SSR failsafe

-

So I just bought a silicone heater (AC powered) for the printer I'm building and I'm new to solid state relays.

On the datasheet of my particular SSR (Omron G3NA-210B) I saw that the most common failure mode for the SSR is in closed circuit, which means that if the thing fails there is no way the Duet can turn it off to prevent a thermal runaway.

What can I do to kill power to the printer if the SSR fails? -

-

Mechanically bond a thermal fuse (aka thermal cut out/TCO) to the heater, i.e. screw it down, place in series with heater. If it over heats, thermal fuse melts and cuts off the power.

You want to attach the fuse to the heater and not just the bed, if the heater detaches you want the fuse to follow the heater.

I've screwed a resettable fuse to the aluminium bed, and single use melt fuse to the heater. The resettable ones may fail to open after many cycles, so the single use fuse is the last line of defence in my case, but I'd rather not replace it so the resettable one has a slightly lower rating.

-

Get a one-shot TCO and mount it on the heater (unless you have a mechanical means of ensuring that the heater will always be in contact with the bed plate). If you use the self-adhesive type heater, the adhesive may eventually let go (I have been getting about 2 years from 468MP) and the TCO won't work if it's mounted on the bed plate and the heater comes off.

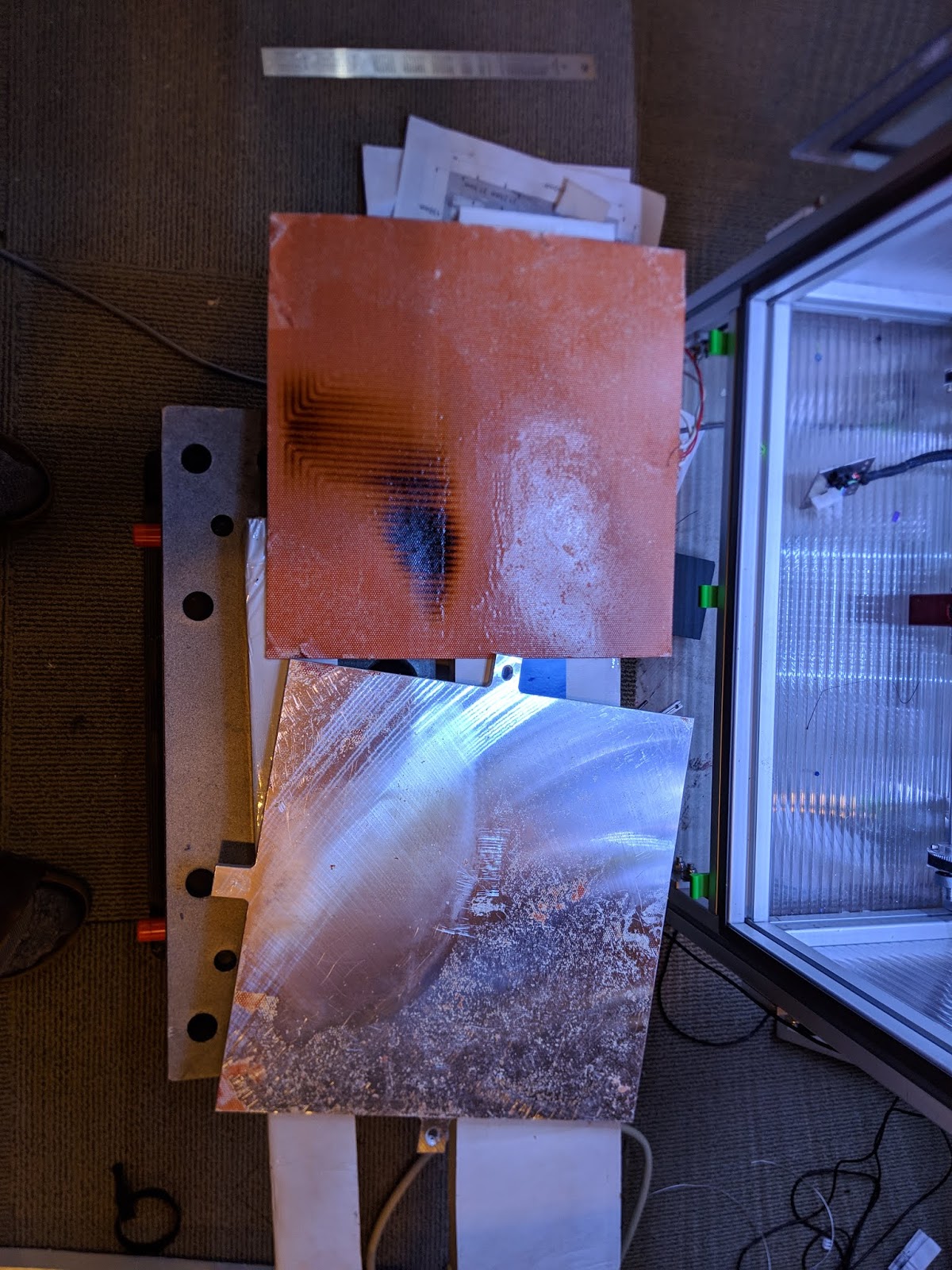

Here's what happens to the heater when the adhesive starts to let go:

It must have been running very hot to toast the silicone like that.

Buy a fully specified TCO from a reliable source like DigiKey or Maplins (?), not from Aliexpress. Cantherm TCO's only cost about $1 each.

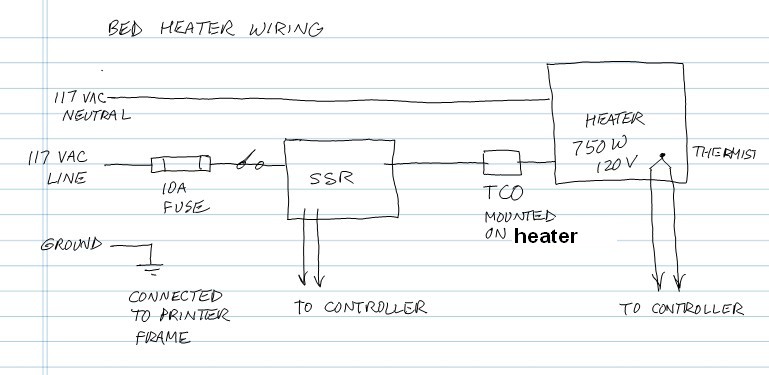

Wire the TCO in series with the bed heater (but don't mount it on the bed plate):

It's a good idea to run a ground lead directly to the bed plate, too.

Some TCO's self-heat, so you have to select the right operating temperature part for your installation. In my machine the TCO is a 184C part that will allow the bed to operate up to about 160C. Check the data sheet for the series of parts you select for proper operating temperature selection criteria.

-

@Phaedrux @bearer Thanks! I hadn't thought of something so simple.

I'll look into a thermal cut off switch and a thermal fuse. -

@mrehorstdmd That looks scary and is exactly what I'm trying to avoid.

Thanks for the wiring diagram. -

I've tried 2 approaches.

One was bonding a thermal fuse (I used 140 degree ones) with RTV silicone directly to the silicone heater. Said fuse is connected in series with the heater. In case a temperature runaway occurs, the fuse breaks and everything is well.

The second one and the one I've settled on in the end for both of my printers is odering heaters with bimetallic themal switches built in them. If you get your heater from Keenovo, they do that for a small extra charge (like a $ or 2), or sometimes waive the charge altogether. This approach is a bit less safe - in case my SSR fails short my bed will oscillate between 130 and 140 degrees. While it's a bit worse than the fuse just breaking, the switch will reset afterwards. So you won't have to bother with replacing it if you accidentally overshoot your max temp or after a failure. And since it's baked in the heater, no need to worry about it ever falling off. Although the last one is hardly a problem is you use RTV silicone.

So, the choice is yours. If you already have a silicone heater - get a tube or RTV silicone and a properly rated fuse/switch. If not - I highly recommend ordering one from Keenovo and just asking them to mould in a switch with the temperature rating of your choice.

-

How are people reliably mounting fuses and snap switches to your V6 hotends?

-

When working with mains voltage best practice is to switch both live and neutral rather than only live. You can get IEC style sockets that merge fuse, twin pole switch, and socket into one component.

This gives some protection against accidental inversion of live and neutral which is especially likely when the mains plug/socket is one of the crappy ones that can be easily inverted.

If you are in an area that can use invertable sockets I would consider a twin pole breaker (combined earth leakage overcurrent would be best) rather than fuse on the inlet. Without this if the socket is inverted and you get a short to earth the level of overcurrent will be set by the building's fuse (as it will be conducting through the neutral that is not fused and dumping to the earth) rather than the fuse installed on the machine.

Finally buy youself a plug in mains socket tester if you don't have one. Only about £10 in the UK and it makes sure your live and neutral are present on the expected pins on the wall socket and there is an earth.

-

There is a £55 a pop reason why you don't see RCBOs on most home 3D Printers.

https://uk.rs-online.com/mobile/p/rcbos/1533467/

A similar level of protection would not be offered by a second fuse on the neutral line because in a overcurrent situation either fuse could pop first due to manufacturing differences. If the true neutral side went first there would still be live voltages in the machine.

Edit: But if you have checked your socked and have checked live and neutral aren't inverted on the machine then a similar level of protection is afforded by a plug in earth leakage detector in you wall socket and a single fuse on the machine's live side.

-

@doctrucker Aren't all homes (at least in the better parts of EU) equipped with this by law? I thought it's enough to properly wire the ground for the protection to be there.

-

Be carefull installing two RCCB after eachother. If you have one in your cabinet and one at the printer it might not trip at all

It's better to trust the 25mA installed in your breaker panel if your installation isn't really old.

It's better to trust the 25mA installed in your breaker panel if your installation isn't really old.No need to break both phases. You just need to break one to prevent the thermal runaway. If something fails your printer should be grounded and RCCB will handle it or the fuse. The thermal cutoff is just when the SSR fails shorted.

-

I was under the impression that the greater the seperation between the RCD and the device the greater it's reaction time.

Anything to read up on regarding the dangers of two RCDs on the same circuit? I thought the only risk was lack of disemination (think that's the word) where there's no certainty on which protection device will trip in a fault.

Edit:- The two RCD in series being a bad thing only appears to be against loss of discrimination, and some seem to suggest that the one nearest the main supply to the building is most likely to go first. If that is the case so what? In the case of the RCBO that I linked the over current will work regardless it's just an earth fault will pull down the live leg of the whole circuit of wall sockets. It could however save a users life if they haven't had their circuits checked since buying the house (or at all) and the RCD higher in the circuit has failed.

-

@mike said in SSR failsafe:

The second one and the one I've settled on in the end for both of my printers is odering heaters with bimetallic themal switches built in them. If you get your heater from Keenovo, they do that for a small extra charge (like a $ or 2), or sometimes waive the charge altogether.

That's exactly what I did. Keenovo, ordered with self-resetting limiter built in. 24 inch (604 mm) round heater, about 1400 watts (110/120V, USA). It's been a while... if I recall, about $200 USD and 3 weeks. The extra charge for the protection was so small I don't remember the amount.

I sleep well.

-

Luckily used the search function and found this gem! So I have a 1500W heater running 13-14A using an SSR and I can see that a thermal cutoff makes sense. I have been looking into these and I'm not exactly sure what I should search for. If I'm mounting this in series am I looking for a specification where it is rated for at least 14A or should I be looking for a max temperature at which point from what I understand it breaks the connection? If anyone has a recommended brand that would fit this bill I would be super grateful! Also is anyone grounding there bed to the chasis of their printer?

-

At a bare minimum you need to ground your bed chassis to the protective earth. If this is a stick on heater then please don't rely on a coincidental earth connection between the spreader and the chassis.

With regards to my earlier comments on two RCDs in series I could find no evidence of this negatively effecting safety. The only thing I could find was it was against regulation for the hard wiring of your house. This is because there is little ti know fault discrimination available and therefore a fault on one circuit could take out the lighting, leaving you wondering around at night in the dark, thus making it more dangerous. I always shut down my machines using the test button on a plug in RCD, which is therefore much better tested than the RCD that protects all the mains sockets in my house.

That said I will accept any warning against chaining RCDs in series if links to a good source (IEE etc) can demonstrate the safety hazard of doing so.

-

@singhm29 You need to consider both values when choosing the thermal fuse. I'd advise to go well beyond your normal current rating, something like a 20 A one. The max temp really depends on how high your bed can go and how high you're usually pushing it. I'd recommend bonding it to the silicone with RTV cement instead of a bracket when it comes to mounting it.

I'd second @DocTrucker on grounding - please don't rely on your bed being grounded via the chassis. Unless it's a delta and there are no moving parts in the bed assembly and you've tested that there's a low resistance electrical connection between the bed and the ground of the chassis.

-

Hmm not sure if I might be mixing things up but as it stands my heated bed came with two power wires but nothing for ground (I think that is normal for all heated beds) so I used a 3 prong power plug any have my SSR connected up correctly. However, the ground wire at this point is not connected and it was my belief based on this video that I should connect that ground wire using a screw in spade connector to my bed chassis. Does that sound incorrect/unsafe? My heated bed is secured from below by 2 aluminum extrusions, adhesive and 4 screws so I think I don't need to worry about it free falling from the printer if the adhesive wears out.

Currently, I'm only printing PLA at around 60C, what is the max temperature people want for their heated beds to cover most materials? I would assume 120C is a safe bet? So the thermal cutoff parameters I should be looking for would be above 120C and 15A or above? Essentially if either of those are exceeded it will trip the fuse?

Sorry for all the questions here I would just rather have things spelled out instead of making assumptions when it comes to safety!

-

I would suggest bringing the mains into your system through and IEC socket module combined with a double pole switch and fuse. Take the live and neutral from there to your relay. I would mount am earth stud on the chassis close to the socket and take the earth spade of the IEC to a ring connector around the earth stud. Ground the heat spreader to this point and ground any other bits of metalwork close to the heater to that too.

Grounding the negative of the psu to the main earth point has resulted in a more stable ethernet connection for me. I mean to do thus a little better but haven't had the chance yet.

-

You should consider a double mechanical pole contactor/relay between the mains input and the SSR. This doubles up the protection that the thermal cut off gives. If the duet detects a fault, it can be set to drop PS_ON which could be connected to this relay.

I'd always play on the safest side possible when using mains in anger.