Uneven layers

-

@Eumldeuml YEah I actually did that yesterday.

As I have 3 seperate steppers for Z I measured them all and when requested 0.32mm i got between 0.30-0.32mm every time so I don't think that's where the problem is.

The part allways comes out with the correct height as well.One thing I notice from your post was that link from one of the posts, and by that I should have a line width of 0.92mm and not 0.72mm as I have atm.. I will try that when I get home and see if there's any diffrence.

-

@Eumldeuml Nope, diden't do anything

-

Check the X any Y axis as well. Home them, move them somewhere to middle with controls and then try to move by hand. There should be no play while the motors hold position.

-

@OBELIKS Hi,

X and Y are very stable, also the Y axis has a 1:3 reduction and X axis a 1:2 reduction.

-

@Haggan90

Its mechanically interesting that your wall variations match each other on the x face and the y face. Do the indents and outdents match each other on the positive and negative x face as well? In other words, if you turn your cube to see the side profile of both X walls, do the indents look like\ \

/ /

\ \ indicating some kind of wobbleOR

\ /

/ \

\ / indicating some kind of compression or extrusion issueWhat kind of lead screws are you using and at what pitch?

What is the infill % and type you used on this print?

What power setting do you have on your Z stepper motors?

Are you using bed mesh leveling and have you updated it recently?

-

@spudaddict Hi!

It's more like the second option, some kund of compression or extrusion issue but very random.

/

/I'm using 3 seperate sterppers for Z, each one with a 3:1 reduction gearing and 10mm steel enforced GT2 belts.

This was printed with 0% infil and 2 perimiters.

I think they are running at 1A each, rated to 1.3A I think.

No, only true bed leveling with the 3 Z motors. -

Could you try to print the cube rotated by 45°?

-

@OBELIKS I will try that when I get home from work tonight

-

@Haggan90

I see you have tried a lot of options already so kinda stretching on some additional ideas:On the reprap config tool, wondered what motor current you set for the Z stepper motor.

Have read the Duet board needs backside cooling as well as driver cooling. Any chance you are having an overheating issue?

I'm a mechanical engineer and new to the Duet so total N00b with firmware - but I think the true bed leveling (G32) is for independent z motors (each with their separate driver). If your 3 Z motors are tied together to a single driver (electrically or mechanically) you should be using the bed mesh compensation. Probably not related to the issue you are having, but can improve your prints.

-

@spudaddict said in Uneven layers:

Have read the Duet board needs backside cooling as well as driver cooling. Any chance you are having an overheating issue?

You cool the stepper drivers by cooling the back of the board - the stepper driver chips have metal pads on the underside which are soldered to the PCB to allow them to transfer the heat from the chip to the PCB. The mass of little holes (thermal vias) are to help in transferring this heat to the large copper areas under each stepper driver

Cooling the back of the board is enough. The top of the chip is plastic and therefore does not help in dissipating heat from the internals.

-

@Haggan90 Your image is very interesting: in the upper part, Y layers are going outside, X inside. At the middle just below the X letter, X and Y both inside. Could you please look how it behaves at the back for those specific layers: if to inside, then at the opposite also to inside, or to outside? If to the other direction, them it would mean it is printed in correct lemgth, but simply shifted. Then I think the LM12/LM8 ball carriages may have play (or something other like bed screws) and at a Z movement the bed shifts sometimes. You could test by a spring at the opposite side at the bed, so the carriage is always running at one side on the shaft. Hope you understand what I mean....

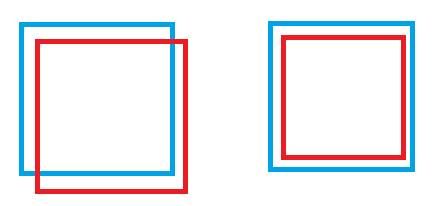

I mean: is it (exaggerated, every color is a layer) case 1 or 2?

Case 1 could be a cause like above.

Case 2, it could be something like different warping because of different temperatures of the nozzle. -

Ok. I read your other thread, so case 2. I think it has to do with the temperatures, or your filament clogs the nozzle sometimes or temperature is too high (what are the black dots in your sample?).

-

One more thing you could try is setting A and B stepper to endstop position for every layer you begin, so errors like spinning/slipping gears will show up (because if you reset at each layer, the error will disappear). Maybe you have spinning gears all the time, but it shows up after long movements like at the layer changes.

-

@JoergS5 said in Uneven layers:

Ok. I read your other thread, so case 2. I think it has to do with the temperatures, or your filament clogs the nozzle sometimes or temperature is too high (what are the black dots in your sample?).

Also make sure you have run heater tuning on the bed heater and you are running it in PID mode. Running the bed heater in bang-bang mode can cause banding like that.

-

Thanks for all the answers!

I do have independent drivers for each z axis and I do cool the underside of both the duetwifi and the duex2.I don't think it has anything to do with temperature, iv'e tried a bunch here..

It could have something to do with the Z shafts and bearings, but I can't feel any play what so ever. I use 4 16mm shafts with LMU16 bearings.

Some more photos around a new print I just did, from all angles.

-

@dc42 yeah i know, atm I don't have any heated bed and I do run PID on the nozzle.

-

This post is deleted! -

Not sure you say anywhere, it is this a coreXY printer? I’d guess there’s a loose motor pulley, just enough to shift occasionally when the perimeter direction changes, but not enough to totally slip. The diagonal shift would correlate with one loose axis on a CoreXY.

You say you’re using a reduction on X and Y, so the extra belts/pulleys may contribute to greater backlash. What belt type are you using?

Ian

-

This post is deleted! -

@Haggan90 If it's this printer https://forum.duet3d.com/assets/uploads/files/1558767109505-155876705849450689945205442146.jpg then your white belts are with steel and may be broken.