Cura 4.2.1 Config help

-

@Shaun said in Cura 4.2.1 Config help:

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

Your Z axis is limited to 180mm/min (3mm/s), which I think is the stock setting; my Cartesian machine (though dual Z motors) is set the same, and your other motor settings are stock. It may be that you need to test if it can actually do these speeds; it's possible there's more weight on the Z axis, so it actually has to be lower. Or, as you've got 4000 steps per mm (0.5mm pitch on your Z leadscrew, I think), at full speed the motor has to do 6 revolutions per second to move 3mm; it may just not physically be able to do this.Try sending

G1 Z10 F180thenG1 Z-10 F180to check movement. If you do this at Z=0, you should be able to see if it returns to the same place. If it doesn't, try lowering the feedrate from F180 until it does move reliably.In Cura, the Z Hop speed is set to 10mm/s, which my delta can do, but my Cartesian machine definitely can't! But the config.g setting will limit it to 3mm/s. I don't usually have Z Hop turned on on my Cartesian printer, as the slow Z movement can cause as many, though different, printing problems as having it switched off.

If this doesn't help, can you upload the gcode as @Danal suggested, then we can see what it's actually doing during a print.

Ian

-

@droftarts said in Cura 4.2.1 Config help:

@Shaun said in Cura 4.2.1 Config help:

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

Your Z axis is limited to 180mm/min (3mm/s), which I think is the stock setting; my Cartesian machine (though dual Z motors) is set the same, and your other motor settings are stock. It may be that you need to test if it can actually do these speeds; it's possible there's more weight on the Z axis, so it actually has to be lower. Or, as you've got 4000 steps per mm (0.5mm pitch on your Z leadscrew, I think), at full speed the motor has to do 6 revolutions per second to move 3mm; it may just not physically be able to do this.Try sending

G1 Z10 F180thenG1 Z-10 F180to check movement. If you do this at Z=0, you should be able to see if it returns to the same place. If it doesn't, try lowering the feedrate from F180 until it does move reliably.In Cura, the Z Hop speed is set to 10mm/s, which my delta can do, but my Cartesian machine definitely can't! But the config.g setting will limit it to 3mm/s. I don't usually have Z Hop turned on on my Cartesian printer, as the slow Z movement can cause as many, though different, printing problems as having it switched off.

If this doesn't help, can you upload the gcode as @Danal suggested, then we can see what it's actually doing during a print.

Ian

Super, ill try drop the speed and also removing z hop.

-

Morning, ok so changed the speed and removed the rim. This time is printed but the layers where way to far apart leading me to the conclusion that my Z steps are way off.

My Config.g

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.0.3 on Fri Sep 13 2019 19:45:33 GMT+0100 (British Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"CR10" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z4000.00 E1222.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z10.00 E250.00 ; set accelerations (mm/s^2)

M906 X950 Y950 Z950 E950 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X280 Y280 Z350 S0 ; set axis maxima

;M557 X10:280 Y35:270 S12.6 ; Define mesh grid for full bed print

;G31 X-43.2 Y31.9 Z2.132 P25; Endstops

M574 X1 Y1 Z1 S1 ; set active high endstops

;M558 P5 X0 Y0 Z1 H7 F500 T4000 ; Set Z Probe to type Switch or Digital output where Z probe connector is used

;M31 P25 X0 Y0 Z1 ; Set Z probe trigger value, offset and trigger height; Z-Probe

;M574 Z1 S2 ; set endstops controlled by probe

M307 H7 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P5 H1 F500 T5000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X8.5 Y-50 Z0.38 ; set Z probe trigger value, offset and trigger height

M557 X5:205 Y5:205 S10 ; define mesh grid; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S260 ; set temperature limit for heater 1 to 260C;Disable Heater to free up PWM channel

M307 H7 A-1 C-1 D-1 ; disable heater for BLTouch; Fans

M106 P0 S1 I0 F500 H1 T45 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T150 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M501 -

@Shaun said in Cura 4.2.1 Config help:

M92 X80.00 Y80.00 Z4000.00 E1222.00 ; set steps per mm

4000 steps per millimetre on Z looks like an order of magnitude too high...

-

@grizewald said in Cura 4.2.1 Config help:

4000 steps per millimetre on Z looks like an order of magnitude too high...

With the sole exception that he is using a M5 threaded rod. But yes, more common these days are TR8x8 lead-screws which have 400 steps/mm.

-

@grizewald said in Cura 4.2.1 Config help:

@Shaun said in Cura 4.2.1 Config help:

M92 X80.00 Y80.00 Z4000.00 E1222.00 ; set steps per mm

4000 steps per millimetre on Z looks like an order of magnitude too high...

Aaaahh yes that should be 400. My fat fingers again. Will fix and test.

-

Funnily enough I use M5 rod on mine, so Z4000 looked right to me! I think I remember thinking "I wonder what a CR10 has for leadscrews?" at the time I wrote it, but then forgot!

@Shaun You can probably turn the speeds for Z back up now, as the motor will probably be able to lift the Z much faster now, assuming it has enough torque to move the Z that fast. But do test it at it's maximum speed.

Ian

-

Could this be it?

;FLAVOR:RepRap

;TIME:194

;Filament used: 0.0936418m

;Layer height: 0.2

;MINX:131.371

;MINY:132.221

;MINZ:0.2

;MAXX:148.663

;MAXY:148.664

;MAXZ:10

;Generated with Cura_SteamEngine 4.2.1 -

@Shaun That just gives the minimum and maximum coordinates this print will reach for every axes. In this case your part is 10mm high according to these comments.

-

@Shaun said in Cura 4.2.1 Config help:

@grizewald said in Cura 4.2.1 Config help:

@Shaun said in Cura 4.2.1 Config help:

M92 X80.00 Y80.00 Z4000.00 E1222.00 ; set steps per mm

4000 steps per millimetre on Z looks like an order of magnitude too high...

Aaaahh yes that should be 400. My fat fingers again. Will fix and test.

And there I was feeling silly after wilriker's comment, but I was fairly sure that in all the pictures I'd seen of the CR10, it was using a lead screw and not a threaded rod.

I feel vindicated!

Hope it fixes your Z height problem.

-

@grizewald said in Cura 4.2.1 Config help:

And there I was feeling silly after wilriker's comment, but I was fairly sure that in all the pictures I'd seen of the CR10, it was using a lead screw and not a threaded rod.

Ooops! Besides being the wise-guy that I am sometimes (=most of the time

) I actually wanted to express that I think you were right. Sorry I did not bring that across.

) I actually wanted to express that I think you were right. Sorry I did not bring that across.

-

Still struggling to get this resolved, any other ideas i could try? Thinking i should scrap Cura and try something else to see if it resolves the problem.

-

@Shaun said in Cura 4.2.1 Config help:

Still struggling to get this resolved, any other ideas i could try? Thinking i should scrap Cura and try something else to see if it resolves the problem.

Can you please make the entire gcode file available, thanks.

-

@burtoogle said in Cura 4.2.1 Config help:

@Shaun said in Cura 4.2.1 Config help:

Still struggling to get this resolved, any other ideas i could try? Thinking i should scrap Cura and try something else to see if it resolves the problem.

Can you please make the entire gcode file available, thanks.

Hi,

Here’s a link to “CCR10_Golf_Green_Marker.gcode” in my Dropbox:

https://www.dropbox.com/s/j82sd95kngk4gjr/CCR10_Golf_Green_Marker.gcode?dl=0 -

Thanks for the gcode file. I can't immediately see any obvious issues with it. What exactly is the problem you are having?

-

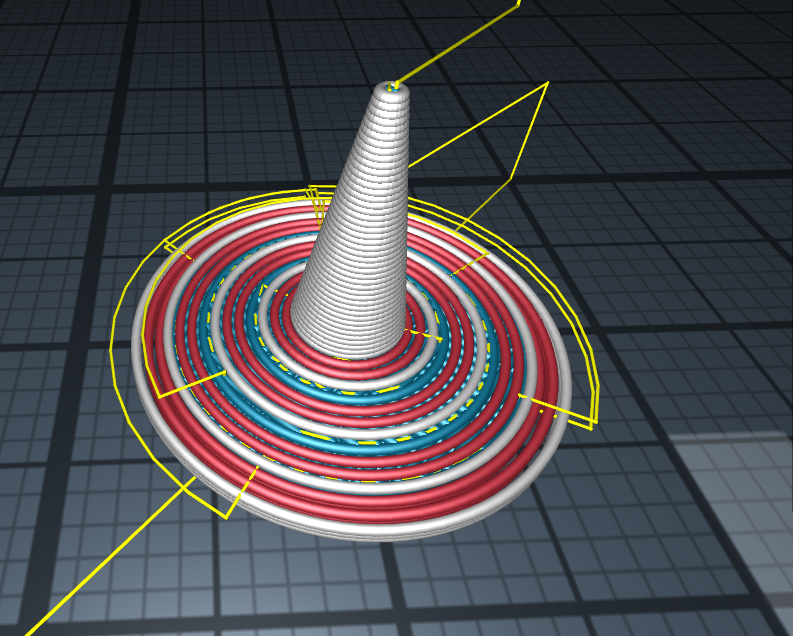

-

Does look like a problem with scaling in Z. The gcode looks OK.

-

@Shaun This gcode should only be 10mm high, but your axis looks like it has moved a lot further than that.

Can you send these commands and report the output from the console:M92andM350

This should report the steps per mm and microstepping in use.

Can you also post your current config.g and, because there's an M501 at the end, your current config-override.g

Measuring how far a Z movement of 10mm moves the axis might be helpful too, as well as a picture of your Z rod with a ruler next to it for scale.Ian

-

@droftarts said in Cura 4.2.1 Config help:

M350

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.0.3 on Fri Sep 13 2019 19:45:33 GMT+0100 (British Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"CR10" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z4000.00 E1222.00 ; set steps per mm

M566 X900.00 Y900.00 Z6.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z10.00 E250.00 ; set accelerations (mm/s^2)

M906 X950 Y950 Z950 E950 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X280 Y280 Z350 S0 ; set axis maxima

;M557 X10:280 Y35:270 S12.6 ; Define mesh grid for full bed print

;G31 X-43.2 Y31.9 Z2.132 P25; Endstops

M574 X1 Y1 Z1 S1 ; set active high endstops

;M558 P5 X0 Y0 Z1 H7 F500 T4000 ; Set Z Probe to type Switch or Digital output where Z probe connector is used

;M31 P25 X0 Y0 Z1 ; Set Z probe trigger value, offset and trigger height; Z-Probe

;M574 Z1 S2 ; set endstops controlled by probe

M307 H7 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P5 H1 F500 T5000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X8.5 Y-50 Z0.38 ; set Z probe trigger value, offset and trigger height

M557 X5:205 Y5:205 S10 ; define mesh grid; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S260 ; set temperature limit for heater 1 to 260C;Disable Heater to free up PWM channel

M307 H7 A-1 C-1 D-1 ; disable heater for BLTouch; Fans

M106 P0 S1 I0 F500 H1 T45 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T150 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M50110:29:39 AMM92

Steps/mm: X: 80.000, Y: 80.000, Z: 4000.000, E: 1222.000M350

; config-override.g file generated in response to M500 at 2019-09-13 22:58

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 A87.8 C796.7 D0.7 S1.00 V12.1 B0

M307 H1 A419.9 C136.9 D4.1 S1.00 V11.9 B0

M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0

;M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00Microstepping - X:16(on), Y:16(on), Z:16(on), E:16(on)

I have checked and when i send a +5 Z moves 5cm up.

-

@Shaun said in Cura 4.2.1 Config help:

M92 X80.00 Y80.00 Z4000.00 E1222.00 ; set steps per mm

Z4000 for the steps per mm is probably an order of magnitude too high for a CR-10. Z400 is likely the correct value.