that works, you may be able to raise it slightly, watching for the edges. To start with, something like

M557 R105 S20 -

@danal said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Try a radius of 105, for diameter of 210, to keep things well away from the edges. If that works, you may be able to raise it slightly, watching for the edges. To start with, something like

M557 R105 S20Hi @Danal,

I changed the M557's R value to R105, R90 and R80 but the third stop of the autocalibrate still ran into issues (regardless of the R-value the was set).

With R105, it looks like the IR probe is just hovering outside of the edge of the bed, while the nozzle is inside the bed area. When I started lowering the R-value, the IR probe position didn't change. Here's a picture:

So it looks like the IR probe doesn't see the bed and keeps dropping, while the nozzle is inside the area of the bed, and this ends with nozzle contact as a result. And lowering the R-value doesn't not change this position.

I think we're close, but the nozzle's refusal to reflect any of the R-values is odd.

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

and then changed the bed.g G31 line to: G31 X0 Y32.82 to account for the IR probe distance from the nozzle. I then ran auto-calibrate.

The Z probe offset is measured from the nozzle to the probe. So Y32.82 means the probe is 32.83mm in the +Y direction relative it the nozzle. Looking from the front of the printer towards the Z axis at the back, this means the sensor is behind the nozzle.

If the sensor is actually 32.82mm in front of the nozzle, you should use Y-32.82 in the G31 command.

-

Edit: Hi @dc42 - Changing the Y-value did not change anything with the nozzle. The hot-end/IR probe went to the same position as it did on previous attempts. No change.

-

If physical results have stopped changing even when you change the numbers in two different commands, then something is not saving, or not reseting, or something...

While you should NOT have to do this, just for debugging, try a power cycle between each change.

-

Terrible results when I try to print.

-

Good News: I've taken care of the Z-probe setup. I changed the bed.g file settings to only use three calibration points and it worked. So I went back to the 10-point settings and changed any that went off the bed. When I click Auto-Delta Calibration, all 10 calibration points now complete successfully - the nozzle comes within 0.2mm of the bed, the Z-probe LED flashes and the nozzle retracts then goes to the next point. I have placed the M500 code at the end of bed.g and M501 at the end of config.g.

-

Bad News: Whenever I upload a gcode file of a 0.2mm test circle (after performing a calibration prior), the nozzle buries itself hard into the bed. Every time. And while I am not fast enough to power off the nozzle (it's dropping that fast), I think I'm at my last ropes here. I'm attaching whatever config files I have at this point.

-

More Bad News: The Duet Wifi web interface keeps disconnecting when I open the webpage in either Google Chrome or Microsoft Edge. It takes 30 seconds or more to allow me to reconnect, or I have to manually restart the board.

-

Question: Why does the nozzle bury itself into the bed when I just auto-calibrated the printer a few seconds before? Why is there a height difference that puts the Z-position below the bed after the auto-calibration?

config.g:

; Configuration file for Duet WiFi (firmware version 1.20 or newer) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P1 ; Set firmware compatibility to look like RepRapFirmare ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 R134 L270 B85 H300 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 Pduettest M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Z-Probe M558 P1 X0 Y0 Z0 H30 F1000 T5000 ;I1 ; Set Z probe type to DC42 and the dive height + speeds G31 X0 Y-32.82 Z0 P500 ; Set Z probe trigger value, offset and trigger height M557 R80 S20 ; Define mesh grid ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z80 E96 ; Set steps per mm M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Set active high endstops ; Heaters M305 P0 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M305 P1 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S275 ; Set temperature limit for heater 1 to 275C ; Fans M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled M501 ; Custom settings are not configuredbed.g:

; bed.g ; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 M561 ; clear any bed transform G31 X0 Y0 Z20 ; POSSIBLE PROBLEM WITH Z=32.82 ;G31 X0 Y0 Z32.82 ; don't want any probe offset for this - ADDED 5/21/2018 G28 ; home the printer M401 ; deploy the Z probe ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 10 points, 6 factors, probing radius: 105, probe offset (0, 0) M98 Pdeployprobe.g G30 P0 X0.00 Y105.00 Z-99999 H0 G30 P1 X90.93 Y52.50 Z-99999 H0 G30 P2 X55.00 Y-65.00 Z-99999 H0 G30 P3 X0.00 Y-80.00 Z-99999 H0 G30 P4 X-72.00 Y-50.00 Z-99999 H0 G30 P5 X-87.00 Y52.50 Z-99999 H0 G30 P6 X0.00 Y52.50 Z-99999 H0 G30 P7 X45.47 Y-26.25 Z-99999 H0 G30 P8 X-45.47 Y-26.25 Z-99999 H0 G30 P9 X0 Y0 Z-99999 S6 M98 Pretractprobe.g M402 ; retract the Z probe G1 X0 Y0 Z150 F15000 ; get the head out of the way of the bed M500 ; Save resultshomedelta.g:

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 G91 ; relative positioning G1 S1 X400 Y400 Z400 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 X-5 Y-5 Z-5 F1800 S2 ; go down a few mm G1 S1 X10 Y10 Z10 F360 ; move all towers up once more (second pass) G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning ;G1 X0 Y0 F6000 ; move X+Y to the centre -