Horrible print results.Help needed?

-

I didn't see that you'd edited your post with your results. I don't think the forum sends a notification on an edit, nor does it show up as an unread post, so I totally missed it.

Those pictures look much better than the first ones, so I think you're on the right track.

Now that you have the correct thermistor values, you should rerun a PID tune on your hotend heater. https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control#Section_Setting_the_model_parameters_by_auto_tuning

Then I think it would be a good idea to retune your e steps. Choose a temp you'd normally be printing at, like 210c. Mark your filament at 110mm above where the filament enters the extruder. Use

G1 E100 F60to slowly extrude 100mm of filament. When it's done, measure the distance from your mark to the extruder body, and useold_e_steps * (100 / (110 - distance_to_mark))to find your new e steps value. You may need to redo this a few times to get it dialed in.Lastly, you'll want to calibrate your filament flow value for the slicer to fine tune your flow rate. Usually this is done by printing a small single wall object to get your extrusion width right. Something like this: 0_1555018807413_100mm rounded.stl

Print it in vase mode or spiralize contour mode in Cura. Set your extrusion width to match your nozzle size and print at something like 30mm/s. For your 0.3 nozzle a layer height of 0.15 would be ideal. Set the flow rate in Cura to 100%. Then once it's printed use a caliper to measure the wall thickness at the top middle of all four walls, take the average thickness and use

Old Flow Rate * (Expected Thickness/Measured Thickness) = New Flow Rate.. You may need to redo this a few times to get it dialed in.Another good way to tune the flow rate is to print a large square (same STL as above) and watch the solid infill lines. If your first layer height is accurate, you should be able to use the extrusion multiplier slider in the DWC or PanelDue to adjust your line thickness until you're getting a nice first layer. Take the resulting percentage you set on the slider and use the same formula as above to find your new flow rate.

Another good way is to print that same STL with zero infill, zero top and bottom layers and 2 perimeters. Use the same speed for inner and outer walls. Extrusion width same as the nozzle for both. Layer height 50% of nozzle width. Use a brim to keep it anchored. This works best when you're already close to having the right flow. Let it print several layers and watch the two walls reduce the extrusion multiplier until you can see a gap between the walls then slowly bring it back up until the gap is gone.

You can use the same method to adjust your print speed by adjusting the print speed up or down with the speed slider until things are starting to look smooth. Then using the resulting percentage to scale the values you used in the slicer.

That same STL can work well to dial in your first layer height once the flow rate is distilled in too. Baby step until it's putting down perfect layers and adjust the z probe offset accordingly.

Once you've got the temps and extrusion rate nailed down I think you'll notice a big improvement in print quality.

A good way to help with the part cooling for such small parts is to use no heated bed at all if you can get away with it. Pointing a small fan in the general direction of the parts on the bed can help a lot too.

-

I tried everything you mentioned above Phaedrux and the prints look much much better but there is definitely some room for major improvement.I am currrently printing at 200 degrees.This is my first PLA+ roll so I am not really sure if 200 is good but I am going to print a few test cubes at different temps to see which one gives me the best results.I printed an empty cube with a .3 wall thickness in spiralize mode and the results where amazing.I will print another and post results.

Here is the last print

-

Still looks over extruded and maybe still too hot. Try 195c and reduce the flow rate 5 percent.

-

I had already started another print at 190 so I will post those results when they are done printing.The parts pictured above are really strong and have almost eliminated the crazy amount of stringing so the results are headed in the right direction.I raised the minimum layer time from the 5 second Cura default to 10 seconds.I don't know if that should be adjusted a bit higher?

-

Minimum layer tone can have a negative impact as well if there isn't adequate part cooling because it slows down so much that the nozzle is just hanging around keeping things hot with not enough fan to cool it of. 5-10 seconds is a good setting. And min speed or 10-15mm/s. Then get some part cooling in there.

Another way to force some layer cooling in there is along the lines of printing more than one of the small parts. You can add a simple cylinder a way away from the part. That way it has to travel over to the cylinder every layer giving the main part a chance to cool. Especially useful with models that have tall skinny sections at the top.

-

Hi,

I suggest you stick to printing PLA test cubes until you have the basic values in your firmware and slicer working well.

Then you can try other test objects aimed at testing stringing, bridging, etc.

Don't try to do too much at once.

I have tried several brands of PLA and I have found that 190 works best for me. But my 190 might be different than your 190 depending on how accurate our respective temp sensors are.

My hotend is a stock E3D v6 being fed filament by a Zesty Nimble. I highly recommend the Nimble.

And for PLA I run my bed at 60.

Just out of curiosity why the 0.3 nozzle?

Thanks.

Frederick

-

I started with one on my original printer and it worked really well for me so I continued using it.I have a few volcano set ups coming in the mail and about 15 nozzles in varying sizes from .6 up to 1.20 so I will try that out once I get the printer working as it should.I will start testing temps with the test cubes next.I will keep this thread updated and I will be back with retraction and jerk settings questions.

-

Here are a few more pictures of some of my prints.I am currently printing these with the same settings as before but at 185 degrees.

-

That's not too bad really. Maybe a little bit of over extrusion still. Otherwise it's much cleaner.

Are you happier with the results?

-

are you sure that you have a semitec thermistor on your hotend?

185 for pla+ seems a bit low.

did you correct the m305 entry?

-

I posted the config above and it is set for the Semitec. I also had adjusted the flow to 95 percent for the last set of prints pictured. I can drop that down to 90if that would help?

-

@siblues said in Horrible print results.Help needed?:

I posted the config above and it is set for the Semitec. I

and i answered that your config was incorrect for a semitec. that is why i asked if you have corrected it as otherwise that would give you wildly inaccurate numbers.

-

I haven't changed that line since I received two responses with different answers.I was wondering does the print look like it is being printed too hot too cold or what does it look like is happening aside from the M305 line not being changed?

-

you will be printing at the wrong temperature.

go to https://configurator.reprapfirmware.org/Heaters

select semitec and you will see that it generates a line withn the c value set. -

I understand that Veti.I am asking what does it look like is happening with the print?I mean to say if you just look at the print does it look over extruded or printed too hot or too cold.I don't have enough experience to just look at a print and know if any of those things are happening.I will change the line and I will be back in here tonight with results.I have 6 more semitecs in the mail to make sure I don't have a bad one.

-

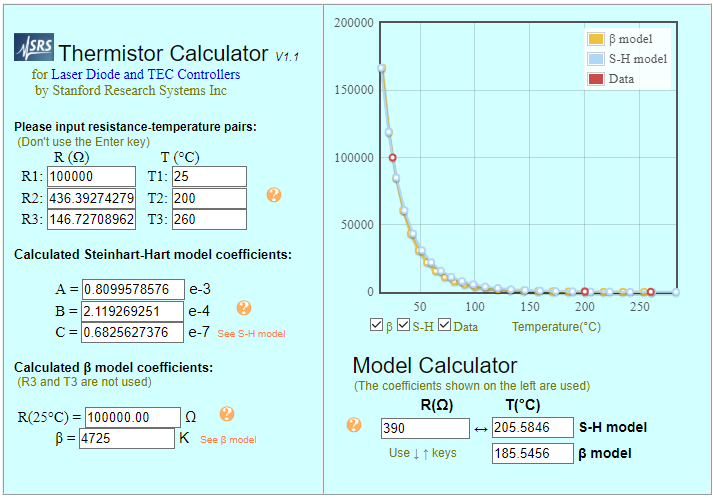

You think you are printing at 185 but you are actually printing at 205. That is a 20 degree difference.

-

It looks too hot and or over extruded. Fixing the thermistor values may fix both.

-

@siblues said in Horrible print results.Help needed?:

I can do the retraction test but the temp tower I can not figure out how to adjust the temps in Cura to work.I am new to all of this so I am still trying to learn even the basic stuff at the moment.

I just want to address this one - The temp towers in Cura are a bit tricky but REALLY worth the effort. What you have to do is this:

-

Go to Thingiverse and open the Customizer on the model @Veti linked. Create your model (suggestions below). Save the model (Publish) don't make it public unless you want to.

-

Load the model into Cura, setup the settings you want with the Default Temp set to the HOTTEST you'll go (say 220° for PLA). Be sure the two Initial temps MATCHES the default temp. Final temp should be the lowest the tower will be doing.

-

Slice the model and go to Preview. Slide the layers slider all the way down then go up until it reaches the first temp switch point, Write down the layer number. Keep going up, writing the layer numbers at each switch point.

-

Now go to the top menu choose Extensions -> Post Processing -> Modify G-Code. Then Add a Script.

-

What you want is ChangeAtZ. It will have Trigger - Change that to LAYER No. and put the first layer change you wrote down (say 35). Go down and Check the box Change Extruder 1 Temp and put the first step DOWN that you need (like 215° if it's changing by 5° increments). Leave the rest of the settings alone.

-

Add a Script again and repeat step 4 for the next change point you noted (say layer 70) and change temp down to 210°. Repeat until the you have all the changes down to say 180°.

-

SLICE AGAIN then save your G-Code. ALSO go to the File -> Save and save it as a Cura project (see below)

-

Print away.

NOTE WELL: CURA REMEMBERS THOSE SETTINGS EVEN IF YOU CLOSE THE PROGRAM!!!!

YOU NEED TO REMEMBER TO GO INTO IT AGAIN AND REMOVE THE CHANGEATZ SCRIPTS OR YOU'LL GO NUTS WONDERING WHY YOUR FUTURE PRINTS GO SCREWY ON YOU!!!!!Ask me how I know ...

It's gotten me more than once, just last week it got me again, I was going CRAZY at a model not printing right and found Cura was dropping the temp every 35 layers because i forgot I did a Temp Tower! I felt SO stupid.

It's gotten me more than once, just last week it got me again, I was going CRAZY at a model not printing right and found Cura was dropping the temp every 35 layers because i forgot I did a Temp Tower! I felt SO stupid.One way to avoid all this work next time (and there WILL be a next time) is to SAVE the print, not just as a G-Code, but as a Cura PROJECT. Then you go in immediately and delete the ChangeAtZ commands while you remember it.

Temp towers will really help you in dialing in your temps, which appears to be what you're battling.

I run one every time I get a new type of filament. Write the settings on the reel. Some say they do it for every reel as it changes a bit, but that's nuts for most good filament. The change will be minor.

However, I find COLOR matters! Black eSun PLA will not print the same temps as Aqua eSun PLA. Do a tower for each type of filament, it's worth the work.The tower I like is the same one @Veti linked. You use the Customizer to create the exact range you need.

Generally I start my tests at 10° over the top temp recommended by the filament maker and take it down to 5° under (don't go too low you'll start grinding in the extruder), go down 5° steps. Be sure to slice at the speed you expect to use for real prints.

Once you get the temp basic range that's best for your machine you can try another tower with 2 degree steps to really get the best spot (if you're OCD like me ... LOL!)

Just File -> Open the project file (.3mf) in Cura and change the starting temp & temps for each step, then re-slice. (The numbers will be wrong on the print, but just use your head, easier than redoing the Thingiverse tower). I assume you can subtract by twos ...

It's a bit of a pain, but once you have done a few you'll have a better handle on what temp you should actually use for that brand & type of filament. Just don't forget to remove those changeatZ commands!

Have fun! You may want to print this as a guide as you go. Like most things, 1st time is the hardest.

BTW, a general tip - stop trying to go fast. Seriously.

This is a hobby that requires patience. If you slice at 70mm/s then slice at 40mm/s you'll find it's not that different, but the quality sure will be. Speed kills in this hobby. Printing twice because you pushed the speed is dumb, be patient, you'll get much better results. As you get better and you dial in the machine you can sneak up but in general, slow and steady saves the print.

Good luck!

-