How to configure drivers 10 and 11 on CONN_LCD?

-

Hi,

I have a Duet2WiFi in CoreXY configuration with 3 Z motors so I am using all 5 on board drivers. I want to use drivers 10 and 11 on the CONN_LCD connector for two external extruder drivers with STEP/DIR/ENABLE interfaces. I am using the following configuration:

M584 X0 Y1 Z2:3:4 E10:11

M563 P0 D10

M563 P1 D11but I get this message:

Error: M563: Tool creation: bad drive number

What are the correct G-Code commands to describe this configuration?

Thanks

-

Check out this page, maybe it will help you?

https://duet3d.dozuki.com/Wiki/Using_external_stepper_motor_drivers

-

Also see https://duet3d.dozuki.com/Wiki/Gcode#Section_M584_Set_drive_mapping

You may have to unmap your existing extruder drives before assigning new ones.

-

@timcurtis67 I have read this page already, it tells you how to connect the external drivers to the CONN_LCD pins, which I have done, but not what G-Code commands to use to actually enable drivers 10 and 11.

-

@timcurtis67 This is what I think I am doing with M584 X0 Y1 Z2:3:4 E10:11 - doesn't this map the first two extruders to drives 10 and 11? How do you unmap existing extruder drives? There is no mention in the wiki anywhere about driver unmapping. The M584 documentation only mentions setting the drive mapping and gives one example which is very similar to what I am using but does not work.

-

To unmap a driver, it's number is simply left out of the M584 command.

-

@Phaedrux That's exactly what I am doing when I use M584 X0 Y1 Z2:3:4 E10:11 but then M563 P0 D10 still reports "Error: M563: Tool creation: bad drive number" - there must be something else that needs to be done to be able to use driver 10 as an extruder and this is not documented anywhere

-

@catalin59 said in How to configure drivers 10 and 11 on CONN_LCD?:

@Phaedrux That's exactly what I am doing when I use M584 X0 Y1 Z2:3:4 E10:11 but then M563 P0 D10 still reports "Error: M563: Tool creation: bad drive number" - there must be something else that needs to be done to be able to use driver 10 as an extruder and this is not documented anywhere

From https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M563_Define_or_remove_a_tool

D The 'D' field specifies the drive(s) used by the tool ... Drive 0 is the first drive in the machine after the movement drives (usually X, Y and Z).

You've defined the stepper driver you're using already with M584, and as you don't have any other extruder drives, it should just be:

M563 P0 D0

M563 P1 D1Ian

-

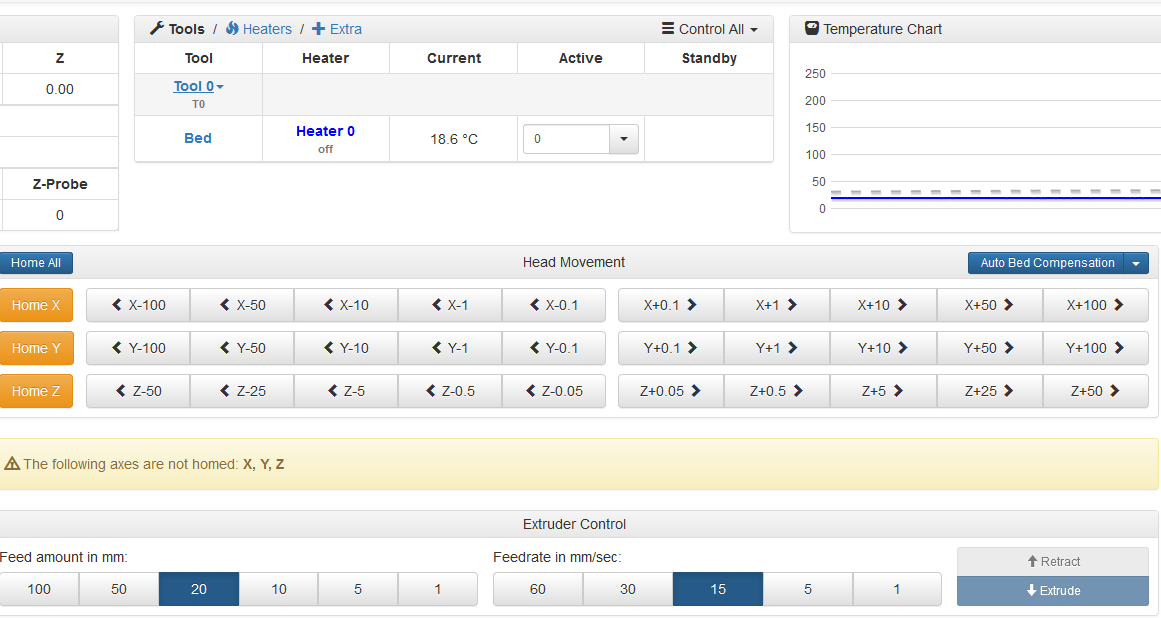

@droftarts OK, so drive 10 in M584 is drive 0 in M563, I did not see that one coming, I really appreciate the help. M563 P0 D0 does not issue any errors so it's a step forward, however I still cannot move the extruder motor. I enabled cold extrusion with M302 P1 (I do not have a hotend yet, I am just moving X, Y, Z and E axes for now) but the Retract/Extrude buttons in the Extruder Control panel of Duet Web Control are greyed out and G1 Ennn does nothing.

I see the tool in Web Control, I enable it but I cannot move it. There is still something missing to enable the external motor driver on CONN_LCD and it's like finding a needle in a haystack. I had the XYZ movements (CoreXY with three Z motors) working like a charm, it was nothing compared with this extruder thing.

-

This post is deleted! -

@catalin59 I'm a bit late coming to this thread or I might have been able to help. The extruder drive number thing has bitten my in ar#e twice - the second time I knew about it but it still caught me out. In a nutshell, for M563 the "D" parameter refers to the extruder drive, not the motor drive (but you know that now).

Ref the inability to move the extruder, it might just be that you need to make the tool active (even though it has no heater) so try sending a T0 first. Then M302 P1. Then G1 Enn

-

@deckingman I am doing both M302 P1 (allow cold extrusion) and T0 already and I can see the tool status change in the Web Interface accordingly. But the two Retract and Extrude buttons are always greyed out and the extruder motor never moves.

-

@catalin59 said in How to configure drivers 10 and 11 on CONN_LCD?:

@deckingman I am doing both M302 P1 (allow cold extrusion) and T0 already and I can see the tool status change in the Web Interface accordingly. But the two Retract and Extrude buttons are always greyed out and the extruder motor never moves.

Can you post your whole config.g?

Ian

-

@droftarts This is a work in progress (no endstops, no extruder heaters, no fans yet) but CoreXY, 3-motor axis Z and bed heater are working already:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.0.4 on Fri Sep 20 2019 21:45:29 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer nameM667 S1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P5 S1 ; physical drive 5 goes forwards

M569 P6 S1 ; physical drive 6 goes forwards

M569 P7 S1 ; physical drive 7 goes forwards

M569 P8 S1 ; physical drive 8 goes forwards

M569 P9 S1 ; physical drive 9 goes forwards

M584 X0 Y1 Z2:3:4 E10 ; set drive mapping

M563 P0 D0 ; set tool 0 to driver 10 (first extruder on CONN_LCD)

M350 X16 Y16 Z16 E16:16:16:16:16:16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E800.00:800.00:420.00:420.00:420.00:420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E12.00:12.00:120.00:12.00:12.00:12.00:12.00 ; set maximum instantaneous speed changes (mm/min)

M203 X60000.00 Y60000.00 Z1200.00 E1200.00:1200.00:1200.00:1200.00:1200.00:1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z250.00 E250.00:250.00:250.00:250.00:250.00:250.00:250.00 ; set accelerations (mm/s^2)

M906 X1600 Y1600 Z1600 E1600:1600:1600:1600:1600:1600:1600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z200 S0 ; set axis maxima; Endstops

M574 X0 Y0 Z0 S0 ; set active low and disabled endstops; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M140 H0 ; enable heated bed

M305 P0 X500 R4700 ; set PT1000 for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

After startup, on top of this I execute manually:

M302 P1

M564 S0 H0

M563 P0 D0

T0I can move on XYZ as expected, I can control the bed heating but I cannot move the extruder motor connected to driver 10 on CONN_LCD. I know that the extruder driver and motor are working because the STEP/DIR/ENABLE interface works when tested separately. The Extrude and Retract buttons on the Web Interface are greyed out.

Thanks a lot for the offer to help with this issue. It looks like I am the first one using all 5 onboard drivers for XYZ and the two CONN_LCD extra interfaces for extruders, I have found the documentation on how to connect this but nothing on the required G-Code comands to set this up.

-

M563 P0 D0 H1 F0 ; define tool 0

Your tool definition references a heater that doesn't exist. Perhaps it doesn't like that. Perhaps try adding a dummy heater definition for H1. Even if it doesn't actually exist, it shouldn't matter as long as you're allowing cold extrudes.

-

@catalin59 These are just some annotations to your config.g, perhaps you will give them a try?

• You define tool0 (M563) a bit too often: first in section "Drives“, then under "Tools“ where the M563 G-code belongs, and on top of that, you execute it manually. As you use different parameters with M563, I really can’t tell you which of them RRF applies. Please stay with the tool definition in the section "Heaters“.

• There, you should remove H1 from M563, as for now, you don’t have specified that heater yet. Also in that section, you should comment-out the line "G10 P0 R0 S0“. - No heater = no temperatures to be set.

• Then, I’m puzzled with your assignments in "Drives“: with M569, you tell the board to control 10 steppers (P0-P9)? Remove the lines who have no physical counterpart. On the other hand, there is no M569 entry for P10 - the drive you assign to the first extruder in M584 … E10. Maybe you should add this.

• To be safe, you should move the Entry M584 … from „Drives“ way up, according to the docu, it should come earlier than some other G-codes in the config.g. I’m not sure whether or not your extruder assignment is counted as a new axis, but it is better to take no risk:

M584 must come earlier in config.g than any M350 and M906 commands. If it creates new axes, it must also be earlier than any M92, M201, M203, M208, M350, M566, M574 , M667 and M669 commands.

-

@catalin59 I tend to agree with all of @infiniteloop suggestions above! You'll also want an M569 for each of drives 10 and 11, to define which way they turn.

To check that the motors on drivers 10 and 11 actually work, rather than go to the effort of defining heaters and tools, define these two motors as extra axes. Then you'll get simple jog controls in the DWC, rather than having to define the heater etc. Change your M584 to:

M584 X0 Y1 Z2:3:4 U10 V11 E5 ; set drive mapping(The E5 is just a temporary mapping)

Add the U and V motor settings to M92, M566, M203, and M201. M350 and M906 are set by the stepper driver, the Duet cannot control these.

Depending on which external stepper driver you are using (what are you using?) you may need to change the length of the pulse that tells the stepper driver to move; see the T parameter of M569.

Finally, you won't be able to move the axes without homing. The easiest way to do this is to give the motors a position. Send

G92 U100 V100, then you should be able to jog the axes.Ian

-

@infiniteloop All these are good suggestions. I tried to implement them and also cleaned up config.g which now looks like this:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.0.4 on Fri Sep 20 2019 21:45:29 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer nameM667 S1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable TelnetM584 X0 Y1 Z2:3:4 E10 ; set drive mapping

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P10 S1 ; physical drive 10 goes forwards

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E800.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E12.00 ; set maximum instantaneous speed changes (mm/min)

M203 X60000.00 Y60000.00 Z1200.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z250.00 E250.00 ; set accelerations (mm/s^2)

M906 X1600 Y1600 Z1600 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z200 S0 ; set axis maxima; Endstops

M574 X0 Y0 Z0 S0 ; set active low and disabled endstops; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M140 H0 ; enable heated bed

M305 P0 X500 R4700 ; set PT1000 for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

;M563 P0 D0 H1 F0 ; define tool 0

M563 P0 D0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

I execute manually T0 and M302 P1 but nothing has changed, the Extrude/Retract are still greyed out and G1 Ennn does nothing.

-

@catalin59 Well, when moving M584 upwards, you overlooked one command it should precede - hint: M667 in the “General“ section. After that, you should follow @droftarts’ advice… Forget Extrude/Retract in DWC for a moment, the primary objective is not to paint it black (hm, why does this remind me of one of my favourite tunes?), but to convince the stepper to do what he’s built for. With @droftarts’ proposal, it’s easy to test the drive mappings - first things first.

-

I moved M584 before M667 and changed it to M584 X0 Y1 Z2:3:4 U10 V11 E5. I see now two more axes U and V in the web interface. Movement commands on X, Y and Z work as expected. Movement comands on U are ignored and it takes a couple of seconds for something to time out before the next move command is processed. For example, if I move U and immediately X, nothing happens for about 3 seconds then the X move gets executed.

I have tested the STEP/DIR driver interface by manually creating STEP pulses with an external 3V/2mA source and the extruder motor does move so I am pretty sure this is not some connectivity problem but still a G-Code issue. Drivers 10 and 11 on CONN_LCD are special and something different must be done compared with the 5 onboard ones.