Z axis issue: wrong movement (layers)

-

@Phaedrux said in Z axis issue: wrong movement (layers):

Can you test the repeatability of your Z axis? Set to a known position marker and then move the z axis up and down many times and see if it returns to the same starting position.

Thanks for your replay.

I'll try later. -

@Phaedrux said in Z axis issue: wrong movement (layers):

Is there a gear reduction involved?

There is a 1 to 1 ratio

-

@Phaedrux said in Z axis issue: wrong movement (layers):

Is the belt slipping the teeth?

Belts are quite tight, I don't think they can slip (I hope… no noises , nothing that make me to think they are slipping )

-

@Phaedrux said in Z axis issue: wrong movement (layers):

Ideally you should set the current to be 70-85% of the rated max current of the motor.

Ok, it was too low. I set 1200 mA (80% of 1.5A). Unfortunately the error doesn't disappear.

-

@Phaedrux said in Z axis issue: wrong movement (layers):

You're using anti-backlash nuts. They typically are not necessary on the Z axis since there is constant downward force on the bed from gravity and the bed is always dropping away from the nozzle during a print. They can increase friction however to the point they cause binding.

Have you lubricated the lead screws?I'll try to remove nuts and use normal ones. Also I'll try to clean and re-lubricate the lead screws

-

News:

-Repetitivety Is ok, tested with a dial indicator

-I've change the nut. Some improvements but the error doesn't disappear.Other advices?

-

it looks like a z-wobble dubble (tripple) check the Z-Axis motion this must be stable and run smooth (it can be a nightmare to find the right position)

-

@SIam

I've printed a piece in order to fix the lead screws at the exactly center of the two rods, quite good but I didn't solve the problem.Any suggestions?

-

@zecchi said in Z axis issue: wrong movement (layers):

-I've change the nut. Some improvements but the error doesn't disappear.

Look for more sources of binding. The smooth rods and bearings would be my next target.

-

Also rods are checked. Z axes is absolutely perfect, tested with a dial indicator (only 0.01mm of error in 300mm ). I've also printed a jig in order to have the rods at the same distance.

But , layer are, still, inconstant (0.24, 0.18, 0.22 ecc...) And this cause the blob (I'm pretty sure about that ). -

@Phaedrux said in Z axis issue: wrong movement (layers):

What is the full step resolution of your z axis?

@zecchi What is the pitch/lead of your lead screws?

The problem really seems to be similar to trying to print at a layer height that isn't a multiple of the full step resolution of the Z axis.

-

@Phaedrux

2mm pitch. (I ordered the 8mm pitch but it arrived wrong). -

@Phaedrux

I've shorter 8mm pitch lead screws. I'll try with them. -

@zecchi said in Z axis issue: wrong movement (layers):

2mm pitch.

Well there goes that theory.

With a 2mm lead, and 1.8 degree motors (deduced from your 1600 steps per mm on Z) your full step resolution is 0.01mm. So you have no limits there.

What are the motor specs?

-

@Phaedrux

So, if my layer height is 0.2mm isn't a problem, correct?Motor: 1.5A , 1.8°. Classic 17HS4401 stepper motor.

-

@zecchi said in Z axis issue: wrong movement (layers):

@Phaedrux

So, if my layer height is 0.2mm isn't a problem, correct?Correct

-

@zecchi said in Z axis issue: wrong movement (layers):

Motor: 1.5A , 1.8°. Classic 17HS4401 stepper motor.

I'm unable to find a data sheet that seems close. There are many sub-models of 17H4401 between many manufacturers. I didn't even see any that were 1.5a.

Can you find a data sheet that seems to match your motor based on what you know about it?

-

@Phaedrux

Second line of this datasheet:

17HS2408-MotionKing.pdfNow I realize that the seller made fun of me selling this motor as 1.5A instead 1.3A (I re-cecked and in the description is written 1.5A

).

). -

@zecchi

My fault , the line is actually the number eight. So the current is 1.7A. awesome.This is the link :

€ 21,62 20%OFF | Nema17 Stepper Motor 42 motor Nema 17 motor 42BYGH 1.5A 38mm 17HS4401 motor 4-lead for 3D printer CNC

https://a.aliexpress.com/BBHPrX2gL -

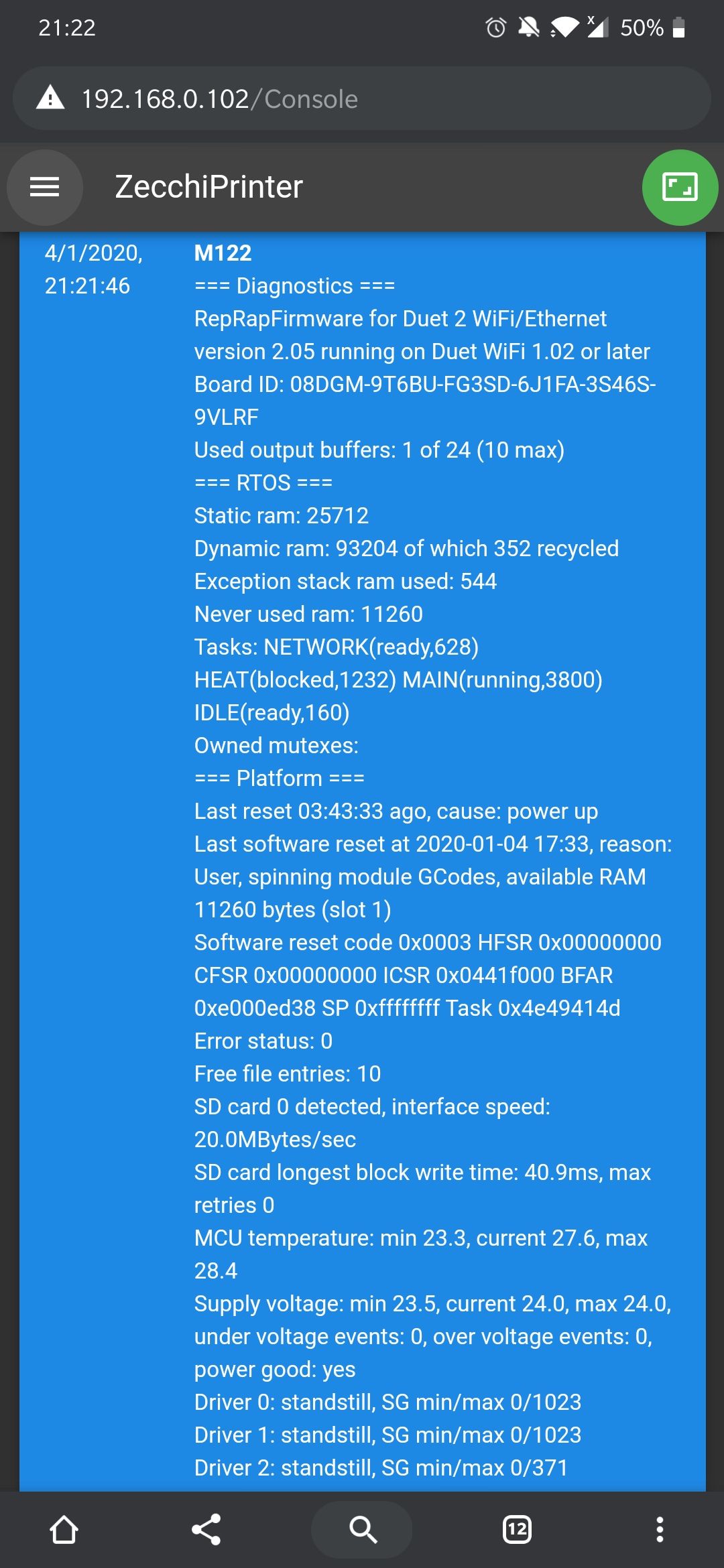

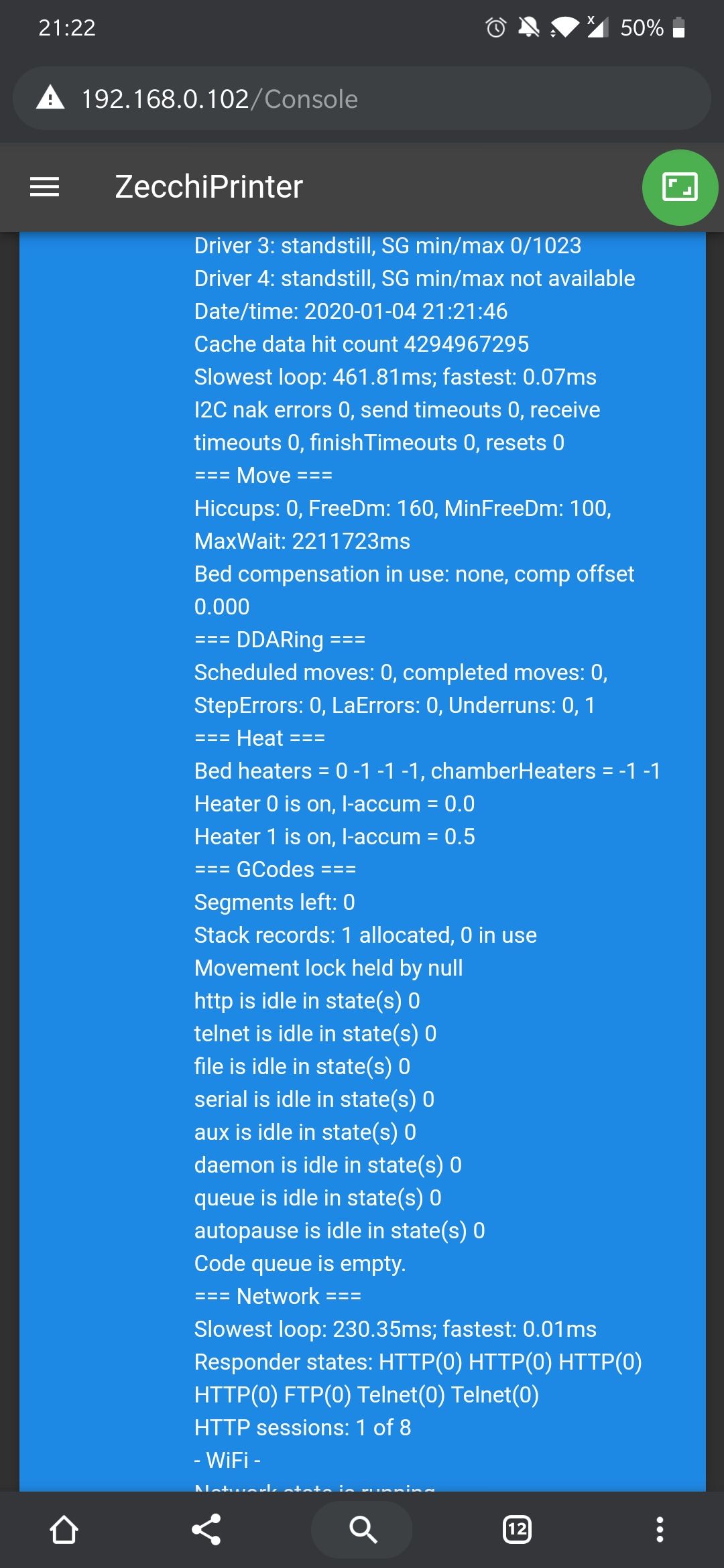

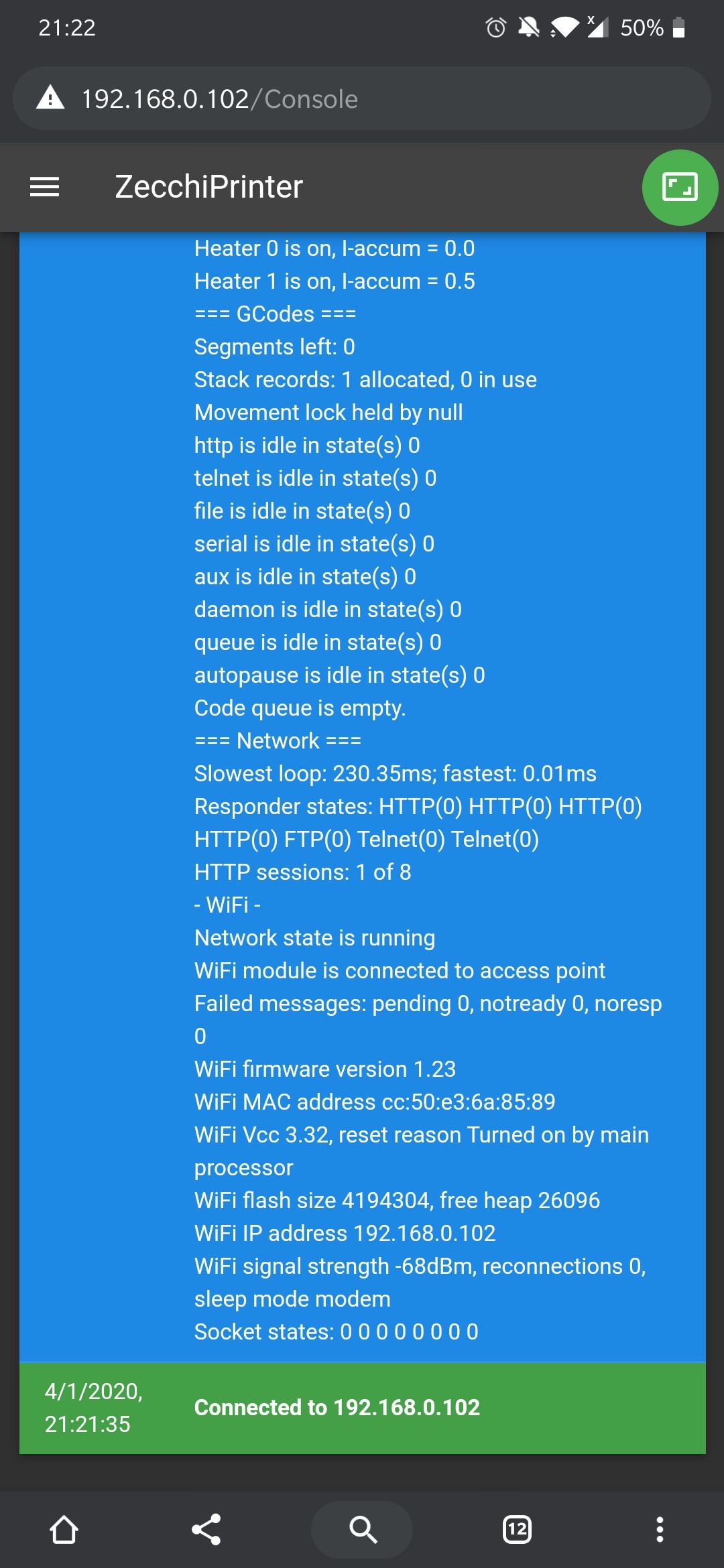

This is the response to M122 command:

If you see something strange ,please let me know.