Reed switch endstops. Anybody else using them?

-

For reference (since there is fluff on my photo, sorry) the unit is a

ms-213-3-1-0500, shows up like a rash in searches.

I just discovered this, from the manufacturers website. In particular:How to achieve highest switching accuracy

- Magnetic field should be "spot focussed" towards the contact area of the Reed Switch. Providing single pole actuation, smallest possible switching difference is the result.

- Lowest hysteresis of Reed Switch is recommended since difference in switching distance between ON and OFF is very small for this type

- The less tolerances for the magnet and Reed Switch, the better

I'm at a loss over the last line.. but the rest makes me think I need to redesign my carriage brackets with the magnets mounted vertically, I got the maximum range in this parallel configuration but seeing their argument about 1 pole vs both makes me think I should change the magnet orientation.

@fcwilt said in Reed switch endstops. Anybody else using them?:

As you observed, micro-switches work just fine, so a person's preference then depends on other things, such as esthetics.

Very much agree, I can also see the attraction of something complex, the hall effect sensors have bi-colour leds on them, which is also cool (I quite like flashing lights on futuristic things, too much SciFi in my youth).

-

@EasyTarget said in Reed switch endstops. Anybody else using them?:

@bearer said in Reed switch endstops. Anybody else using them?:

Curious to hear how you get on with different temperatures.

Interesting point, I've also got expansion in the 2020 columns to consider, never given that much attention. I guess the Delta grows fractionally as she heats, could be worth setting a dial gauge up above a column and seeing what happens. My printroom is dry, fan ventilated and stable in temperature.

oh, just in case youre thinking of taking a heatgun to your printer to test; don't . magnets will permanently demagnetize if heated above their Curie temperature, which is usually somewhere between 80 to 150C.

-

@bearer said in Reed switch endstops. Anybody else using them?:

oh, just in case youre thinking of taking a heatgun to your printer to test; don't

I was thinking of positioning the dial gauge on a convenient shelf so it is touching the column top, and then putting my printbed to 70C and leaving it for half an hour to see how the needle shifts from the index. Eg seeing what happens in realistic scenarios, applying direct heat would be silly, and unrepresentative.

Im not worried about Curie temperatures; in this case it is 400C, though field strength will decrease well before that of course.. It should be acceptable over the temperature range I can expect.

-

@EasyTarget said in Reed switch endstops. Anybody else using them?:

The printer which I'm working on has end switches that looks exactly same.

They are triggered by magnets. When magnet is away switch is open (infinite resistance). Magnet close - switch is closed (resistance under 1 ohm)

But how exactly did you plug them in the board?

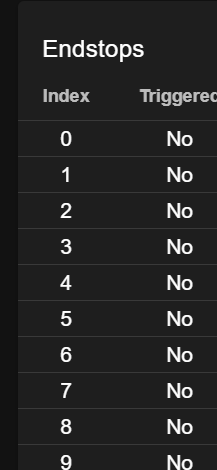

I plugged mine to +3.3V and to io.in of IO_0, IO_1, IO_2 but somehow when I'm in "Machine specific" page Endstops table doesn't show Yes when it should... -

I would expect snap microswitches to be a LOT more repeatable than reed switches.

Sorry, I think you took a big step backwards.

If your preferences lean toward magnetic, sealed, etc. Hall effect sensors are the way to go.

-

I never had any luck with Reed switches. They aren't very reliable from experience

-

I have a 3DS Cubex Duo that came with reed switch endstops installed.

-

@monster said in Reed switch endstops. Anybody else using them?:

@EasyTarget said in Reed switch endstops. Anybody else using them?:

The printer which I'm working on has end switches that looks exactly same.

They are triggered by magnets. When magnet is away switch is open (infinite resistance). Magnet close - switch is closed (resistance under 1 ohm)

But how exactly did you plug them in the board?

I plugged mine to +3.3V and to io.in of IO_0, IO_1, IO_2 but somehow when I'm in "Machine specific" page Endstops table doesn't show Yes when it should...I mean end switches on my BFB are exactly as on this topic picture:

Quite frankly I'm not sure is it reed or Hall effect, I just thought if that would be a Hall then it wouldn't be sharp step from indefinite resistance to almost zero. But anyway those switches were functioning very well under original BFB controller. And they look cool

hehe and very nicely integrated into construction.

hehe and very nicely integrated into construction.

So I got to go with those at least for now.

My problem for the moment is I can't get Duet 3 to see them. I'm sure I did not right connection

I did plug them in IO_0, IO_1, IO_2

1 wire to 3.3 another wire to io.in - that seemed logical (to me ) as switch closes --> 3.3 volts comes to io.in and controller can sense that end point reached.

) as switch closes --> 3.3 volts comes to io.in and controller can sense that end point reached.

Though :

Or is there an additional configuration needed before it can be seen in here?

Or should that be not 3.3 but rather 5v pin? -

Hall effect sensors have 3 wires, not 2.

Reed switches are normally-open so when using RRF3 you will need to use S1 and invert the pin name in the M574 command.

-

@dc42 said in Reed switch endstops. Anybody else using them?:

Hall effect sensors have 3 wires, not 2.

Ups

Good to know

-

@monster said in Reed switch endstops. Anybody else using them?:

My problem for the moment is I can't get Duet 3 to see them. I'm sure I did not right connection

I did plug them in IO_0, IO_1, IO_2

1 wire to 3.3 another wire to io.in - that seemed logical (to me ) as switch closes 3.3 volts comes to io.in and controller can sense that end point reached.firstly you'll need to know what type of switch it is; but if i goes "indefinite resistance to almost zero" lets assume it functions as an normally open* switch. in that case you need to connect it between ground and the input pin.

*)suppose it could be normally closed, depends on the state your description started off in

-

@bearer said in Reed switch endstops. Anybody else using them?:

@monster said in Reed switch endstops. Anybody else using them?:

My problem for the moment is I can't get Duet 3 to see them. I'm sure I did not right connection

I did plug them in IO_0, IO_1, IO_2

1 wire to 3.3 another wire to io.in - that seemed logical (to me ) as switch closes 3.3 volts comes to io.in and controller can sense that end point reached.firstly you'll need to know what type of switch it is; but if i goes "indefinite resistance to almost zero" lets assume it functions as an normally open* switch. in that case you need to connect it between ground and the input pin.

*)suppose it could be normally closed, depends on the state your description started off in

Ah! It is ground and input pin!?

Well that might explain everything!!! I didn't know it works that way!

You see how bad am I

-

@monster said in Reed switch endstops. Anybody else using them?:

Ah! It is ground and input pin!?

for swithces, yes. (inputs uses a pull up resistance so it is normally 3.3v, as such connecting the other end to 3.3v never has any effect)

-

Wooohooo! Got it!

End stops are working now!- I did reconnect as @bearer said

- I did some googling/reading and find out that "M574 X1 Y1 Z1 S1 " is depricated. Added separate lines for each.

- UI was replying that pins need names and then I found an example on forum with names like P"xstop" - used it

- Then UI was replying that names are wrong. I was banging my head for a bit

And then found: https://duet3d.dozuki.com/Wiki/RepRapFirmware_3_overview#Section_Pin_names_for_Duet_Num_3

Here is how it looks

; Endstops ;M574 X1 Y1 Z1 S1 ; set active low and disabled endstops M574 X1 S1 P"!io0.in" M574 Y1 S1 P"!io1.in" M574 Z1 S1 P"!io2.in" - I did reconnect as @bearer said

-

I found this repeatability test

https://bbs.homeshopmachinist.net/forum/general/29522-reed-switch-repeatability-test-for-cnc

which suggests a repeatability of +0.01-0.03 mm.

However, using stronger magnets absolutely does NOT improve the repeatability because the switch just triggers farther away. The magnetic field isn´t any more "defined" at the triggering distance.

I´d like to know how differing environmental influences affect the triggering distance, i could imagine EMI could drastically change that.

All in all it would be too much of a risk for my liking only to get the novel factor. -

I think it would be interesting to see how it behaves when it's mounted close to a stepper that is actively stepping. You'd think the motor design would contain the field from the coils/magnets fairly well, but it probably doesn't take too much "leakage" to close a reed switch.

-

@monster said in Reed switch endstops. Anybody else using them?:

@monster said in Reed switch endstops. Anybody else using them?:

@EasyTarget said in Reed switch endstops. Anybody else using them?:

The printer which I'm working on has end switches that looks exactly same.

They are triggered by magnets. When magnet is away switch is open (infinite resistance). Magnet close - switch is closed (resistance under 1 ohm)

But how exactly did you plug them in the board?

I plugged mine to +3.3V and to io.in of IO_0, IO_1, IO_2 but somehow when I'm in "Machine specific" page Endstops table doesn't show Yes when it should...I mean end switches on my BFB are exactly as on this topic picture:

Quite frankly I'm not sure is it reed or Hall effect, I just thought if that would be a Hall then it wouldn't be sharp step from indefinite resistance to almost zero. But anyway those switches were functioning very well under original BFB controller. And they look cool hehe and very nicely integrated into construction.

hehe and very nicely integrated into construction.Can you imagine? Right after writing this good words about switches - one of them started to flicker (when no trigger/magnet around). In Endstops table only after attempt to park X axis it begins to flicker Yes-No. Before first homing attempt that doesn't happen.

Yesterday I spend whole evening tackling this. Using multi-meter it looks good, looks like normally opened, no sudden closings. But once used with controller and homing attempted - flickering happen (No/Yes) so homing stops 0-2 sec after start.

Wires of end switch are going very closely packed with relevant motor wires. Could there be an induction from motor wires? In the end when unplugged no such behavior noticed. And it is the only end switch with goes tightly packed with motor wires.

In the end when unplugged no such behavior noticed. And it is the only end switch with goes tightly packed with motor wires. -

They know. Just like dogs can smell fear... or printers can smell deadlines...

-

@monster The motor leads should be twisted (two twisted pairs- one for each coil) as should the endstop leads. That helps prevent inductive coupling.

-

@monster said in Reed switch endstops. Anybody else using them?:

Could there be an induction from motor wires?

With normally-open endstop switches, capacitive (not inductive) coupling from stepper motors wires to endstop wires can cause false triggering. That's one of the reasons that normally-closed switches are preferred. If using normally-open switches, use shielded cable for the endstops.