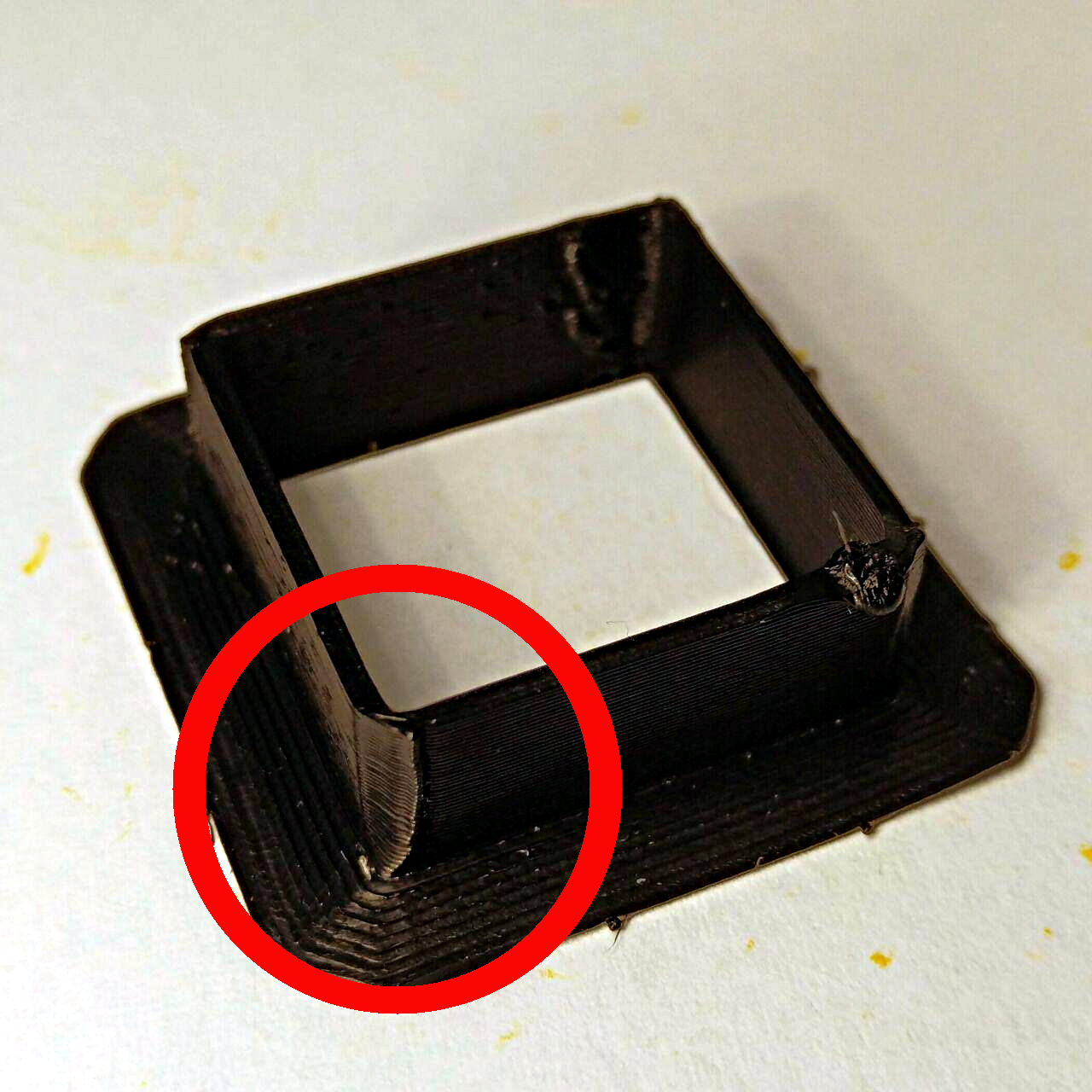

Calibration cube corners.

-

When I printing a calibration cube (ABS filament), its angles are strongly "twisted".

Please, tell me how to deal with this?(The printer is "Anycubic Linear Plus" (Delta)(Duet WiFi)).

-

I don't often print with ABS, but my guess is that you are printing the corners too fast or at too high a temperature.

-

@dc42 Unfortunately no. It is printed slowly (more than 20 min.), The temperature is calibrated too.

I do not even know now where to start to fix this ...? -

@vapvap Post your config.g, then people will be able to help you

-

@vapvap said in Calibration cube corners.:

@dc42 Unfortunately no. It is printed slowly (more than 20 min.), The temperature is calibrated too.

I do not even know now where to start to fix this ...?Have you tried reducing the extrusion temperature by 5C ?

-

In addition to temperature suggestions, I would look for carriage backlash or loose arm joints. (Start grabbing parts and wiggling them to feel for play.) At least one delta column will be changing direction at a 90 degree turn like this.

On the temperature standpoint, either add a little bit of fan airflow or print a much larger object (like 80mm box) to give the fresh material more time to cool before the next nozzle pass.

-

@rcarlyle Once again, I checked everything, there are no backlashes (roads on magnets).

P.S. earlier (without my "Smart Effector" + "Duet WiFi") on this delta, I printed much smaller things. -

@dc42 Cube "-5°C".

-

@obeliks My "config.g":

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Mon Aug 06 2018 00:13:45 GMT+0100 (IST); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R105.6 L267 B90 H212 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them; Network

M550 PMy printer ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E407 ; Set steps per mm

M566 X1200 Y1200 Z1000 E1000 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z12000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P5 R0.4 H5 F1200 T6000 ; Set Z probe type to effector and the dive height + speeds

G31 P100 X0 Y0 Z-0.1 ; Set Z probe trigger value, offset and trigger height

M557 R90 S20 ; Define mesh grid; Heaters

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P1 D0 H1 ; Define tool 1

G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

T1 ; Select first tool

M501 ; new commands override the ones earlier in your config.g -

Can you take a photo from the side of the print? Still looks like a mechanical issue to me, but need to see more angles I think.

-

-

Side like looking at the perimeters, not top, thanks

-

I’m nearing my wit’s end (usually not a long journey), and would really appreciate some help. I print with a FlashForge Creator Pro, using a glass planers for a bed, and ABS juice for adhesion. I’ve been having problems with some prints. I’ve been through the print quality guides on duet3d but haven’t yet found the magic formula. I’m printing a simple 10X20X20mm cube that exhibits the issues I’m having. The .STL came with the printer. I print with Hatchbox filament.

-

-

-

@rcarlyle Sorry, fixed.

-

@johhnyalter, the cube printed 5C lower appears to me to have better corners. Can you confirm that? If so then it confirms my view that excessive speed and/or temperature is the problem. So I suggest you reduce temperature, or add a little fan cooling, or reduce XY acceleration and/or jerk.

-

The fact that the base starts at the correct shape and then it deforms increasing amounts near the heatbed, then gets a little better as it gets higher... that really suggests that it's an issue with the plastic not cooling fast enough. Proximity to the heatbed = more heat. Small print = not much time for heat to conduct away from the top layer. Corners = slower nozzle motion for more heat radiation into the print.

Do you have an insulated hot block?

Do you have ANY kind of airflow, even gentle airflow, in the printer? I find ABS quality benefits enormously from very gentle airflow.

What happens when you print something 4x bigger (ie more time for plastic to cool before the nozzle approaches again)? -

It IS kind of unusual geometry for a corner overheating/undercooling issue, though. Would really like to see video of the box printing.

-

ABS suffers from slow printing, too much heat is transferred and you end up sagging the layers under the layer you are printing, try bringing the speed up to 50mm/sec. A small amount of air flow will sharpen up the edges but will also make the part super brittle unless you can keep the air temp above 60*C.

You also are clearly over extruding which will be exacerbate the layer issues

you're going in the wrong direction! like this:

you're going in the wrong direction! like this: